Patents

Literature

39results about How to "Improve sampling productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tritium-containing exhaust gas discharge monitoring automatic sampling system

InactiveCN103063482AReduce labor intensityImprove sampling productivityWithdrawing sample devicesAutomatic controlSolenoid valve

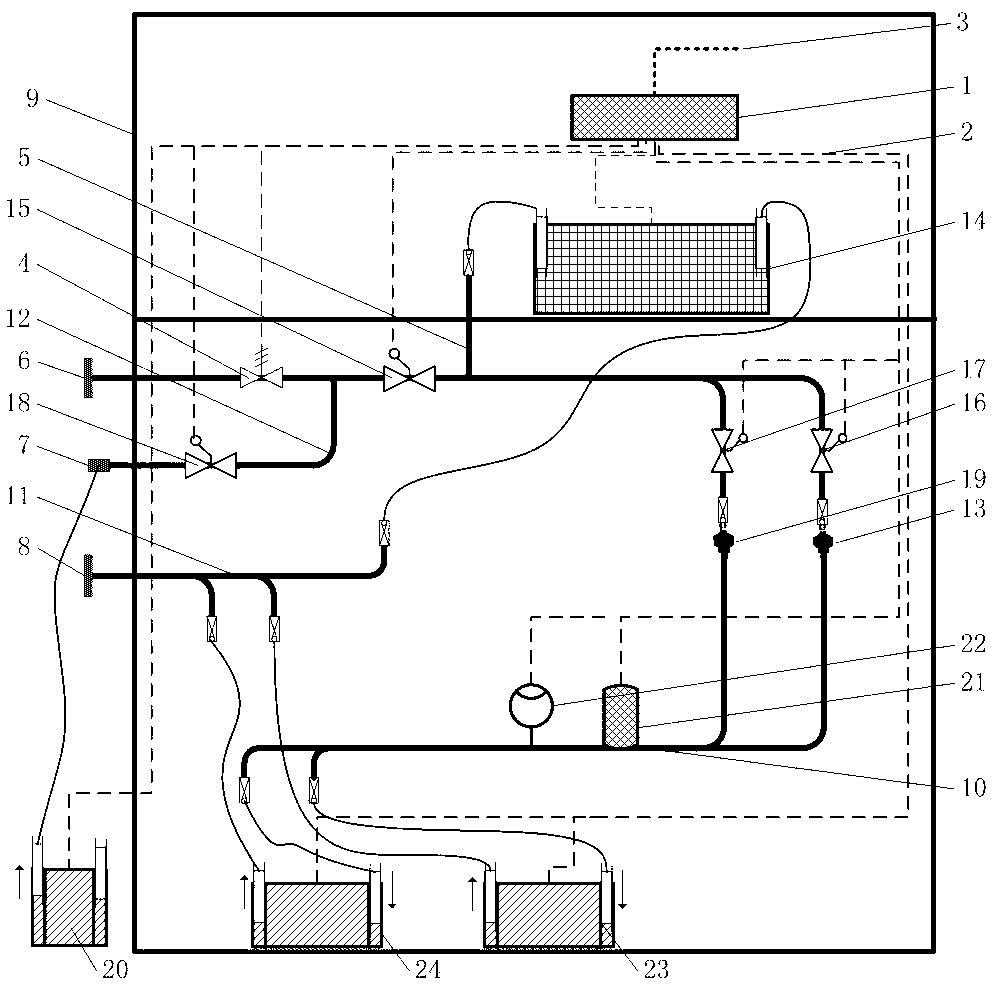

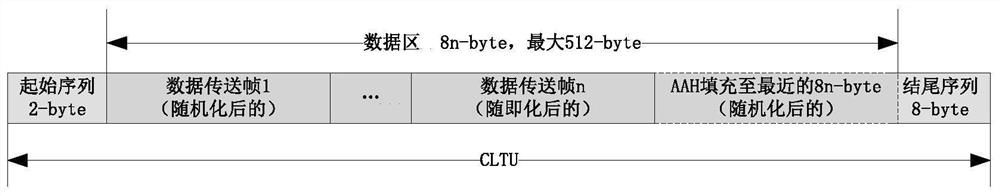

The invention provides a tritium-containing exhaust gas discharge monitoring automatic sampling system and belongs to the technical fields of radiation protection and environmental protection. The air inlet tube joint in the sampling system is connected with a flow control valve, solenoid valves, dust filters, a mass flow meter and a pressure meter through a gas tube and then is connected with the gas inlets of pumps, and the gas outlets of the pumps are connected with the joints of an exhaust tube through exhaust tubes; the gas inlet and the gas outlet of a total tritium sampler are connected with a gas collection tube and the exhaust tube through flexible tubes respectively; and the signal input end of an automatic control unit is in external connection with a chimney flow monitoring PLC controller, and the signal output end of the automatic control unit is connected with the total tritium sampler, the flow control valve, the solenoid valves, the mass flow meter, the pressure meter and pumps respectively. The sampling system which allows the sampling precision to be less than 1min has the advantages of intelligent regulation and control, strong practicality, improvement of the fragmentary discharge of a tritium effluent, improvement of the representativeness of a tritium monitoring sample when the concentration difference is large, mitigation of the labor intensity of an effluent monitoring sampling personnel, and improvement of the working efficiency.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

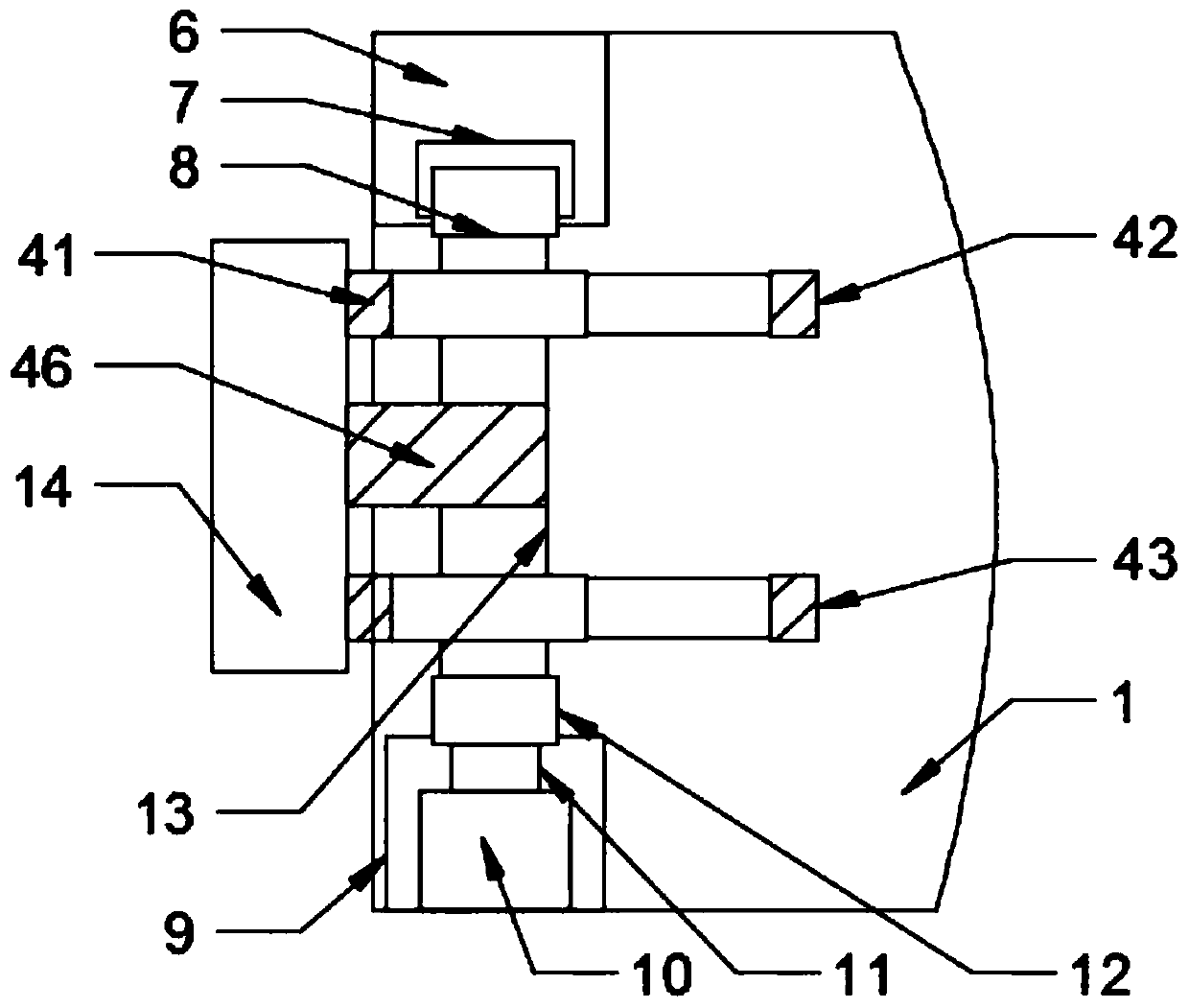

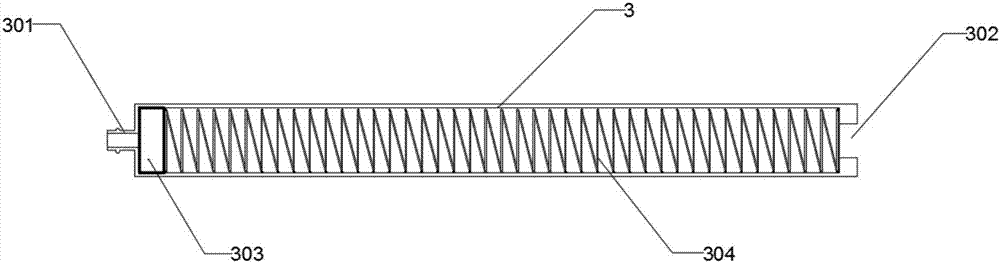

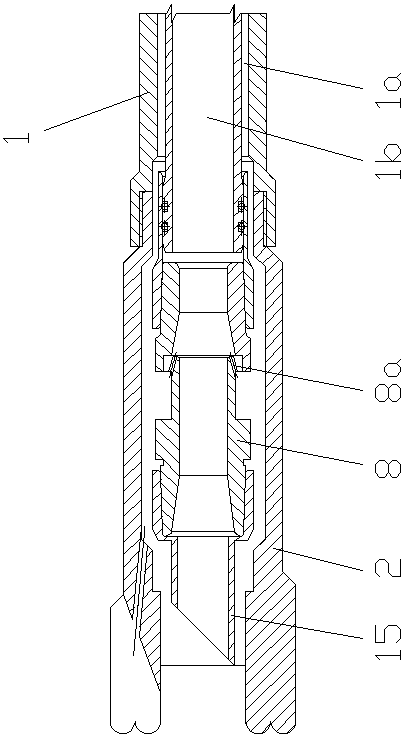

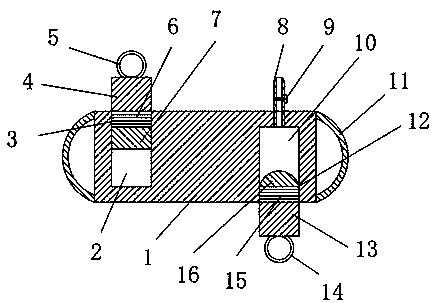

Positive and negative pressure combined plug flow fixed-point sampling device

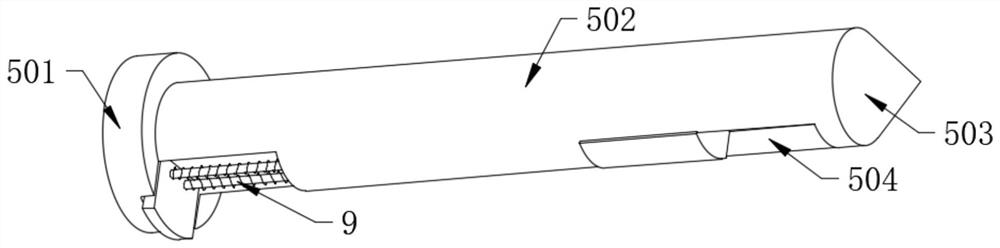

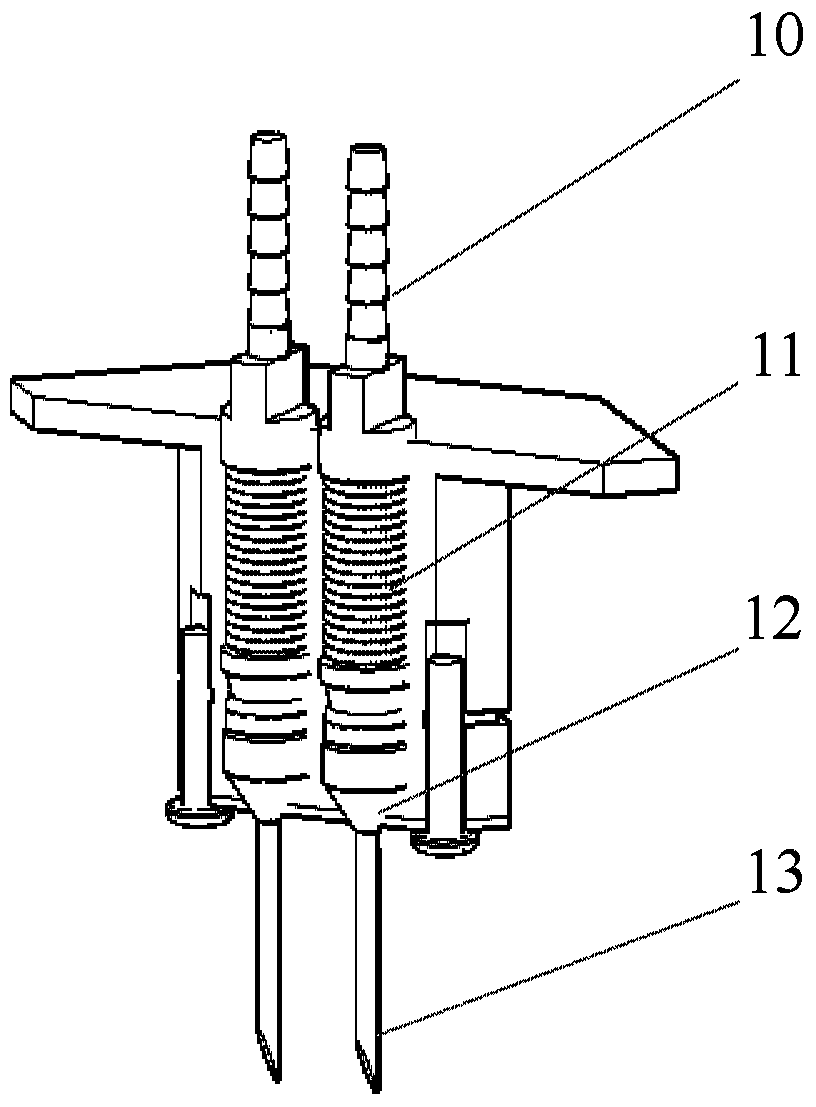

ActiveCN102798548AMove fastDrilling smoothlyWithdrawing sample devicesPreparing sample for investigationGas solidDouble wall

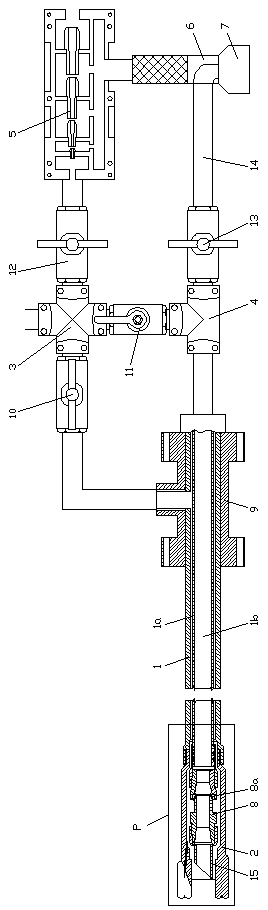

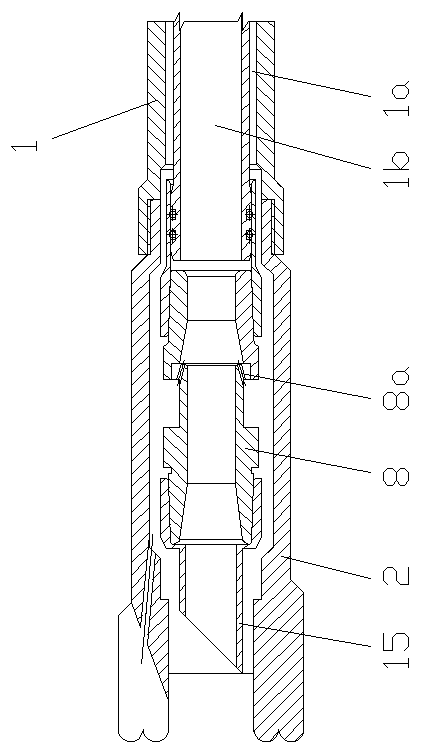

The invention discloses a positive and negative pressure combined plug flow fixed-point sampling device, which includes a double-wall drill rod, a drill bit, a four-way connector, a three-way connector, a negative pressure generator, a gas-solid gravity separator and a sample collection tank, as well as an annular nozzle ejector disposed in the drill bit. The rear end of the double-wall drill rod is sleeved with a two-channel faucet on the outside. The first channel of the two-channel faucet is connected to a first interface of the four-way connector, and the second channel of the two-channel faucet is connected to a first interface of the three-way connector. The second interface of the four-way connector is communicated with the second interface of the three-way connector. The third interface of the four-way connector is connected to the first air inlet of the negative pressure generator. During sampling, a material plug with a section of a sample and a section of compressed air is formed in a double-wall drill rod in-inner wall channel, and has small motion resistance in the double-wall drill rod in-inner wall channel. Driven by a negative pressure, the sample moves fast, and the sampling work has high efficiency. No plugging or drilling is needed in a sampling process, and the process is simple. Sampling can be performed at any drilling point, thus realizing fixed-point sampling.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

