Tricone PDC concentric drill bit

A technology of three cones and drill bits, which is applied to drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of serious drill bit effectiveness, short footage of a single drill bit, and slow ROP, etc., and achieves good self-cleaning effect and expands Use range, reduce the effect of tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

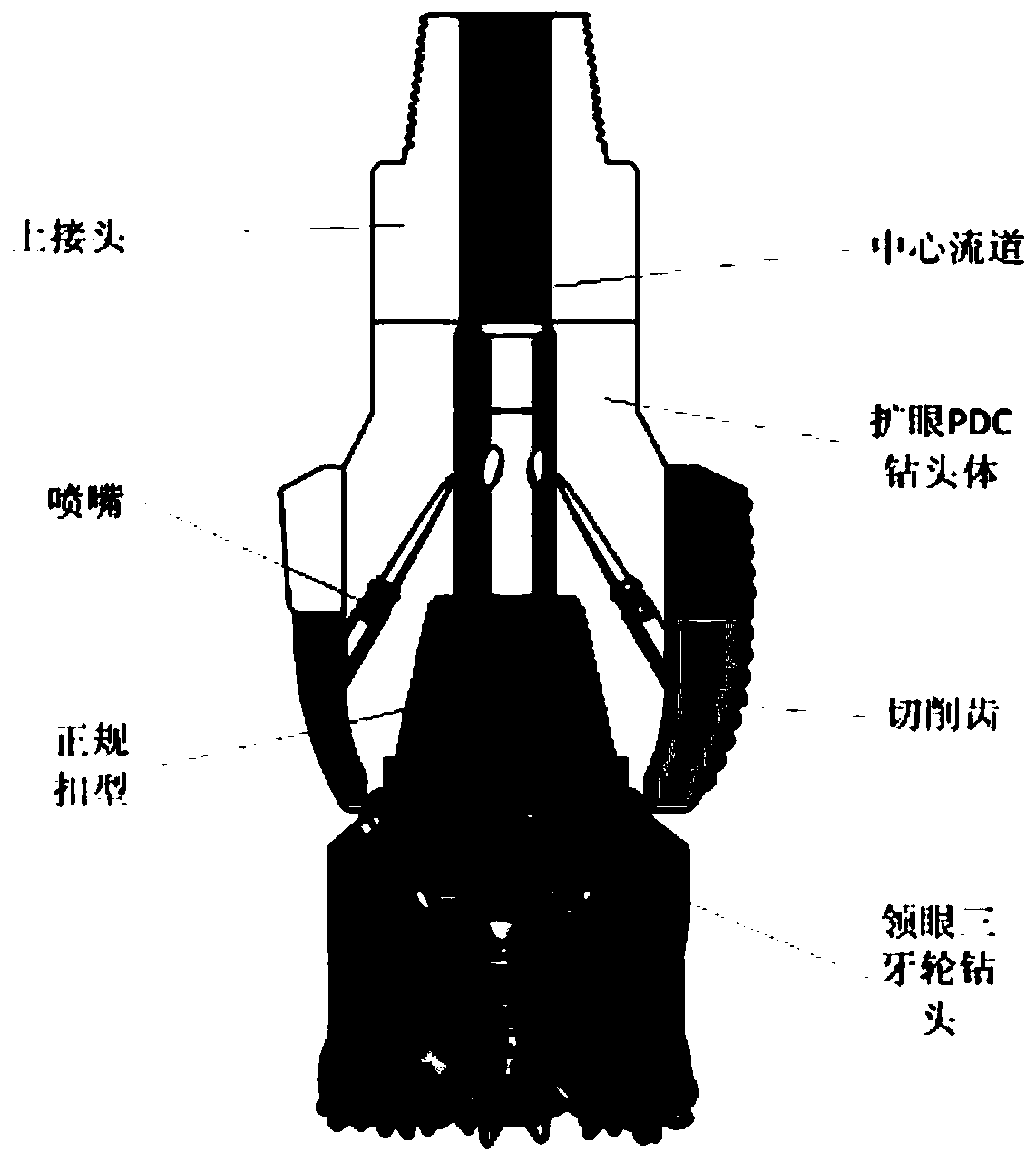

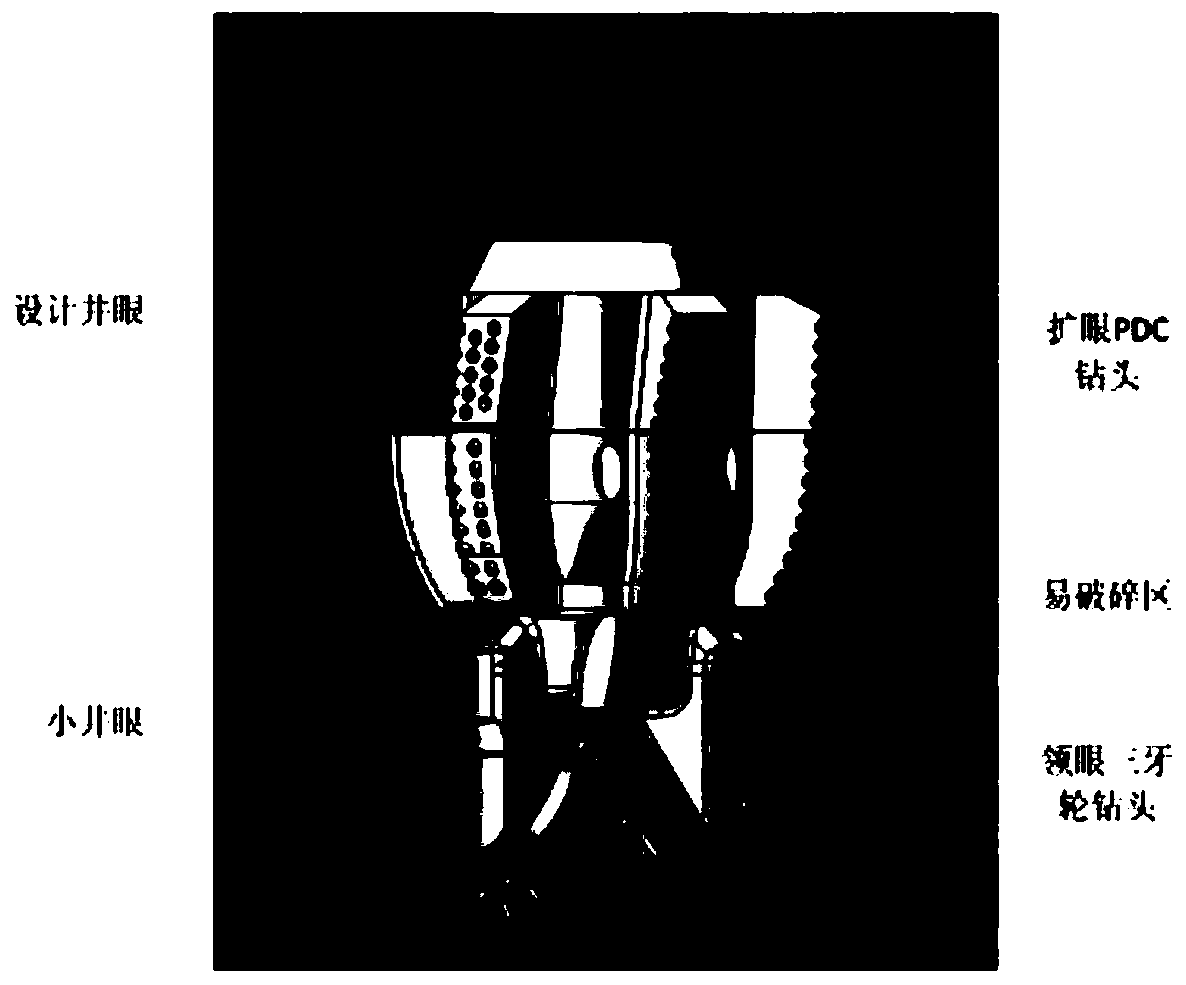

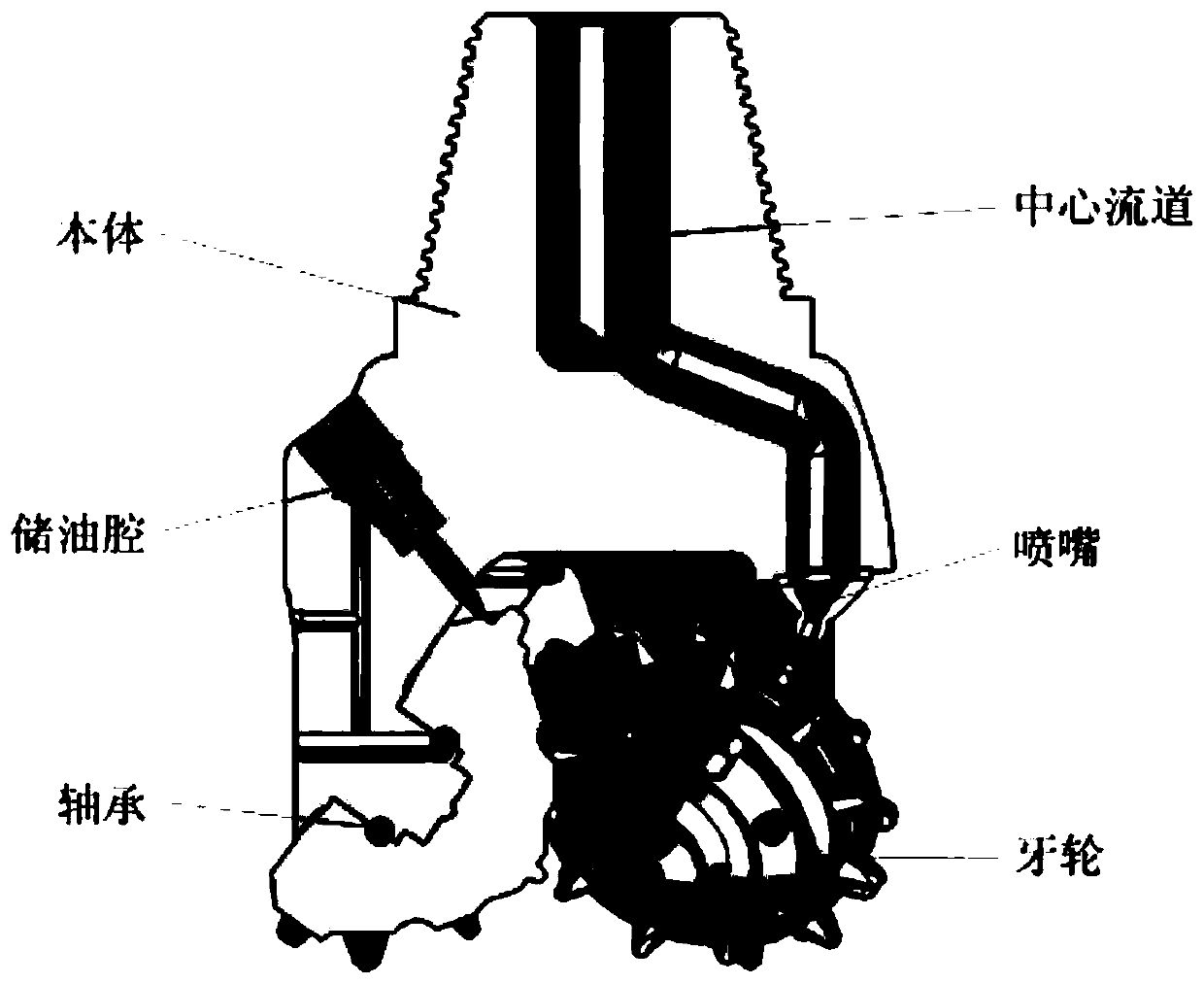

[0026] The traditional tricone bit and the PDC bit have different structures and different rock breaking methods, and each has advantages and disadvantages in the drilling process. Therefore, this embodiment considers the organic combination of the tricone bit and the PDC bit to form a tricone PDC double bit. High-grade drill bits, the drill bits are set concentrically, so as to improve the formation applicability of the drill bits and exert the best rock breaking effect.

[0027] see figure 1 , The three-cone PDC concentric bit is composed of a three-cone bit and a PDC bit, of which the front-end pilot bit at the lower part of the three-cone PDC concentric bit is a three-cone bit, and the reaming bit following its mouth is a PDC bit, thus forming Double-stage drill bit, and the rotation axes of the upper and lower drill bit are coincident. The tri-cone bit and the PDC bit are connected by a taper thread regular button type, which is convenient for changing the tri-cone bit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com