Deep groove sealing sampler

A technology of deep groove sealing and sampler, which is applied in the field of sampler, can solve the problems that the sampling spoon can only get to the surface of the pulp, affect the process inspection progress, and cannot provide effective data, etc., so as to reduce the cost of labor and pump sampling, The effect of improving sampling work efficiency and reducing sampling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

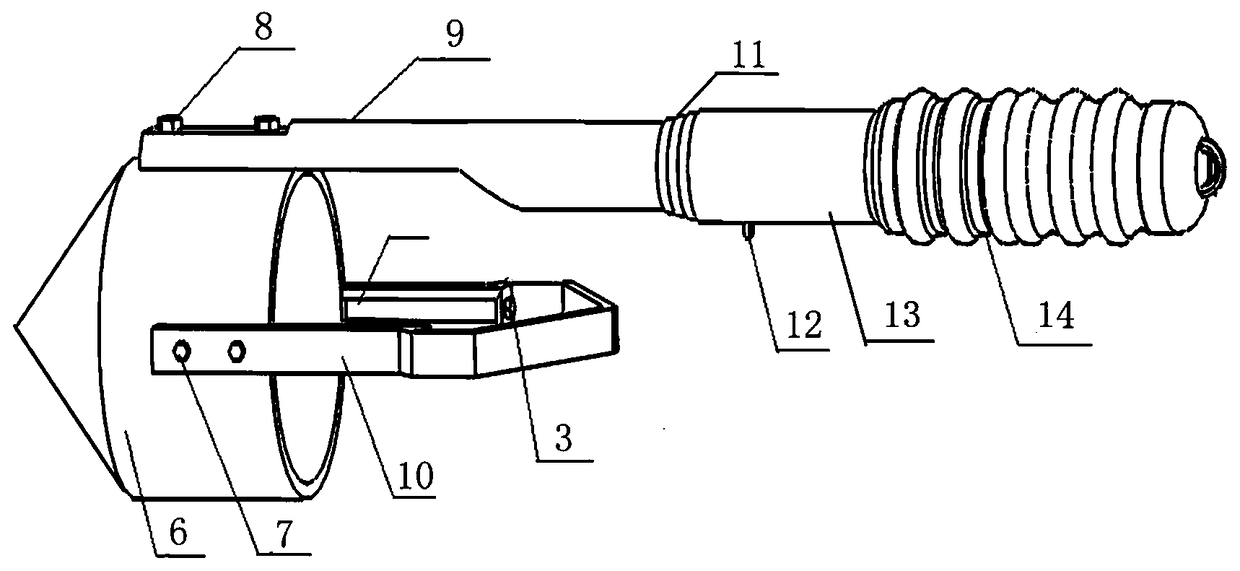

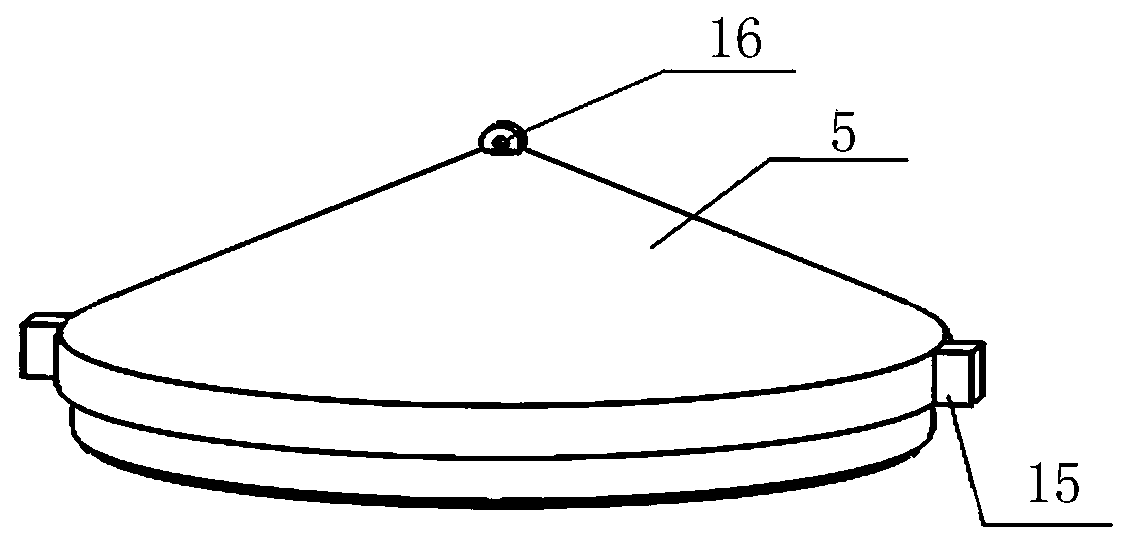

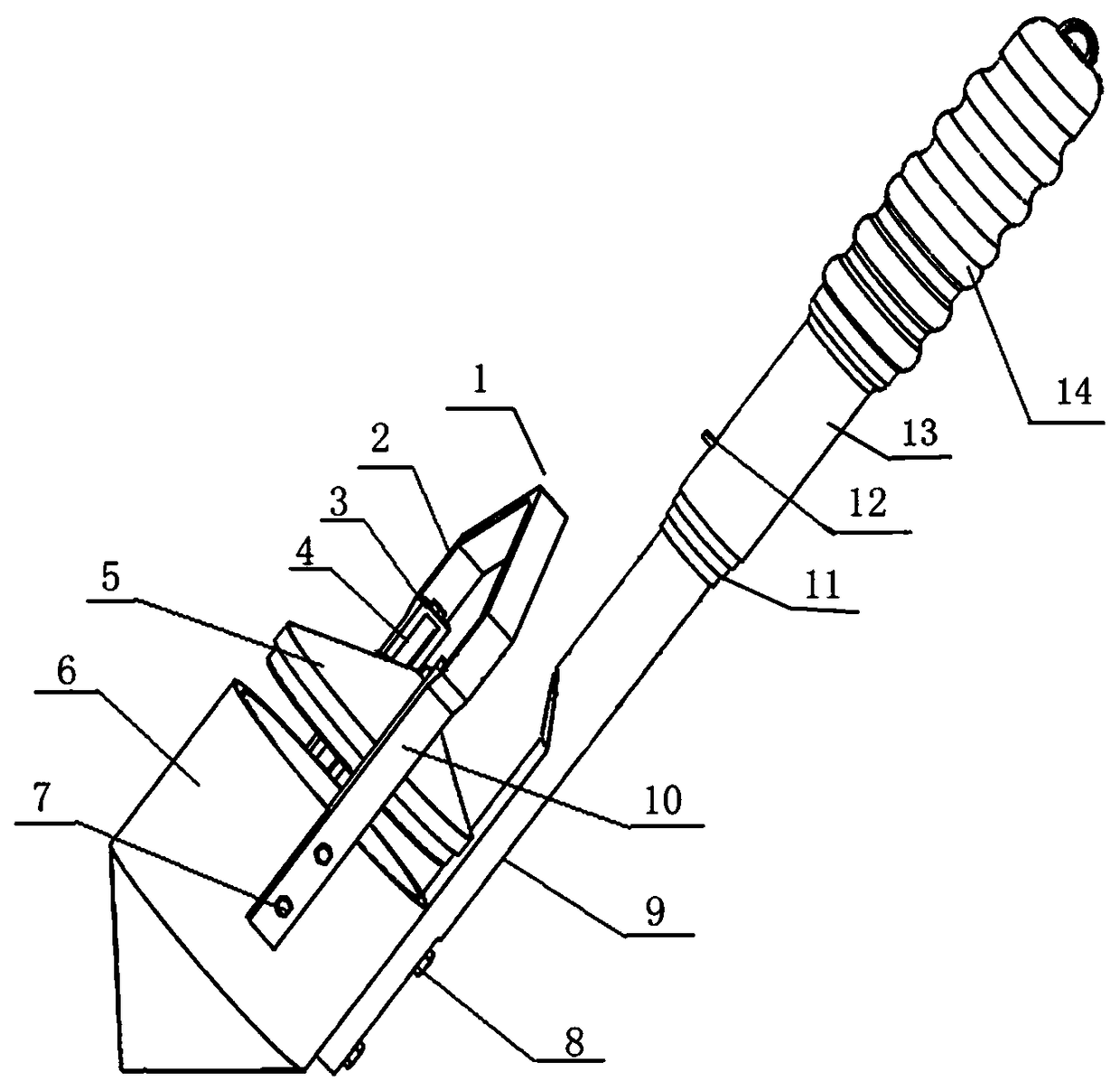

[0020] Embodiment 1: as Figure 1-3 As shown, a deep groove sealed sampler includes a support 1, a guide groove 4, a guide block 15, a pot cover 5, and a pot body 6. The pot body 6 is a cylindrical container, and its outer bottom is conical. The bracket 1 is fixed on the outer wall of the pot body 6 through connecting bolts A 7 and is in the shape of a handle. The bracket 1 is composed of a vertical part 10 and a cap top 2. The vertical part 10 of the bracket 1 has a guide groove 4 inside. There is a guide block 15 on the edge of the pot lid 5 that matches the guide groove 4. The pot lid 5 can slide up and down along the guide groove 4. The top of the pot lid 5 is provided with a hanging hole, and the traction rope is tied to the hanging hole.

Embodiment 2

[0021] Embodiment 2: as Figure 1-3 As shown, a deep groove sealed sampler includes a support 1, a guide groove 4, a guide block 15, a pot cover 5, and a pot body 6. The pot body 6 is a cylindrical container, and its outer bottom is conical. The bracket 1 is fixed on the outer wall of the pot body 6 through connecting bolts A 7 and is in the