Tobacco lamina sampling device

A sampling device and sheet tobacco technology, which is applied to the sampling device and other directions, can solve the problems of difficulty in repacking, time-consuming, loose sheet tobacco, etc., and achieve the effects of improving sampling work efficiency, low learning cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

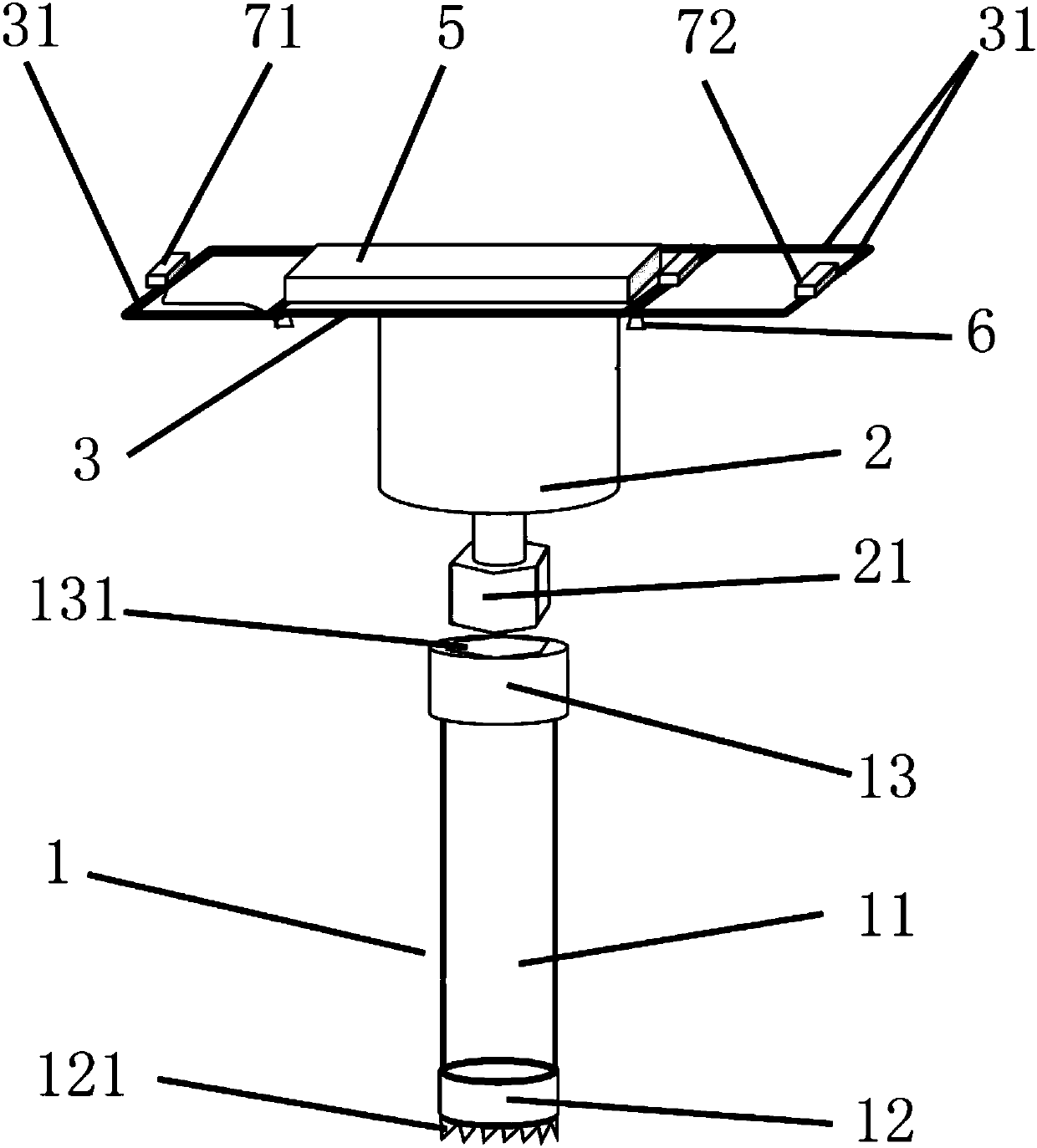

[0032] Such as figure 1 Shown is a schematic structural view of the tobacco sampling device in Example 1 of the present invention. The invention provides a cigarette sampling device, which comprises a tobacco sampling tube 1, a rotating power device 2, a bracket assembly 3, a power supply device 5, an illuminating device 6 and a switch assembly.

[0033]The cigarette sampling tube 1 includes a sampling tube body 11 , a cutting part 12 and a transmission connecting part 13 . One end of the sampling tube body 11 is detachably connected to the cutting part 12 , and the other end is detachably connected to the transmission connecting part 13 . The cigarette sampling pipe 1 is connected with the rotary power device 2 through the transmission connecting piece 13 . A toothed blade 121 is disposed on a periphery of the cutting member 12 . A hexagonal prism counterbore is arranged inside the transmission connector 13, and a first connecting member is provided on the side of the hexa...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that it also includes a screw rod built in the sampling tube body 11, one end of the screw rod is fixed on the transmission connector 13, and when the transmission connector 13 is disassembled, the screw rod can follow the The transmission connector 13 is separated from the sampling tube body 11 together.

[0047] When the tobacco sampling device is pressing down to sample, the screw rod and the tobacco sampling tube 1 rotate together, and its helical blades can drive the tobacco that enters the tobacco sampling tube 1 to move, so that the tobacco that enters the tobacco sampling tube 1 moves upwards. Lifting, so that the tobacco that enters the tobacco sampling tube 1 moves to the direction of the rotary power device 2 .

[0048] When the sampling is finished, the screw rod is gradually pulled out from the sampling tube body 11 through the transmission connector 13. With the pulling out of the screw rod, the sc...

Embodiment 3

[0053] The difference between this embodiment and Embodiment 2 lies in that: the screw rod is built into the sampling tube body 11 , and the screw rod is connected to the transmission connector 13 through a reducer. The speed reducer is used to change the rotational angular velocity of the screw so that the rotational angular velocity of the screw is different from the rotational angular velocity of the cigarette sampling tube 1 . The beneficial effect of the cigarette sampling device provided in this embodiment is that there is a difference in rotational angular velocity between the screw rod and the tobacco sampling tube 1, which can control the rising speed of the tobacco to obtain a better sampling effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com