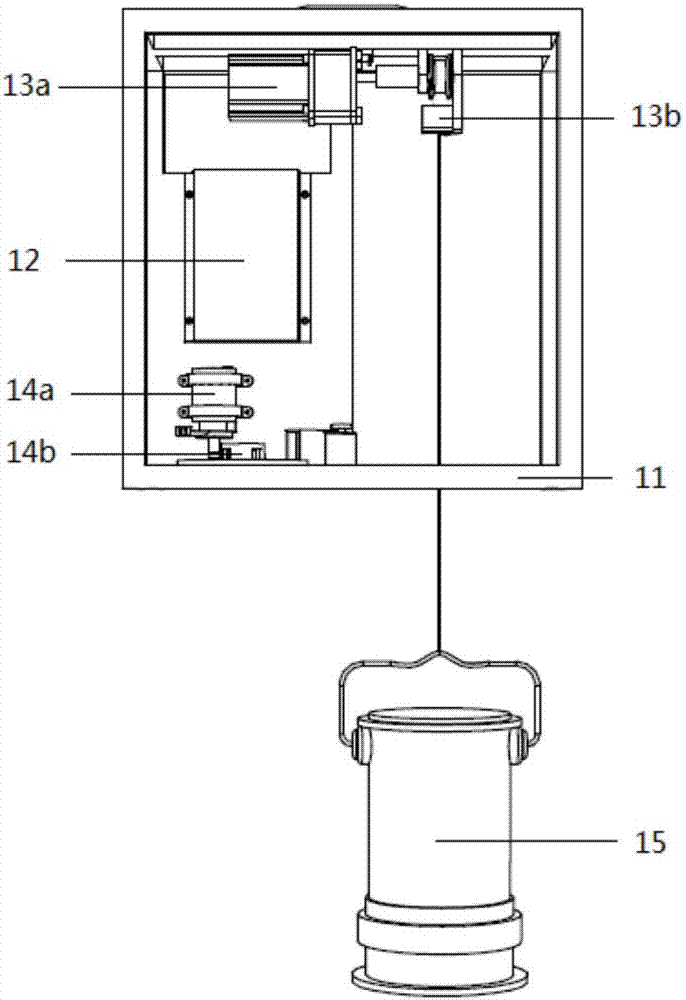

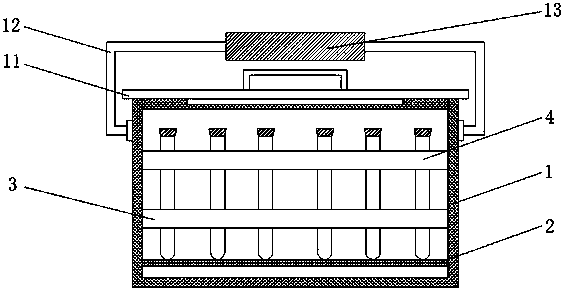

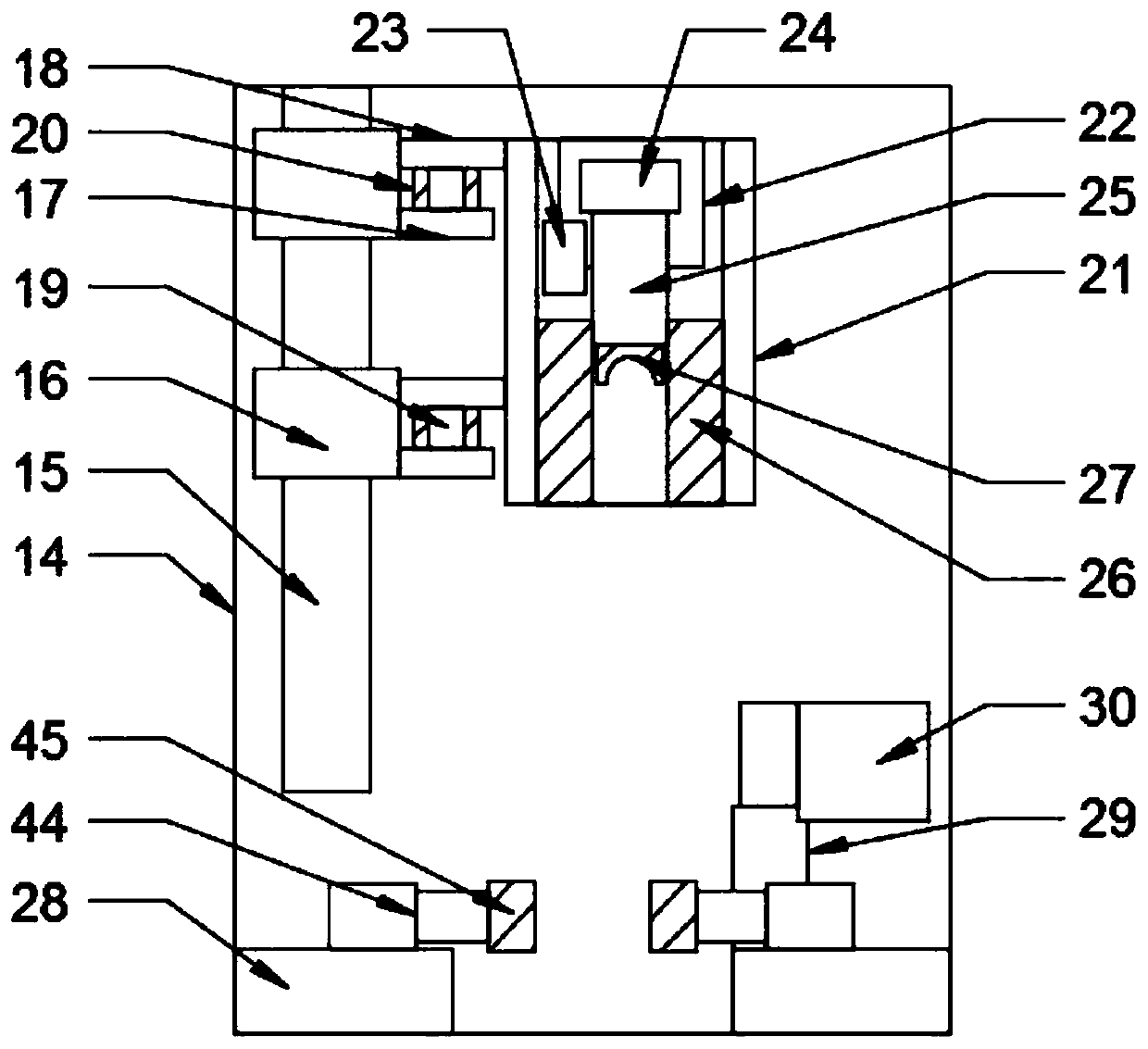

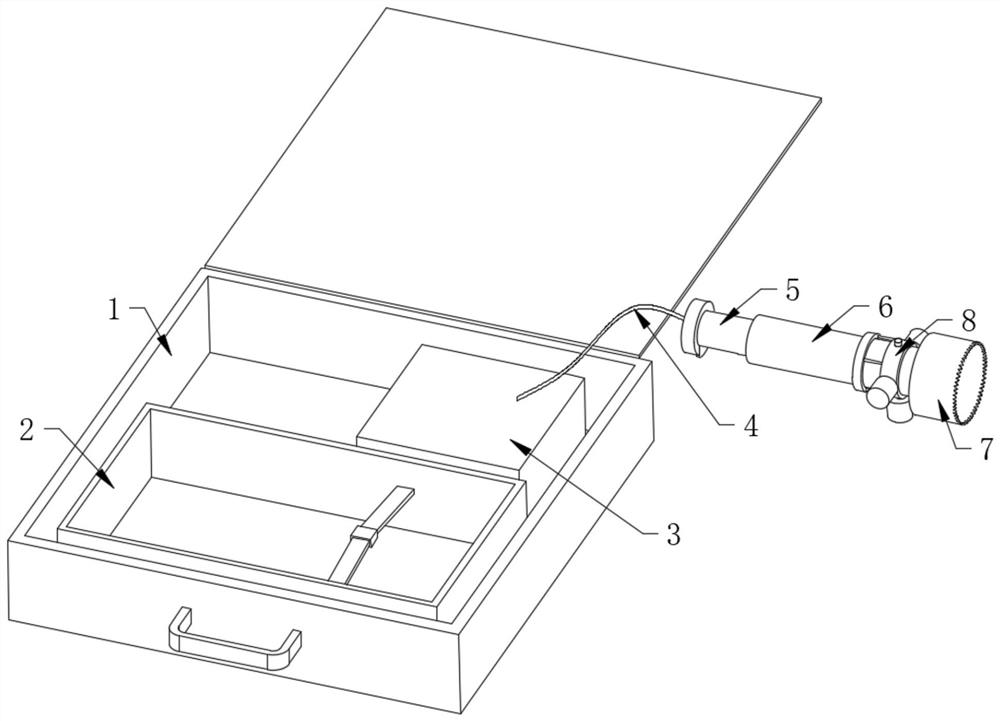

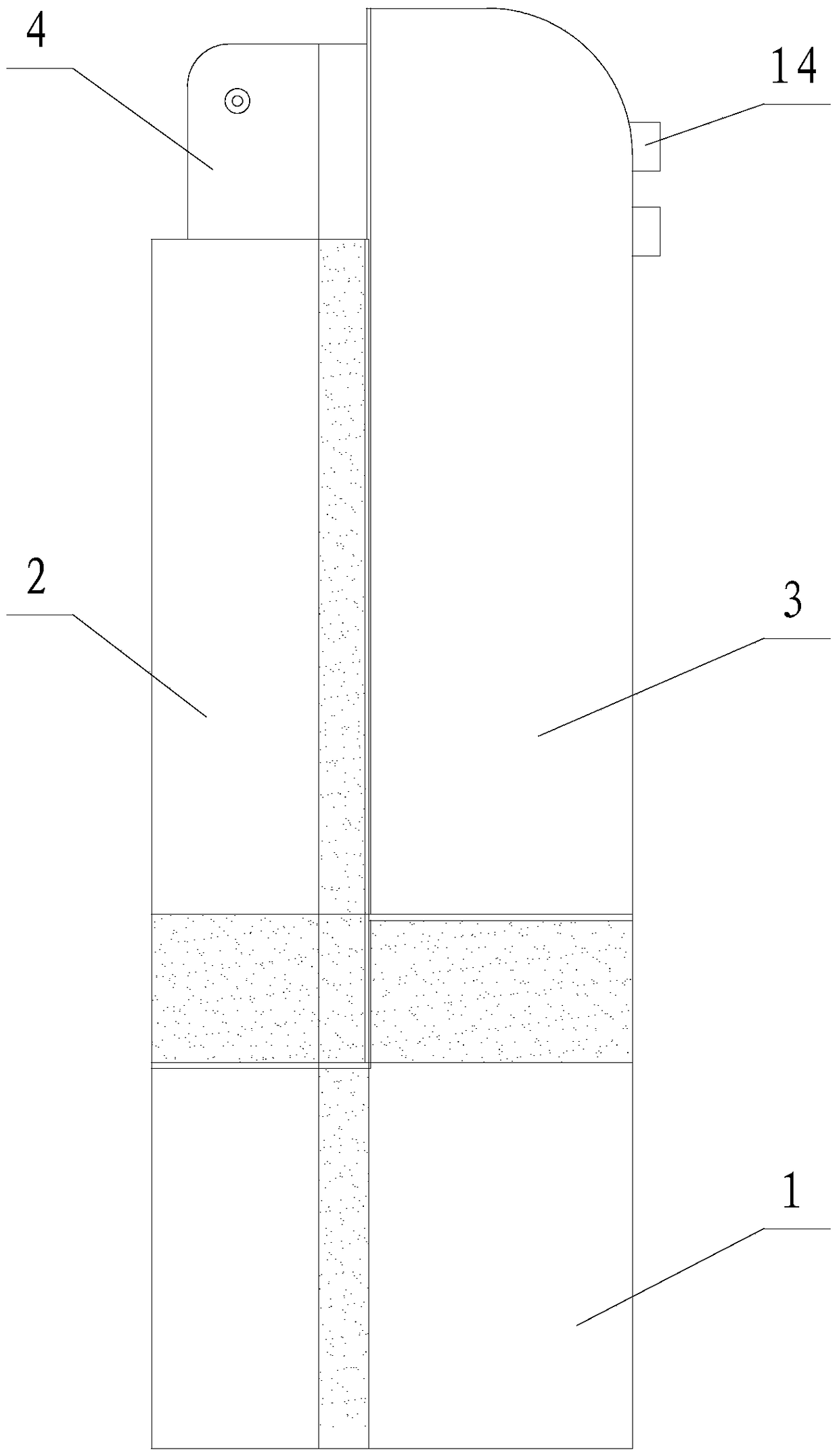

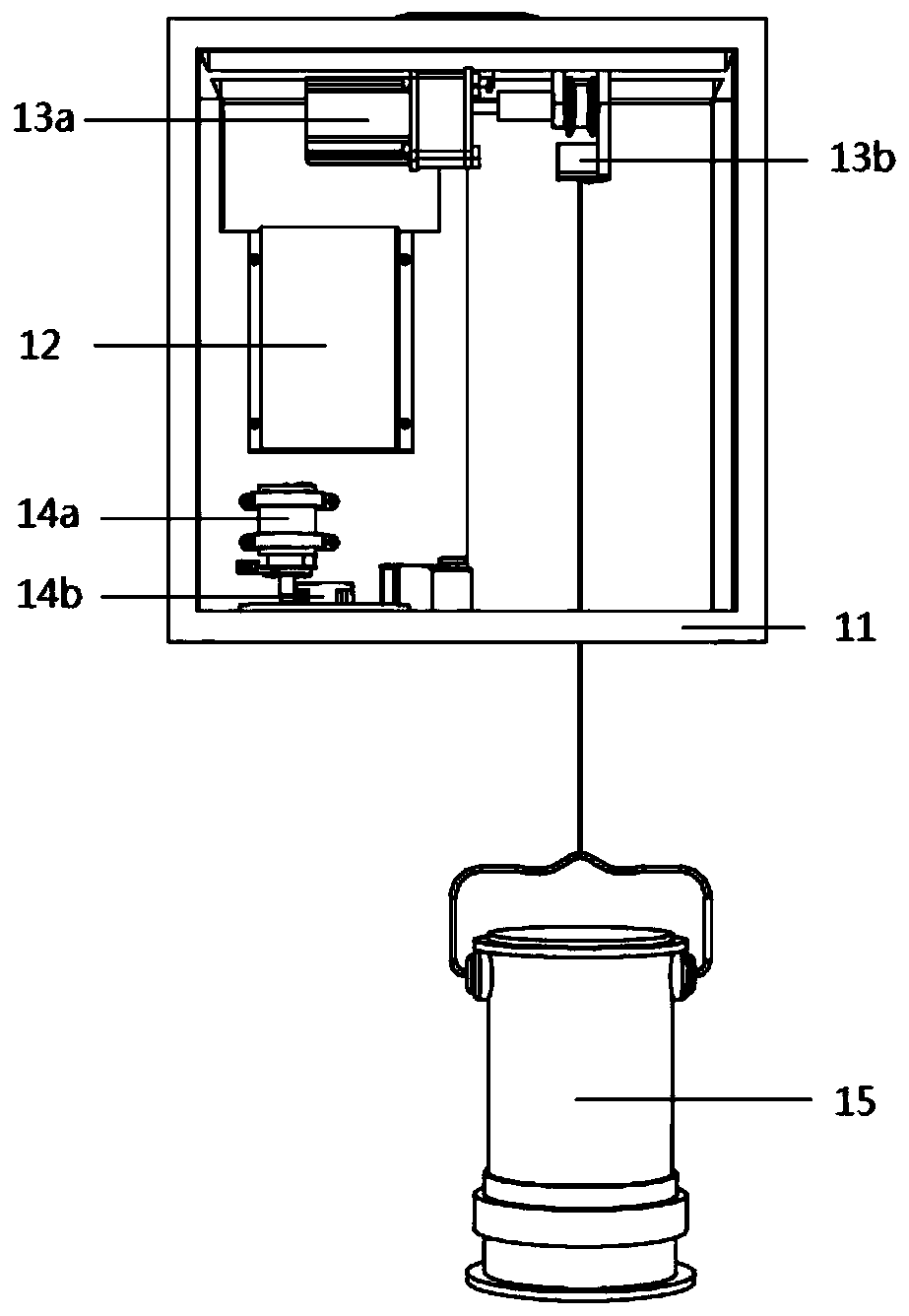

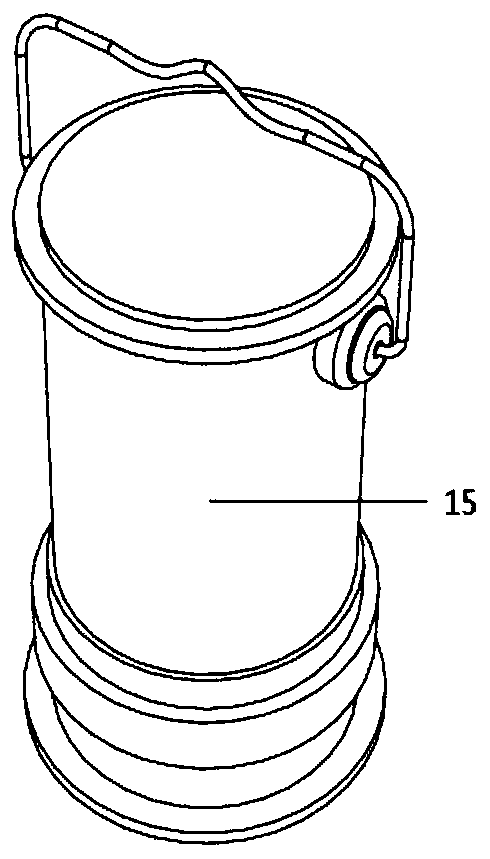

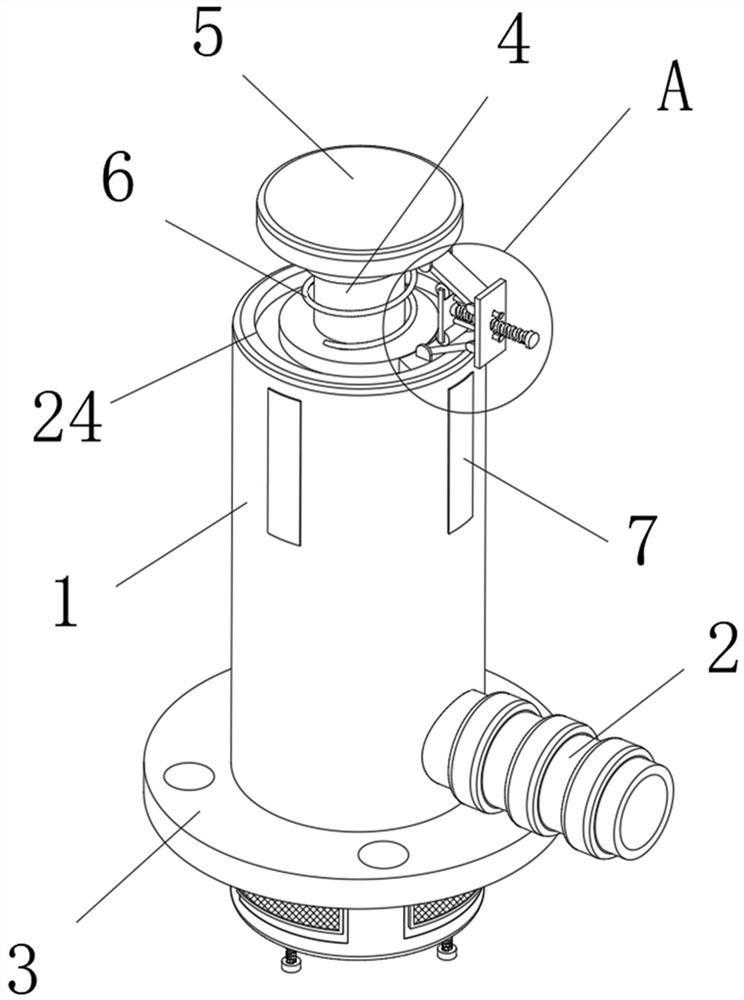

Shipborne automatic water quality sampler

ActiveCN107402143AEasy to carry and installImprove sampling productivityWithdrawing sample devicesWater qualityEngineering

The invention relates to a shipborne automatic water quality sampler, which mainly includes a sample collector and a sample storage box. The sample collector is composed of a support frame, a suspension device, a sample suction device, a sampling bucket and a controller. The sample storage box consists of a storage box body, a sample bottle and a sample splitter. The sample collector and sample storage box of the shipborne automatic water quality sampler adopts a split structure, can be suitable for installation and use by various manned and unmanned ships. Water quality samples of different depths can be collected into a designated sample bottle automatically, thus improving the automation level and sampling efficiency of water quality sampling work. The sampling bucket has a sampling way identical to manual sampling, a water sample at the position where the bucket is located can be acquired precisely, and the objectivity and accuracy of the sampling result can be effectively guaranteed.

Owner:北京中科涌泉科技发展有限公司 +1

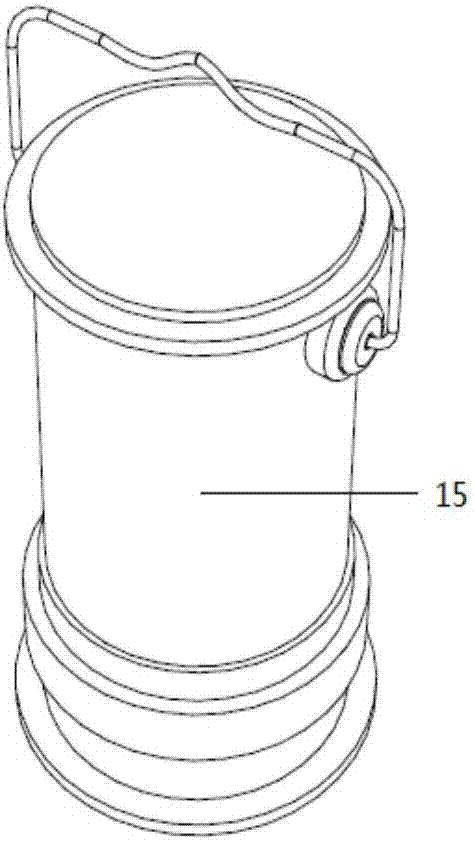

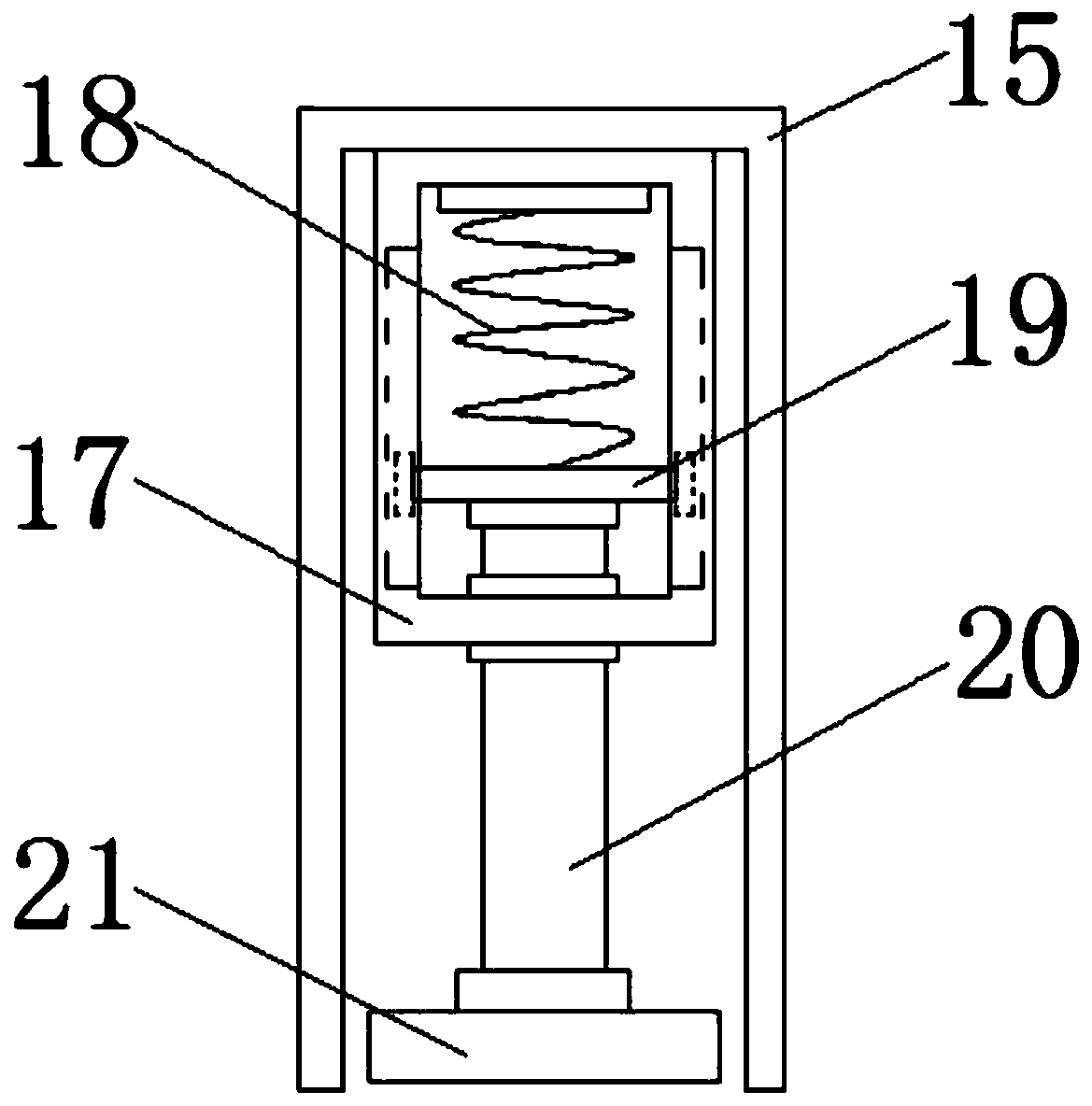

Deep-trough ore pulp sampler

ActiveCN105890925AImprove representationNovel structureWithdrawing sample devicesMining engineeringMechanical engineering

The invention relates to a deep-trough ore pulp sampler. The deep-trough ore pulp sampler comprises a handle, a hollow pipe, a piston connecting rod, a tensioning spring, a piston-connecting-rod positioning block, a connecting body, a piston, a sampling barrel and a piston fixing block. The deep-trough ore pulp sampler is novel, unique, simple, convenient, rapid, and safe, flexible and reliable in operation and use, sampling working efficiency can be greatly improved, and the deep-trough ore pulp sampler is a great innovation in ore pulp samplers and ways; the problems that vertical positioning sampling in continuously-stirred ore pulp can not be achieved, consumed time is long, sample representativeness is poor, and potential safety hazards in sampling are large are effectively solved.