shape of a handle. The bracket 1 is composed of a vertical part 10 and a cap top 2. The vertical part 10 of the bracket 1 has a guide groove 4 inside. There is a guide block 15 matching the guide groove 4 on the edge of the pot cover 5, and the pot cover 5 can slide up and down along the guide groove 4. The top of the pot cover 5 is provided with a hanging hole, and the traction rope is tied to the hanging hole; the sampler Also comprise a telescoping rod, described telescoping rod is divided into hand-held part 14, telescoping part 11, connecting part 9 three parts, described connecting part 9 is fixed on the kettle body 6 by connecting b...

Embodiment 3

[0022] Embodiment 3: as Figure 1-3 As shown, a deep groove sealed sampler includes a support 1, a guide groove 4, a guide block 15, a pot cover 5, and a pot body 6. The pot body 6 is a cylindrical container, and its outer bottom is conical. The bracket 1 is fixed on the outer wall of the pot body 6 through connecting bolts A 7 and is in the shape of a handle. The bracket 1 is composed of a vertical part 10 and a cap top 2. The vertical part 10 of the bracket 1 has a guide groove 4 inside. There is a guide block 15 on the edge of the pot cover 5 that matches the guide groove 4, and the pot cover 5 can slide up and down along the guide groove 4. At the end of the guide groove 4, there is a bar 3 that prevents the guide block 15 from slipping out. The top of the cover 5 is provided with a hanging hole, and the traction rope is tied on the hanging hole; the sampler also includes a telescopic rod, and the telescopic rod is divided into three parts: a hand-held part 14, a telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com