Patents

Literature

43results about How to "Improve lubrication environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

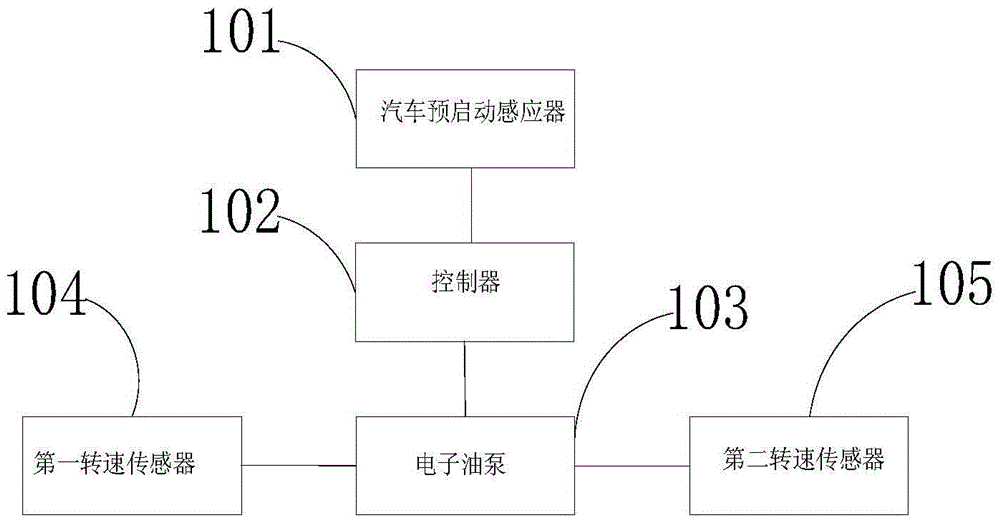

Control method and device for automobile lubrication system as well as automobile lubrication system

ActiveCN105422207AAvoid wear and tearImprove lubrication environmentMachines/enginesPressure lubrication with lubrication pumpElectricityInductor

The invention provides a control method and device for an automobile lubrication system as well as the automobile lubrication system and relates to the automobile field. The control method for the automobile lubrication system is applied to the automobile lubrication system. The system comprises an automobile pre-start inductor, a controller, an engine and an electronic oil pump, wherein the controller is electrically connected with the automobile pre-start inductor and the electronic oil pump respectively. The method comprises steps as follows: before operation of the engine, the controller receives a pre-start signal sent by the automobile pre-start inductor and controls the electronic oil pump to operate after receiving the pre-start signal. With the adoption of the method, the device and the system, the condition of abrasion of mechanical parts such as the engine, a booster and the like due to the fact that the oil pump is started after the engine in the prior art is avoided, a good lubrication environment is provided for the mechanical parts such as the engine, the booster and the like before start, the normal use of the mechanical parts is guaranteed, and the service life of the mechanical parts is prolonged.

