Microwave dielectric ceramic material, microwave dielectric ceramic antenna and preparation method thereof

A technology of microwave dielectric ceramics and antennas, which is applied in the field of microwave dielectric ceramic antennas and their preparation, microwave dielectric ceramic materials and their manufacture and use, and can solve the problems of microwave dielectric ceramic antennas without serialization, large volume, and narrow application range of antennas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The microwave dielectric ceramic antenna of the present disclosure has the advantages of convenient preparation process, cheap raw materials, good repeatability, no pollution to the environment, convenient mass production, and is a microwave dielectric ceramic antenna with broad application prospects.

[0040] The disclosed antenna has a simple and compact structure, and has good characteristic parameters such as gain, output impedance, radiation efficiency, polarization and frequency bandwidth of the antenna.

[0041] The present disclosure has the following beneficial effects.

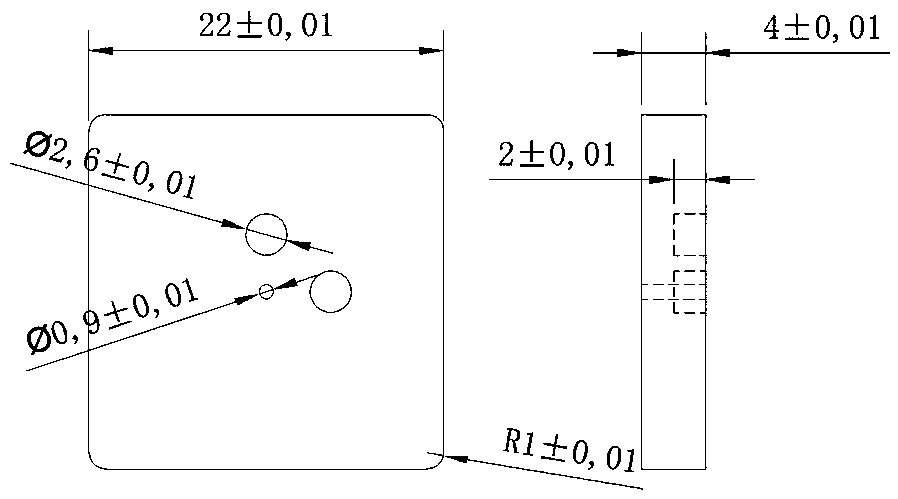

[0042] This disclosure adopts the solid phase reaction method to prepare the required Zn 2 SiO 4 Ceramic powder, and composite TiO 2 Adjust the microwave characteristics, after passing the microwave characteristic test, put it into the designed and manufactured mold, set the molding parameters, and then press to form. The preparation process is convenient, the raw materials are cheap, and no...

Embodiment 1

[0048] (1) Press Zn 2 SiO 4 Chemical formula ingredients, weighing 73.78g ZnO and 27.23g SiO 2 The ingredients are 100.0g in total; 100.0g of material + 300.0g of zirconia balls + 200.0ml of deionized water are added into a nylon tank, and ball milled for 1.0h in a planetary ball mill with a rotation speed of 200r / min.

[0049] (2) Put the ball-milled raw powder slurry in step (1) into a constant temperature drying oven, dry at 150° C. for 4.0 h, pass through a 20-mesh sieve after drying, and obtain a uniformly mixed powder.

[0050] (3) Pour the powder sieved in step (2) into an alumina crucible, place it in a muffle furnace, and pre-fire it at 1100°C for 4.0h to obtain Zn 2 SiO 4 The ceramic powder is passed through a 20-mesh sieve for later use.

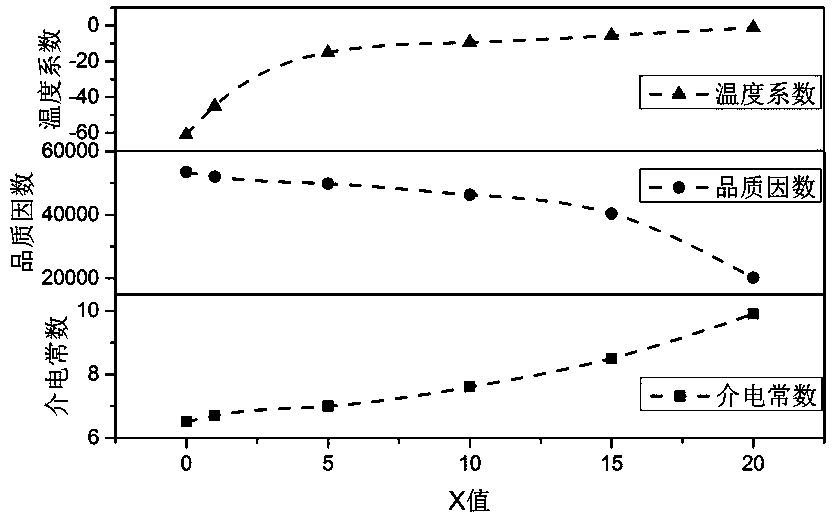

[0051] (4) 1.0g TiO 2 and the 99.0g Zn obtained in step (3) 2 SiO 4 Mix ceramic powder, 100.0g in total; add 100.0g material + 300.0g zirconia balls + 200.0ml deionized water into a nylon tank, and mill for 1.0h in a planet...

Embodiment 2

[0054] (1) Press Zn 2 SiO 4 Chemical formula ingredients, weighing 73.78g ZnO and 27.23g SiO 2 The ingredients are 100.0g in total; 100.0g of material + 300.0g of zirconia balls + 200.0ml of deionized water are added into a nylon tank, and ball milled for 1.0h in a planetary ball mill with a rotation speed of 200r / min.

[0055] (2) Put the ball-milled raw powder slurry in step (1) into a constant temperature drying oven, dry at 150° C. for 4.0 h, pass through a 20-mesh sieve after drying, and obtain a uniformly mixed powder.

[0056] (3) Pour the powder sieved in step (2) into an alumina crucible, place it in a muffle furnace, and pre-fire it at 1100°C for 4.0h to obtain Zn 2 SiO 4 The ceramic powder is passed through a 20-mesh sieve for later use.

[0057] (4) 5.0g TiO 2 and the 95.0g Zn obtained in step (3) 2 SiO 4 Mix ceramic powder, 100.0g in total; add 100.0g material + 300.0g zirconia balls + 200.0ml deionized water into a nylon tank, and mill for 1.0h in a planet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com