Rotary excavating drilling machine squeezing hole-forming construction technique

A technology of rotary drilling rig and construction technology, which is applied in the direction of drill bit, drilling equipment, directional drilling, etc. It can solve the problems of low hole formation efficiency in rock-socketed sections, influence on construction progress, and easy hole collapse, so as to reduce the risk of hole collapse , Save construction cost, reduce the effect of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A rotary drilling rig extrusion hole construction process, comprising the following steps:

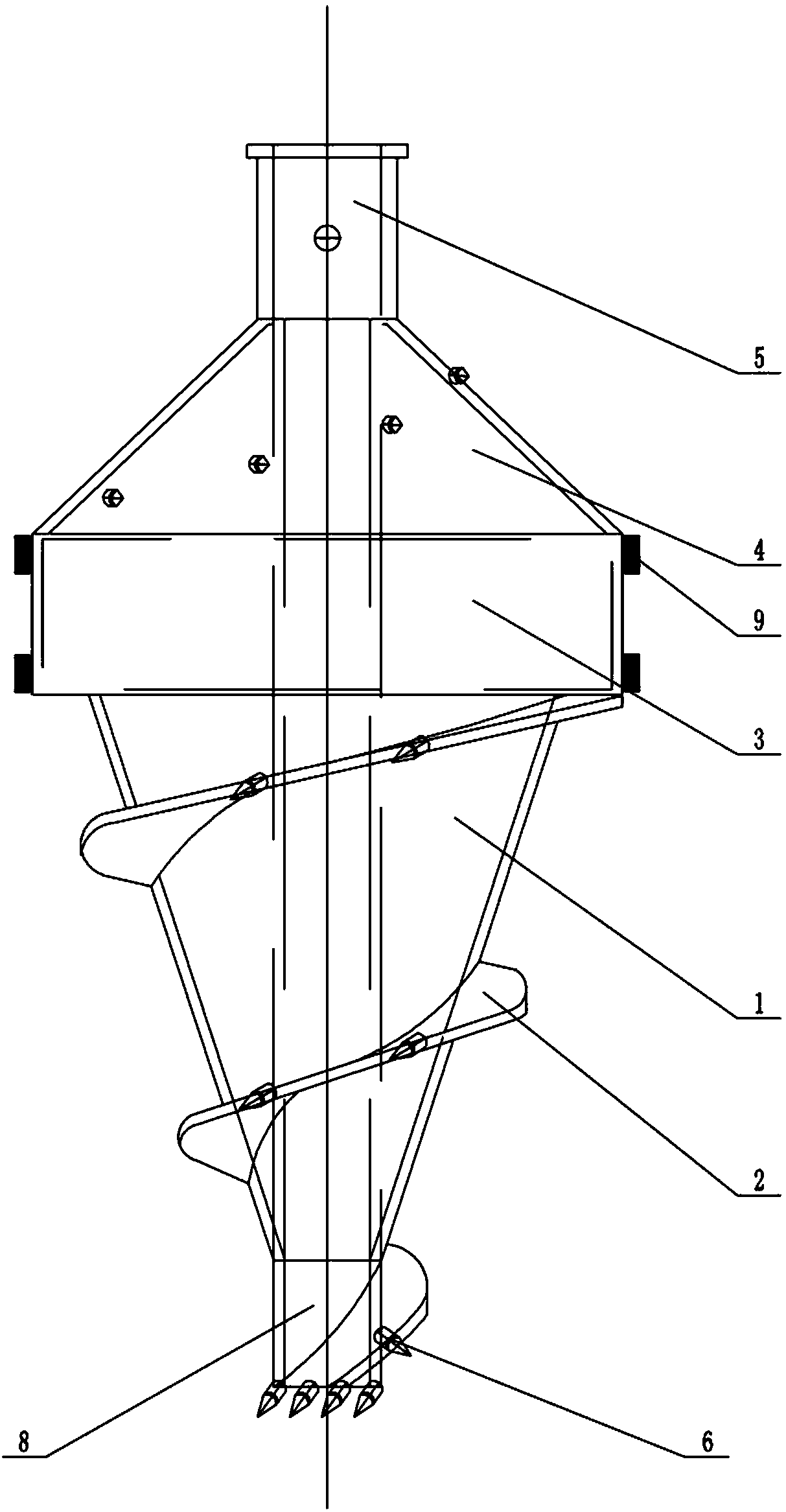

[0029] (1) Construction preparation: Prepare a rotary drilling rig that matches the hole depth and pile diameter, a drill bit for the rotary drilling rig that is the same as the designed pile diameter, and a special drill bit for extrusion drilling, and clay with a moisture content of 12-15% , if there is a soil layer with very poor gradation and serious lack of fine bone filler according to the analysis of the geological survey report, suitable clay can be prepared according to the test pile. Such as figure 1 As shown, from top to bottom, the special drill bit for extruding holes includes a reverse conical slag discharge cylinder 4, an anti-deflection drill body 3, and a conical extrusion cylinder 1 with a large upper part and a smaller lower one. The side wall of the anti-deflection drill body 3 is provided with The wear-resistant material layer 9 and the conical extruding cy...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the anti-deflection drill body 3 of the special drill bit for extruding into holes is provided with a through hole that runs through the diameter of the anti-deflection drill body, and a pressure rod is fixed in the through hole. Both ends of the rod protrude from the anti-deflection drill body and the protruding length can be adjusted. The pressing rod includes sleeves respectively fixed on both sides of the through hole and sliding rods slidably connected in the sleeve and the through hole, and the lengths of the two sliding rods protruding from the sleeve are equal. The sleeve is provided with a plurality of limit holes, and the slide bar is provided with a plurality of jacks matched with the limit holes, and the slide bar can be fixed by passing through the limit holes and the jacks successively by means of bolts and other fixing parts. Adjust the length of the pressing rod according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com