Tritium-containing exhaust gas discharge monitoring automatic sampling system

An automatic sampling and exhaust gas emission technology, applied in sampling devices and other directions, can solve the problems of not being able to truly and objectively reflect the emission source items of tritium-containing exhaust gas, infeasible, unable to reflect the discharge conditions of tritium-containing exhaust gas, etc., so as to improve the efficiency of sampling work. , reduce labor intensity and improve the effect of obtaining representative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

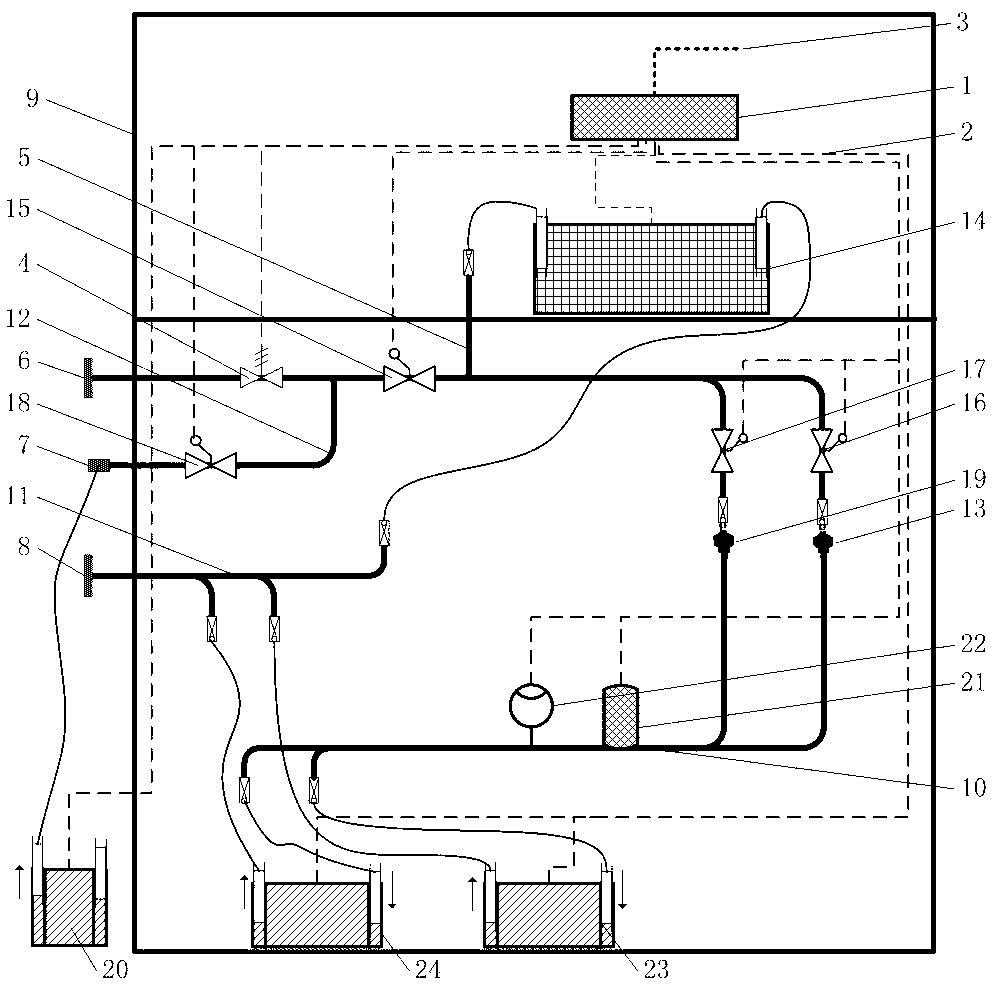

[0018] figure 1 It is a schematic diagram of the structure of the present invention. exist figure 1 Among them, the automatic sampling system for tritium-containing waste gas emission monitoring of the present invention includes an automatic control unit 1, a full tritium sampler 14, a flow regulating valve 4, a first solenoid valve 15, a second solenoid valve 16, a Three electromagnetic valves 17, the fourth electromagnetic valve 18, the first dust filter 13, the second dust filter 19, the mass flow meter 21, the pressure gauge 22, the pump I23 and the pump II24, also include the intake pipe arranged outside the sampling cabinet Joint 6, purge pipe joint 7, exhaust pipe joint 8 and pump III20; Its connection relation is, the inlet pipe joint 6 that is arranged on the outside of sampling cabinet 9 connects one end of flow control valve 4 and first electromagnetic valve 15 successively through air pipe , the other end of the first electromagnetic valve 15 is respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com