Diamond impregnated segment with tooth cavities

A technology of diamond and impregnated inserts, which is applied to cutting elements for geological drilling bits and oil fields, can solve the problem of not being able to prevent heart digging very well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

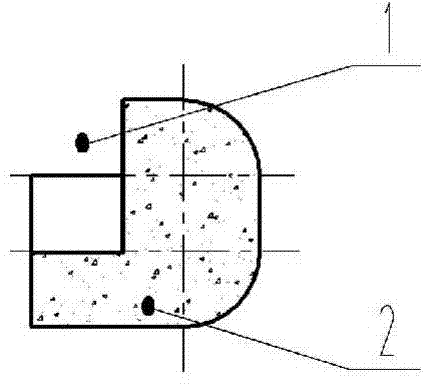

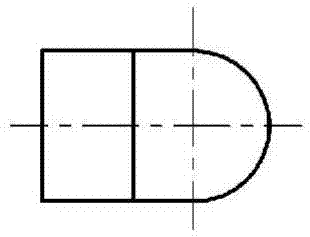

[0028] Such as Figure 1.1 , Figure 1.2 , Figure 1.3 The diamond impregnated block with tooth cavity shown is composed of tooth cavity 1 and diamond impregnated block 2. Tooth cavity 1 is the position for inserting cutting elements. The specific shape is determined by the shape of the cutting teeth used. Diamond impregnated block 2 is a mixed sintered body of diamond particles and matrix powder. The diamond particles are natural diamond particles, artificial diamond, thermally stable polycrystalline diamond and cubic boron nitride block. The matrix powder is 20%~70% tungsten carbide Powder, 20%~60% copper powder, 3%~20% nickel powder, 10%~60% cobalt powder. The arc surface and spherical surface on the diamond impregnated block 2 are to reduce stress concentration and enhance the welding strength of the impregnated block. The diameter of the tooth pocket 1 is the same as the width of the diamond impregnated block 2 .

Embodiment approach 2

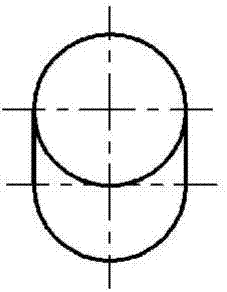

[0029] Implementation mode two: if Figure 2.1 , Figure 2.2 , Figure 2.3 The diamond-impregnated insert with tooth holes shown is the same as that of Embodiment 1 Figure 1.1 , Figure 1.2 , Figure 1.3 The shown diamond impregnated insert with pockets differs in that the width of the diamond impregnated insert 2 is greater than the diameter of the pocket 1 . The curved surfaces of the diamond-impregnated inserts with tooth pockets also change accordingly.

Embodiment approach 3

[0030] Implementation mode three: if Figure 3.1 , Figure 3.2 , Figure 3.3 The diamond-impregnated insert with tooth holes shown is the same as that of Embodiment 1 Figure 1.1 , Figure 1.2 , Figure 1.3 The difference of the diamond impregnated block with tooth pockets shown is that two tooth pockets 1 are arranged on the diamond impregnated block 2, that is, the diamond impregnated block with double tooth pockets.

[0031] It is also possible to design a diamond impregnated block with more than three tooth cavities, the shape of the tooth cavity 1 changes with the shape of the cutting element, and the diamond impregnated block 2 can be designed into more shapes.

[0032] Such as Figure 4.1 , Figure 4.2 , Figure 4.3 As shown, a cutting element 3 is embedded in the tooth pocket 1 of the diamond-impregnated insert 2 with tooth pockets. In addition to the cylindrical shape, the cutting element 3 also has a fan-cylindrical, wedge-shaped, hexahedral, elliptical-cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com