Owner:YUNNAN HUALIAN ZINC & INDIUM

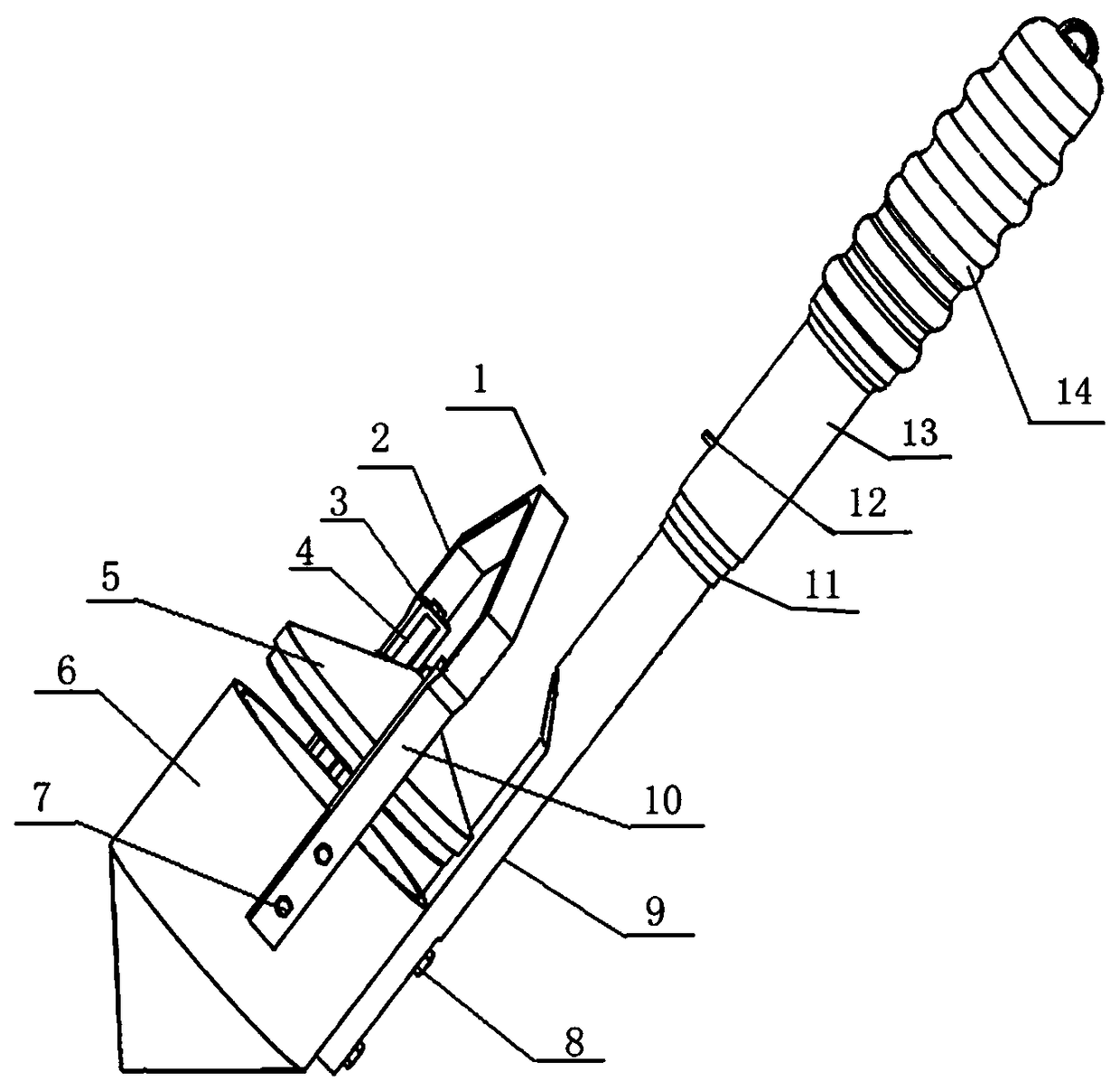

Sampling device for detection of road engineering

InactiveCN108896341AWide range of useSave human effortWithdrawing sample devicesGeotechnical engineeringBevel gear

The invention discloses a sampling device for detection of road engineering. The sampling device comprises a supporting plate, wherein the two sides of the top part of the supporting plate are respectively and fixedly connected with a sliding groove plate; a connecting plate is fixedly connected with the top parts of the sliding groove plates, and a first motor is fixedly connected with one side of the top part of the connecting plate; an output shaft of the first motor is fixedly connected with a first bevel gear. The invention relates to the technical field of engineering detection. The sampling device for detection of road engineering disclosed by the invention has the beneficial effects that the road engineering can be well sampled, holes with different depths can be drilled accordingto the requirements of operators, so that the use range of the device is very wide, the labor is greatly saved, and the working efficiency of sampling is improved to a great extent; after sampling ofthe device, a sample can be better assisted to be ejected out of a sampling drum by elastic deformation of springs, great convenience is brought for cleaning roads and moving the sampling device, andwhen the sampling device works, a good fixing effect for the device is achieved.

Owner:海宁鼎合工程技术开发有限公司

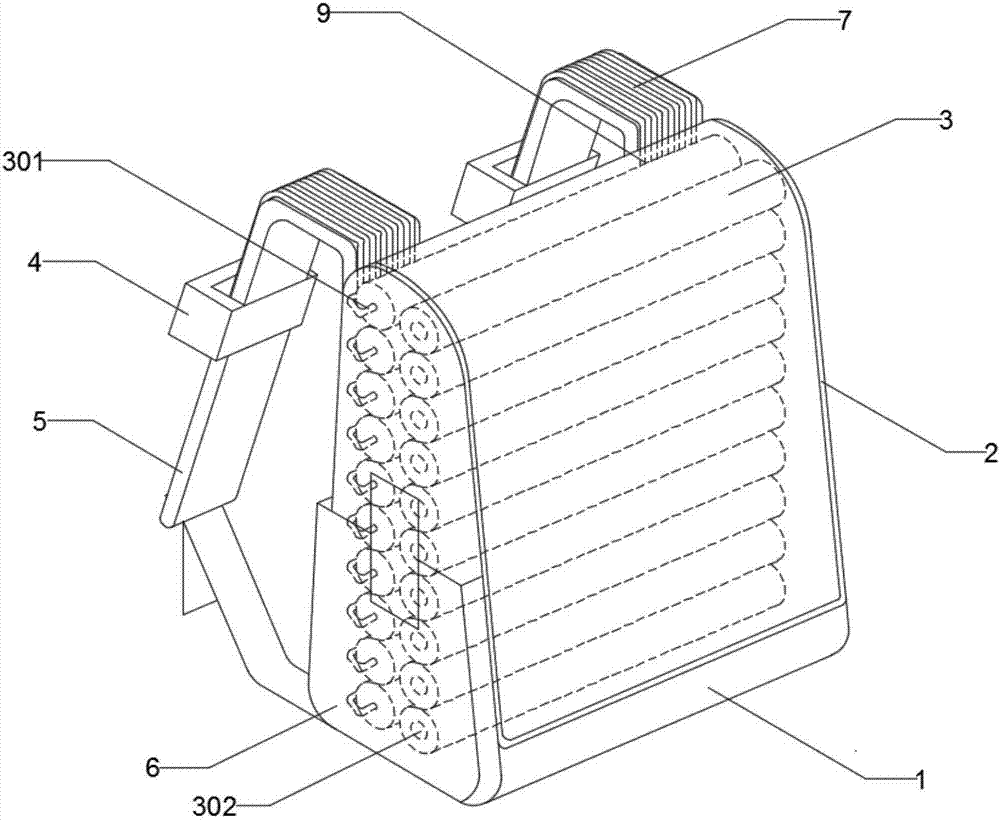

Portable biological sample storage device

InactiveCN107662744AEasy to storeShorten the timeContainers to prevent mechanical damageRigid containersBiochemical engineering

Owner:FOSHAN SHENYAN INFORMATION TECH CO LTD

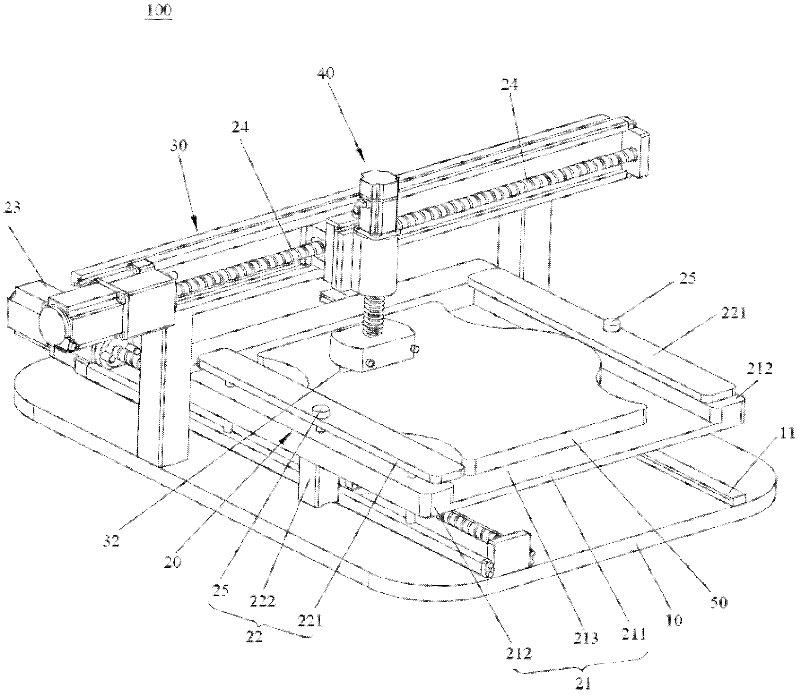

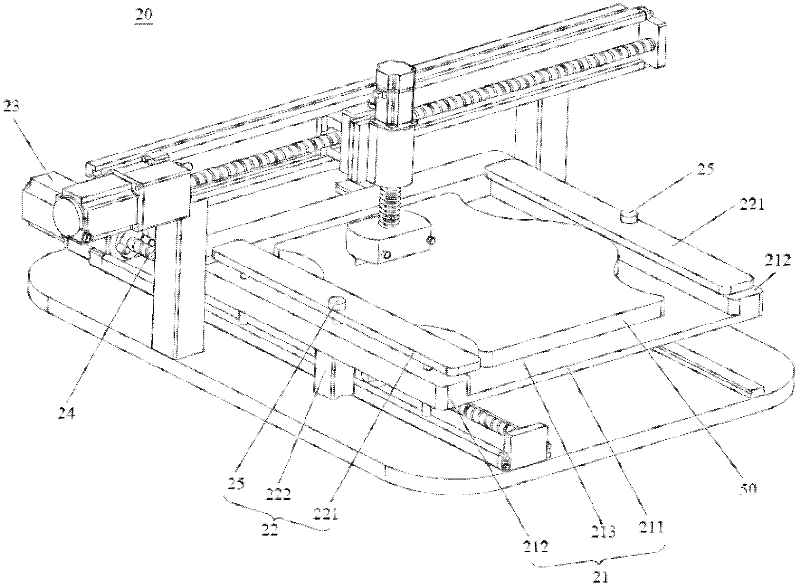

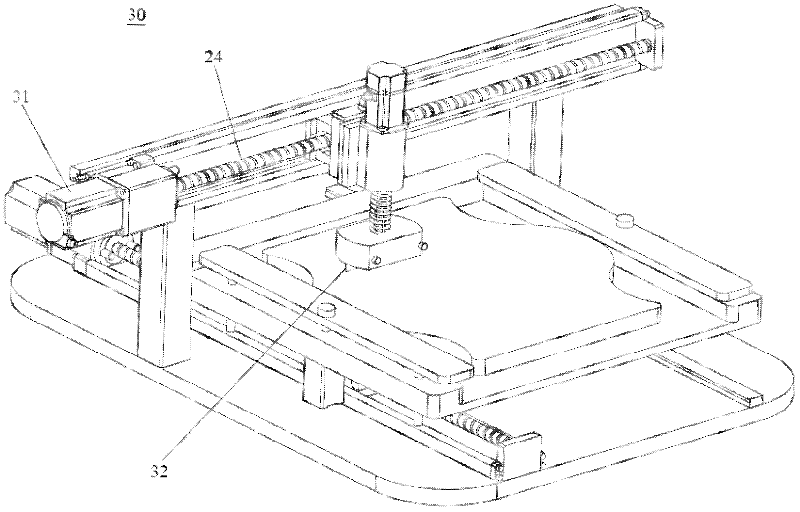

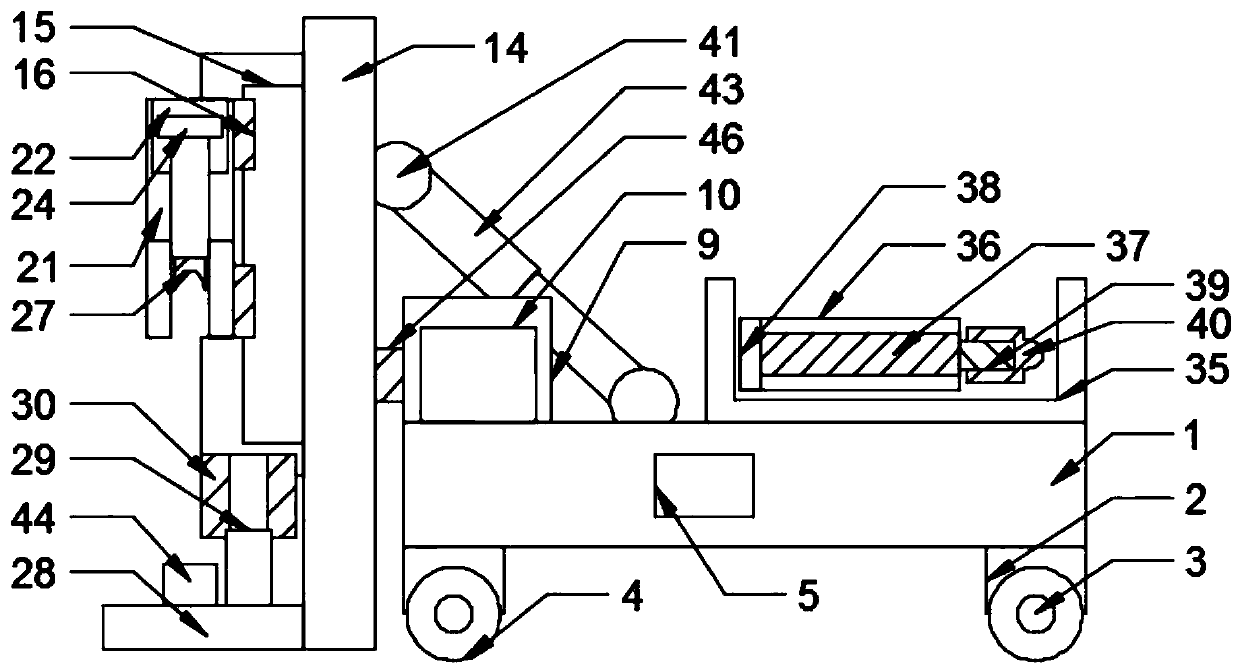

Sample surface coating sampling equipment

InactiveCN102445359AImprove sampling productivityLarge sampling volumeWithdrawing sample devicesEngineeringSurface coating

The invention discloses sample surface coating sampling equipment. The equipment comprises a base which is horizontally arranged, a sample fixing device and a blade sliding control device, wherein the sample fixing device is slidably arranged on the base along the Y-axial direction, and comprises a pedestal and pressing devices arranged on two sides of the pedestal, a sample is loaded on the pedestal, and the pressing devices are used for pressing and fixing the sample; the blade sliding control device is provided with a blade, and is slidably arranged on the base along the X-axial direction; and a blade drive device is fixedly connected with the blade and drives the blade to scrape the surface coating of the sample on the upper surface of the sample in a rotating way. The surface coating sampling equipment disclosed by the invention can be widely applied to scraping the surface coating of the sample, can be used for effectively improving the sampling work efficiency of the surface coating of the sample, and has the advantages of simple structure, convenience in use, large sampling amount, safety and reliability.

Owner:CENT TESTING INT GRP CO LTD

Soil sampling device for monitoring soil environment

InactiveCN110174283AReduce work intensityImprove sampling productivityWithdrawing sample devicesEngineeringAmbient monitoring

Owner:邯郸开发区华骐环保科技有限公司

Coal mine underground gas sampling device and method

A coal mine underground gas sampling device comprises a bag body, gas cylinders, rubber pipes, pipe orifice switchers and an air pump, wherein the gas cylinders are arranged in the bag body side by side, the two ends of each rubber pipe are connected with the corresponding gas cylinder and the corresponding pipe orifice switcher respectively, and the pipe orifice switchers are connected with the air pump. The gas collecting process includes the following steps that one pipe orifice switcher is adjusted to the target gas cylinder to collect a gas sample, and gas collection of the gas cylinder is completed when a gas bag inflates; gas collection of the next pipe is conducted; when the gas samples need to be collected continuously, the corresponding pipe orifice switcher is directly adjusted and sequentially collects the gas sample from other gas cylinders; when the gas samples need to be collected interruptedly, gas collection of the next pipe is conducted after the corresponding pipe orifice switcher exhausts residual gas inside, and collection of different gases is sequentially completed. The gas sampling device is convenient to carry and convenient to operate, effectively reduces the carrying size, ensures gas sample seal performance, meets the requirement of continuous sampling, improves working efficiency of underground safety monitoring staff, distinguishes the underground danger source in time and ensures life safety of staff and economic benefits of an enterprise.

Owner:LIAONING TECHNICAL UNIVERSITY

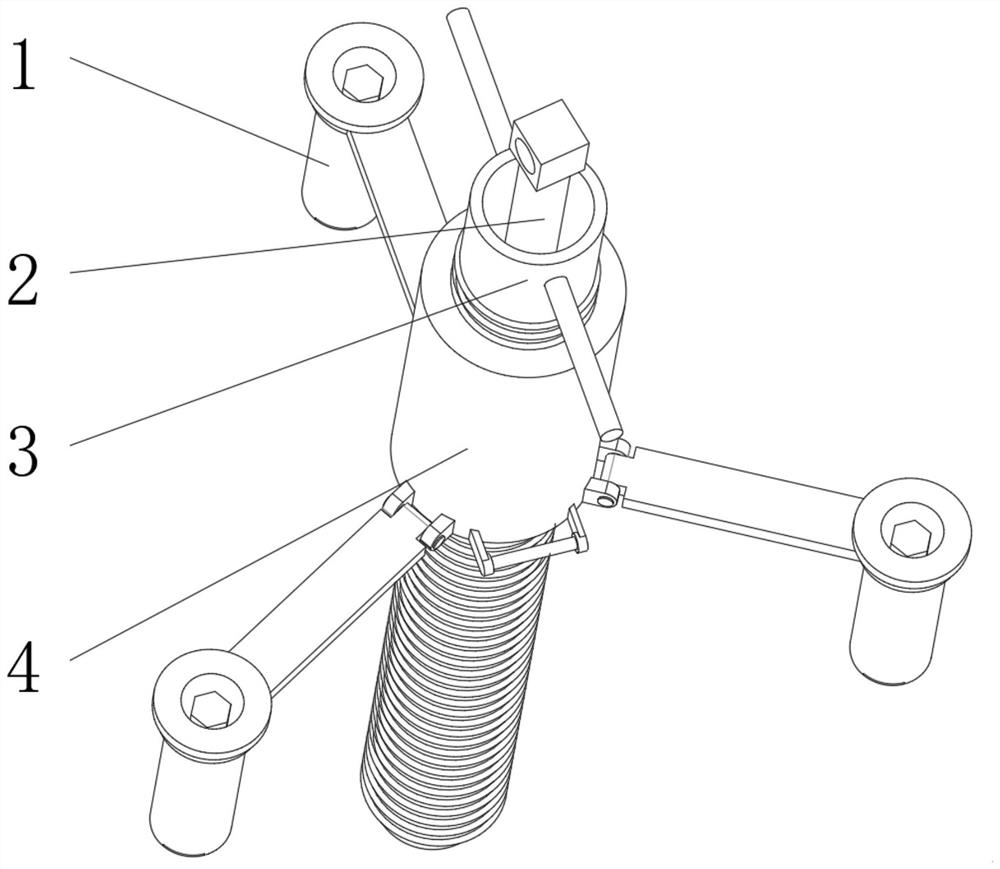

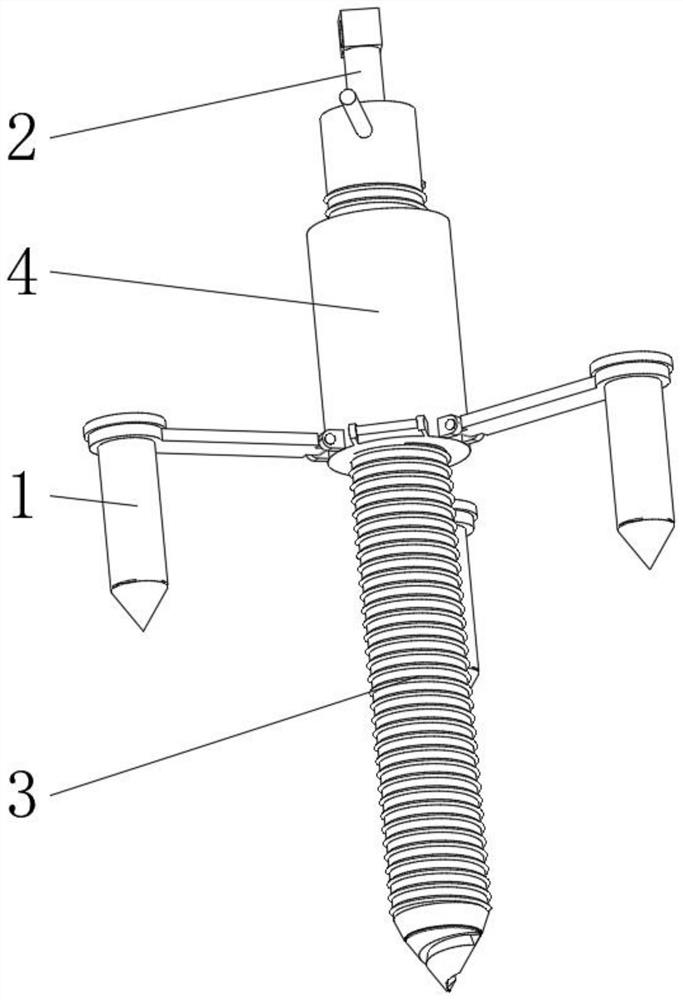

Rock-soil sampling mechanical device for civil engineering

The invention relates to the technical field of rock-soil sampling. The invention discloses a rock-soil sampling mechanical device for civil engineering. The device comprises a sampling needle; a drill bit is arranged at the bottom of the sampling needle; the sampling needle is detachably connected with the drill bit; the outer wall of the sampling needle is sleeved with a telescopic part; a balancing weight is arranged at the top of the sampling needle, and the balancing weight is fixedly connected with the sampling needle; a sampling groove is formed in the outer wall of the sampling needle,the sampling groove is a spiral sampling groove, and the lower portion of the sampling groove extends to the outer wall of the drill bit; and the outer wall of the sampling needle is sleeved with a supporting frame, the lower portion of the supporting frame is detachably connected with a sampling plate, and a driving device is installed on the supporting frame. The technical problem that an existing rock-soil sampling device cannot meet different soil texture requirements and is low in sampling efficiency and short in service life is solved.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

Positive and negative pressure combined plug flow fixed-point sampling device

ActiveCN102798548BMove fastDrilling smoothlyWithdrawing sample devicesPreparing sample for investigationGas solidDouble wall

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

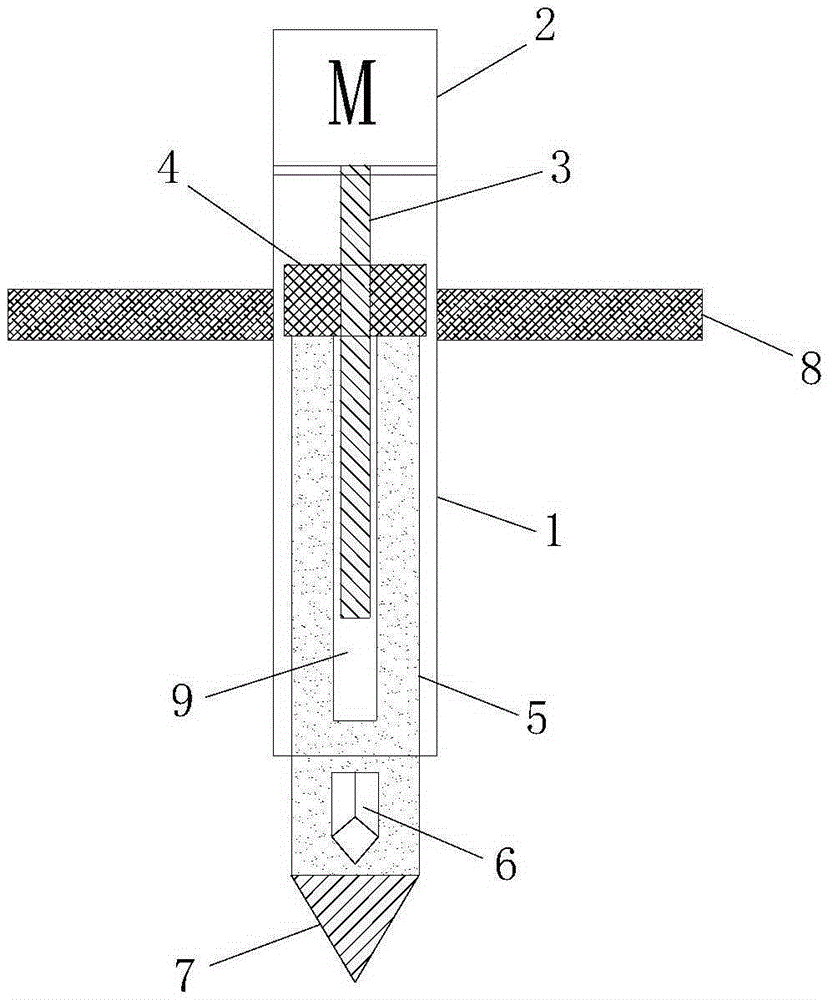

Agricultural soil sampling device

InactiveCN106840746AEasy to sample and analyzeImprove sampling productivityWithdrawing sample devicesElectric machineryEngineering

The invention discloses an agricultural soil quality sampling device. A motor is arranged on the top of the casing, and a rotating shaft of the motor is connected to a screw by transmission. The screw is arranged in the casing, and a nut matched with the screw is arranged on the screw. , the bottom of the nut is connected with a sampling rod, the sampling rod is provided with a receiving hole, the position of the receiving hole corresponds to the screw rod, the bottom of the sampling rod is provided with a sampling groove, and the bottom of the sampling groove faces Inclined downward, the lower end of the sampling rod is connected to a drill bit, and positioning handles are provided on both sides of the housing. The invention can take the soil sample from the sampling tank to the ground surface, and take samples for the underground soil sample. The structure is simple, the use is convenient, and the crops will not be damaged in a large area. Sampling work efficiency, strong practicability.

