Rotary tail pipe hanger capable of respectively drilling and completing

A liner hanger and tubular technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve problems such as inability to cement wells, and achieve reliable drilling, safe operation, and excellent cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

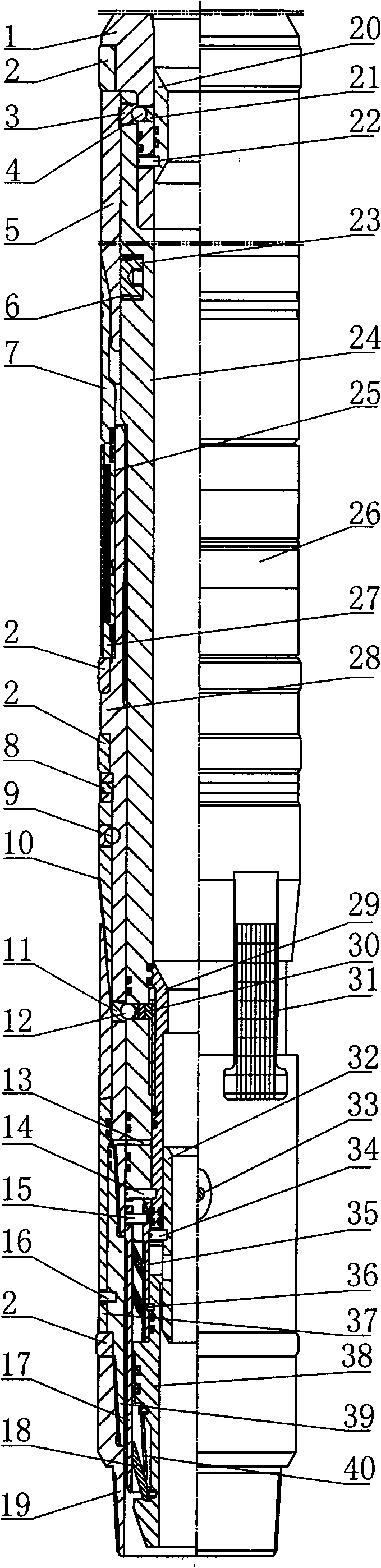

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] Depend on figure 1 As shown, the rotary liner hanger capable of drilling and completion respectively includes a lower joint 19 and an upper joint 1, which are composed of a hollow plug mechanism, a set-hang mechanism, a setting mechanism and a feeding mechanism;

[0031] The described feeding mechanism mainly transmits the torque through the spline, and at the same time, plays the role of emergency release when the unjamming ball 4 is separated from the upper joint 1 and the central pipe 24 . The feeding mechanism mainly includes an upper joint 1 , a retaining pin pressing cap 6 , a retaining pin 23 and a central tube 24 . The central tube 24 is mainly used for connection. The central tube 24 is tubular, and there are splines outside the middle. The splines mainly play a role in transmitting torque. The corresponding holes of the upper joint 1 and the central tube 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com