Torsional impact drilling tool

A technology of percussion drilling and tools, applied in the direction of drilling with vibration, can solve the problems of torsional vibration of the drill string, insufficient penetration depth of the drill bit, adverse effects on the service life of the drill bit and the supporting parts of the drill string, etc., and achieve the effect of reducing the torsional vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

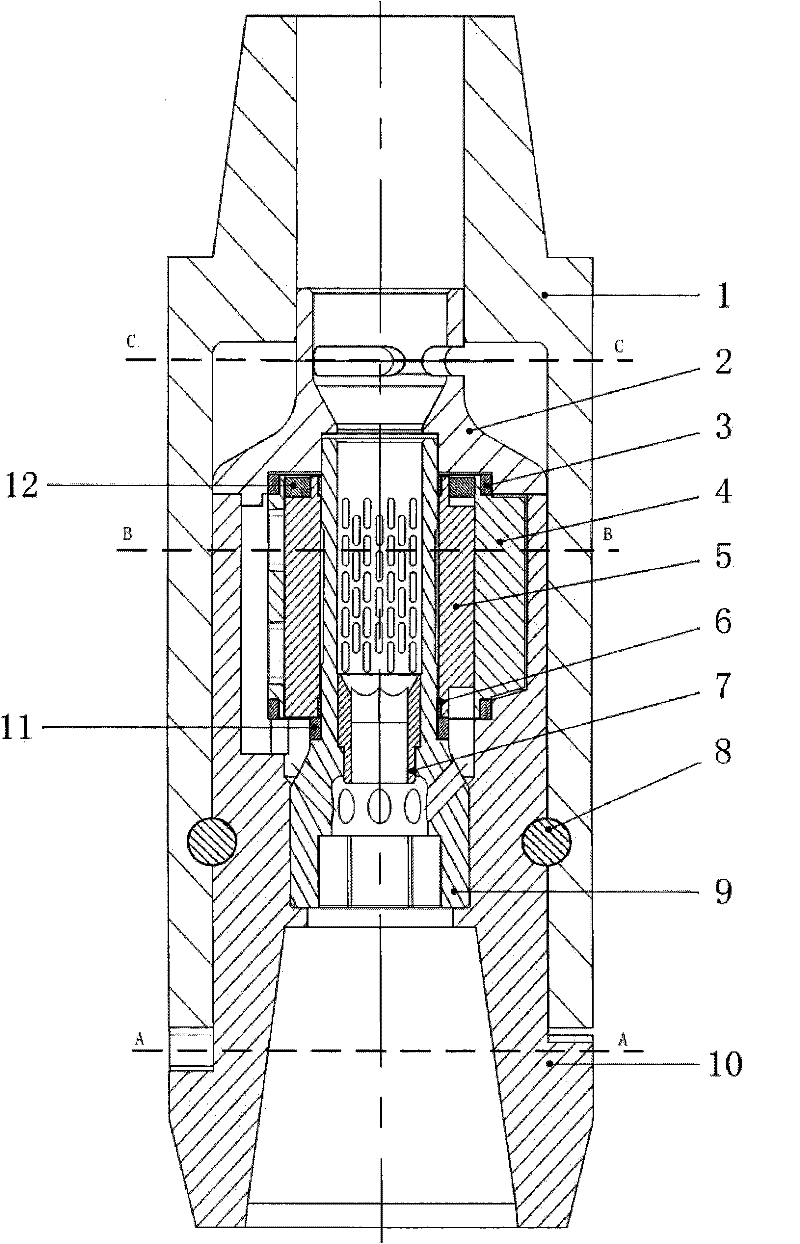

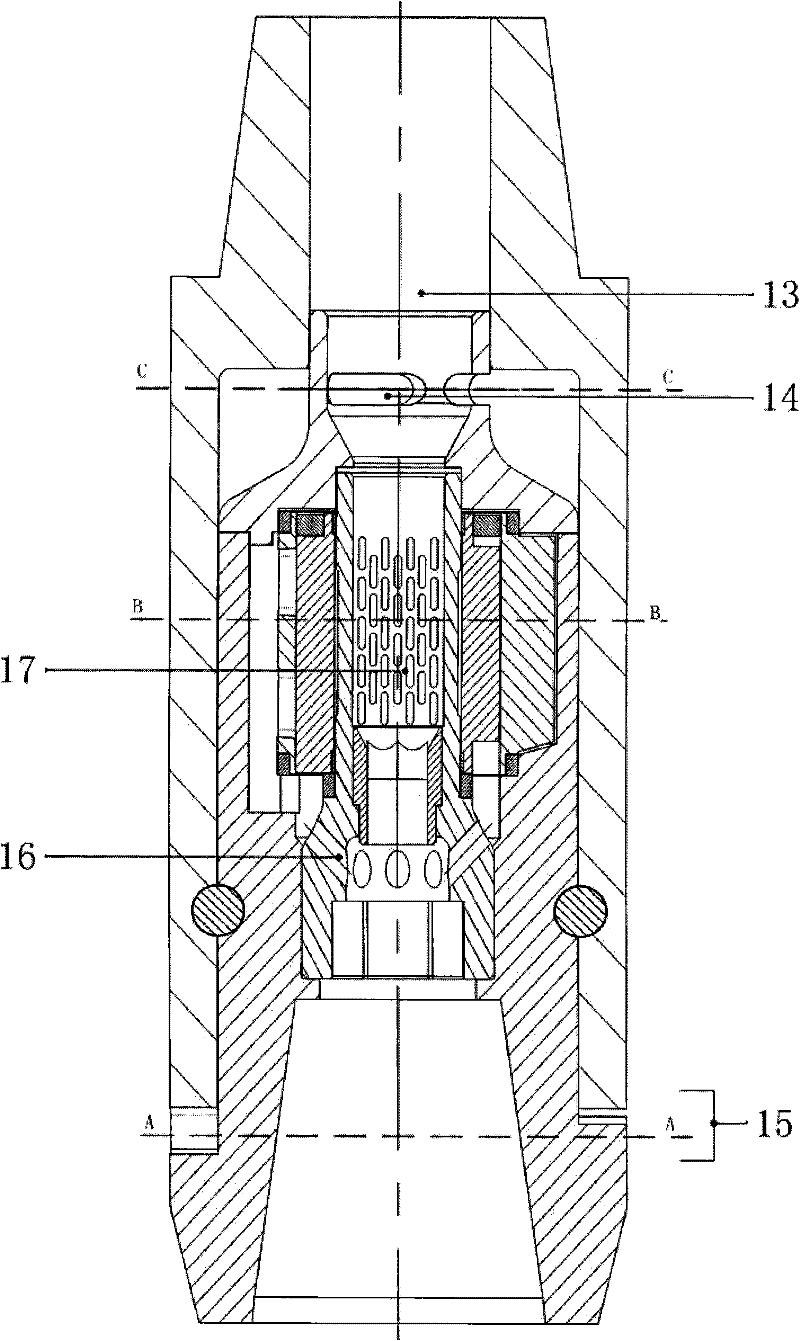

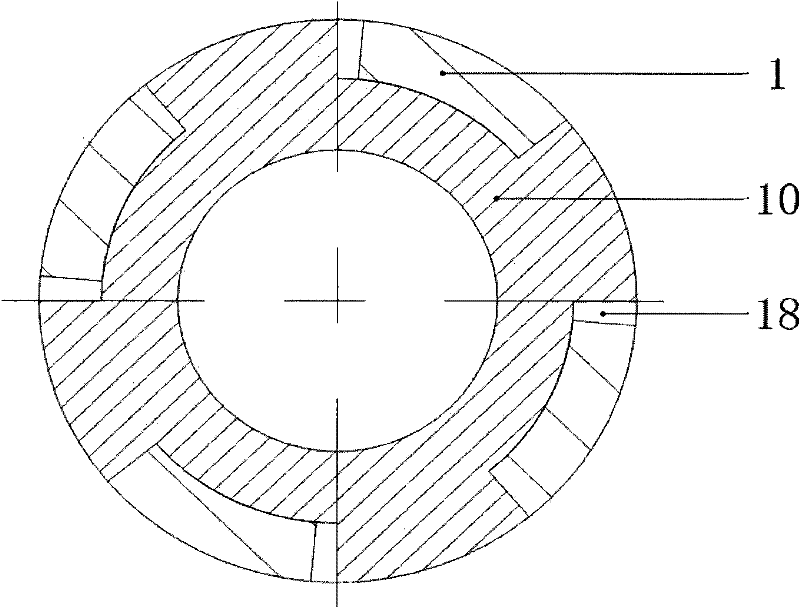

[0020] figure 1 As shown, the torsional impact drilling tool is mainly composed of a drill collar nipple 1, a torsional impact generator and a coupling body 8. The torsional impact generator is mainly composed of a diversion cover 2, a collar 3, an impact hammer 4, a positioning sleeve 5, It is composed of centralizing ring 6, shut-off nozzle 7, screen pipe 9, hammer seat 10, supporting ring 11 and capping ring 12; figure 1 , 2 As shown, the drill collar nipple 1 is outside, and the torsional impact generator is inside. The two are connected by a coupling body 8 and positioned by a spline 15; the coupling body 8 is composed of 20 balls; see figure 1 , 2 , 4, 5, 6, the drill collar nipple 1 is in the shape of a round tube, with threads at the upper end, and an annular gap 18 formed by interlocking splines 15 at the lower end and the outer side of the hammer seat 10; the shape of the hammer seat 10 is cylindrical, and the upper part has Hammer seat flow guide 31, the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com