A roller for transferring labels

一种标签、吸附辊的技术,应用在标签、贴标机、包装等方向,能够解决操作复杂化、小尺寸公差、工厂生产率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

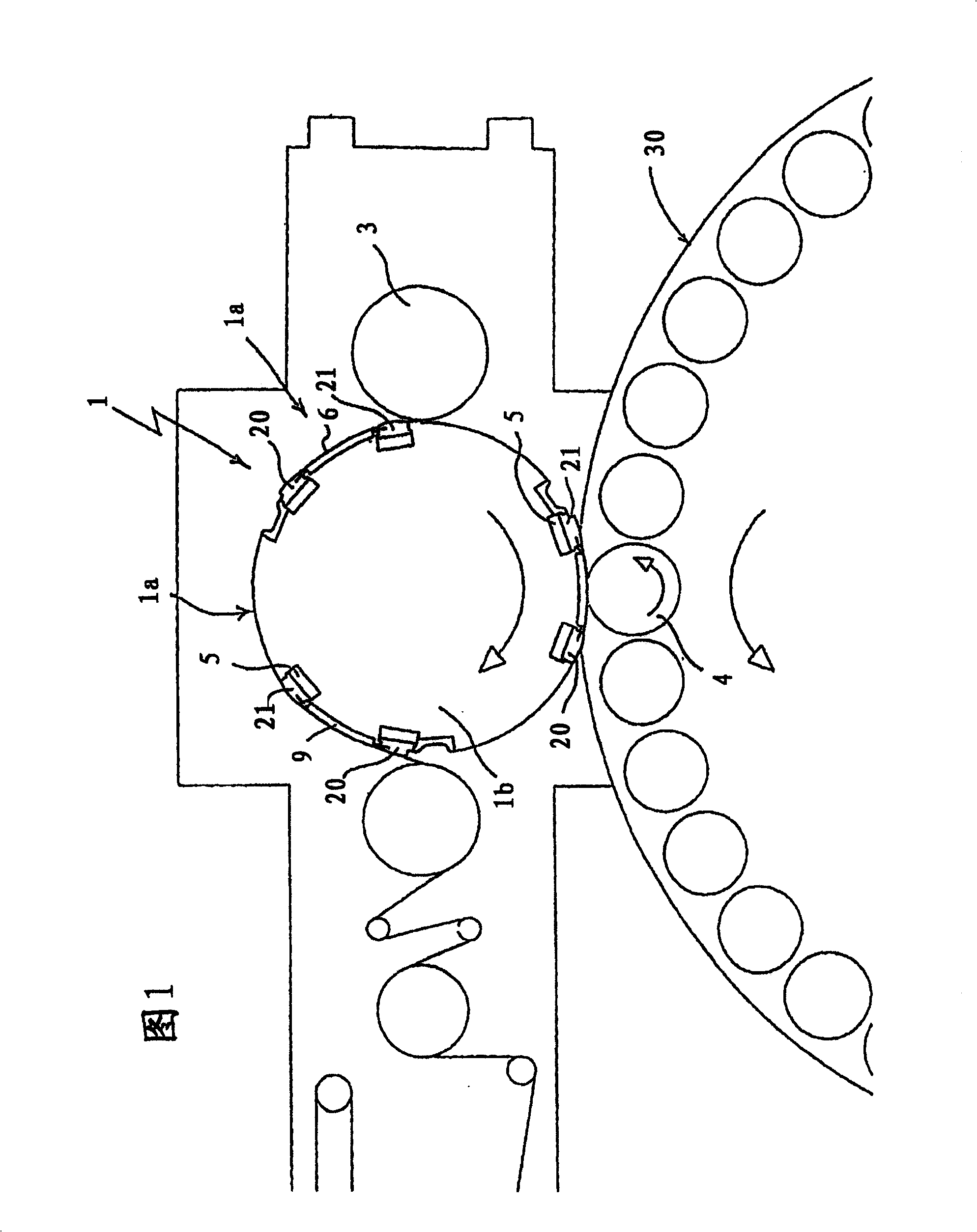

[0041] With particular reference to accompanying drawing 1, the conveying roller of the present invention marked with reference numeral 1 is spherical, and is suction type.