Owner:鄢毅

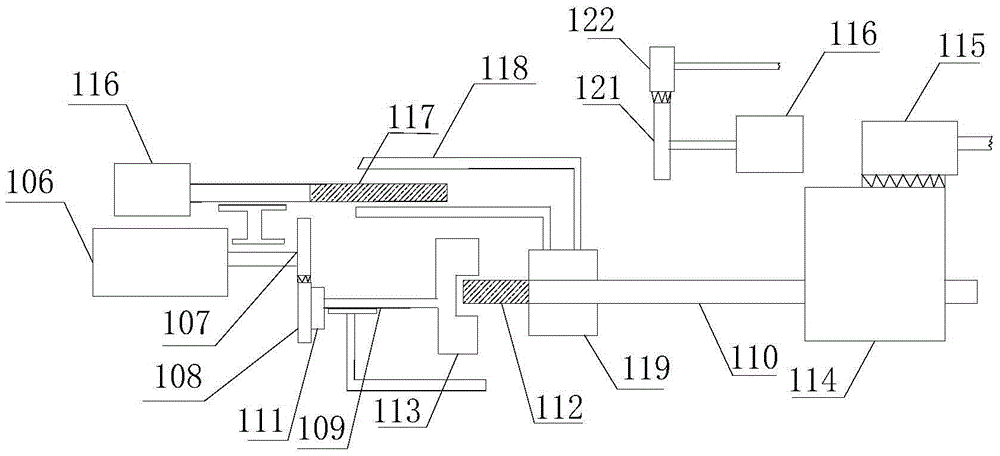

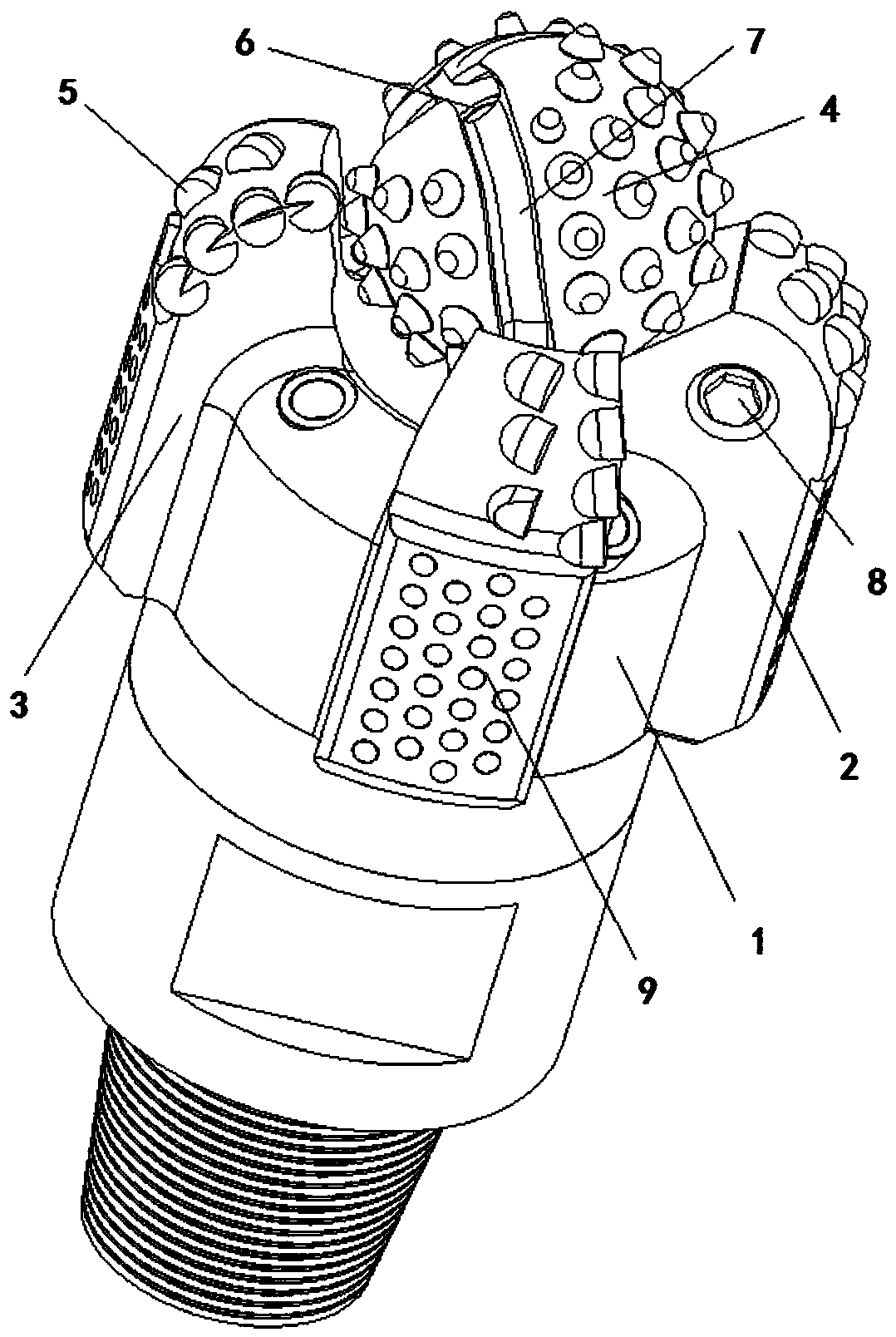

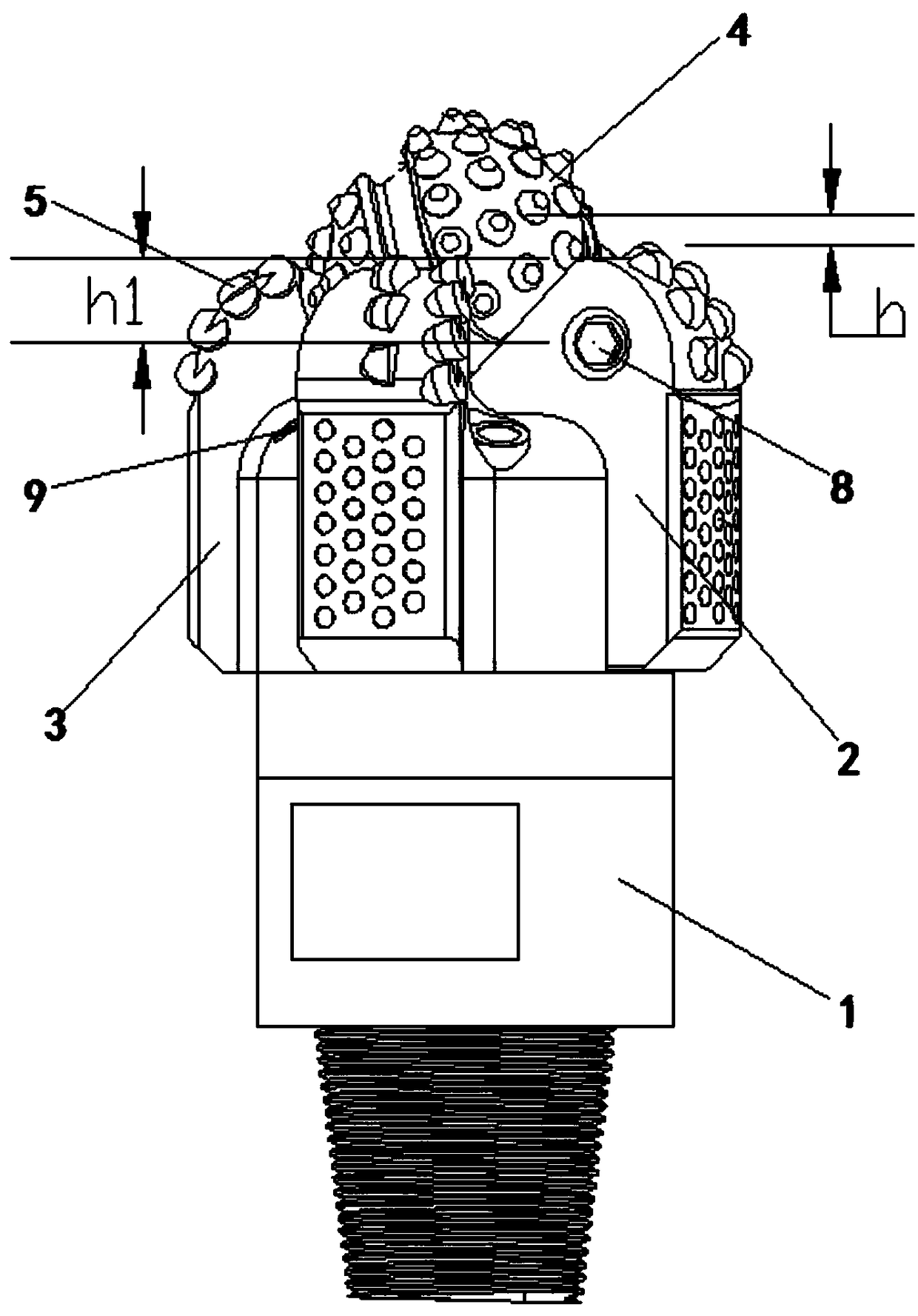

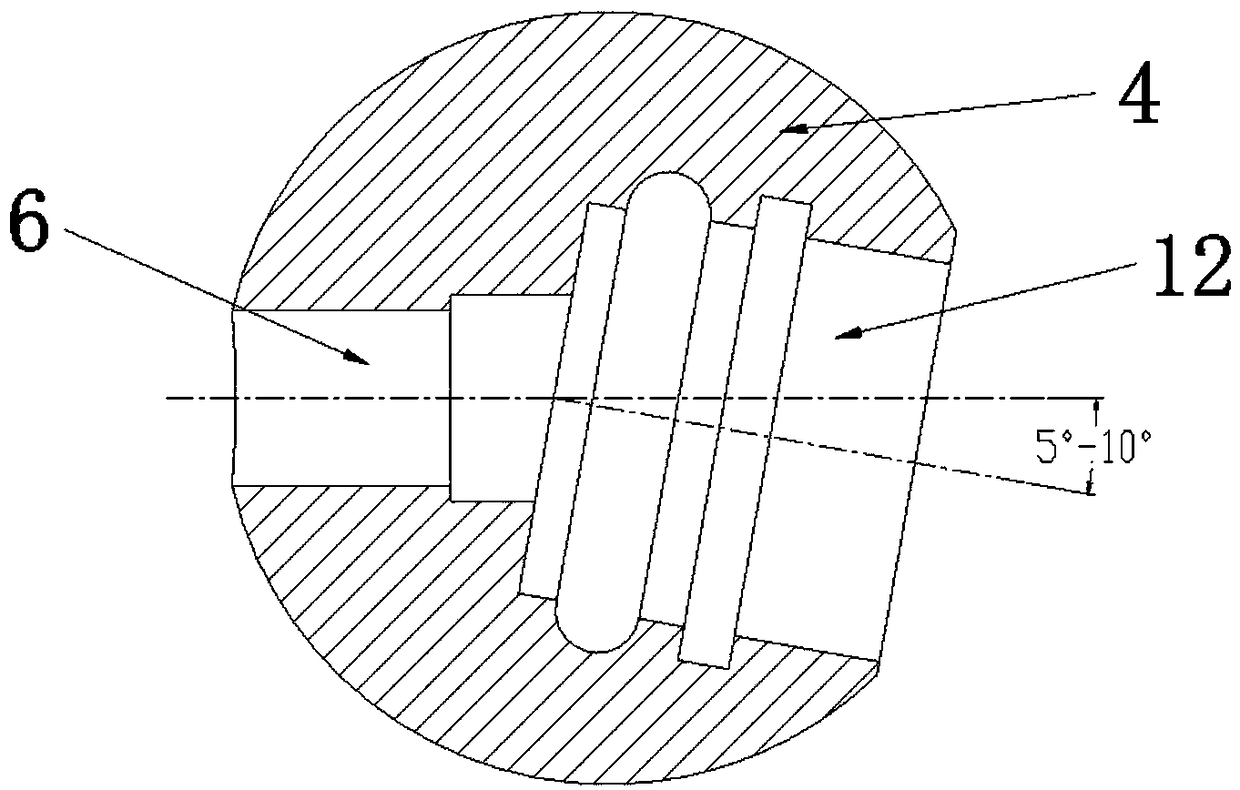

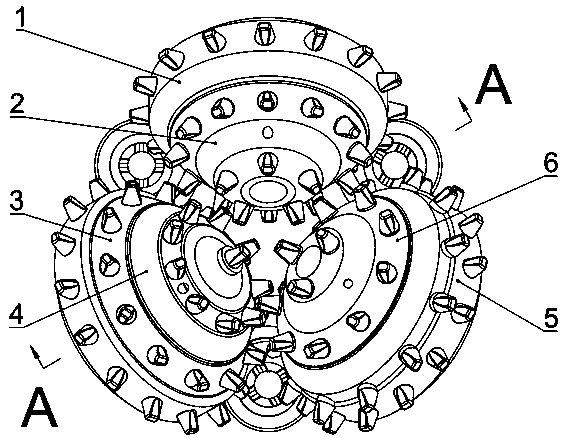

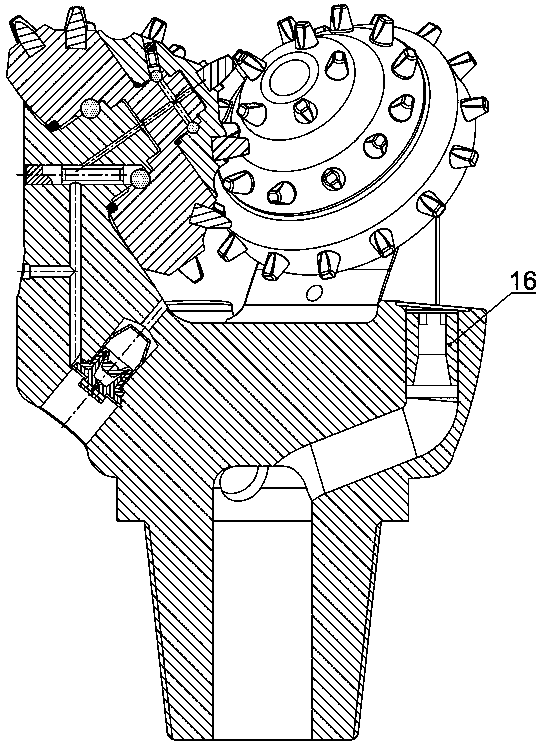

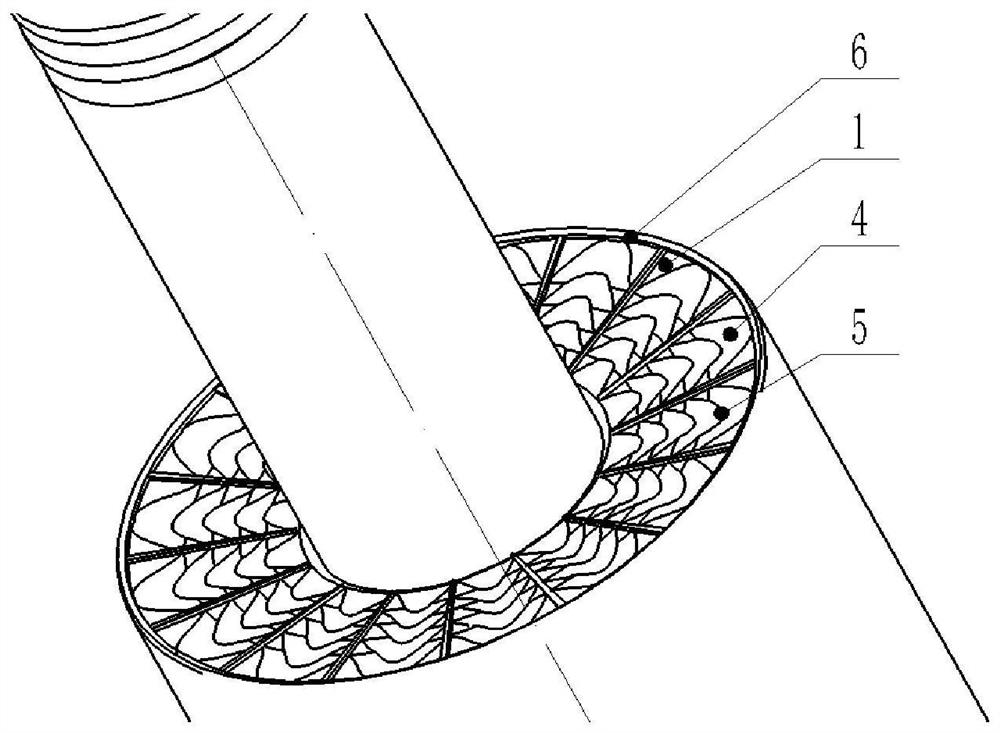

Novel pdc and roller cone composite drill bit

The invention discloses a novel pdc and roller cone composite drill bit. The novel pdc and roller cone composite drill bit comprises a drill bit body, a roller cone palm, a cutting blade, and a spherical roller cone. The spherical roller cone is installed the roller cone palm. The outer sides of the roller cone palm and the cutting blade are provided with pdc cutting teeth and fixed on the drill bit body. The spherical roller cone is positioned above the drill bit body, and a center line of the spherical roller cone is coincided with an axis of the drill bit body. A vertical distance between asphere center position of the spherical roller cone and a highest point of the cutting blade is within a range of 18-29 mm. The side face of the roller cone palm is provided with an oil storage seal.According to the related novel composite drill bit, in a drilling process, a bit pressure is shared by the pdc cutting teeth and the roller cone together, a pressure applied to each tooth is reduced,the wear-resistant capacity of the drill bit is improved, thereby the service life of the whole drill bit is prolonged. In addition, because a position of the oil storage seal is closer to the top ofthe drill bit, a sensitivity of a drill bit lubricating system for sensing a bottom hole pressure is improved, and the drill bit is positioned in the better lubricating environment, so the service life of the drill bit is improved.

