Positive and negative pressure combined plug flow fixed-point sampling device

A fixed-point sampling, positive and negative pressure technology, applied in sampling devices, preparation of samples for testing, etc., can solve the problems of inability to take fixed-point sampling, complicated process, long sampling time, etc., and achieve the effect of high sampling efficiency and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

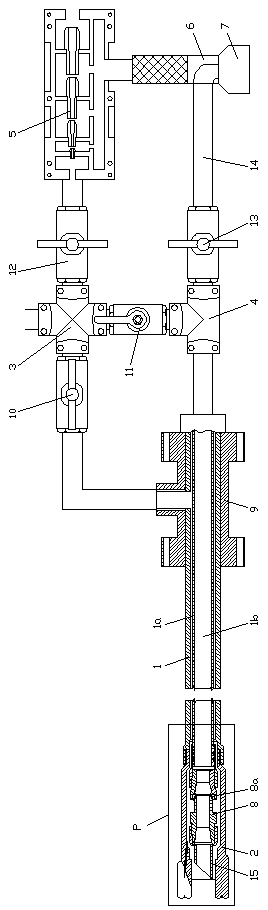

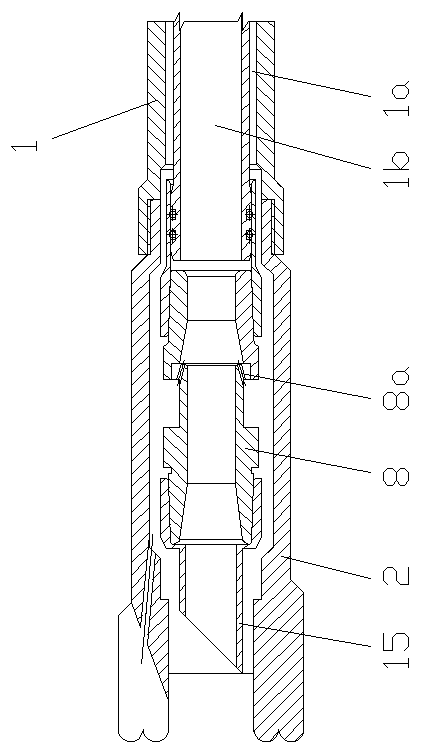

[0015] As shown in the figure, the positive and negative pressure combined plug flow fixed-point sampling device in this embodiment includes a double-walled drill pipe 1, a drill bit 2 arranged at the front end of the double-walled drill pipe 1, a four-way joint 3, a three-way joint 4, and a negative pressure generator. 5, gas-solid gravity separator 6 and sample collection tank 7, the drill bit 2 is fixedly connected with the outer wall of the double-walled drill rod, and the drill bit 2 is provided with an annular nozzle injector 8 fixedly connected with the inner wall of the double-wall drill rod, The ejection end of the annular nozzle injector 8 is provided with an air passage 8a that introduces the airflow outside the annular nozzle injector into the inner channel of the annular nozzle injector, and makes the air flow eject from the outlet side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com