Automatic sampling and reducing device for limestone belt conveyor

A technology of automatic sampling and subdivision device, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of inability to automatically subdivide samples, large safety risks, poor sample representativeness, etc., so as to improve sampling efficiency and eliminate safety risks. , the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

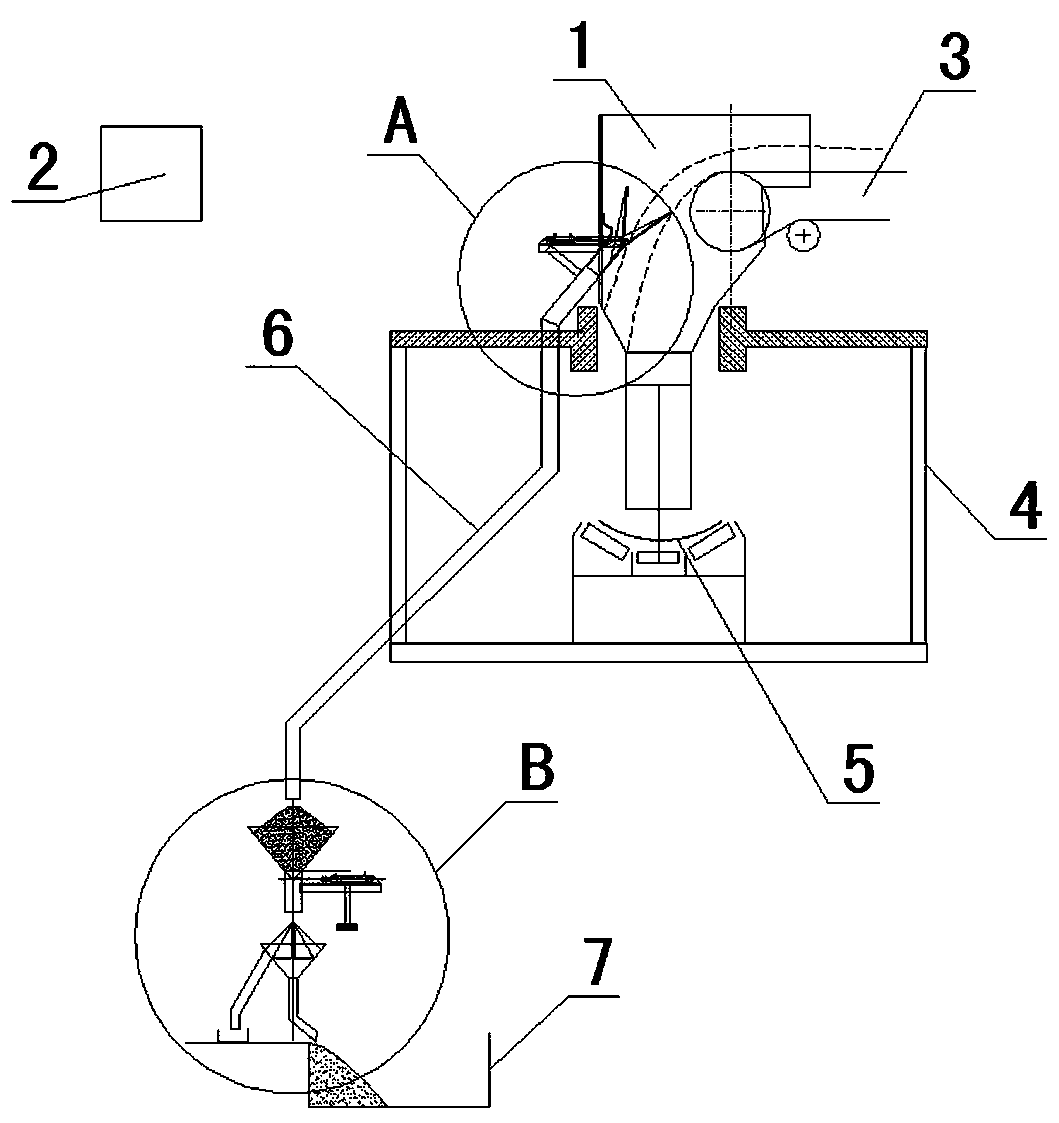

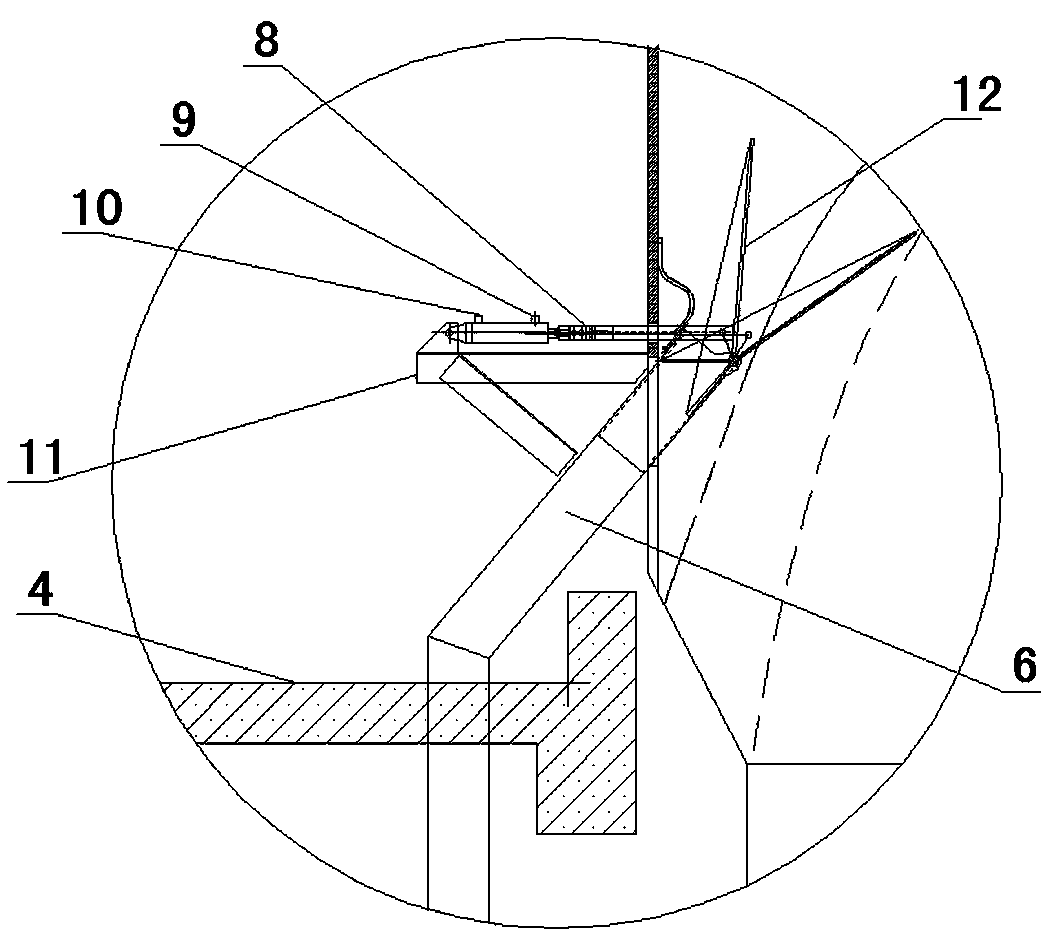

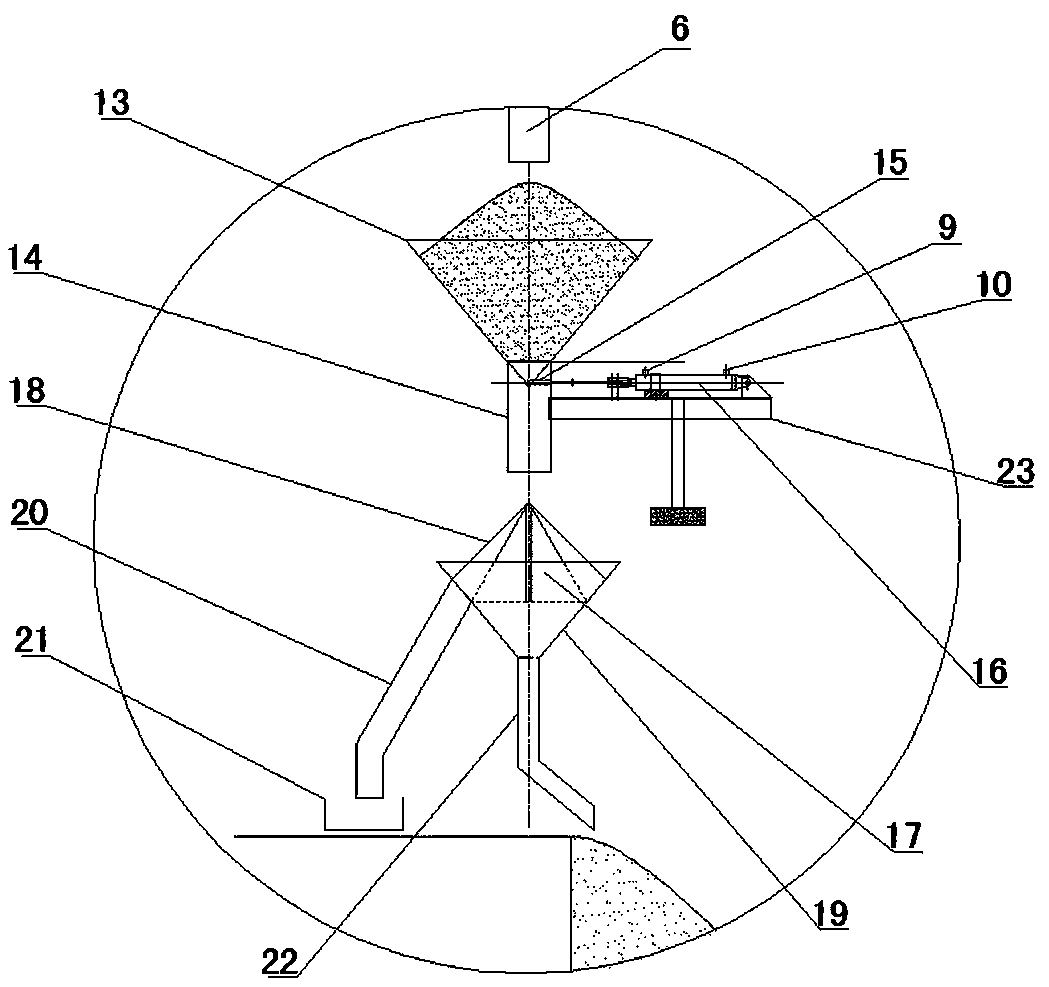

[0015] see figure 1 , figure 2 , image 3 , a limestone belt conveyor automatic sampling and shrinking device, comprising a belt conveyor 3, an electric control cabinet 2, the belt conveyor 3 head is provided with a blanking slide 1 positioned on a belt transfer station support 4, and the outlet of the blanking slide 1 A material receiving belt 5 is arranged below the feed port, and also includes an automatic sampling unit and an automatic shrinkage unit; the automatic sampling unit includes a first electro-hydraulic push rod base 11, a first electro-hydraulic push rod 8 and an overturning hopper 12, and a feeding slide The side wall of 1 is provided with a sampling port, and the first electro-hydraulic push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com