Owner:CHONGQING CITY FULING DISTRICT QIYIZHOU ECOLOGICAL AGRI DEV CO LTD

Isolation type food quality detection sampling device

PendingCN113504071AReduced Possibility of ContaminationImprove work efficiencyWithdrawing sample devicesHollow article cleaningAnimal scienceEngineering

The invention discloses an isolated food quality detection sampling device, and belongs to the field of food sampling equipment. The isolated food quality detection sampling device comprises a working box, a sampler storage box is fixedly installed at the inner end of the working box, and a sampler cleaning box is fixedly installed at the inner end of the working box; food around a to-be-sampled sample can be cut and isolated through an auxiliary sampling cylinder, then the sample is effectively sampled into a sampling groove in a sealed mode through extraction of the sampling rod mechanism in the transparent sleeve, and then the sample is collected in the sampling device in a sealed mode through cooperation of a rotating ring and a telescopic pipe in the sampling and collecting mechanism,the likelihood of contamination of the obtained sample is reduced, and meanwhile, through cooperative use of an auxiliary cleaning mechanism and the sampler cleaning box, the interior of the sampling groove is effectively cleaned in time, the cleaning time of the sampling device is shortened, the use efficiency of the sampling device is effectively improved, and the working efficiency of subsequent food detection is improved.

Owner:XUZHOU COLLEGE OF INDAL TECH

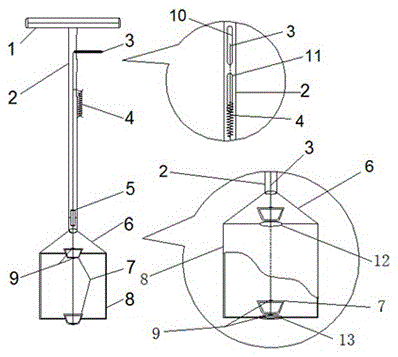

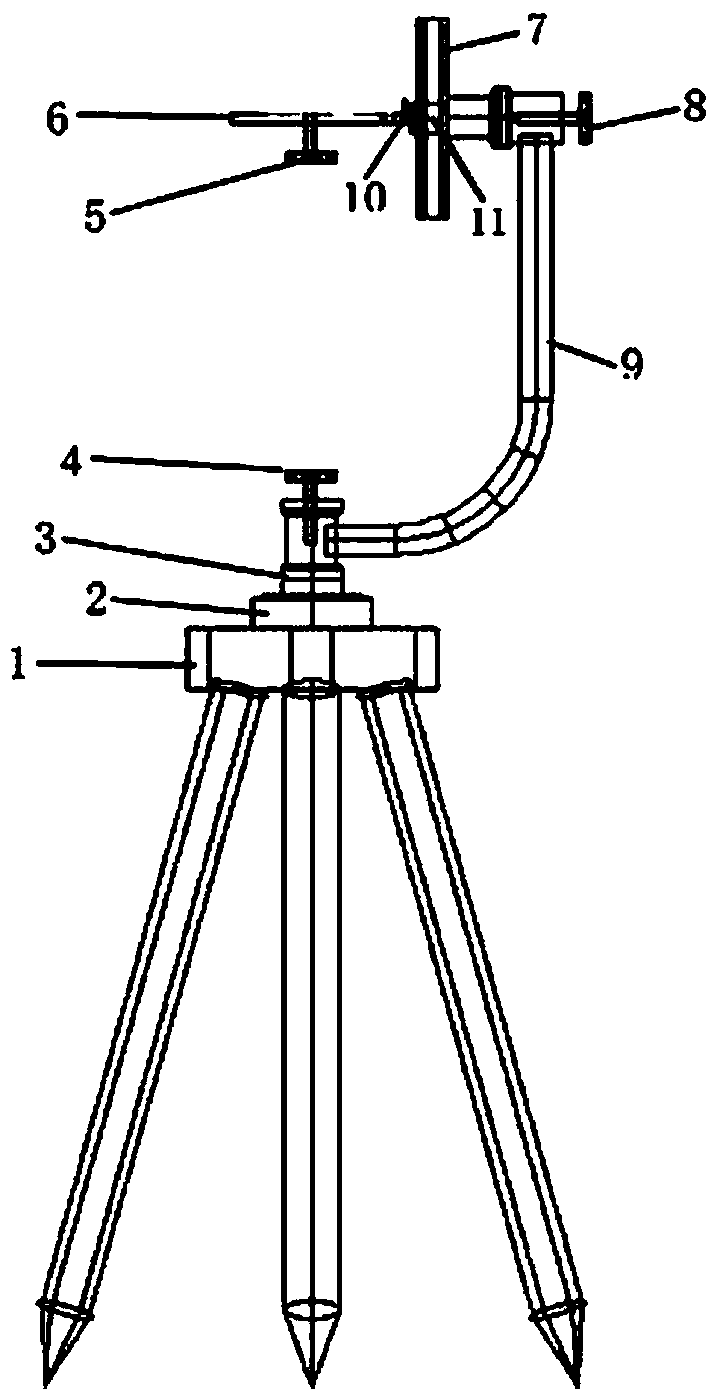

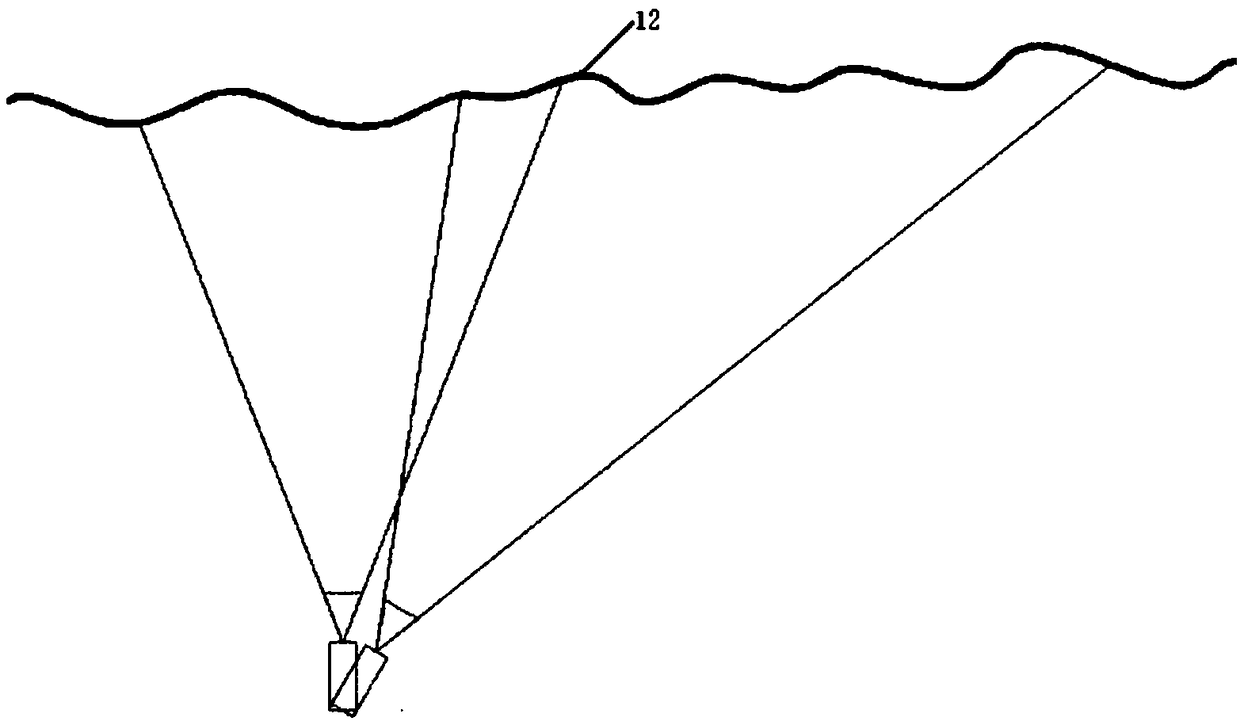

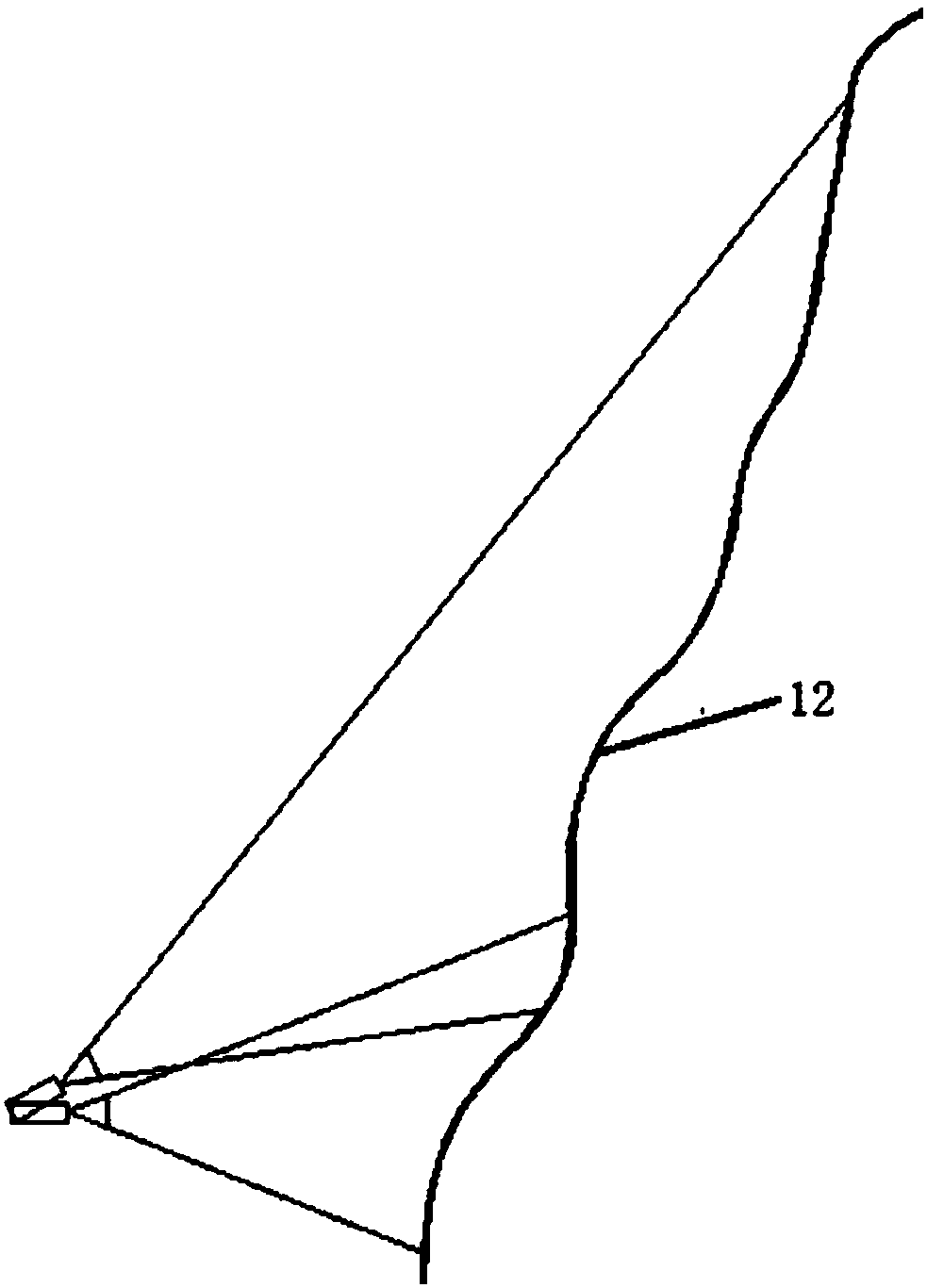

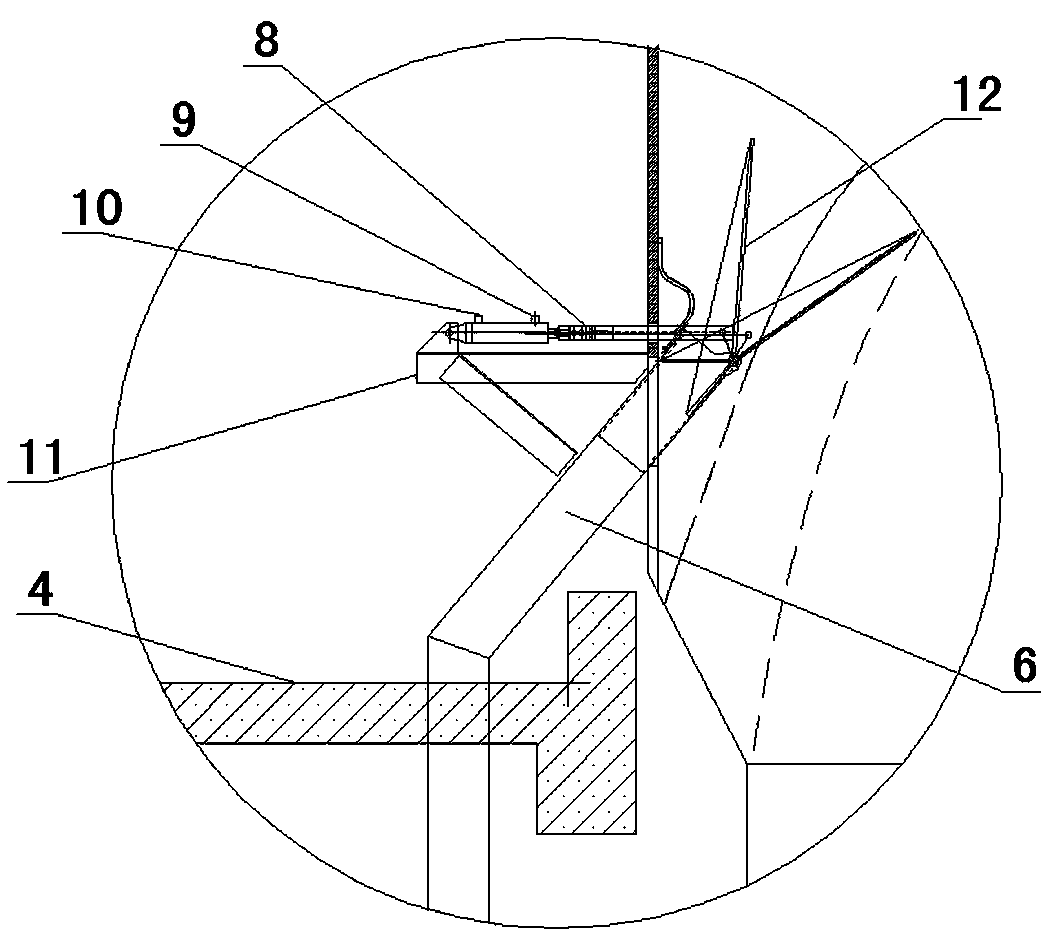

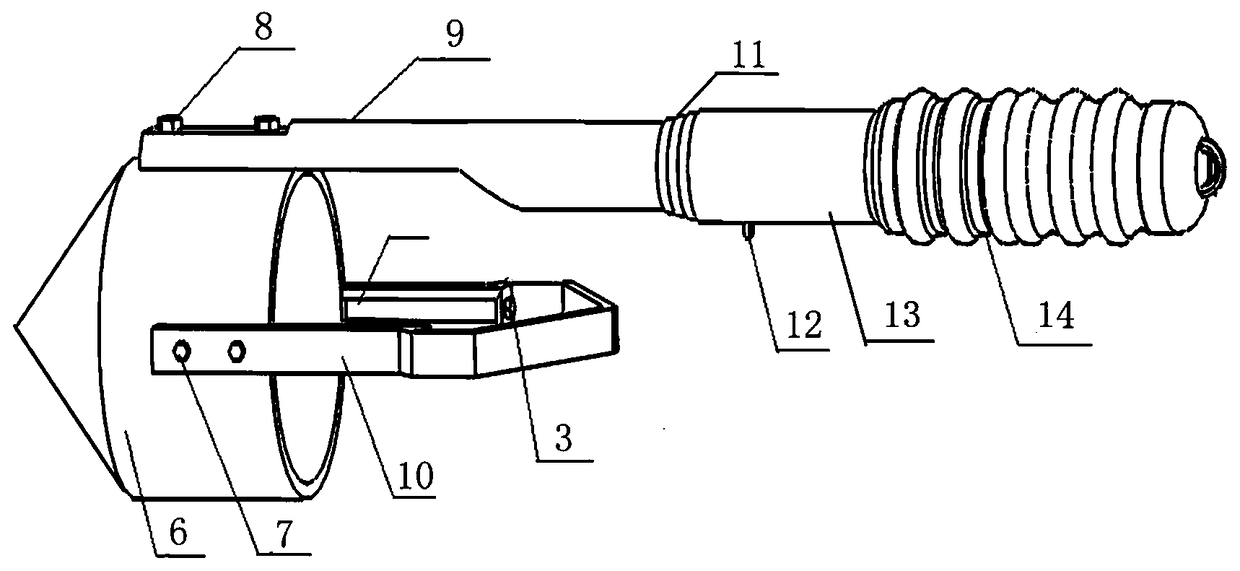

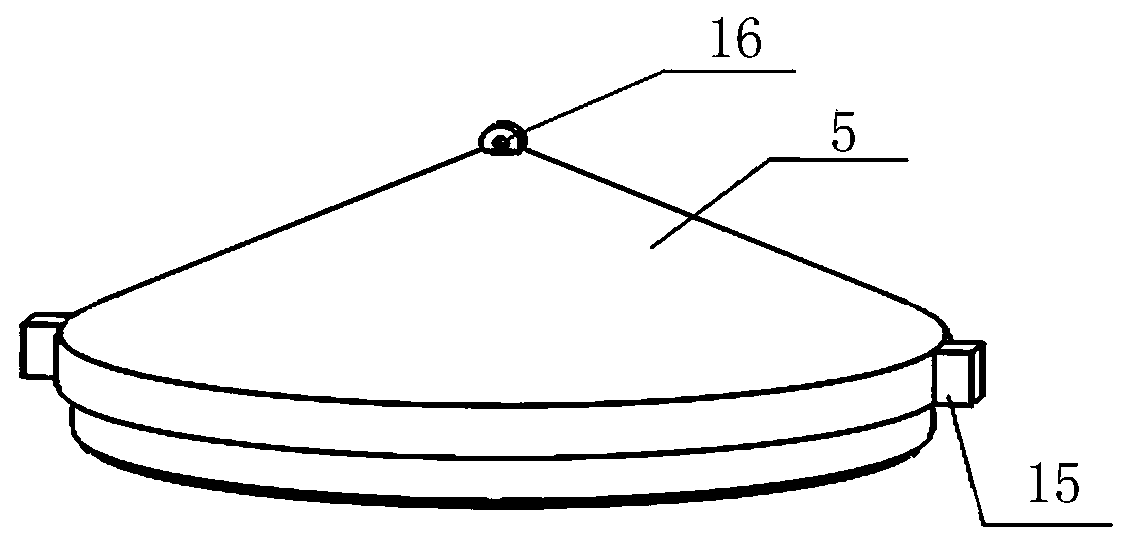

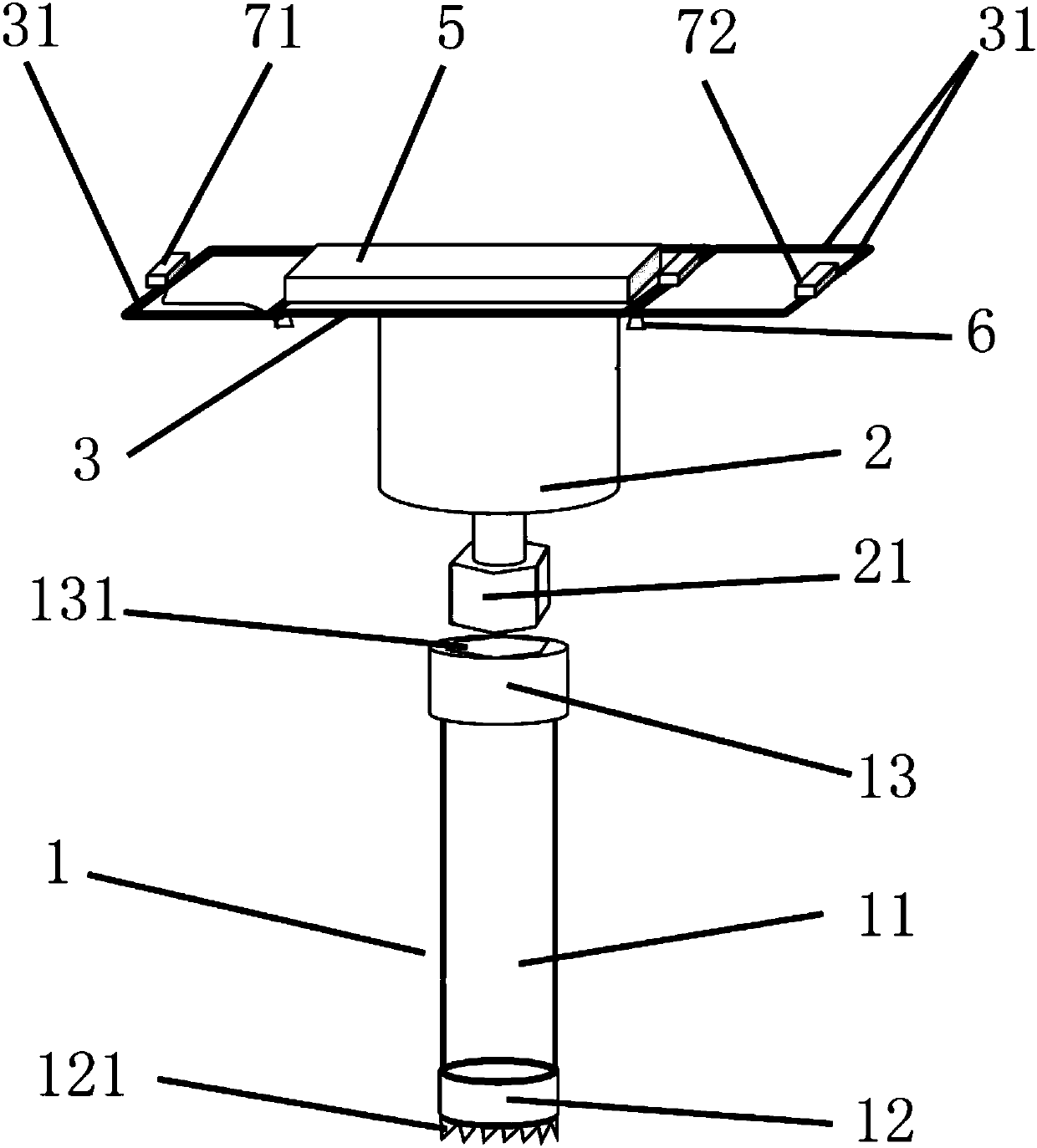

Rotary support for three-dimensional digital geologic photogrammetry system

InactiveCN108204503AExpand the sampling rangeEasy to operatePicture taking arrangementsStands/trestlesEngineeringPhotogrammetry

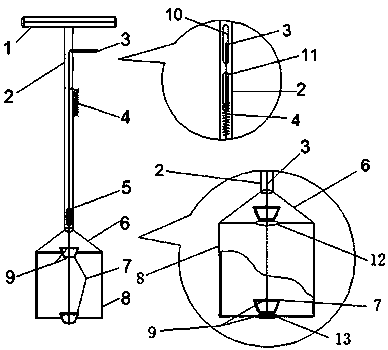

The invention discloses a rotary support for a three-dimensional digital geologic photogrammetry system. The rotary support comprises a tripod (1), a horizontal rotary bent rod (9) and a vertical rotary slide groove (7), wherein a support fixing base (3) is installed on the tripod (1), and connected with the horizontal rotary bent rod (9); the horizontal rotary bent rod (9) is connected with the vertical rotary slide groove (7); and a vertical slide block (11) is arranged in the vertical rotary slide groove (7), and a camera fixing base (6) is installed on the vertical slide block (11). The rotary support disclosed by the invention is capable of conveniently adjusting the rotation angles of a camera in the horizontal direction and the vertical direction, thereby expanding the camera-shooting sampling range; and meanwhile, different pictures can be integrated into a large regional three-dimensional picture through reference points on the pictures.