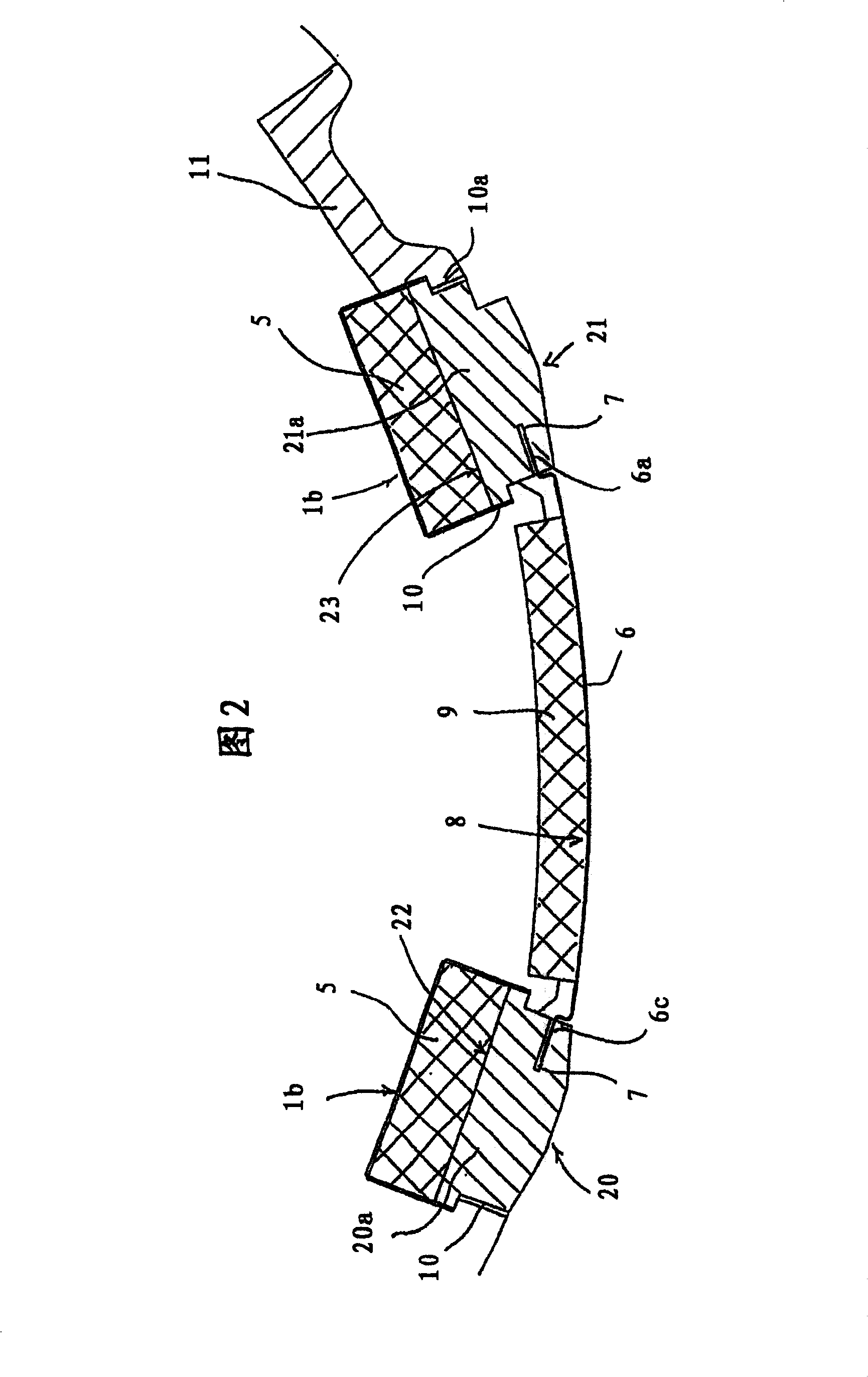

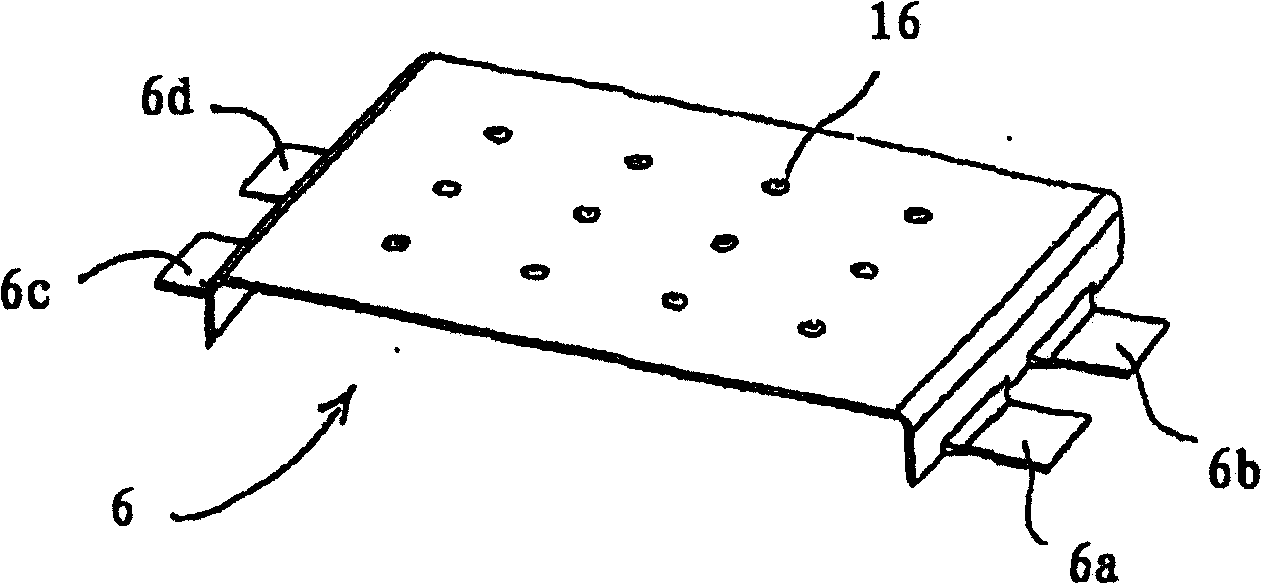

[0042] The roll 1 is provided with pairs of pads 20, 21 protruding relative to the side surface 1a of the roll 1, and on which an edge of a label (not shown) is arranged.

[0043] By means of tangential contact between the pads 20 , 21 and a rubber roller 3 , an adhesive strip is arranged on each of said edges.

[0044] The labels are then conveyed onto a container 4, preferably by a spinner 30, brought into contact with conveying rollers.

[0045] To avoid adverse interference (and possible cracks) between the rubber roller and the pad, the latter is preferably dampened by means of a dampening means 5 inserted in each Between an invisible surface 22 , 23 on the pad 20 , 21 and a structural part 1 b of the roller 1 . In this preferred embodiment, the insert is made of a spongy or polymeric material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com