Diamond drill and method for making same

A diamond drill bit and the technology of the drill bit are used in the manufacture of the drill bit and the field of the diamond drill bit, which can solve the problems of difficult chip removal by the coolant, low work efficiency, and limited drilling speed, so as to reduce the drilling resistance, speed up the drilling speed, alleviate the The effect of percussion drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

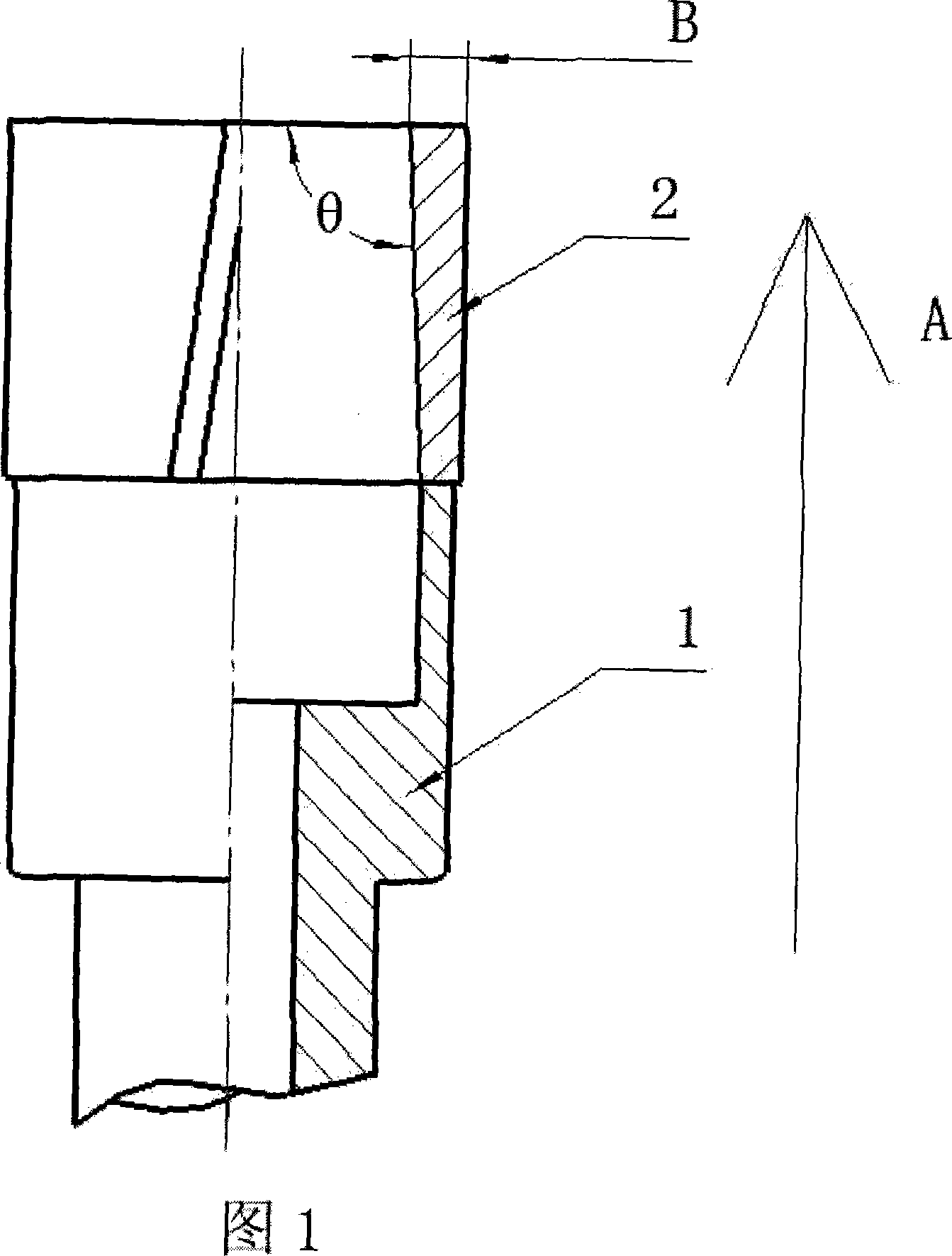

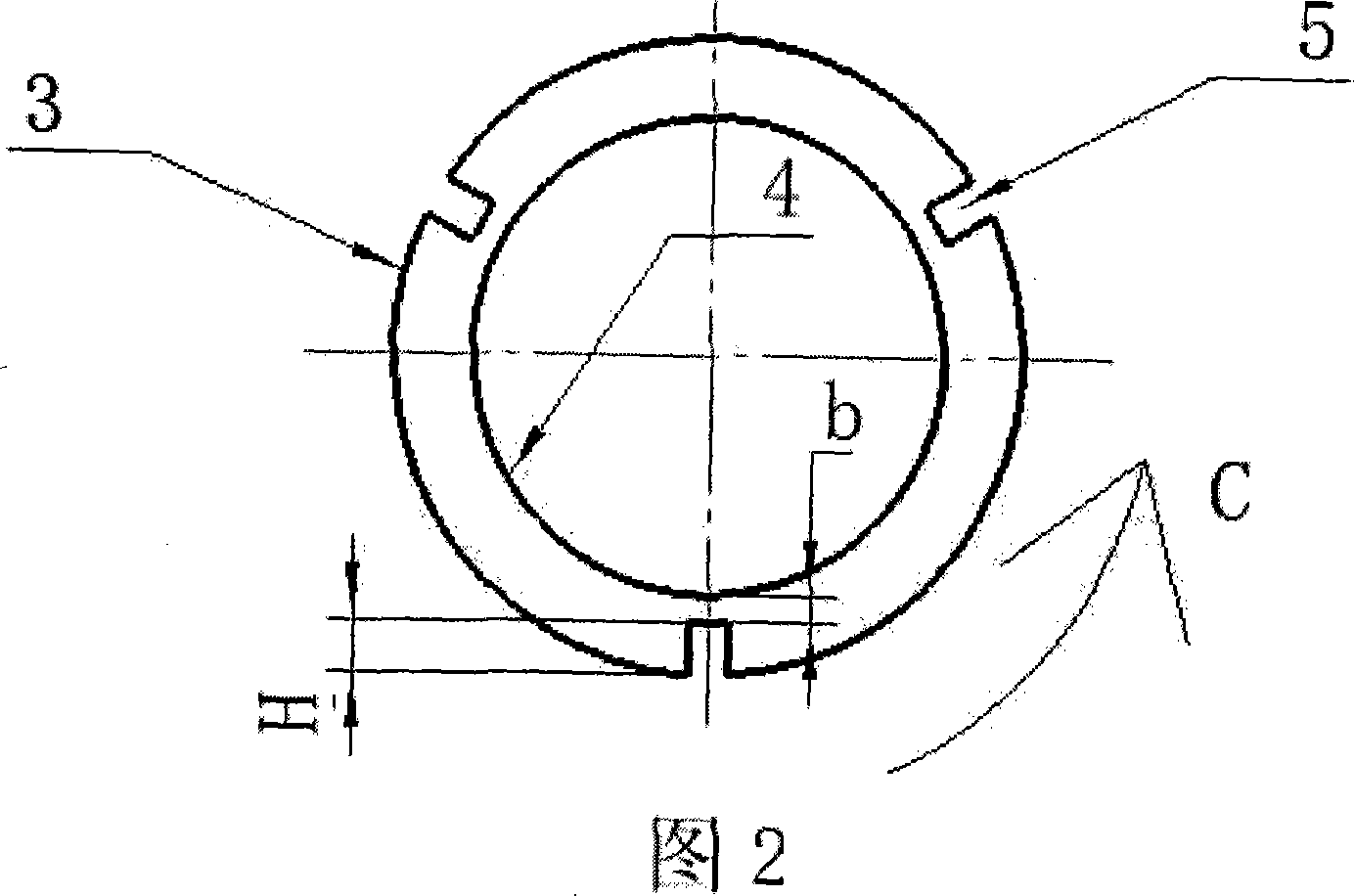