Owner:湖北松日新材料有限公司

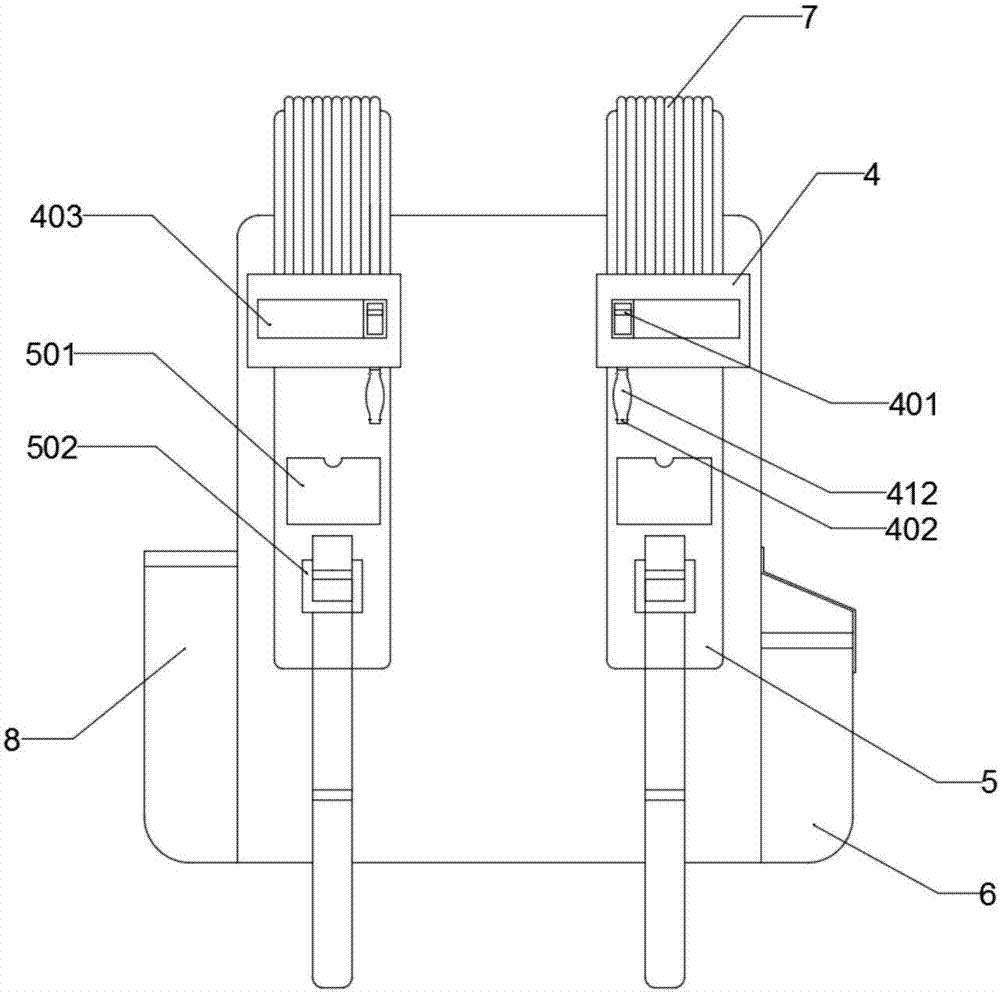

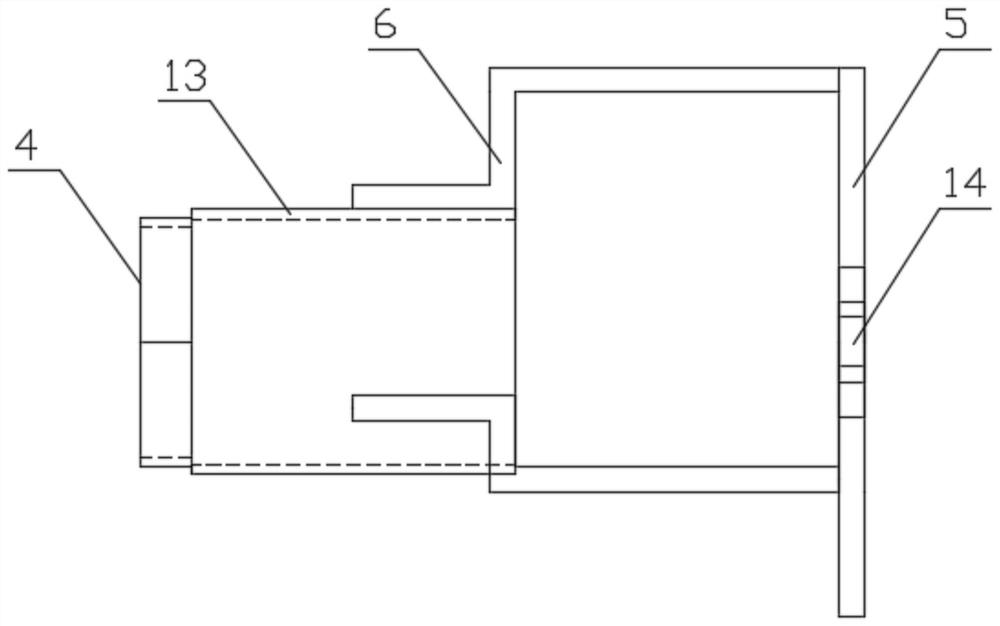

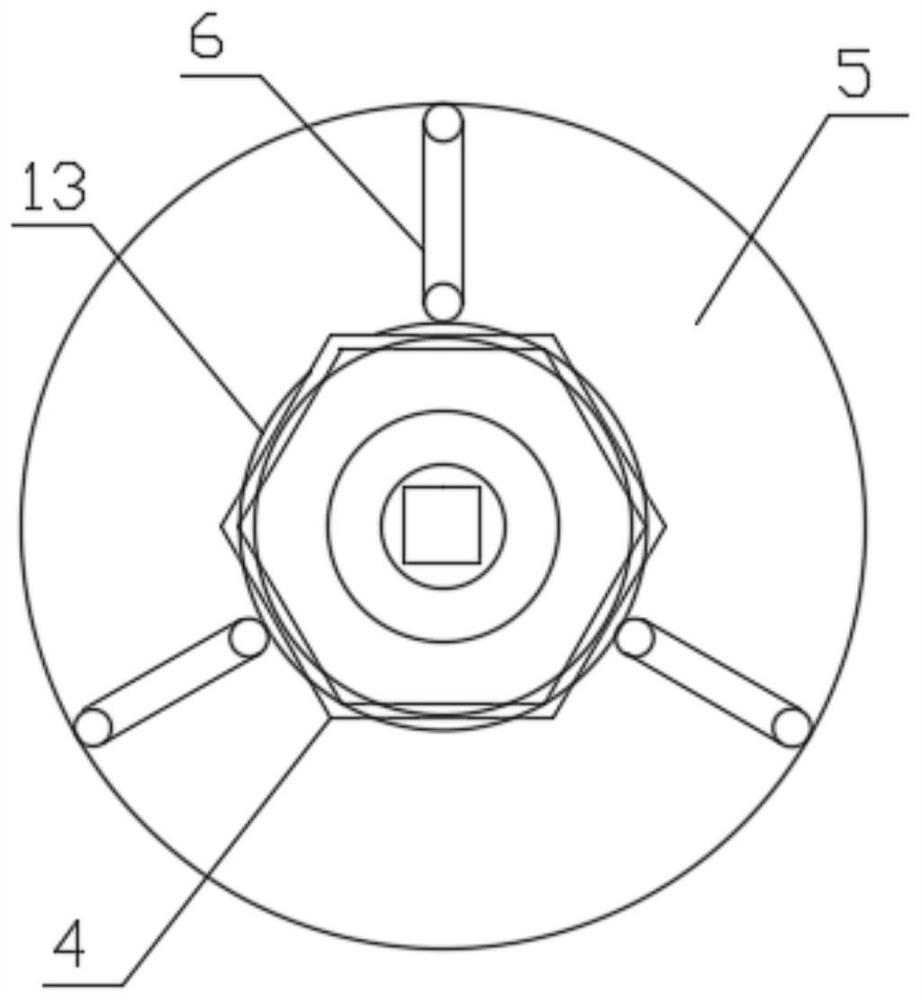

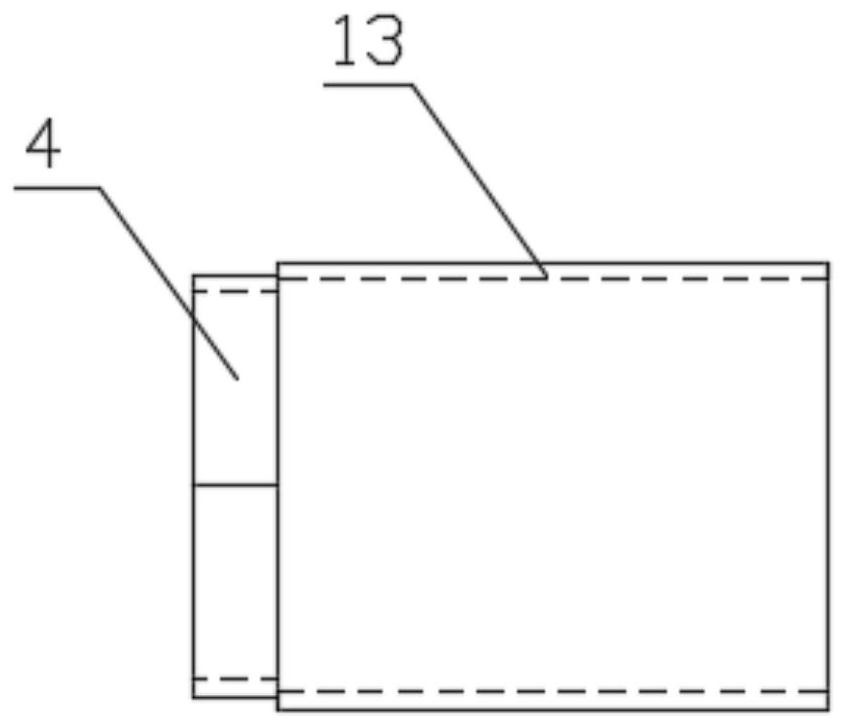

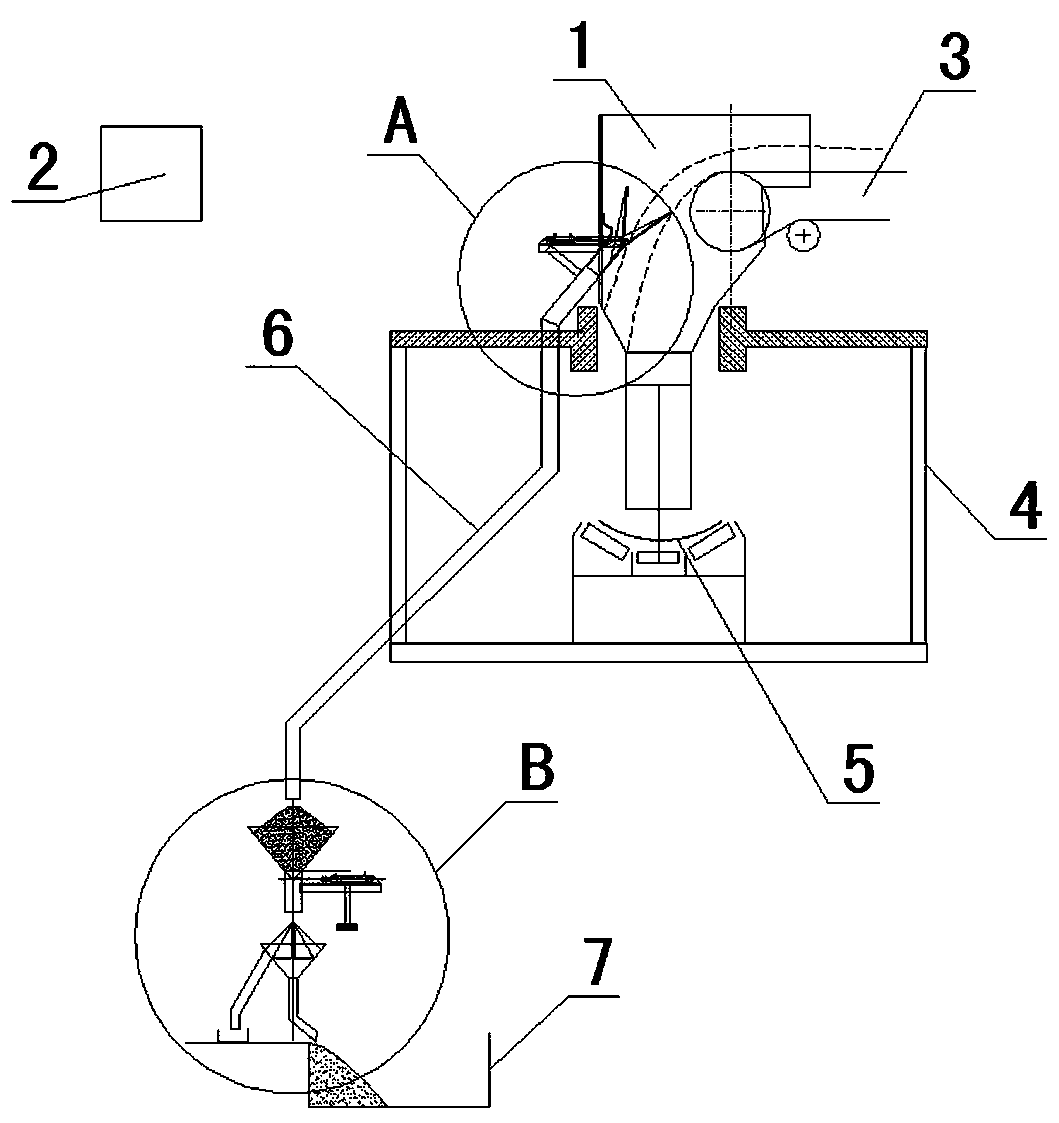

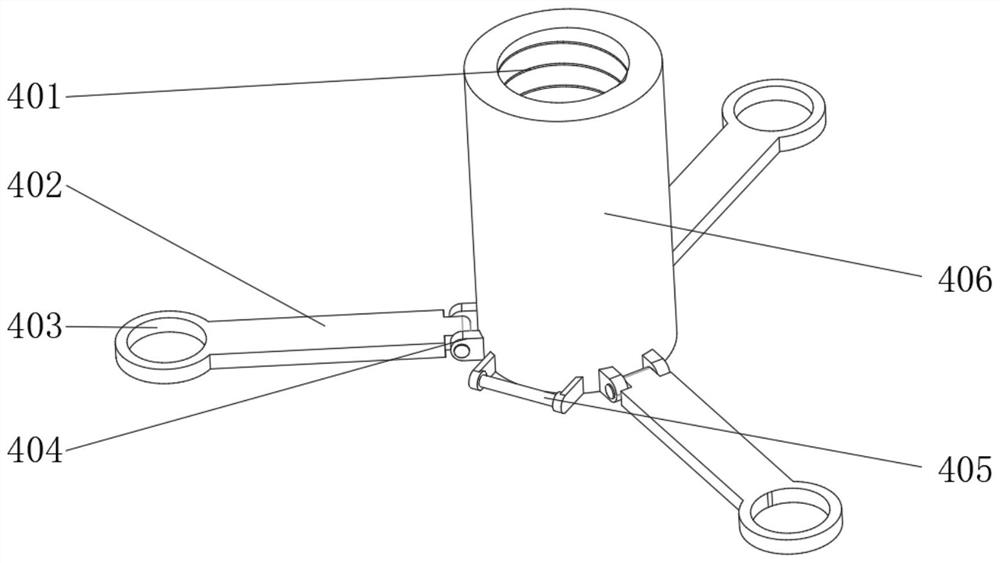

Device for removing cap from oil sample joint in substation oil sampling operation

InactiveCN111924774AImprove work efficiencyLabor savingWithdrawing sample devicesTight-fitting lid removalGear wheelStructural engineering

The invention discloses a device for removing a cap from an oil sample joint in substation oil sampling operation. The device comprises a positioning bracket, an oil sample joint head cap rotating mechanism and an electric torque handle with a power source, wherein the positioning bracket comprises a bottom hexagonal socket sleeve and a top plate connected with the bottom hexagonal socket sleeve,the bottom hexagonal socket sleeve is matched with the hexagonal bottom of the oil sample joint to achieve tool positioning, and the middle position of the top plate is provided with a bearing installation hole in which a sunken bearing is installed; the oil sample joint head cap rotating mechanism comprises a structure frame, a sunken intermediate plug-in transmission gear connected to the structure frame and three geared pawl fingers arranged around the sunken intermediate plug-in transmission gear, the sunken intermediate plug-in transmission gear is in meshing transmission with the gearedpawl fingers, and the center of the sunken intermediate plug-in transmission gear is provided with a transmission hole; and the electric torque handle with the power source comprises a transmission rod, and the transmission rod penetrates through the sunken bearing on the top plate and is inserted in the transmission hole of the sunken intermediate plug-in transmission gear. The device can improvethe sampling working efficiency, reduce the sampling uncapping difficulty and improve the safety and reliability of one-site sampling uncapping work.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

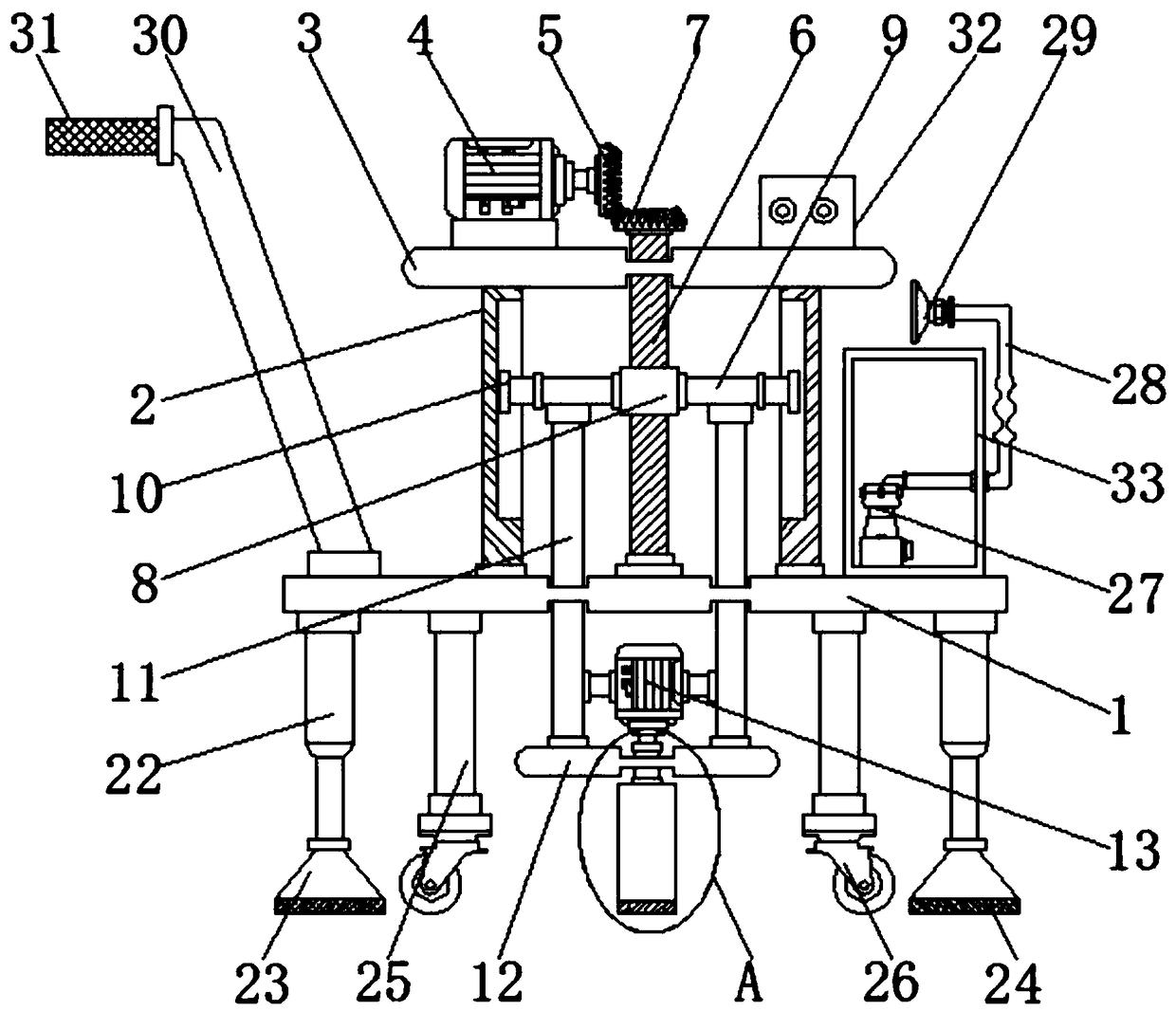

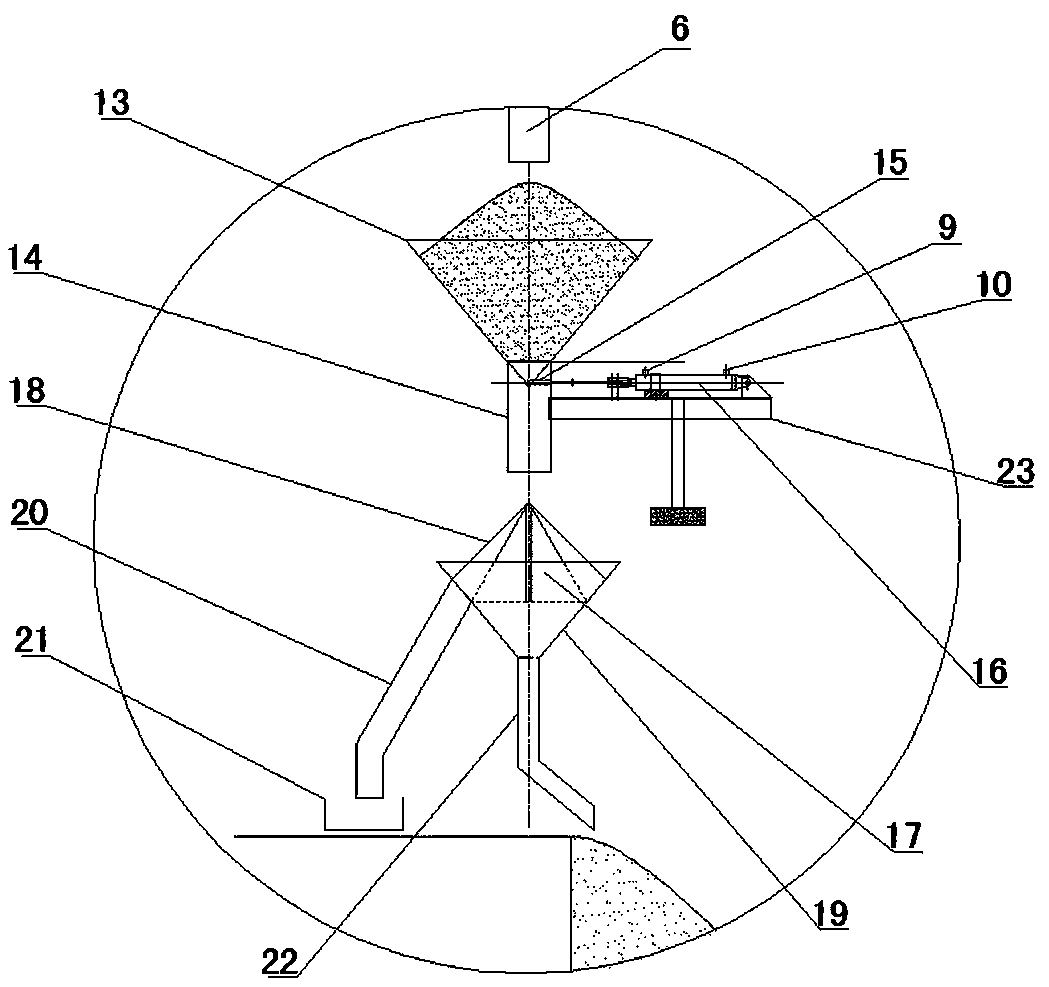

Automatic sampling and reducing device for limestone belt conveyor

PendingCN109132469ASimple structureImprove sampling productivityConveyor partsLime productionEngineeringMaterial resources