Owner:SOUTHWEST PETROLEUM UNIV

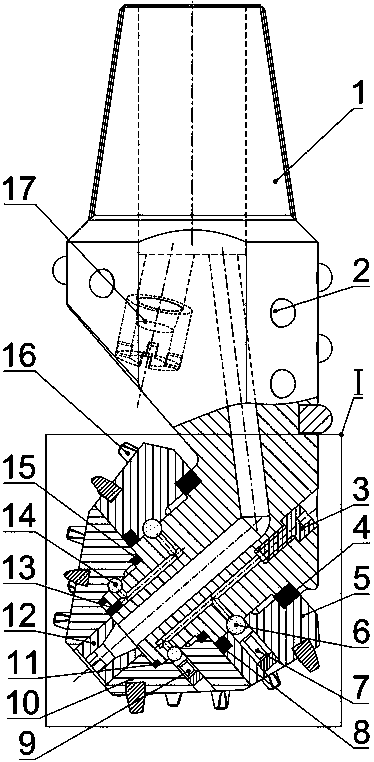

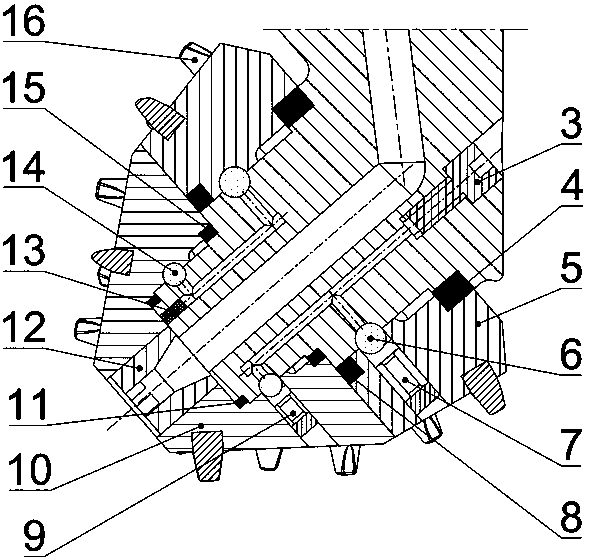

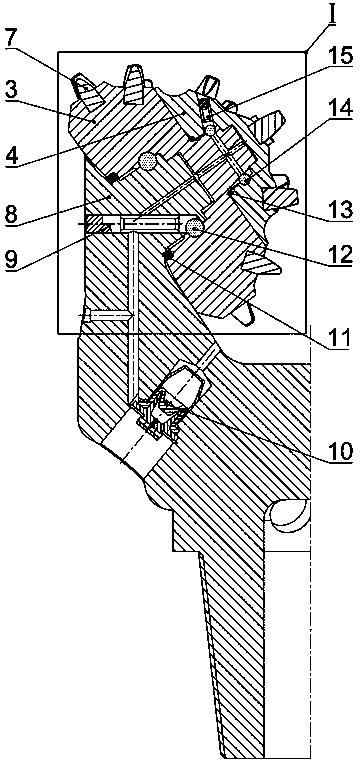

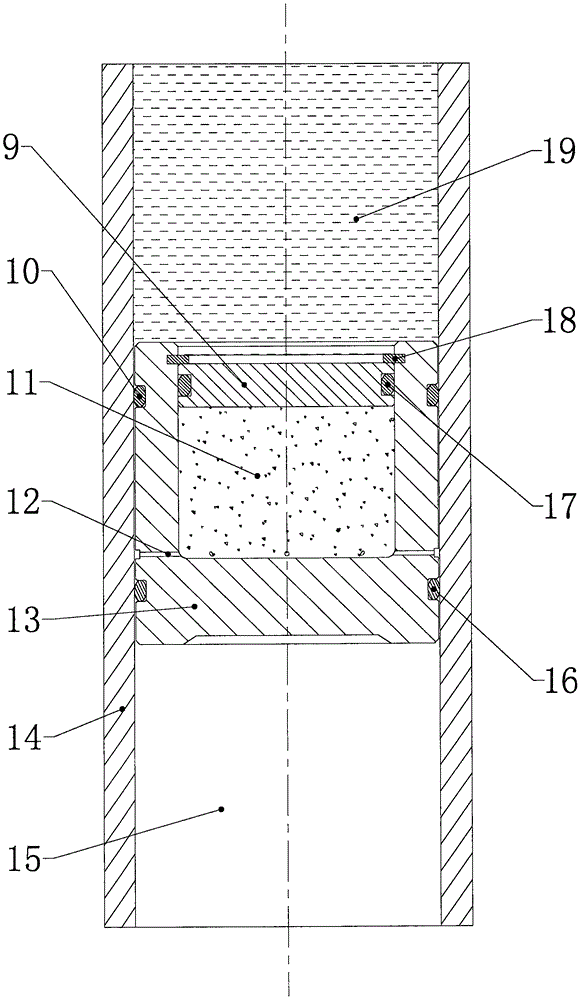

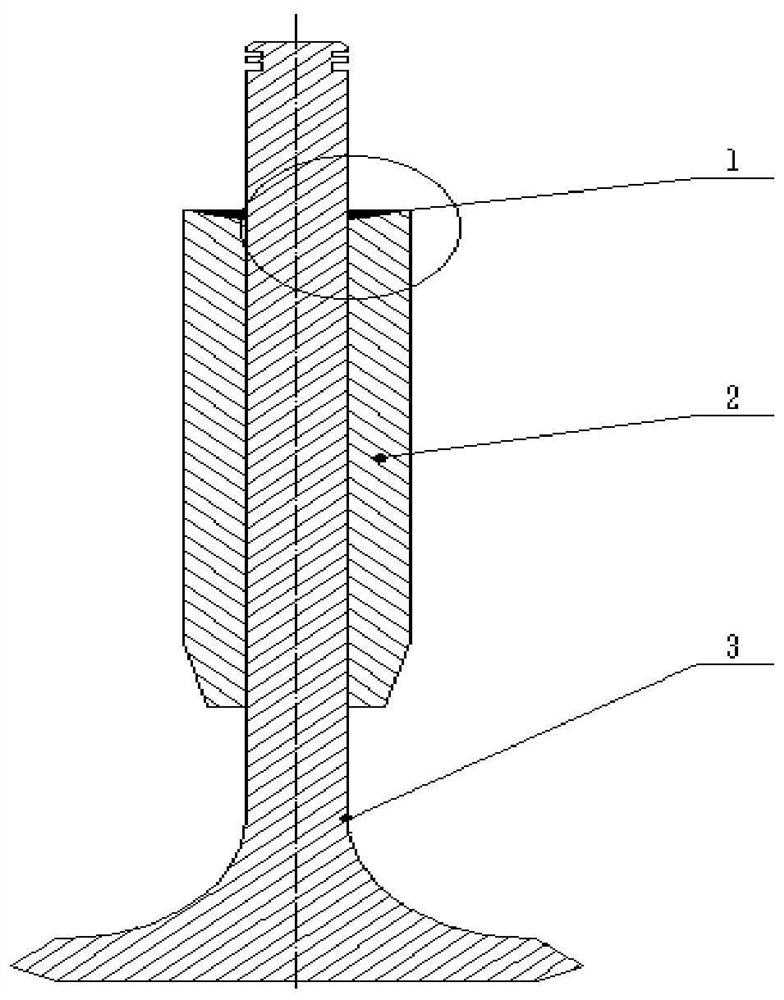

Split single roller bit

The invention relates to a split single roller bit. The split single roller bit is mainly composed of a drilling bit jaw, a cone lower body, a cone upper body, teeth, diameter keeping teeth, a steel ball, a retaining plug, an oil mouth, an oil blocking plug and a rectangular sealing ring. The drilling bit jaw is connected with the cone lower body and the cone upper body through a drilling bit palmaxial neck aslant arranged at the lower end of the drilling bit jaw, and in the drilling process, the cone lower body and the cone upper body rotate along with a bit body and also spin around the drilling bit palm axial neck respectively to achieve the task of scraping and smashing rocks of the cone lower body and the cone upper body. A split structure is adopted by the split single roller bit, the teeth scraping efficiency of a roller small end tooth ring and teeth of a middle tooth ring can be improved, the rock smashing efficiency of the bit is improved, conical structures are adopted by the cone lower body and the cone upper body, the split single roller bit is applicable to smashing a hard stratum, and the effective service life of the split single roller bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +2

