Elastic bearing and manufacturing method thereof

An elastic bearing and connecting piece technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve the problems of lack of elasticity and self-adjusting shock absorption and buffering functions, and achieve large-scale promotion and application, high labor efficiency , the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

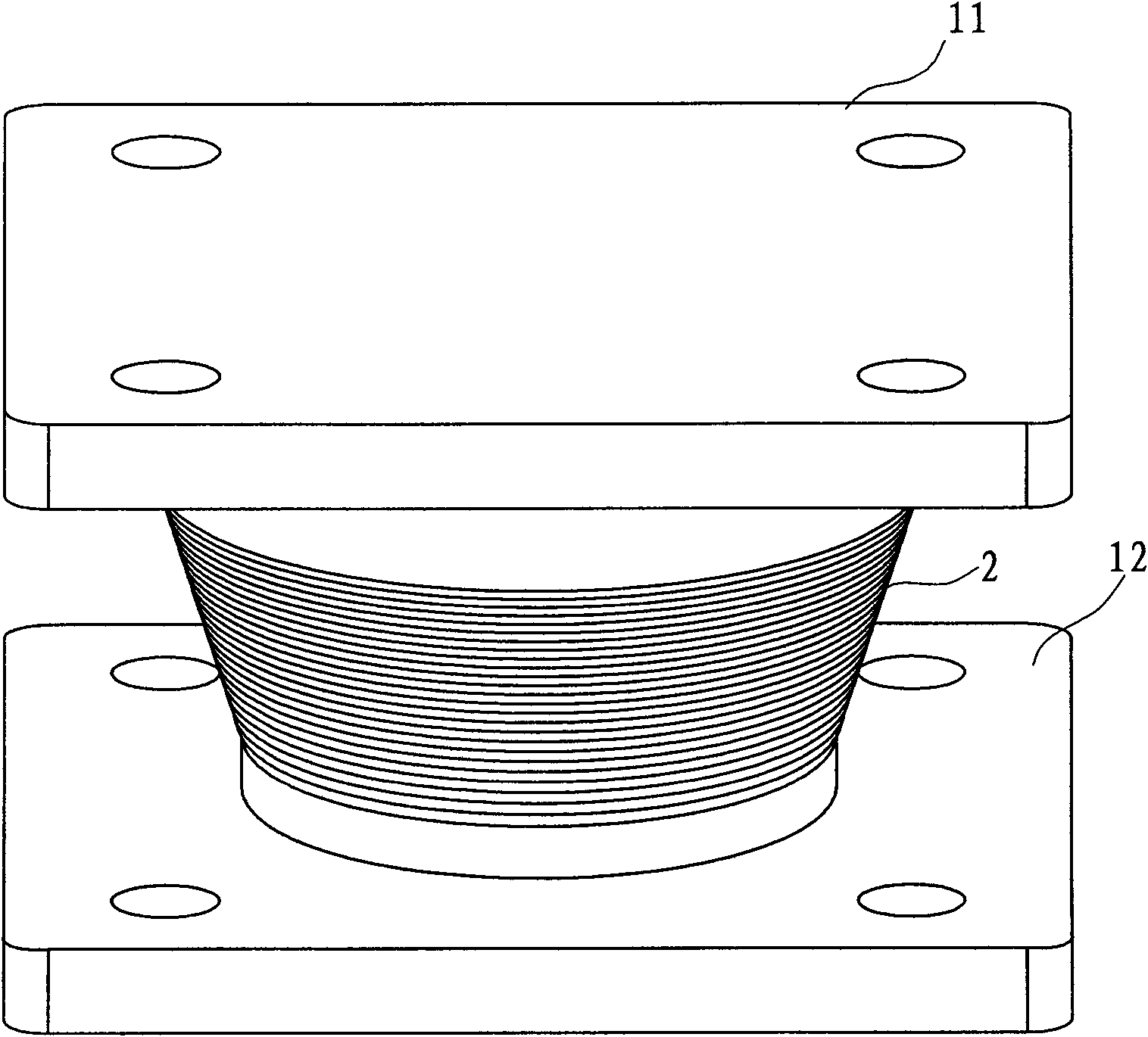

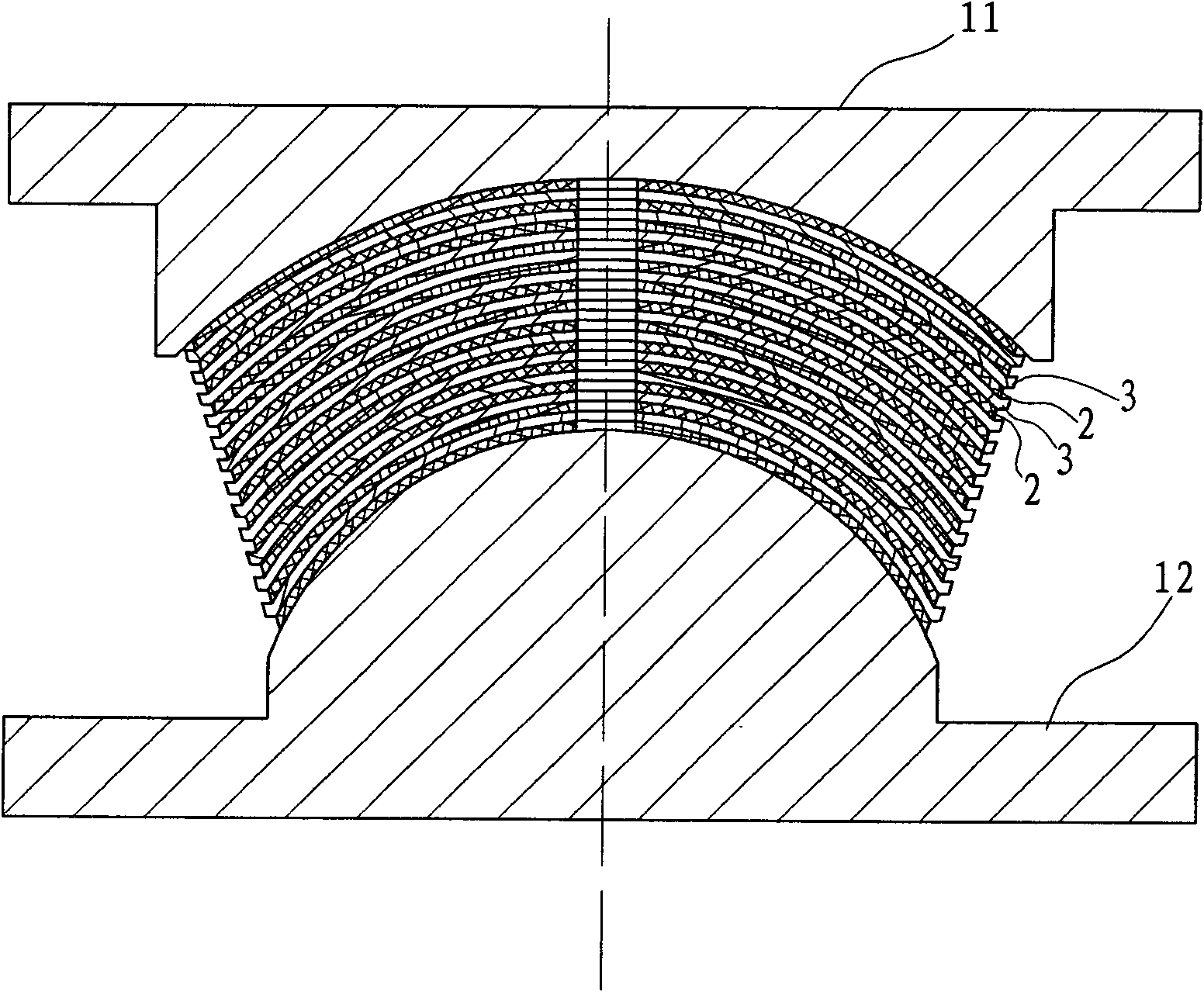

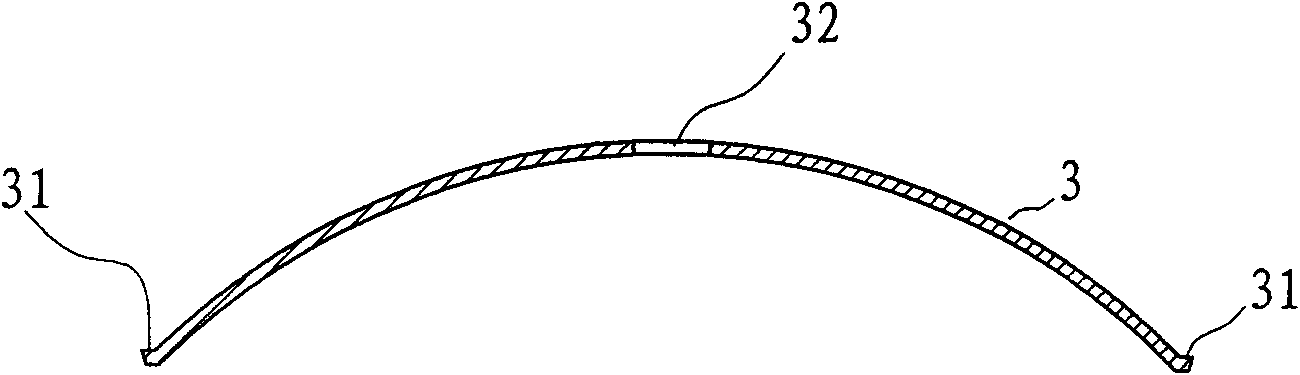

[0022] Such as figure 1 and figure 2 As shown, the elastic bearing in this embodiment includes a first connecting piece 11 and a second connecting piece 12 located at both ends, and a multi-layer rubber with buffering and shock-absorbing functions is bonded between the first connecting piece 11 and the second connecting piece 12. Layers of rubber sheets 2, and metal linings 3 are bonded at intervals between the rubber sheets 2.

[0023] The inner wall of the first connecting piece 11 has an arc-shaped concave surface, and correspondingly, the inner wall of the second connecting piece 12 has an arc-shaped convex surface, and the rubber sheet 2 and the metal lining 3 have a shape suitable for the first connecting piece 11 and the second connecting piece 12. curved surface. This design can meet the needs of adjusting the angle within a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com