The invention relates to an automatic sampling and reducing device for a limestone belt conveyor. The automatic sampling and reducing device comprises a belt conveyor, and an electric-control cabinet,and further comprises an automatic sampling unit and an automatic reducing unit, wherein the machine head of the belt conveyor is equipped with an unloading scraper-trough conveyer on a transfer station bracket of the belt conveyor; a material receiving belt is arranged below a discharge hole of the unloading scraper-trough conveyor; the automatic sampling unit comprises a first electric-hydraulic pushing rod pedestal, a first electric-hydraulic pushing rod and a turnover hopper; a feeding pipeline is arranged on the transfer station bracket of the belt conveyor; an upper-end charge hole of the feeding pipeline is formed in the lower portion of the turnover hopper; the automatic reducing unit is arranged below a lower-end discharge hole of the feeding pipeline; and the automatic reducingunit comprises a material collecting hopper, a second electric-hydraulic pushing rod pedestal, a second electric-hydraulic pushing rod, a sample separator, a sample box and a waste tank. The automaticsampling and reducing device is simple in structure, improves sampling and working efficiency, saves manpower and material resources, eliminates safety risk, and realizes automatic sampling and automatic reducing for large-particle-diameter materials.

Owner:唐山冀东启新水泥有限责任公司

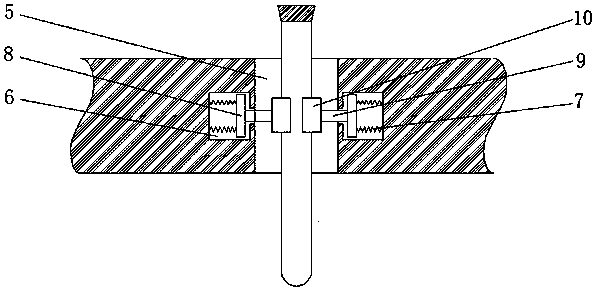

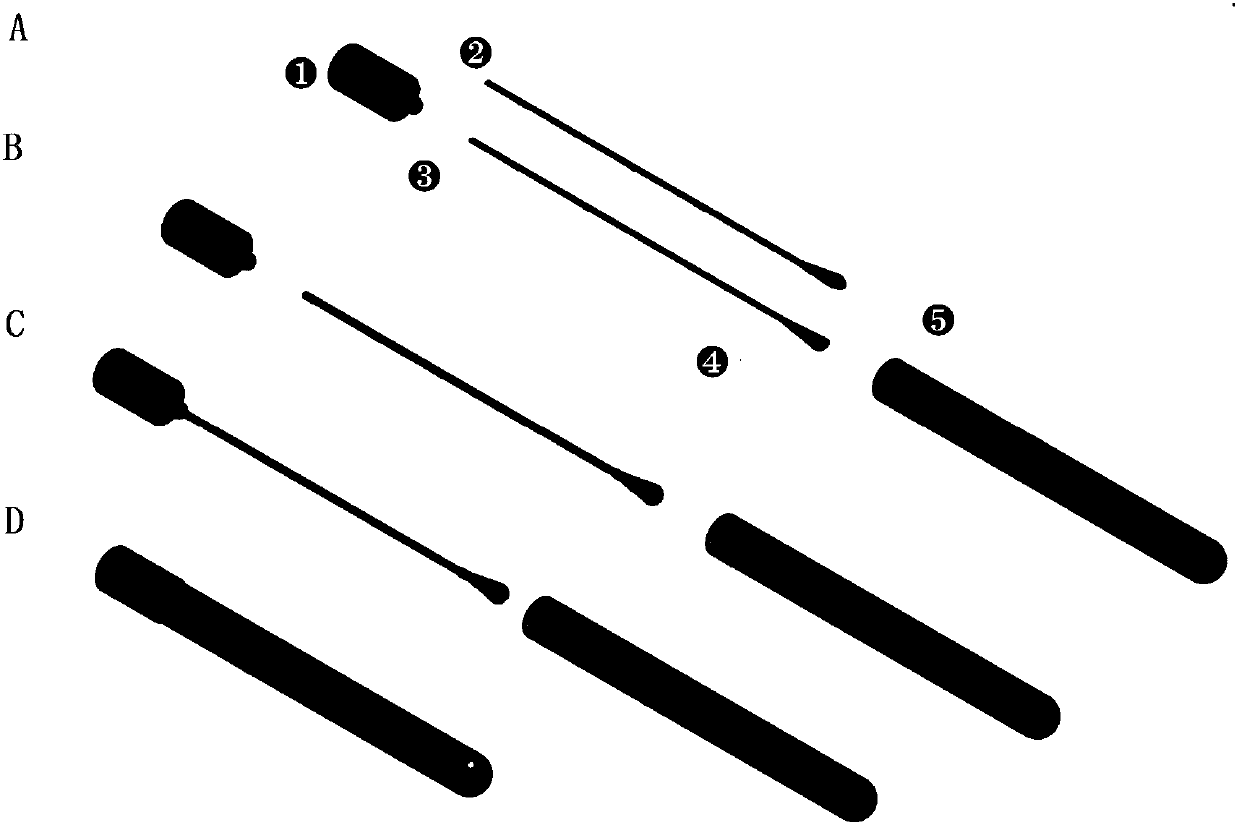

Disposable sterile sampling swab

The invention belongs to the field of medical consumptive materials, and relates to a medical care inspection sampling apparatus, in particular to a disposable sterile sampling swab. The disposable sterile sampling swab consists of a fixing cap, a detachable sampling swab a, a detachable sampling swab b, a C-shaped clip and a sleeve pipe, wherein the head of the detachable sampling swab a and thehead of the detachable sampling swab b are integrally fixed through the C-shaped clip; and the fixing cap is fixedly connected with the handle parts of the detachable sampling swab a and the detachable sampling swab b which are combined, and is placed in the sleeve pipe. Through the using of the disposable sterile sampling swab disclosed by the invention, the disposable sterile sampling swab is simple in structure, convenient to use, and high in practicality; the sampling frequency can be reduced by 50%; the microorganism loading capacity of collected samples is increased, false negative of atesting result is effectively reduced, and valuable laboratory evidence is provided for correct and in-time diagnosis and treatment of clinical infectious diseases; and besides, the discomfortablenessof a patient caused by sampling is alleviated, so that the imparity degree of the patient caused by sampling is reduced.

Owner:SHANGHAI EAST HOSPITAL

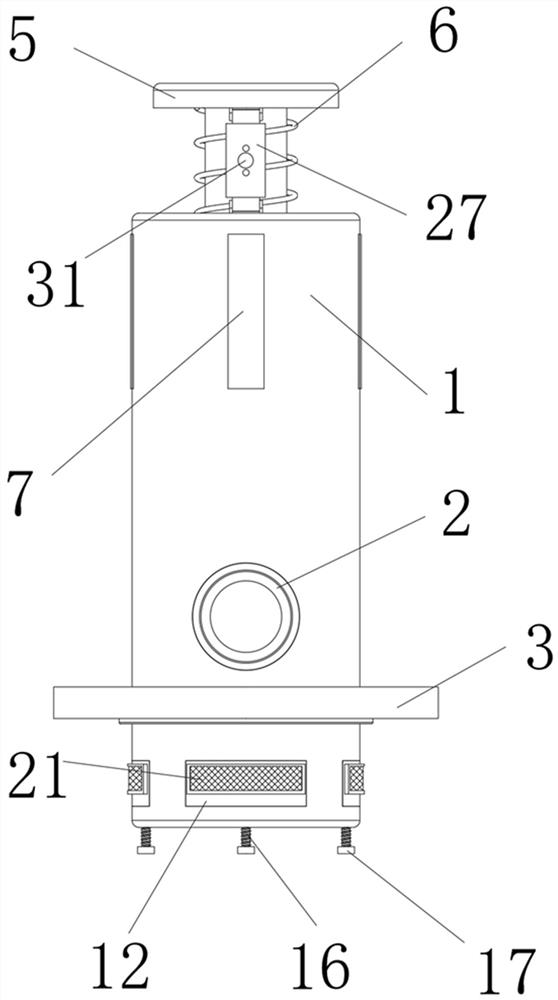

Forestry ecological soil detection soil sampling device

InactiveCN113109081AImprove work efficiencyImprove sampling productivityWithdrawing sample devicesEcologyEnvironmental engineering

The invention provides a forestry ecological soil detection soil sampling device which comprises an outer sleeve and a rotating shaft, a plurality of soil sampling openings are formed in the outer sleeve in the axial direction, a plurality of supporting plates corresponding to the soil sampling openings are fixedly arranged on the rotating shaft, the outer diameter of each supporting plate is equal to the inner diameter of the outer sleeve, the supporting plates are located below the soil sampling openings, a baffle is fixedly arranged on the supporting plate, the baffle can completely cover the soil sampling opening, an extensible arc-shaped scraping plate is arranged on one side of the baffle, the scraping plate is compressed between the baffle and the inner wall of the outer sleeve, and the scraping plate can extend out of the outer sleeve through the soil sampling opening. According to the technical scheme, soil samples with different depths can be taken out at a time, and the working efficiency of soil sampling is improved.

Owner:驻马店市森林病虫防治检疫站

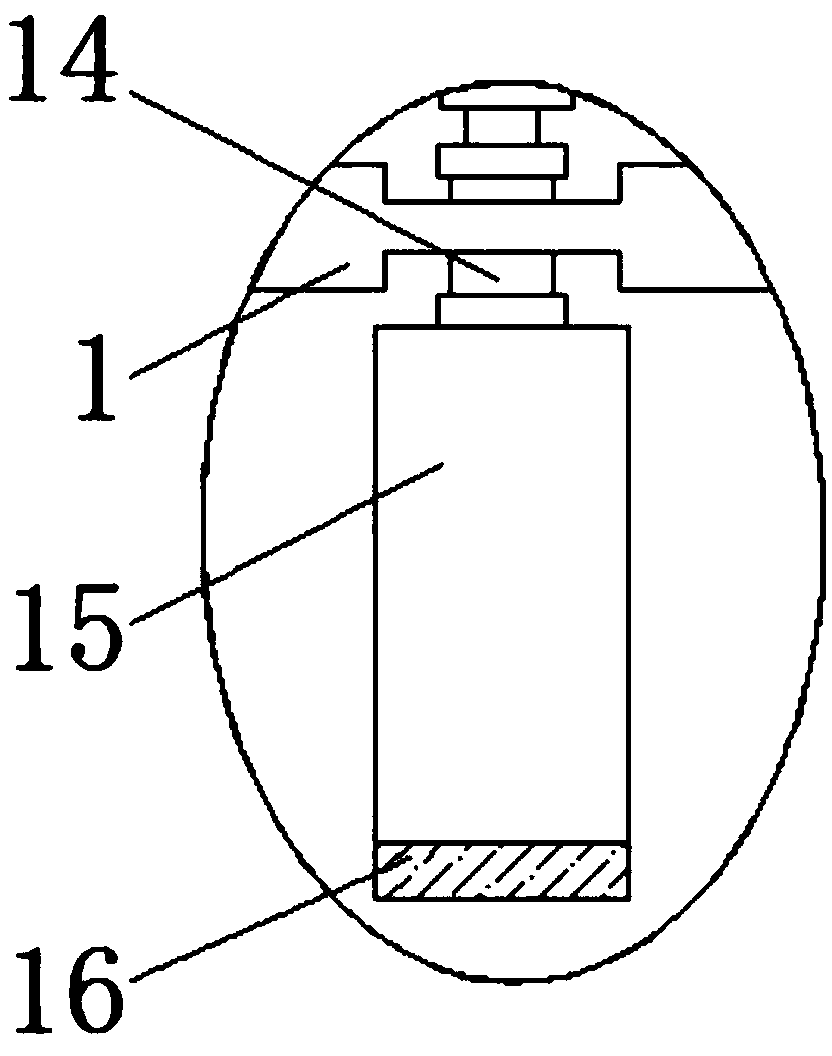

Deep groove sealing sampler

The invention provides a deep groove sealing sampler, a sampler in particular to an ore pulp sampler, which comprises a support, a guide groove, a guide block, a pot lid, and a body, wherein the bodyis a cylindrical container, the outer bottom of the body is conical, the support is fixed to the outer wall of the body through connecting bolt A and is a handle shape. The deep groove sealing samplerimproving the sampling precision, reducing the difficulty of operation, and has great help in guiding the production of the process.

Owner:YUNNAN HUALIAN ZINC & INDIUM

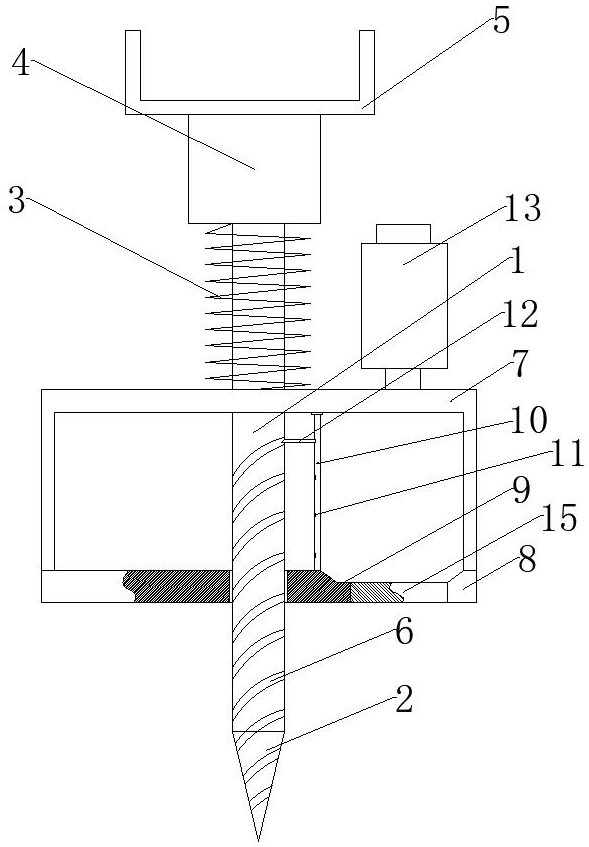

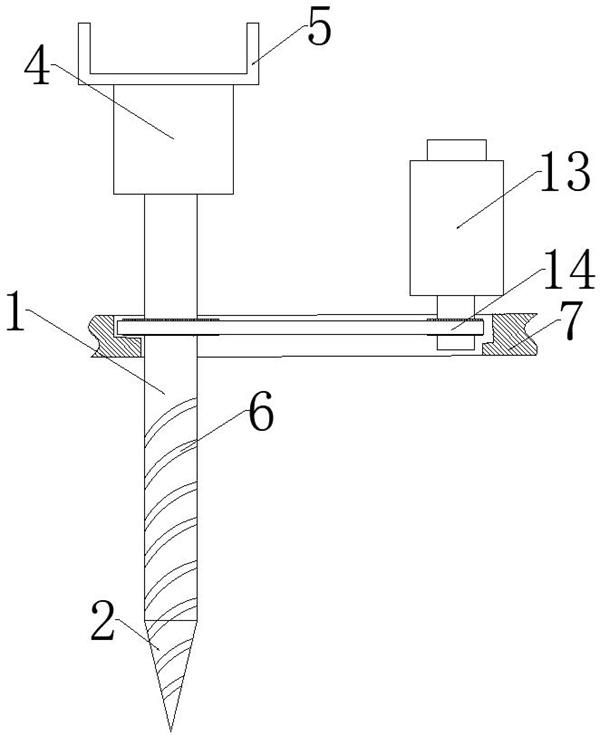

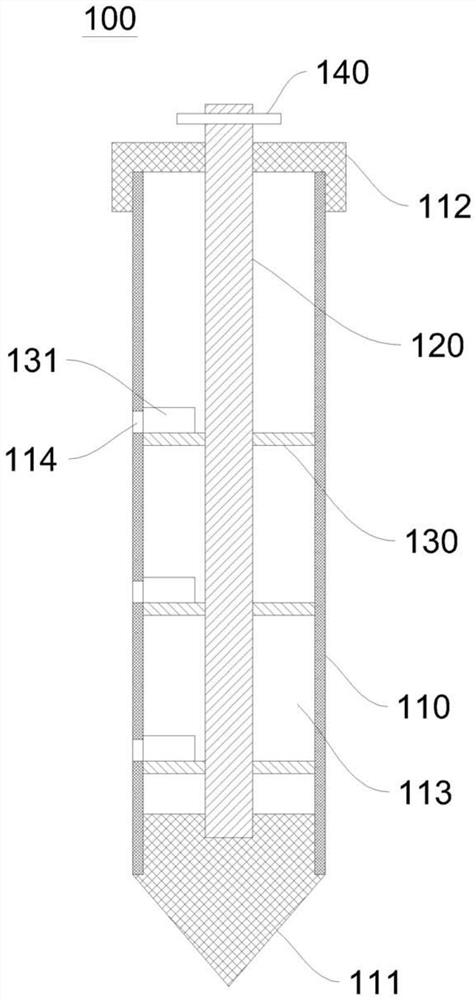

Soil environment detection sampling device

InactiveCN112525593AIncrease travel speedImprove sampling productivityWithdrawing sample devicesAgricultural engineeringSoil science

The invention discloses a soil environment detection sampling device, and relates to the technical field of environment detection. The soil environment detection sampling device comprises a fixed cone, a mandrel, a sampling tube and a sampling sleeve. The mandrel is detachably connected in the sampling tube, and the sampling tube is detachably connected in the sampling sleeve. By arranging the sampling sleeve, the fixed cone can be used for limiting the sampling sleeve during sampling so that the sampling sleeve is stably supported on the ground, the downward rotation of the sampling pipe is conveniently supported, and the purpose of convenient sampling can be achieved by matching with a drill bit on the mandrel; and the fixed cone, the mandrel, the sampling pipe and the sampling sleeve are arranged, when a worker carries out sampling in a field, different parts can be carried by each person, the worker does not need to carry the parts cooperatively, and redundant auxiliary equipment does not need to be carried so that the advancing speed of the sampling worker is increased, and the purpose of improving the sampling work efficiency is achieved.

Owner:梁莉

Storage device used for environmental monitoring

InactiveCN110864936AEasy to take outImprove picking efficiencyWithdrawing sample devicesProcess engineeringEnvironmental protection

The invention discloses a storage device used for environmental monitoring. The storage device comprises a sample storage pipe body, a solid sample storage groove, a solid blocking rod, a solid blocking block, a liquid sample storage groove, a liquid blocking rod, a liquid blocking block, a liquid outlet pipe and a liquid stop valve. According to the storage device, solid and liquid samples can bestored in a classified manner, a good sealing space can be provided for the samples, and the characteristics of the samples can be effectively protected from being damaged. The sampling mode is low in cost, simple to operate and high in sampling work efficiency. The liquid sample is convenient to take out, and the liquid taking efficiency is effectively improved. The storage device is simple in structure, convenient to use, long in service life, easy to manufacture and easy to popularize.

