Mechanical torsional impact drilling tool

A percussion drilling, mechanical technology, which is applied to drilling equipment, driving devices for drilling in boreholes, earthwork drilling and production, etc. It can solve problems such as torsional oscillation, stick-slip, and low ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

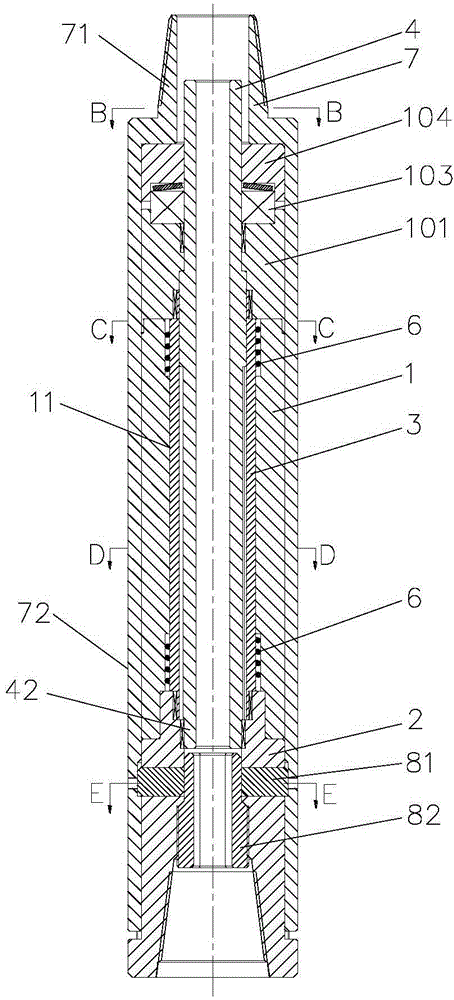

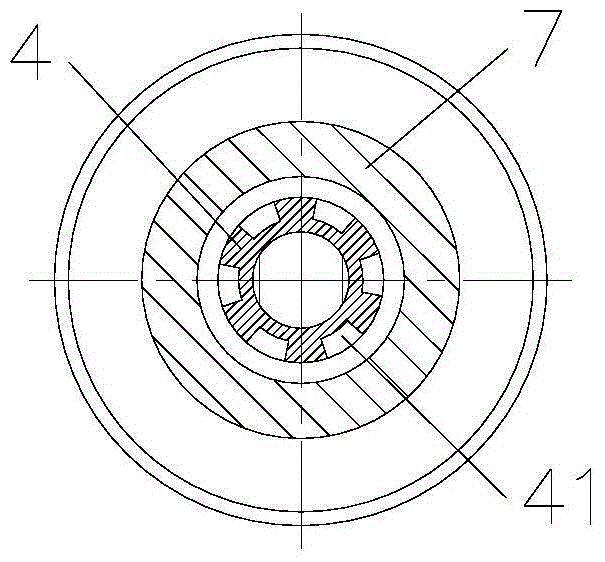

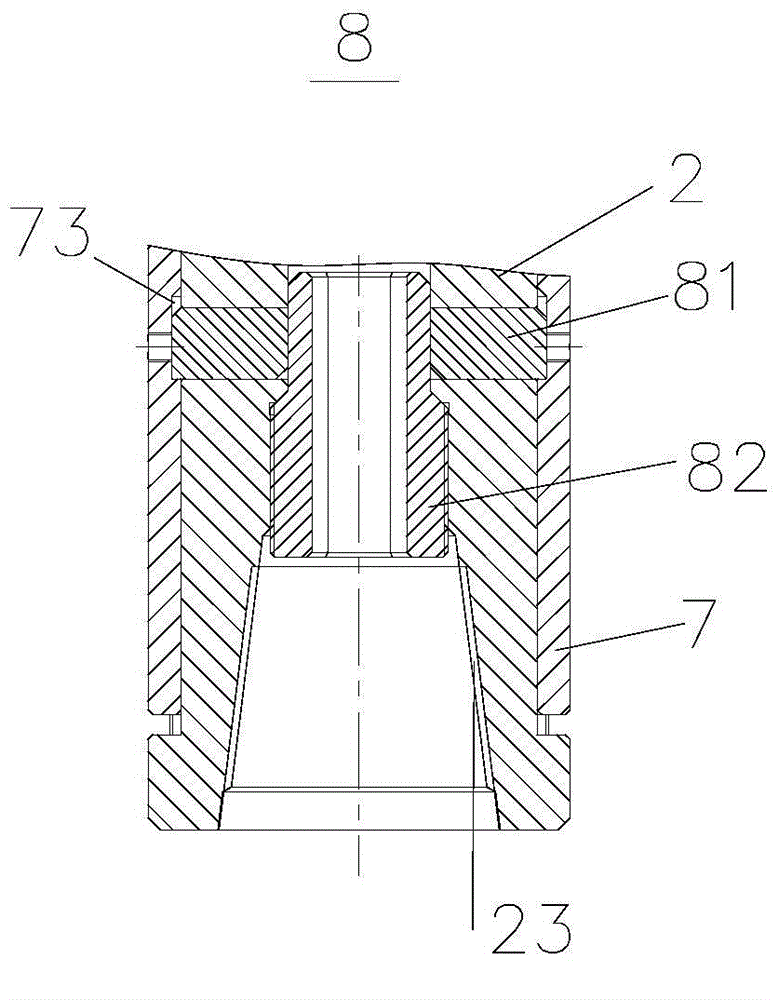

[0031] Such as figure 1 and figure 2 As shown, the percussion drilling tool includes an upper base body 1 , a lower base body 2 , an impact hammer assembly 3 , and a central rotating shaft 4 . The percussion drilling tool is provided with a screw rod or a turbo drill (not shown) on its upper part to provide rotational power, that is, by making the screw rod or the turbo drill in the screw drill or the spline groove provided at the lower end of the turbine rotor and the upper end of the central rotating shaft 4 Set the spline groove 41 (see figure 2 ) to cooperate with the installation, so as to realize the purpose that the screw or the turbine rotor drives the central rotating shaft 4 to rotate together.

[0032] Such as figure 1 As shown, in the embodiment of the present application, the upper base body 1 has a hollow area 11 inside. The shape of the upper base body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com