Deep-trough ore pulp sampler

A sampler and slurry technology, applied in the field of deep groove slurry sampler, can solve the problems of inaccurate data detection results, poor sample representativeness, inconvenient extraction, etc., and achieve good sample representativeness, high sampling efficiency, and convenient conversion of results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

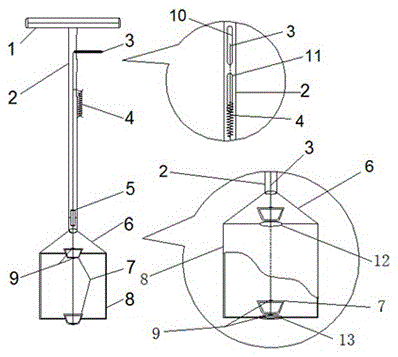

[0015] Embodiment 1: as figure 1 , a deep groove slurry sampler, which includes a handle 1, a hollow tube 2, a piston connecting rod 3, a tension spring 4, a piston connecting rod positioning block 5, a connecting body 6, a piston 7, a sampling cylinder 8 and a piston fixing block 9. The handle 1 is integrated with the hollow tube 2, the piston connecting rod positioning block 5, the connecting body 6, and the sampling cylinder 8. The piston connecting rod 3 is connected with the piston 7 and the piston positioning block 9. The upper end of the piston connecting rod 3 is connected from the middle The upper notch 10 on the side of the empty tube is pierced by 10 mm, the lower end of the tension spring 4 is fixed on the outer wall of the hollow tube 2, and the upper end is fixedly connected to the piston connecting rod 3 through the lower opening 11 on the side of the hollow tube 2, and the piston connecting rod 3 is connected to the piston rod 3. Rod positioning block 5 passes...

Embodiment 2

[0016] Embodiment 2: as figure 1 , a deep groove slurry sampler, which includes a handle 1, a hollow tube 2, a piston connecting rod 3, a tension spring 4, a piston connecting rod positioning block 5, a connecting body 6, a piston 7, a sampling cylinder 8 and a piston fixing block 9. The handle 1 is integrated with the hollow tube 2, the piston connecting rod positioning block 5, the connecting body 6, and the sampling cylinder 8. The piston connecting rod 3 is connected with the piston 7 and the piston positioning block 9. The upper end of the piston connecting rod 3 is connected from the middle The upper notch 10 on the side of the empty pipe passes through 8 mm, the lower end of the tension spring 4 is fixed on the outer wall of the hollow pipe 2, and the upper end is fixedly connected with the piston connecting rod 3 through the lower opening 11 on the side of the hollow pipe 2, and the piston connecting rod 3 is connected from the piston. Rod positioning block 5 passes t...

Embodiment 3

[0017] Embodiment 3: as figure 1 , a deep groove slurry sampler, which includes a handle 1, a hollow tube 2, a piston connecting rod 3, a tension spring 4, a piston connecting rod positioning block 5, a connecting body 6, a piston 7, a sampling cylinder 8 and a piston fixing block 9. The handle 1 is integrated with the hollow tube 2, the piston connecting rod positioning block 5, the connecting body 6, and the sampling cylinder 8. The piston connecting rod 3 is connected with the piston 7 and the piston positioning block 9. The upper end of the piston connecting rod 3 is connected from the middle The upper notch 10 on the side of the empty pipe is pierced by 12mm, the lower end of the tension spring 4 is fixed on the outer wall of the hollow pipe 2, and the upper end is fixedly connected with the piston connecting rod 3 through the lower opening 11 on the side of the hollow pipe 2, and the piston connecting rod 3 is connected to the piston from the piston. Rod positioning blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com