Owner:江苏徐海环境监测有限公司

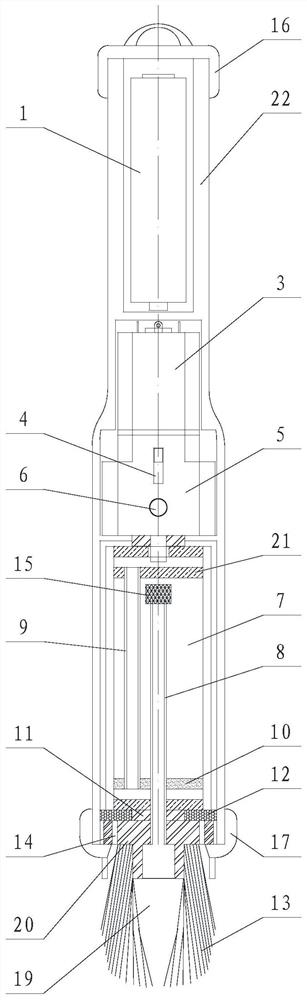

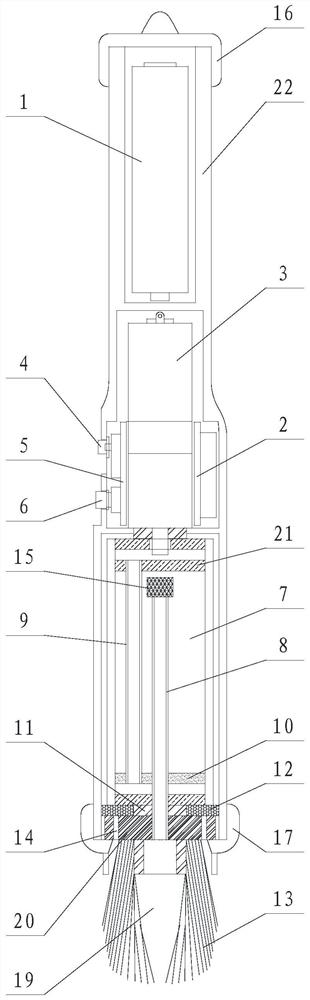

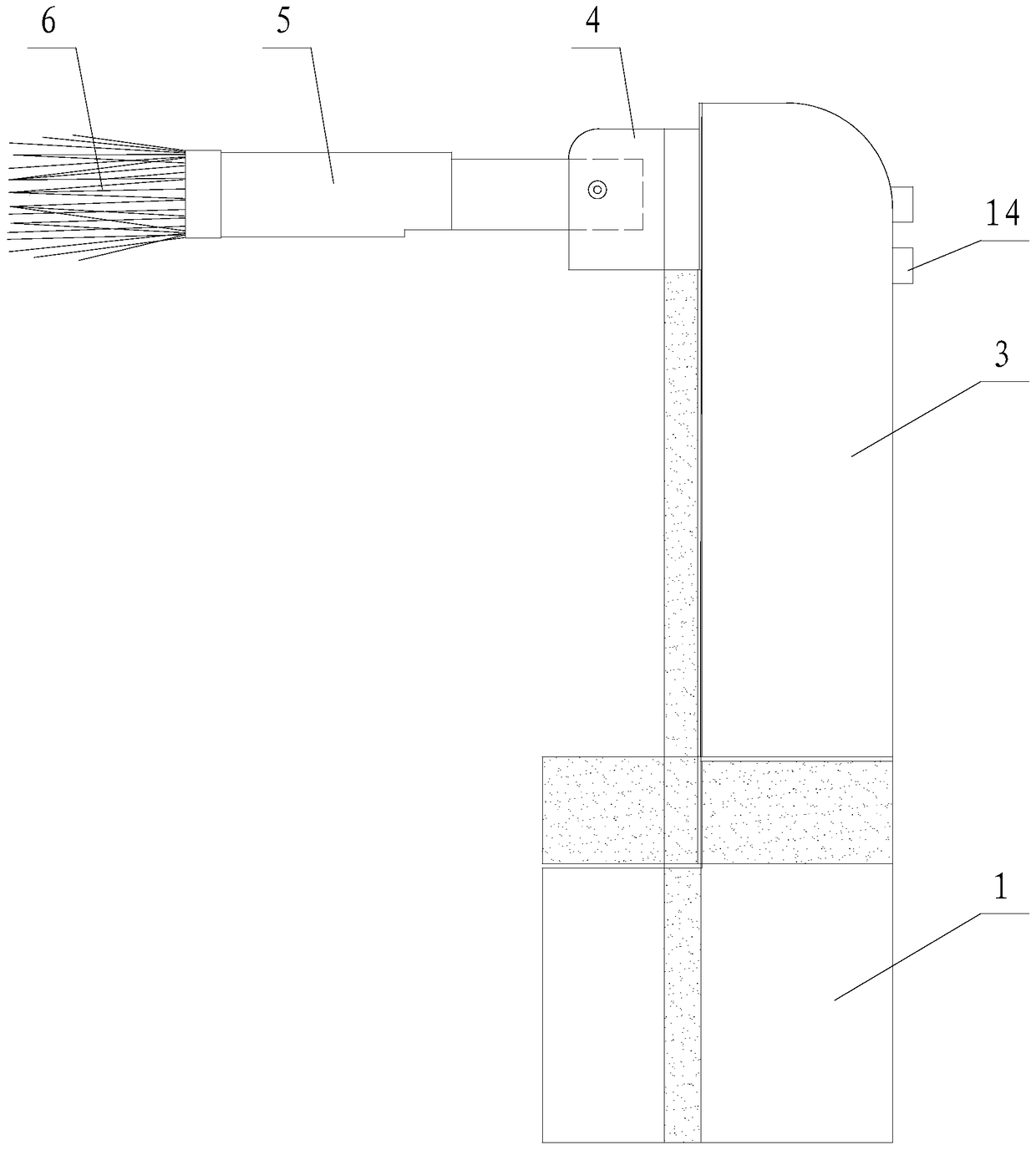

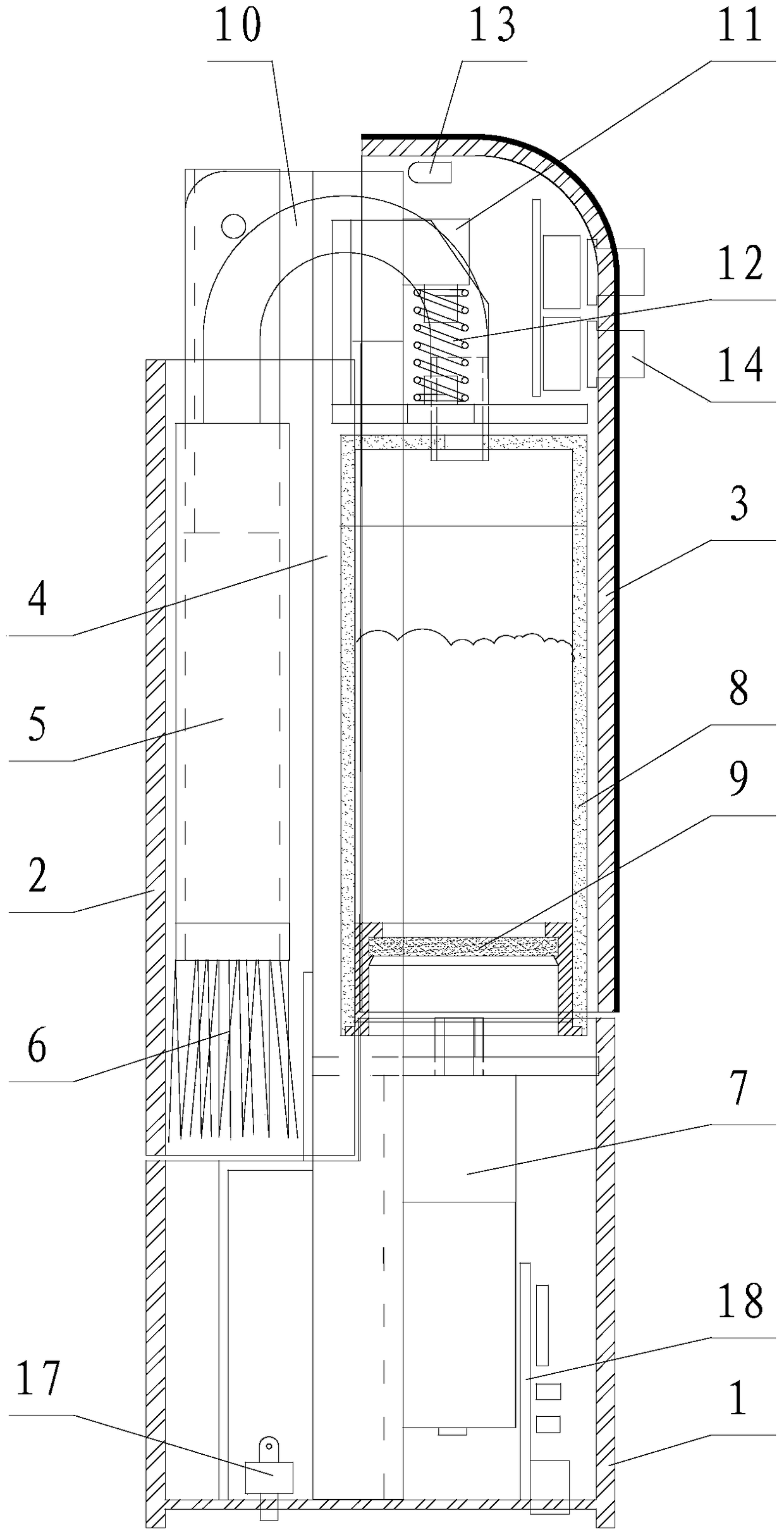

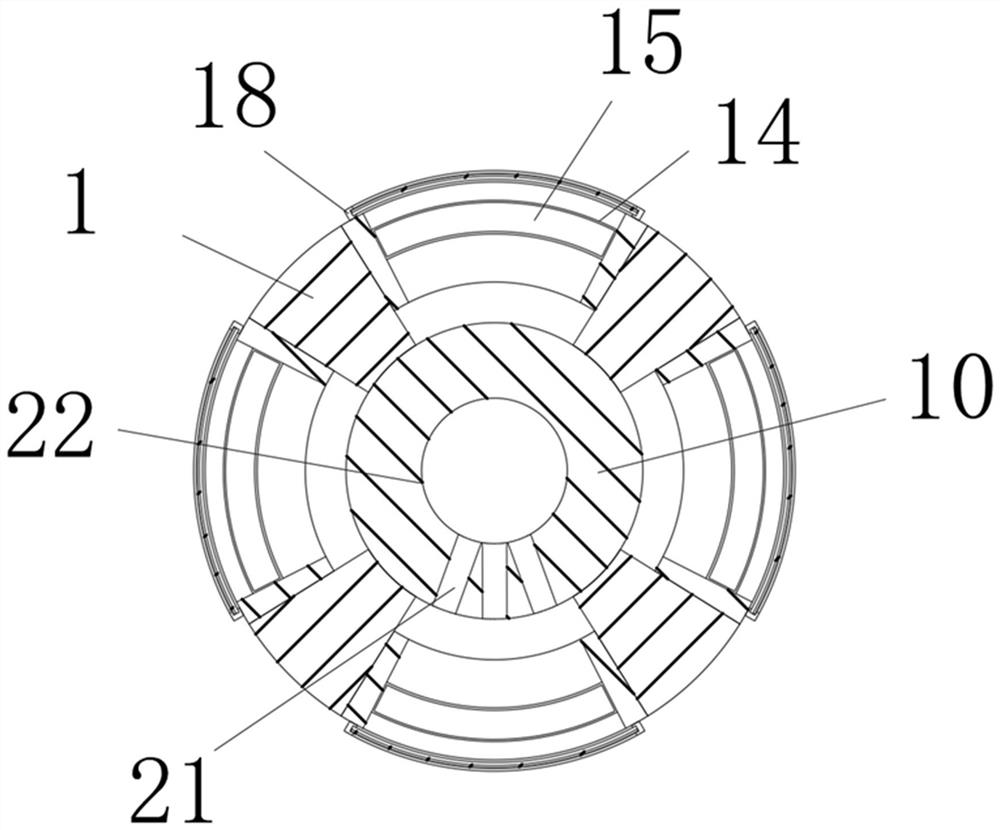

Automatic powder supply trace detection equipment and powder supply method for extracting fingerprints by powder method at crime scene

ActiveCN109419513BAvoid getting lostHow to solve the pollution of ambient airLiquid surface applicatorsDiagnostic recording/measuringFluidized bedPhysical chemistry

An automatic powder supply and trace detection device for extracting fingerprints by means of crime scene powder method and powder supply method thereof; an air pump (3) is in electrical communication with a battery (1), and an air outlet end of the air pump (3) is in communication with a powder bottle (7); an ultra-microporous fluidised bed (10) is installed inside the powder bottle (7), the trace detection powder in the powder bottle (7) being accommodated above the ultra-microporous fluidised bed (10); pressurised air outputted by the air pump (3) passes through the ultra-microporous fluidised bed (10) from below the ultra-microporous fluidised bed (10), forming a plurality of independent air streams acting on the bottom of the trace powder, and producing a mixed gas on the surface of the trace detection powder; one end of an outer shell (22) is provided with a nozzle (20) having a nozzle opening, and a brush head (13) surrounds the nozzle opening, a mixed gas pipe (8) being hermetically connected to the nozzle opening being arranged inside the powder bottle (7), the mixed gas produced in the powder bottle (7) being conveyed to the brush head (13) of the nozzle opening by means of the mixed gas pipe (8), and the trace detection powder in the mixed gas coming into contact with a fingerprint trace and attaching to the surface of the fingerprint trace to form a clear image. The automatic powder supply and trace detection device improves the working environment of police officers, reduces the amount of powder used, and increases the efficiency of sampling work.

Owner:DALIAN SAMAT NEW MATERIAL CO LTD

Automatic powder supply trace detection equipment and powder supply method for extracting fingerprints by powder method at crime scene

ActiveCN105832344BAvoid harmClear tracesLiquid surface applicatorsDiagnostic recording/measuringPowder methodFluidized bed

The invention relates to a trace detection tool in the field of public security criminal investigation, in particular to an automatic powder trace detection device and a powder supply method for extracting fingerprints by powder method at a crime scene. The front cover and the rear cover and the base are respectively installed on the bracket , the air pump and the powder bottle are respectively housed in the inner space formed by the back cover and the bracket, the base and the bracket, and are installed on the bracket respectively, the spray tube is placed in the front cover, one end is hinged with the bracket, and the other end is installed with a fluffy brush; The fluidized bed is located below the powder contained in the powder bottle. The lower end of the powder bottle is connected to the air pump, and the upper end is connected to the spray barrel through the airflow conduit; the pressurized gas provided by the air pump is "boiling" the powder through the fluidized bed. The mixed gas with powder is sprayed onto the trace inspection working surface through the nozzle, the flowing powder touches the trace and is adsorbed on the surface of the trace to form a clear image. , the image after brushing is clearer and more stable.

Owner:DALIAN SAMAT NEW MATERIAL CO LTD

Shipborne automatic water quality sampler

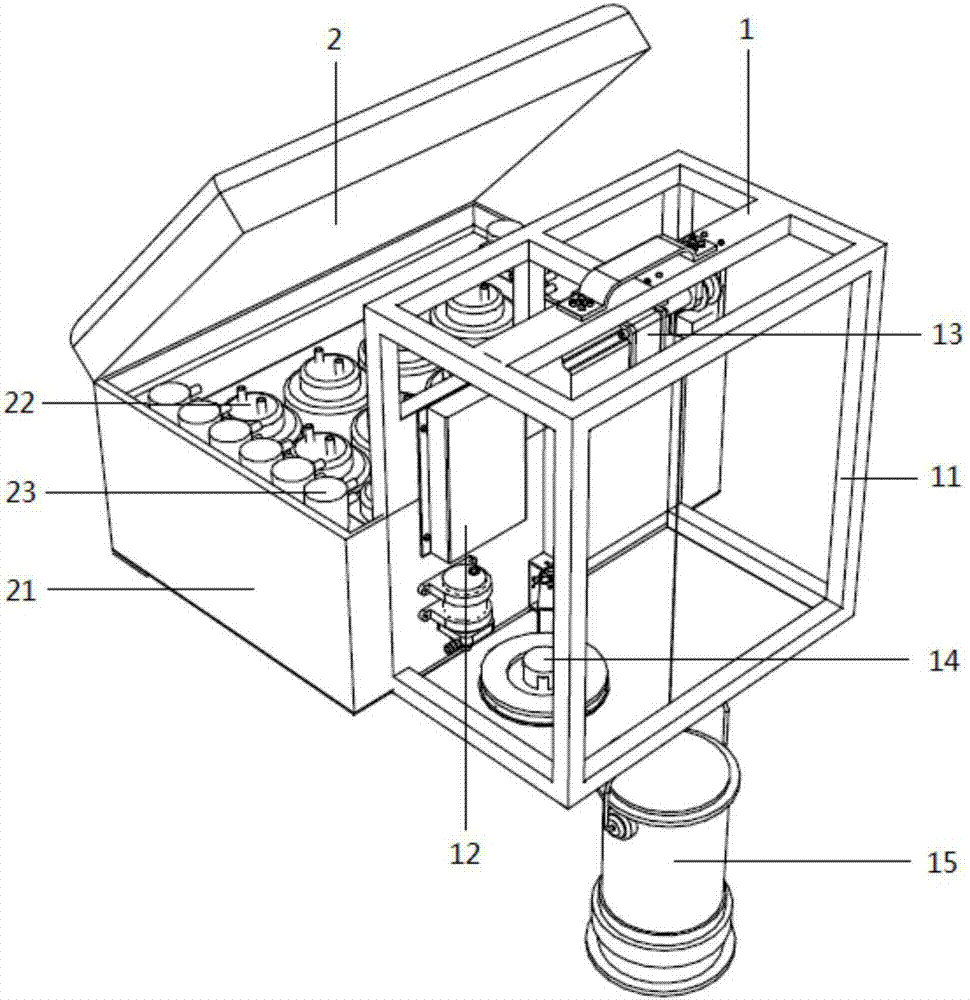

ActiveCN107402143BEasy to carry and installImprove sampling productivityWithdrawing sample devicesWater qualityEngineering

The invention relates to a shipborne automatic water quality sampler, which mainly includes a sample collector and a sample storage box. The sample collector is composed of a support frame, a suspension device, a sample suction device, a sampling bucket and a controller. The sample storage box consists of a storage box body, a sample bottle and a sample splitter. The sample collector and sample storage box of the shipborne automatic water quality sampler adopts a split structure, can be suitable for installation and use by various manned and unmanned ships. Water quality samples of different depths can be collected into a designated sample bottle automatically, thus improving the automation level and sampling efficiency of water quality sampling work. The sampling bucket has a sampling way identical to manual sampling, a water sample at the position where the bucket is located can be acquired precisely, and the objectivity and accuracy of the sampling result can be effectively guaranteed.

Owner:北京中科涌泉科技发展有限公司 +1

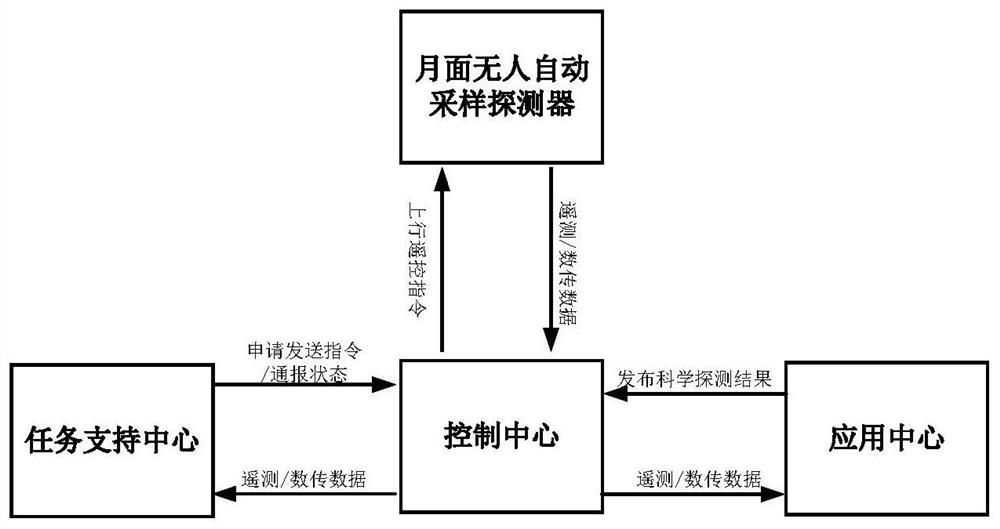

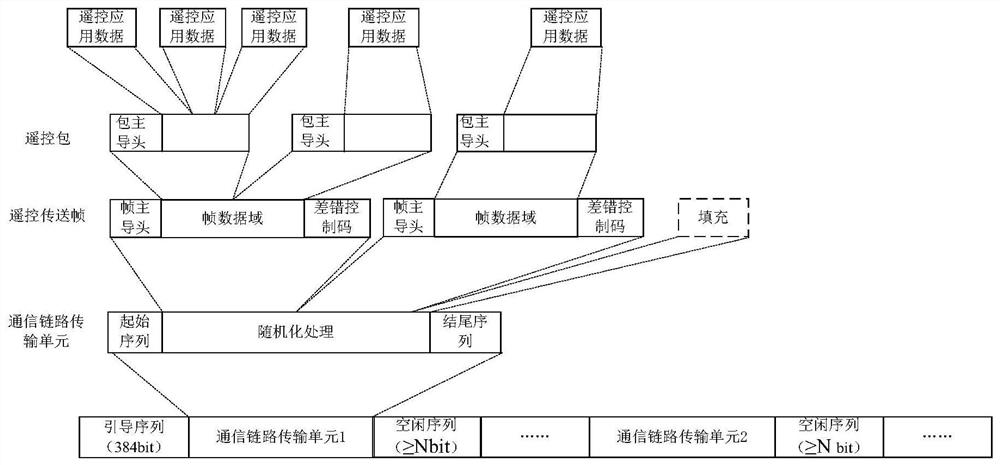

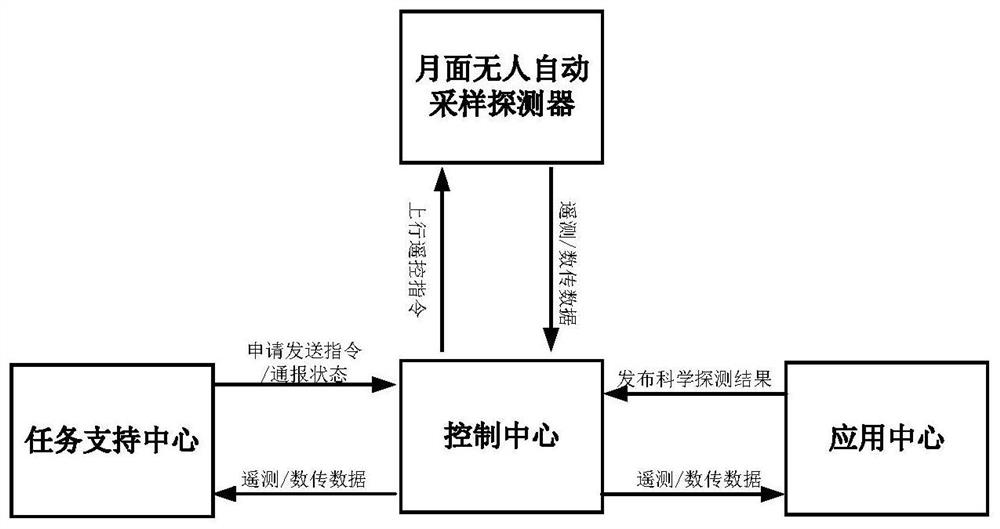

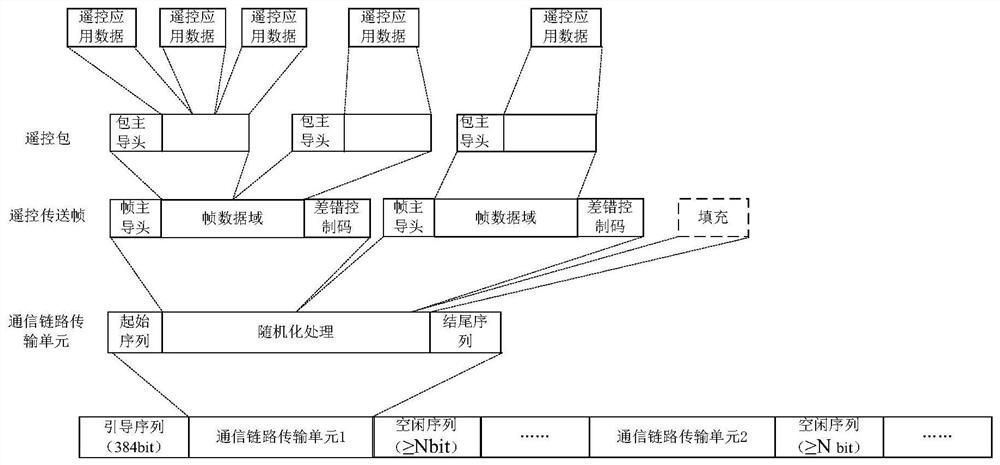

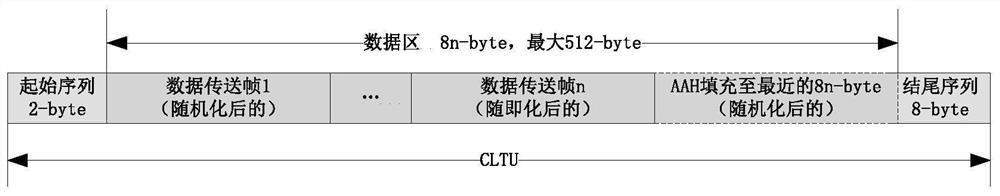

Lunar surface sampling trinity flight control cooperative work flow optimization method

ActiveCN113110308AReduce interactionReduce in quantityTotal factory controlProgramme total factory controlComputer scienceCooperative work

The invention discloses a lunar surface sampling trinity flight control cooperative workflow optimization method, which comprises the following steps: compiling fixed conventional instructions in a cooperative work program into an instruction chain, and in a task implementation process, a task support center only needs to apply to a control center for one time, so that a series of actions can be completed, and interaction between systems is greatly reduced; enabling the pre-established instruction library to quickly select corresponding instructions from the instruction library to quickly form a temporary instruction plan when a field decision problem is dealt with in a task implementation process, so that the number of instructions generated on site is greatly reduced; and adopting an instruction optimization method, so that the number of times of instruction injection during lunar surface sampling is reduced, and the sampling working efficiency is improved. By comprehensively using the optimization method, the efficiency of the lunar surface sampling trinity flight control cooperative work is greatly improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

A deep tank slurry sampler

ActiveCN105890925BImprove representationPromote conversionWithdrawing sample devicesEngineeringSlurry

The invention relates to a deep-trough ore pulp sampler. The deep-trough ore pulp sampler comprises a handle, a hollow pipe, a piston connecting rod, a tensioning spring, a piston-connecting-rod positioning block, a connecting body, a piston, a sampling barrel and a piston fixing block. The deep-trough ore pulp sampler is novel, unique, simple, convenient, rapid, and safe, flexible and reliable in operation and use, sampling working efficiency can be greatly improved, and the deep-trough ore pulp sampler is a great innovation in ore pulp samplers and ways; the problems that vertical positioning sampling in continuously-stirred ore pulp can not be achieved, consumed time is long, sample representativeness is poor, and potential safety hazards in sampling are large are effectively solved.

