Two-stage cutting PDC bit

A technology of drill bits and cutting teeth, applied in the field of two-stage cutting PDC drill bits, can solve the problems of slow ROP, short drill life, fast wear, etc., and achieve the effects of ensuring wear resistance, increasing ROP, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

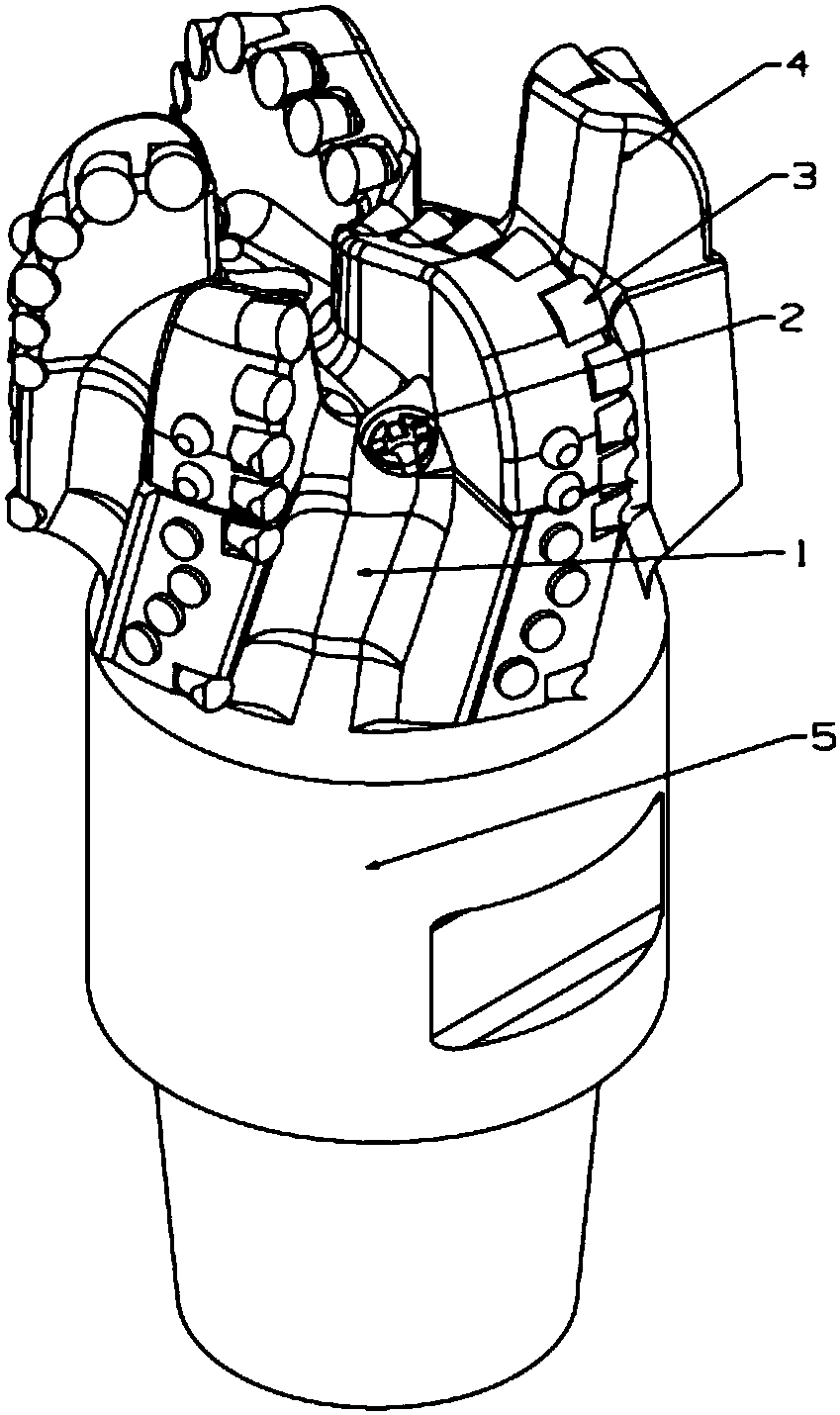

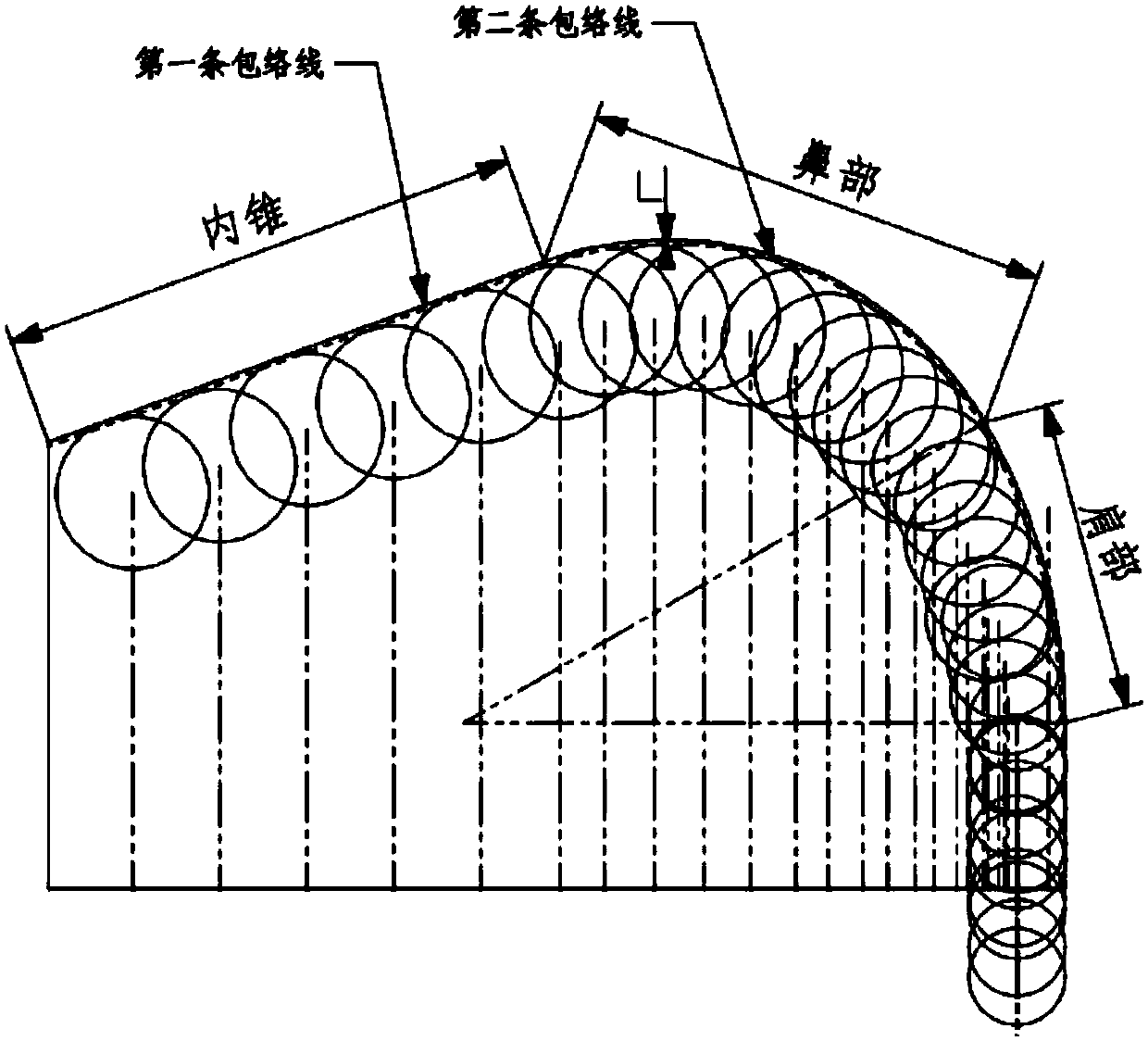

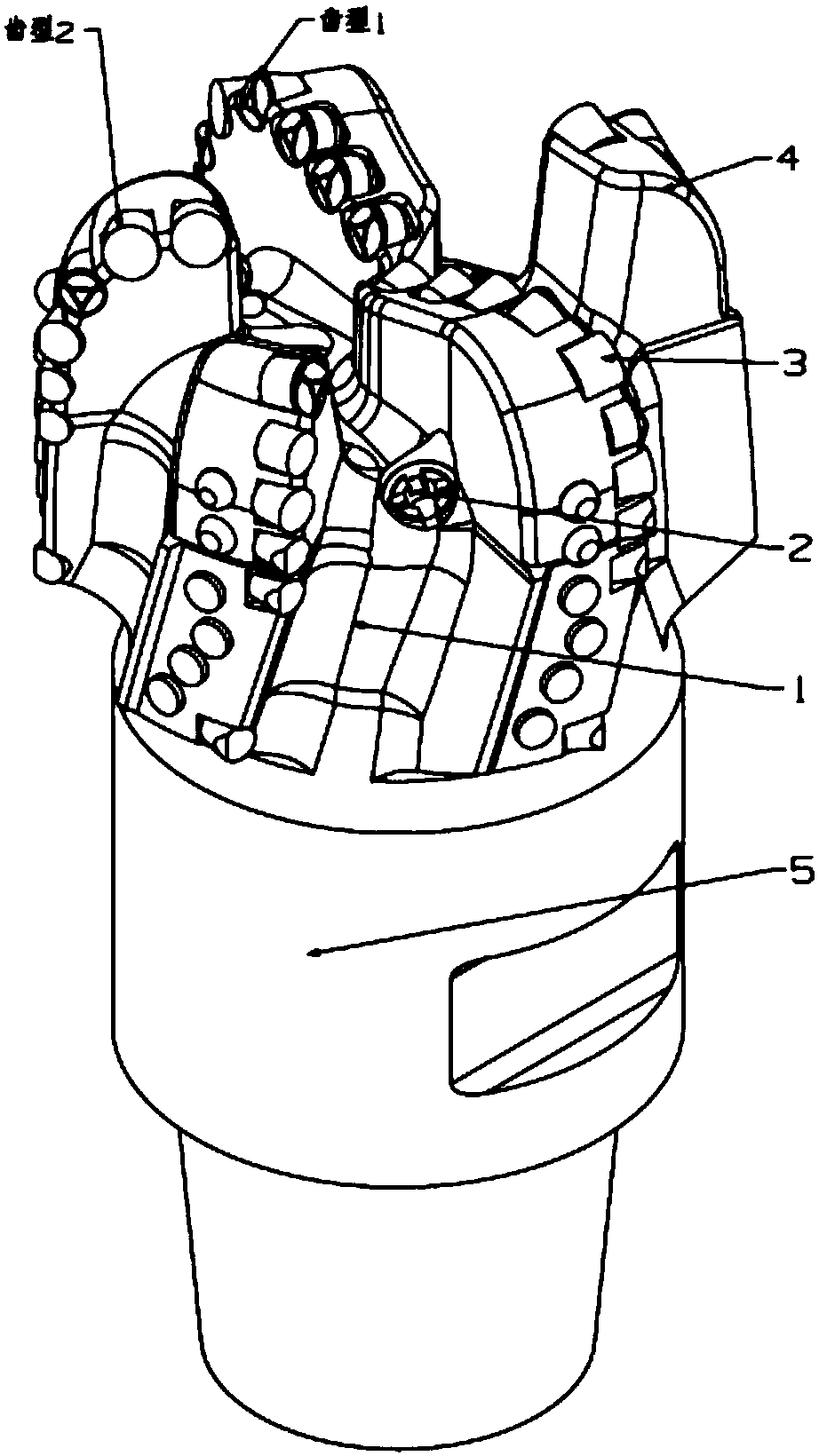

[0015] The first example is figure 1 , figure 2 As shown, a drill body 1 is included, the upper part of the drill body is a drill shank 5, and blades 4 are arranged at intervals along the circumferential direction on the drill body. There are 5 blades, and nozzles 2 are arranged between the blades. Fixed cutting teeth are arranged on the blade along the inner cone, nose, shoulder and gauge section. The fixed cutting teeth are diamond composite sheets, and the tooth shape is cylindrical. The fixed cutting teeth 3 of the inner cone, nose and shoulder on the blade are arranged from inside to outside, covering the entire bottom of the well, and all the fixed cutting teeth of the inner cone, nose and shoulder on the blade are composed of Two sets of corresponding fixed cutting teeth, the two sets of fixed cutting teeth can be arranged alternately in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com