Full-face blasting vibration control construction method for tunnel electronic millisecond electric detonator

A construction method and electric detonator technology, applied in blasting and other directions, to achieve the effect of improving blasting effect, construction efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below in conjunction with the accompanying drawings and embodiments, and this example is only illustrative, rather than limiting the invention.

[0030] 1. Brief introduction of the tunnel:

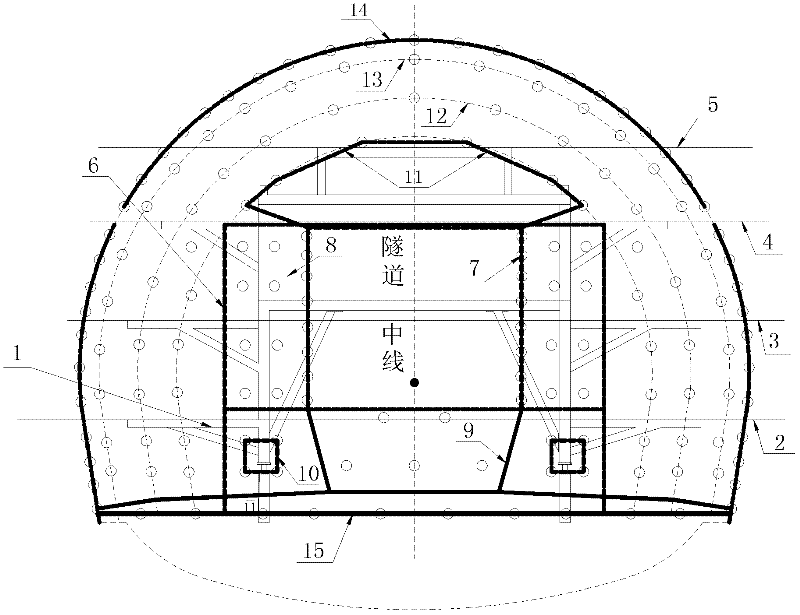

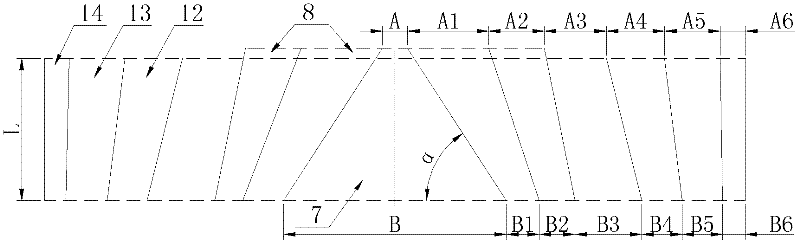

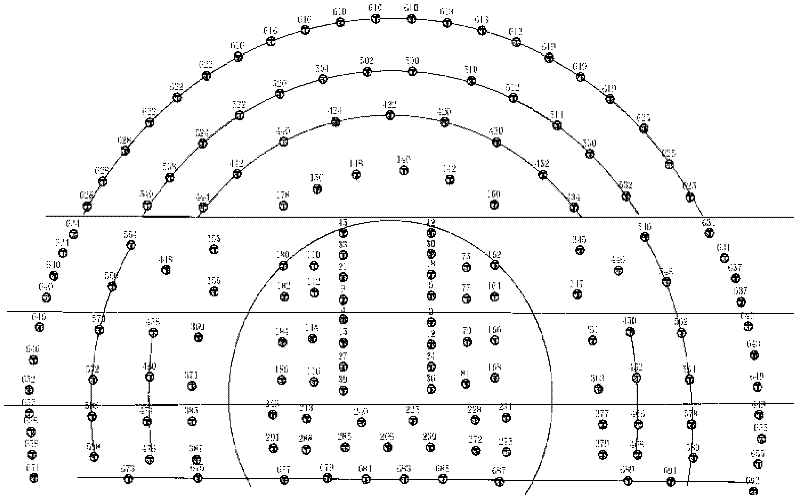

[0031] Changhongling Tunnel (13299m) is the second extra-long tunnel of Yuli Railway, and the exit of the tunnel is located in Jiangchi Town, Fengdu County, Chongqing City. The tunnel passes through Jiangchi Town at section DK183+050~DK183+350, with shallow buried depth and dense houses on the surface. The construction of DK183+000~DK183+400 section adopts controlled blasting, and the surface vibration velocity is controlled to be no more than 1.5cm / s. The geology of the explosion control section is J3s sandstone, the stratum is generally monoclinical, the dip angle of the strata is small, the joint spacing is 0.5-2m, and the extension length is 2-5m; the span of the section is 13.82m, and the height is 11.82m; The height is 9.98m (the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com