Owner:YUNNAN HUALIAN ZINC & INDIUM

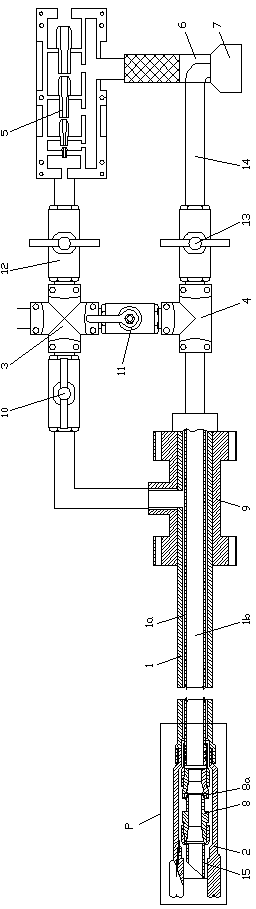

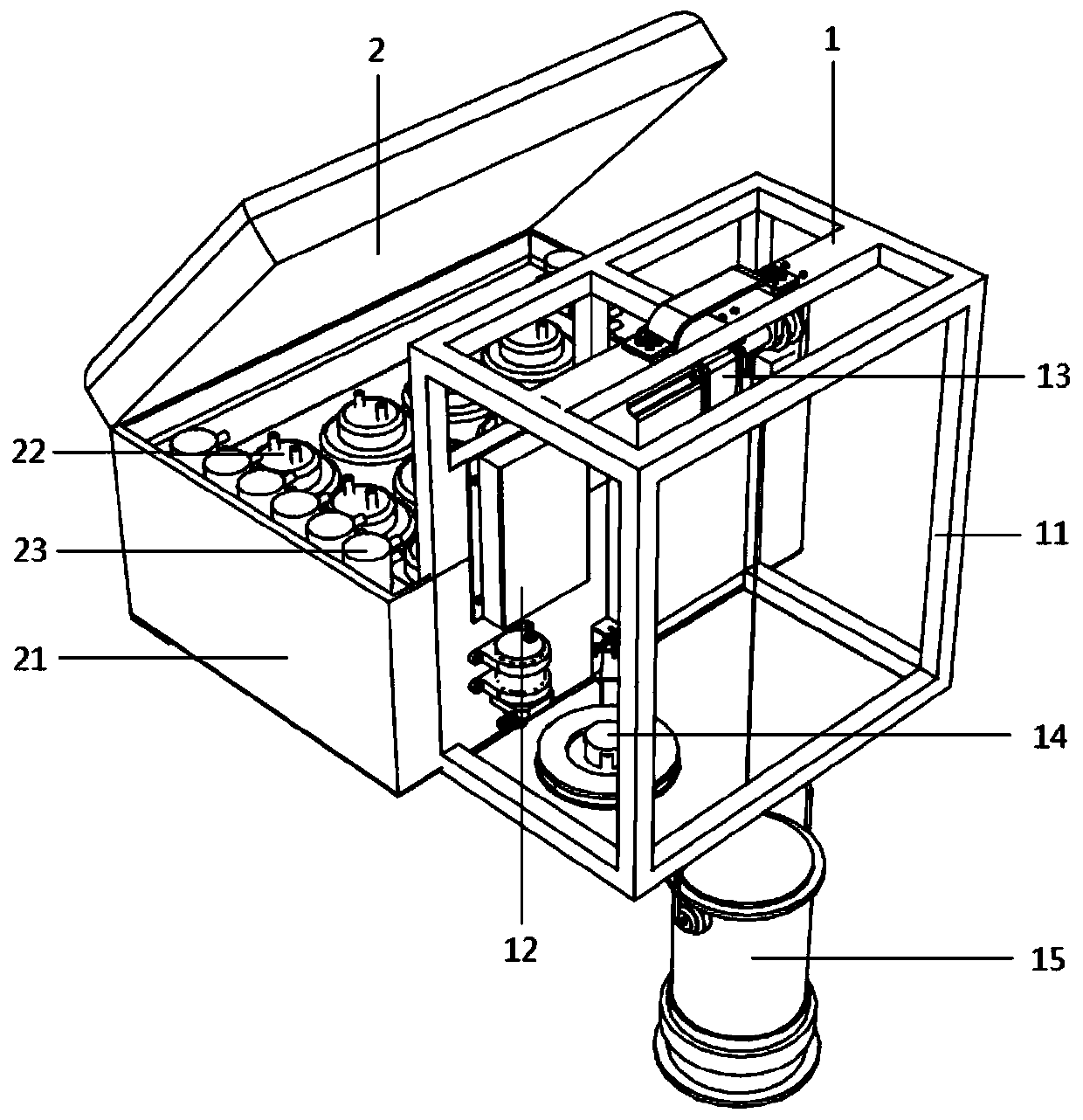

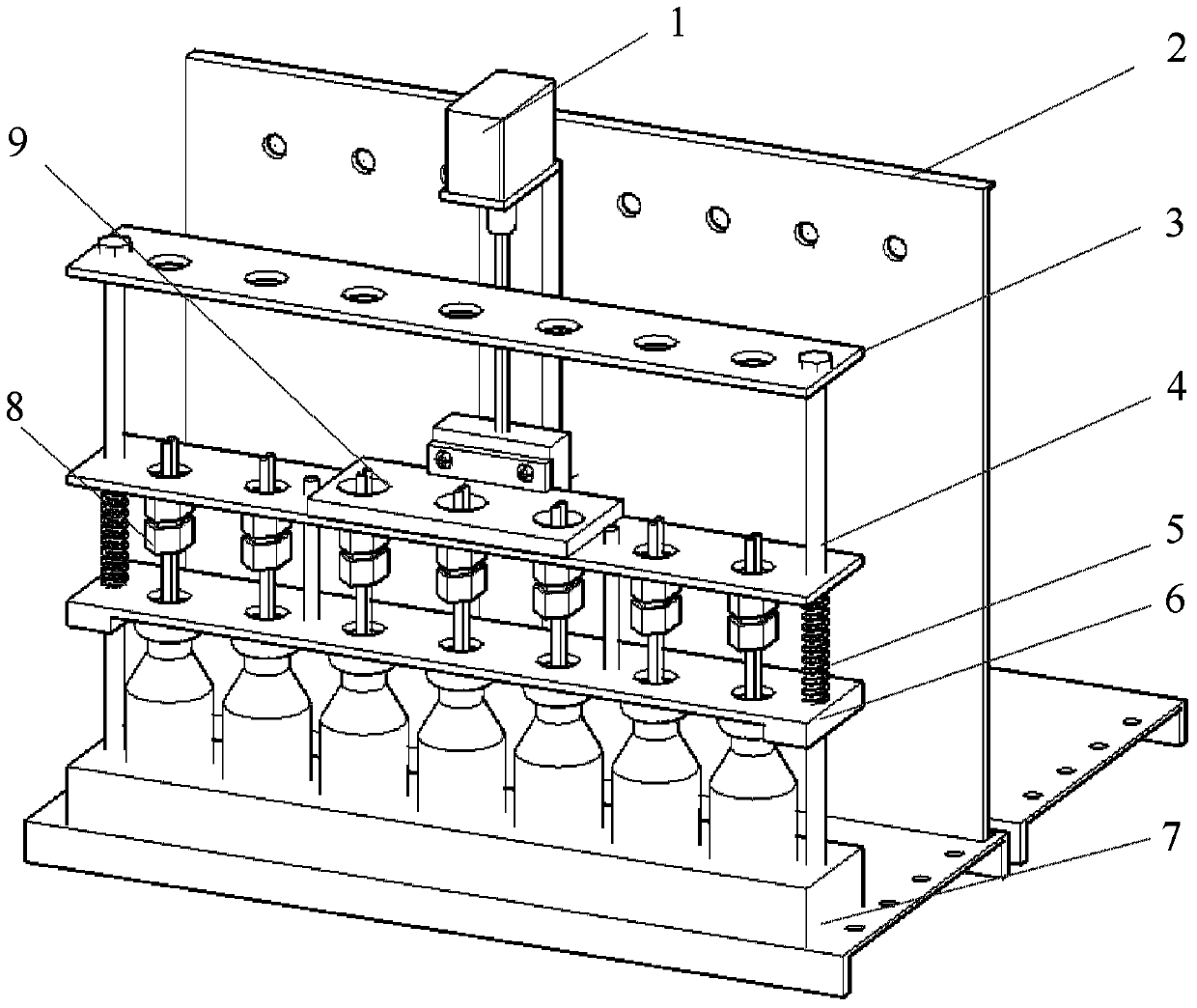

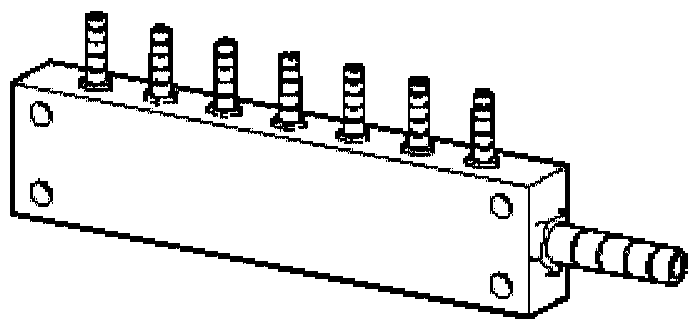

Groundwater sample collection device and method for multi-channel monitoring well

InactiveCN106289874BReduced sampling timeImprove sampling productivityWithdrawing sample devicesEngineeringGroundwater

The invention provides an underground water sample collecting device and method for a multichannel monitoring well. The collecting device comprises N sample collecting and storing units and a multi-distributing valve; the sample collecting and storing units are used for containing N collected underground samples, and water inlets of the sample collecting and storing units extend to corresponding selected sampling positions of the multi-channel monitoring well; the multi-distributing valve is provided with N+1 ports, one port is connected with a pump, and the other N ports are connected with water outlets of the N sample collecting and storing units respectively; the water outlets and the water inlets of the N sample collecting and storing units are each provided with a water stop valve, wherein N is a positive integer larger than or equal to 2. According to the device, the sampling time of the nested multi-channel monitoring well can be shortened, and the outdoor underground water sampling working efficiency can be improved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Sampling valve with labyrinth damping structure

ActiveCN114576380AEasy to take outImprove practicalityOperating means/releasing devices for valvesNuclear energy generationStructural engineeringMechanical engineering

The sampling valve with the labyrinth damping structure comprises a sampling valve shell, a water outlet pipe is fixedly connected to the right side of the sampling valve shell, a connecting flange is fixedly installed on the lower portion of the outer side of the sampling valve shell, a valve rod is movably installed at the top of the sampling valve shell in a penetrating mode, and a control knob is fixedly installed at the upper end of the valve rod. The lower end of the valve rod is located in an inner cavity of the sampling valve shell, a valve element is fixedly installed at the lower end of the valve rod, telescopic rods are fixedly installed on the left side and the right side of the lower surface of the valve element correspondingly, and a rotary blocking block is fixedly connected to the lower ends of the two telescopic rods jointly and movably installed at the bottom of the inner cavity of the sampling valve shell. A connecting groove is formed in the upper surface of the rotary blocking block, and three water inlet holes are formed in the surface of an inner cavity of the connecting groove. The pressure of the sampling liquid outlet can be conveniently adjusted, unnecessary troubles caused by liquid splashing are prevented, and the sampling valve can be effectively prevented from being blocked.

Owner:长春电子科技学院

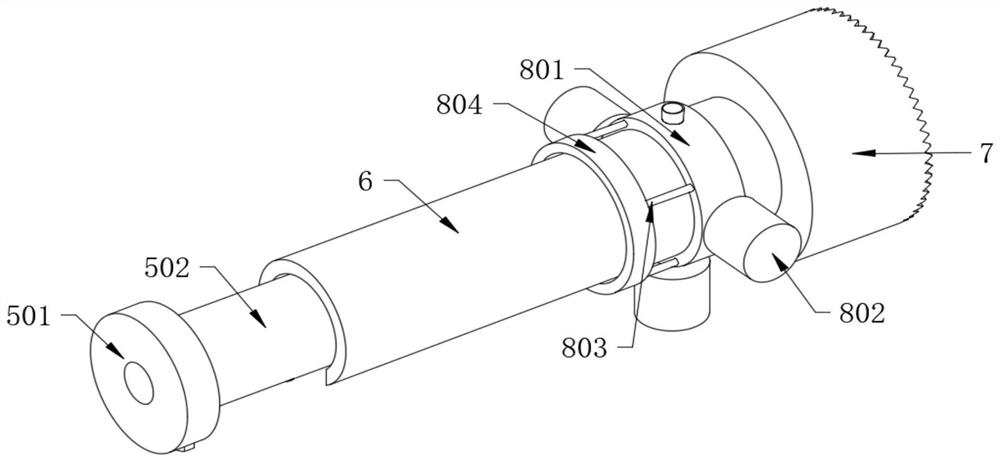

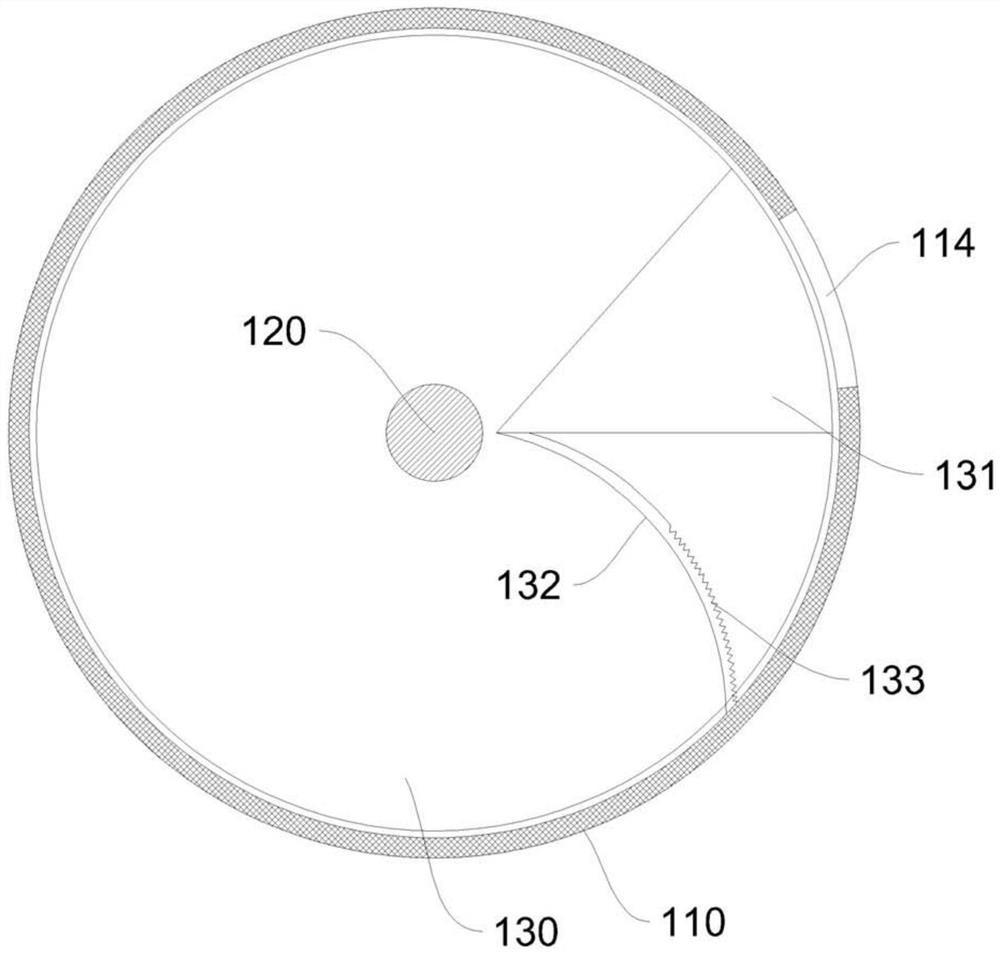

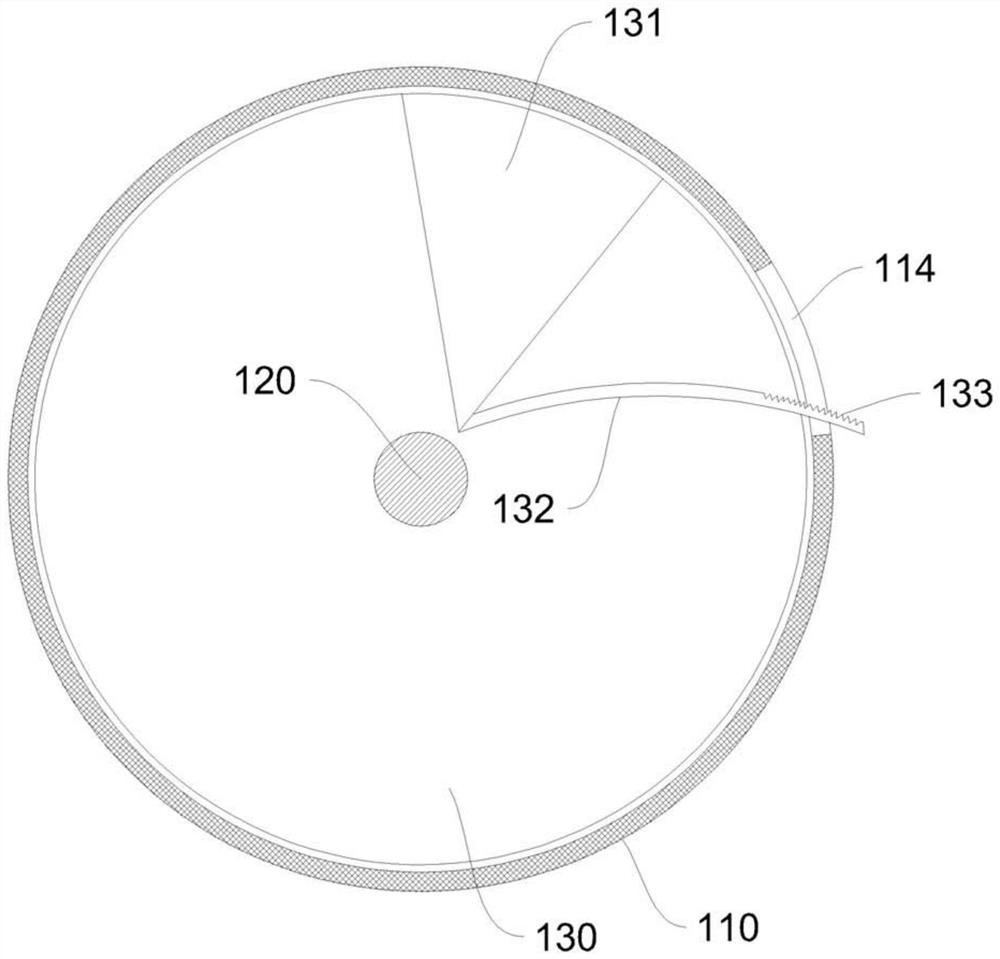

Tobacco lamina sampling device

PendingCN109870321AQuality monitoring light and easyEasy to disassembleWithdrawing sample devicesEngineeringQuality monitoring

The invention relates to the technical field of sampling devices. The invention discloses a tobacco lamina sampling device which comprises a rotary power device, a tobacco lamina sampling tube and a bracket component, wherein a handheld frame is arranged on the bracket component; the rotary power device is fixed on the bracket component; one end of the tobacco lamina sampling tube is detachably connected with the rotary power device through a transmission connecting piece; a cutting piece is arranged on the other end of the tobacco lamina sampling tube; and a toothed cutting edge is arranged on the periphery of the cutting piece. Compared with the prior art, the invention has the advantages that the tobacco lamina sampling device is easy to disassemble, light in weight, convenient to carry, suitable for various working conditions, simple to operate and low in learning cost, which improves the sampling efficiency, and enables the tobacco lamina quality monitoring to be easier. The tobacco lamina sampling device provided by the invention can also realize the function of checking whether the tobacco lamina is mildewed or not without turning over the box.

Owner:HONGTA TOBACCO GRP

A three-in-one flight control collaborative workflow optimization method for lunar surface sampling

ActiveCN113110308BReduce interactionReduce in quantityTotal factory controlProgramme total factory controlSoftware engineeringTask support

The invention discloses a lunar surface sampling trinity flight control collaborative work process optimization method, which compiles the fixed regular commands in the collaborative work program into a command chain. During the task implementation process, the task support center only needs to apply to the control center once, A series of actions can be completed, which greatly reduces the interaction between systems; the pre-established instruction library, in the process of task implementation, can quickly select the corresponding instruction from the instruction library to quickly form a temporary instruction plan when dealing with on-site decision-making problems. The number of on-site generated commands is greatly reduced; the command optimization method is adopted, which reduces the number of command injections during the lunar surface sampling period and improves the sampling efficiency; the comprehensive use of the above optimization methods makes the lunar surface sampling Trinity flight control collaborative work efficiency greatly improve.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com