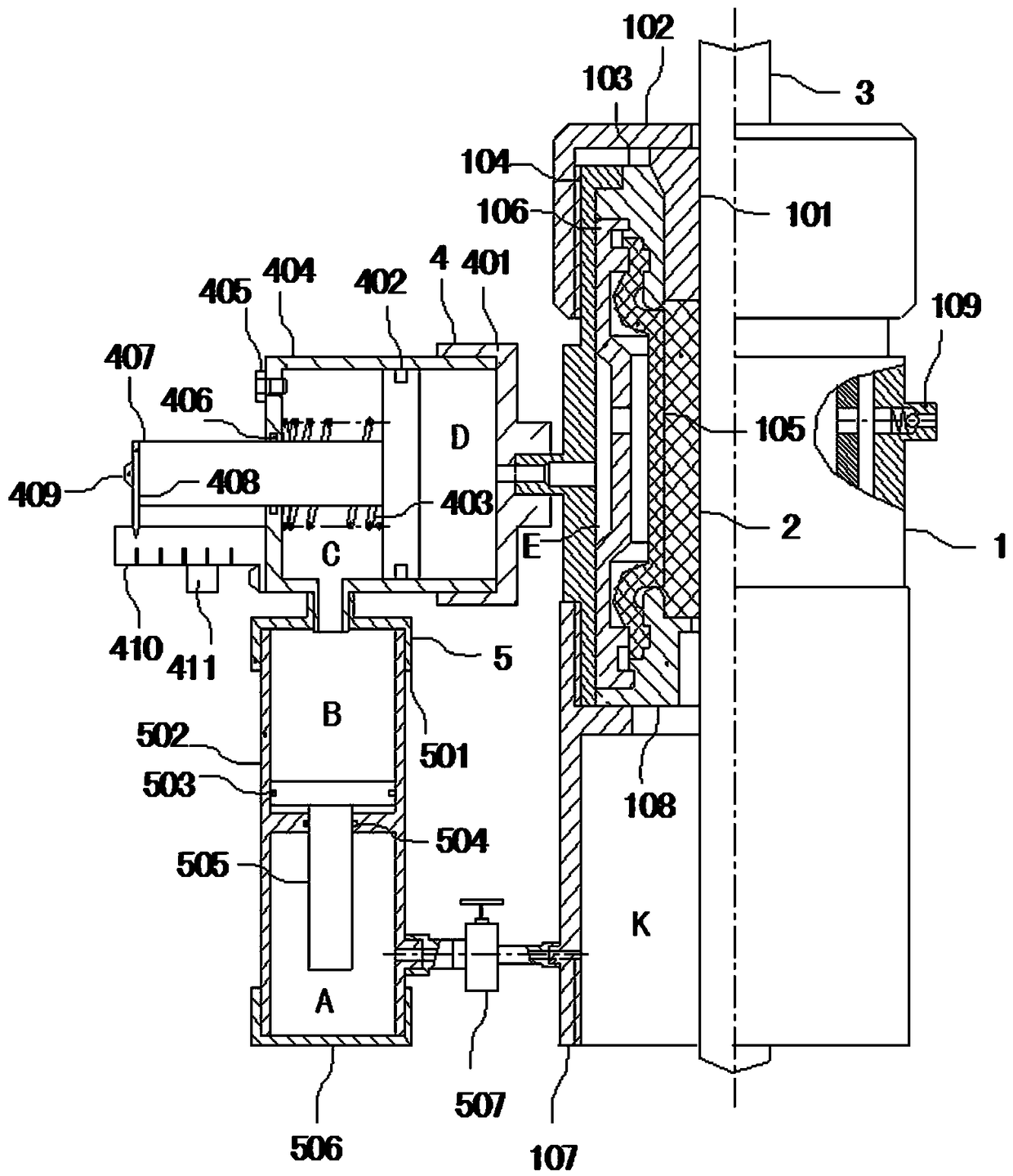

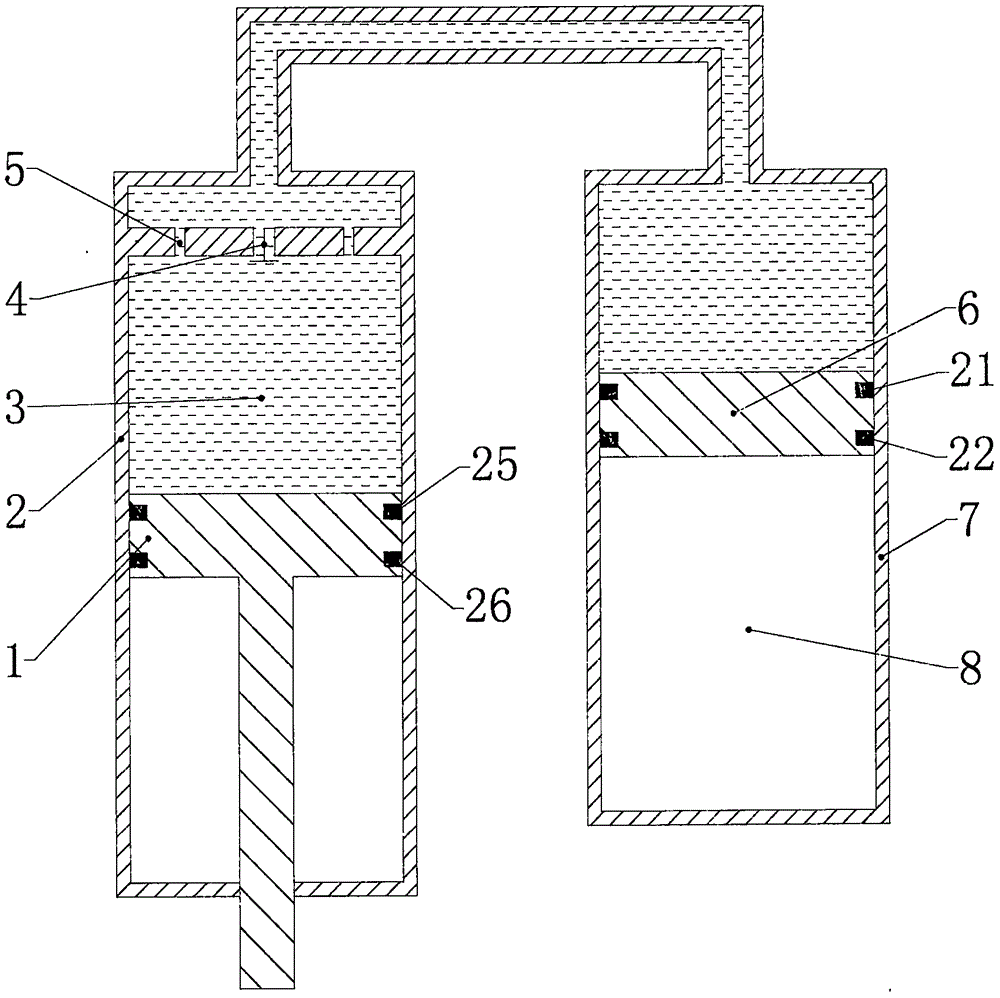