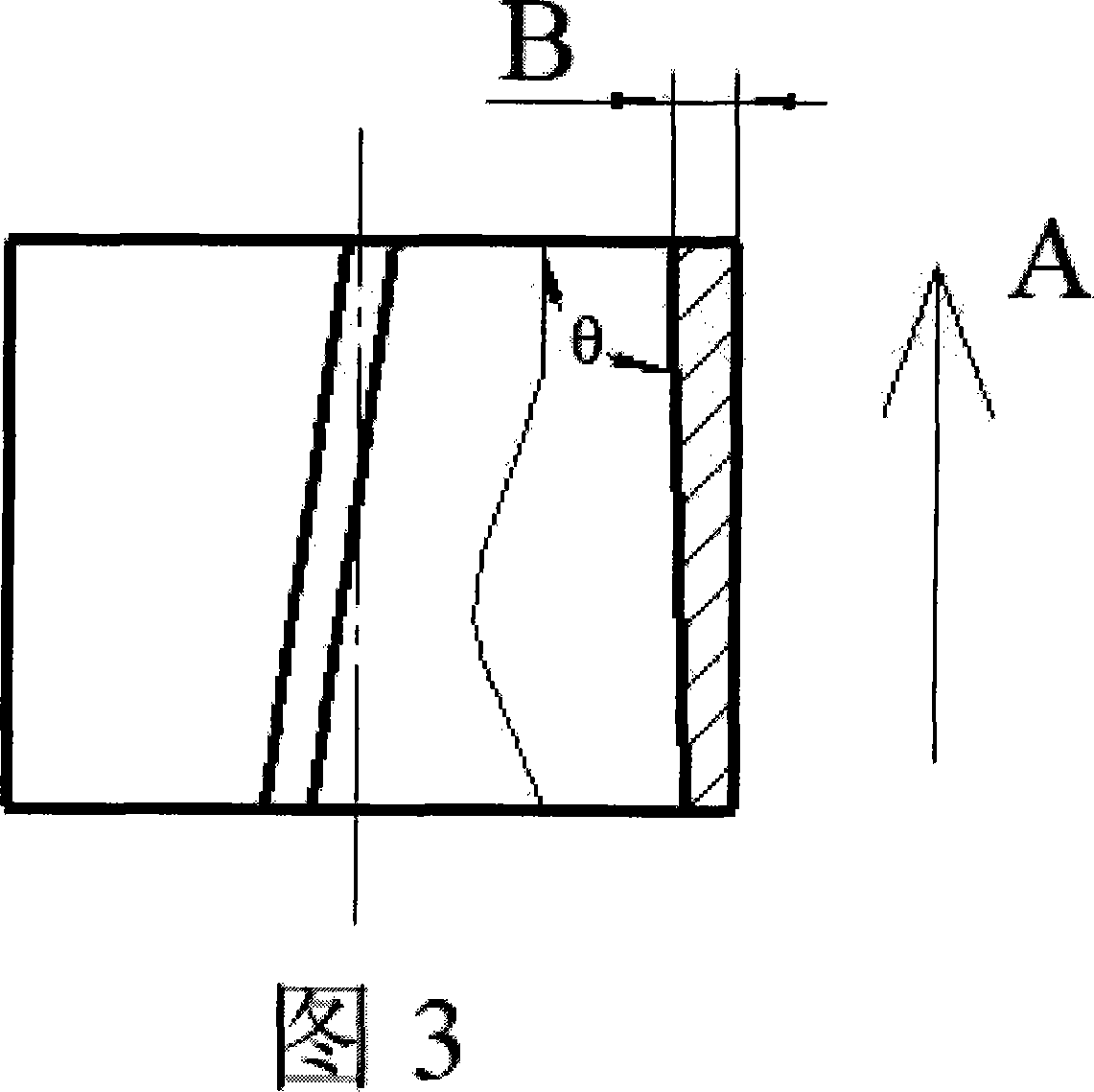

[0039] In the embodiment of the present invention shown in Fig. 1 and Fig. 2, the ultra-thin-wall seamless ring diamond drill includes a drill steel body 1 and a drill tooth 2, and the drill tooth 2 and the drill steel body 1 are integrated. The outer wall 3 of the drill tooth 2 shown in Figure 3 and Figure 4 is provided with a water-through chip removal groove 5, the water-through chip removal groove 5 is a spiral groove, and the rotation direction of the outer wall water-through chip removal groove 5 is shown in Figure 3 and Figure 4 Shown as a positive helical direction, the inner wall 4 is a conical surface whose diameter at the port is the smallest; the water-through chip removal grooves 5 are evenly distributed on the outer wall 3 . The port wall thickness B of the drill tooth is less than or equal to 2 mm, and the depth H of the water-through chip removal groove 5 is generally: 0<H<B, and the optimal value is 0.5B<H<B. In this embodiment the port wall thickness B is 0.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com