Drill bit of replaceable cutter head type structure

A technology of cutter head and drill bit, which is applied in the direction of drill repair, twist drill, drill tool accessories, etc. It can solve the problems of low machining accuracy, unstable rotation, and unstable cutting of the drill bit, and achieve simple structure, improved overall performance, and exhaustion. crumb smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0034] Example.

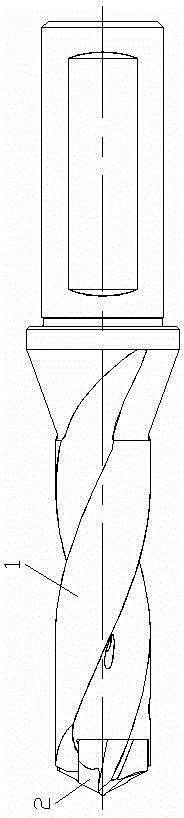

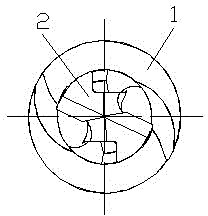

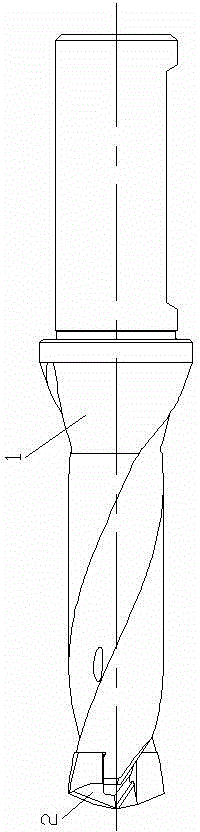

[0035] see Figure 1 to Figure 14 In this embodiment, the drill bit with replaceable cutter head structure includes a cutter bar 1, a cutter head 2 and a fixing screw 3, wherein the cutter bar 1 includes a cutter bar body 11, and a chip removal groove 12 is arranged on the cutter bar body 11 to remove chips. The number of flutes 12 is two, and the flutes 12 can be straight flutes or spiral flutes.

[0036] In this embodiment, the front end of the cutter body 11 is provided with a cutter head positioning groove 13, and the two sides of the cutter head positioning groove 13 are respectively connected with two chip removal grooves 12, so that the chip removal is smoother. In this embodiment, the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com