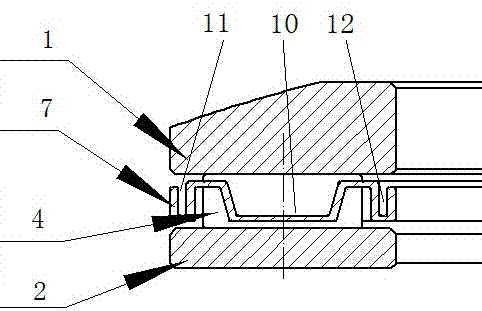

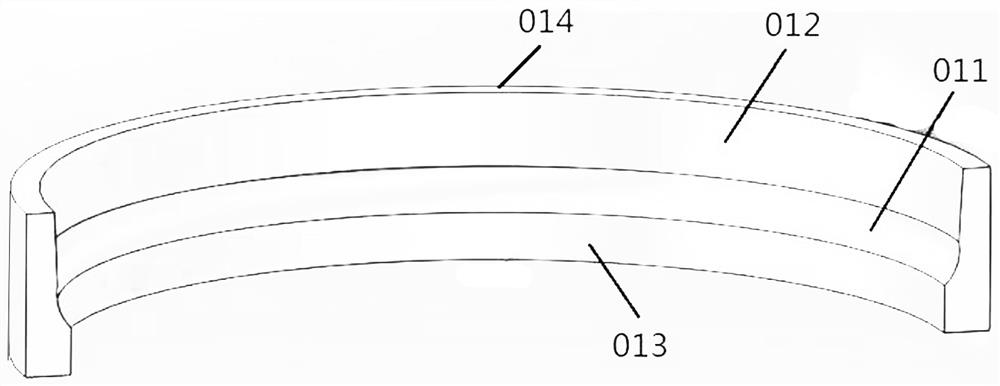

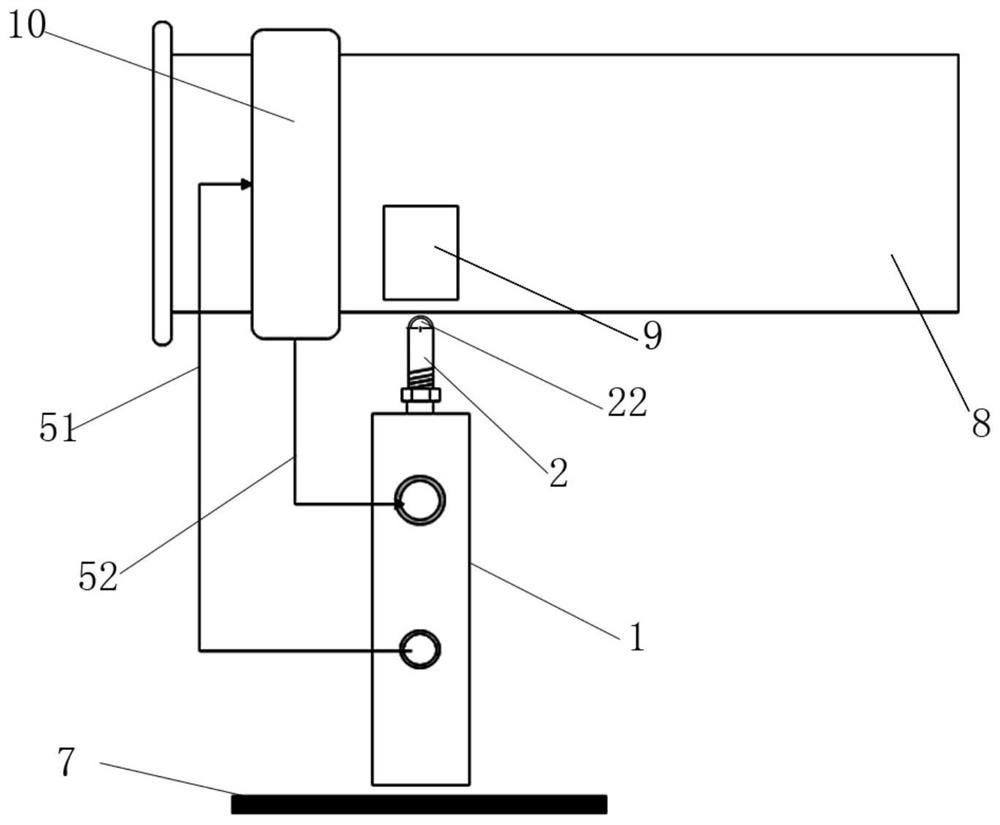

