Automatic anchor rod drill carriage

An automatic technology for rock bolt drilling rig, applied in the field of automatic rock bolt drilling rig and support equipment, can solve the problems of low personnel safety factor, insufficient automation, slow construction process, etc., so as to reduce the risk of accidents and reduce labor intensity. , The effect of drilling smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

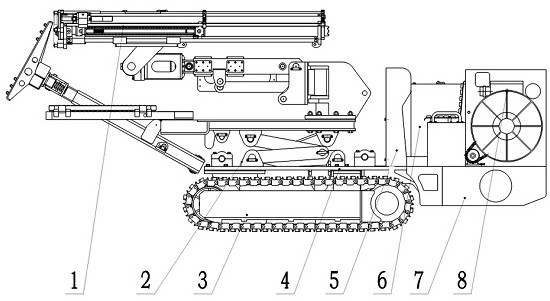

[0032] The present invention is an automatic rock bolter designed for punching holes on the roadway roof and side walls and installing bolts in underground coal mines and other roadway projects. It adopts a lifting device in structure and adds a whole lifting platform, which can According to the height of the roadway, the operators can adjust up and down through the lifting of the platform, so that it is very convenient to realize the mechanized construction of anchor (cable) holes, blast holes and detection holes at different heights and angles in the roadway, and can realize the simultaneous operation of top and side, greatly greatly The support operation time is shortened and the support efficiency is improved.

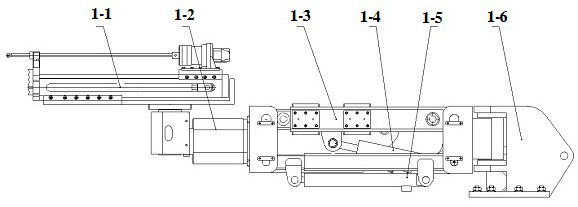

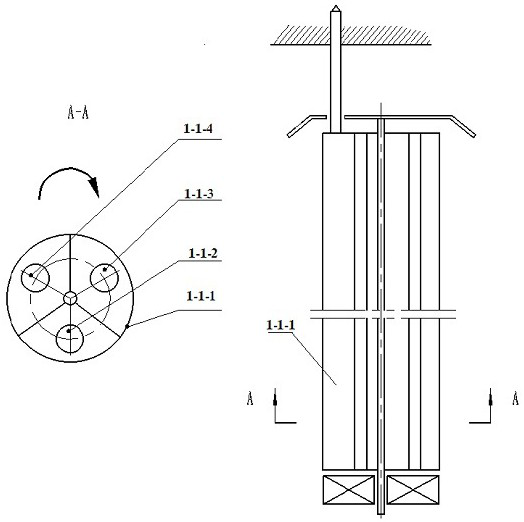

[0033] Combine below Figure 1-7 The present invention is described in further detail:

[0034] Such as figure 1 As shown, an automatic rock bolter includes an anchor drilling system 1, a body part, a walking system 3, a hydraulic system, a waterway system and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com