Natural gas horizontal well drilling mechanism

A technology for horizontal wells and natural gas, which is applied in the exploration and development of natural gas and the petroleum field. It can solve the problems of frequent adjustment of wellbore trajectory control in the horizontal section, the inability of the drill bit to apply effective drilling pressure, and the large fluctuation range of compressive strength, etc., to improve the single drill bit The effects of increasing footage, enhancing sand-carrying ability, and shortening drilling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below.

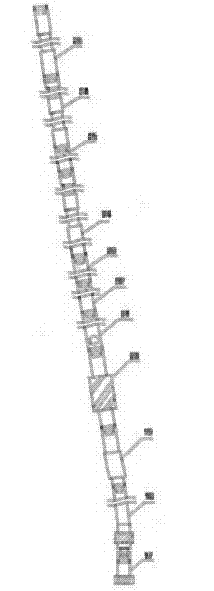

[0016] A natural gas horizontal well drilling process, each well section sequentially adopts the following drilling tool assemblies from bottom to top:

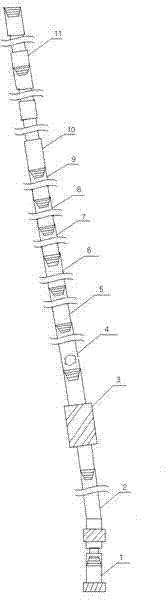

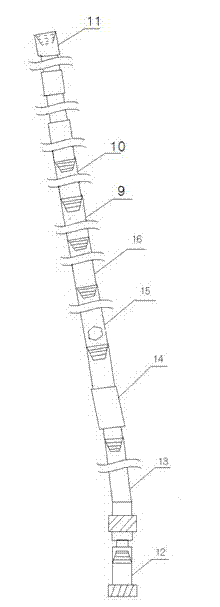

[0017] (1) The drilling tool assembly used in the vertical well section is: Φ228.6mm631PDC drill bit 1, 0.75 degree 7LZΦ185mm630×410 screw rod 2, Φ224mm411×410 rigid centralizer 3, Φ178mm 411×410MWD wireless directional joint while drilling 4, Φ178mm411×410 non-magnetic Drill collar 5, 2 Φ178mm 411×410 drill collar 6, 411×460 adapter 7, 15 Φ165mm 461×460 drill collar 8, 461×410 adapter 9, 45 Φ127mm411×410 heavy drill pipe 10 and Φ127mm411×410 Drill pipe 11. Among them, 411 X410 is the buckle type, "4" stands for 4 inches, the first "1" stands for the inner flat joint, the second "1" stands for the male buckle; "0" stands for the female buckle. When connecting, the male buckle is connected with the female buckle. The lower box of Φ185mm630×410 screw rod 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com