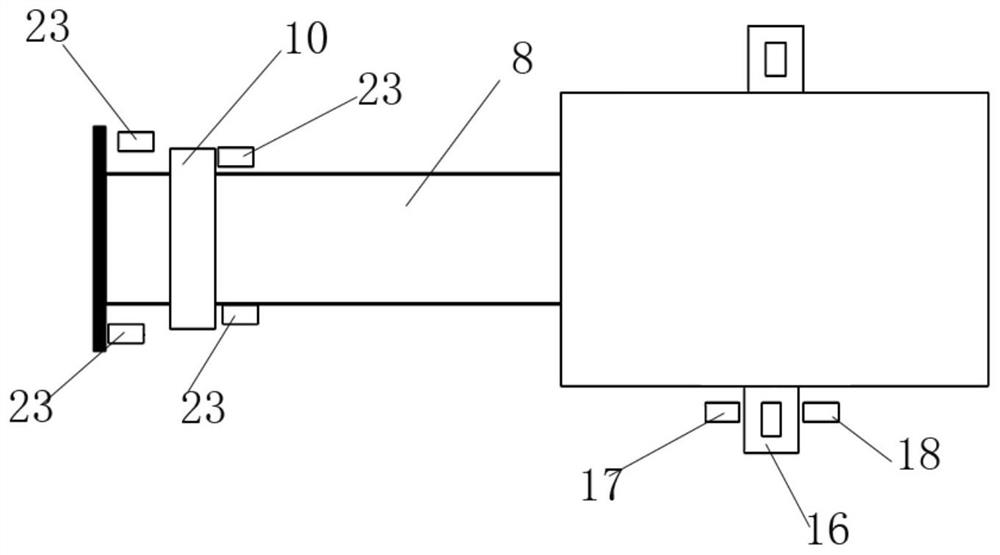

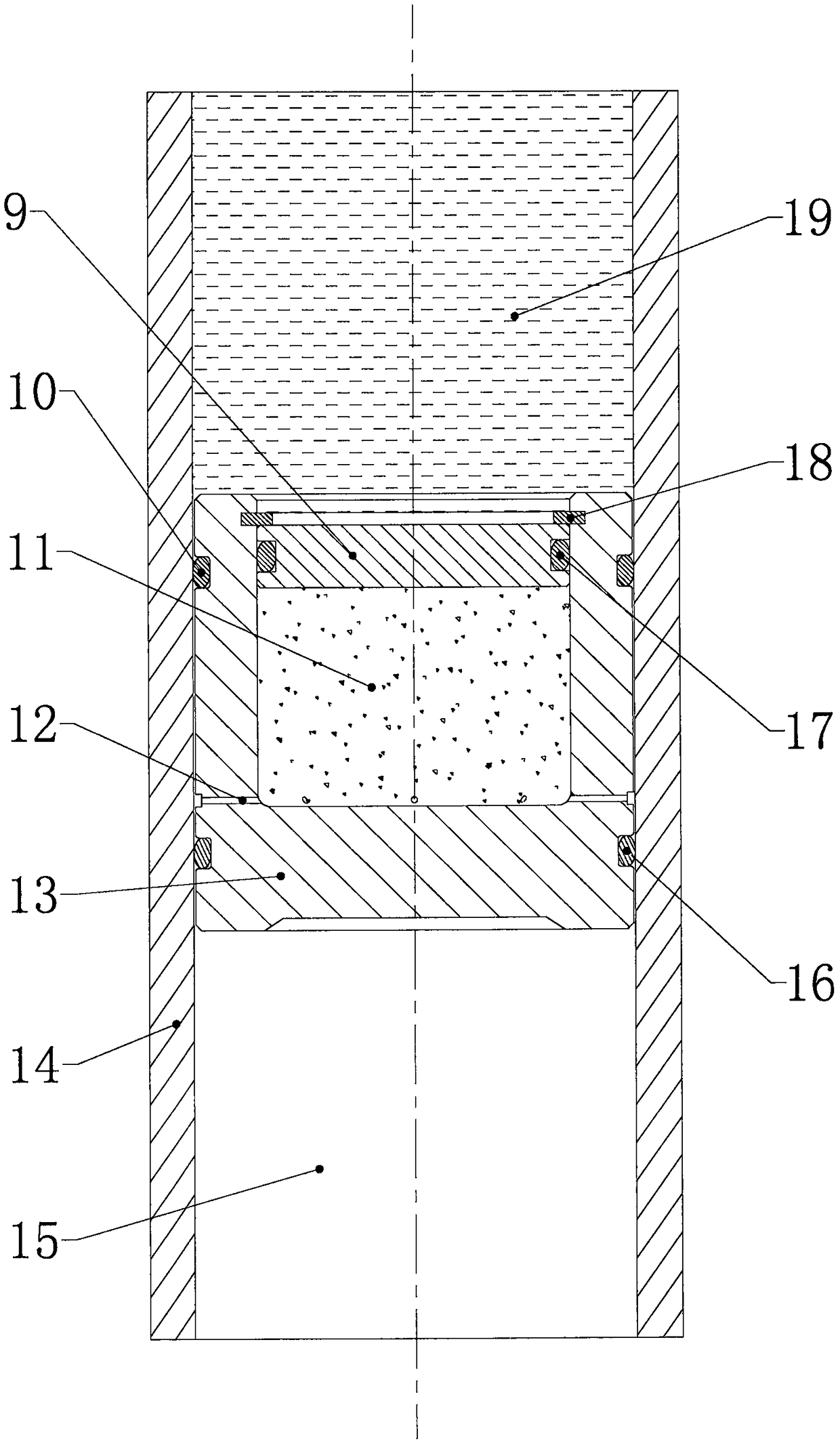

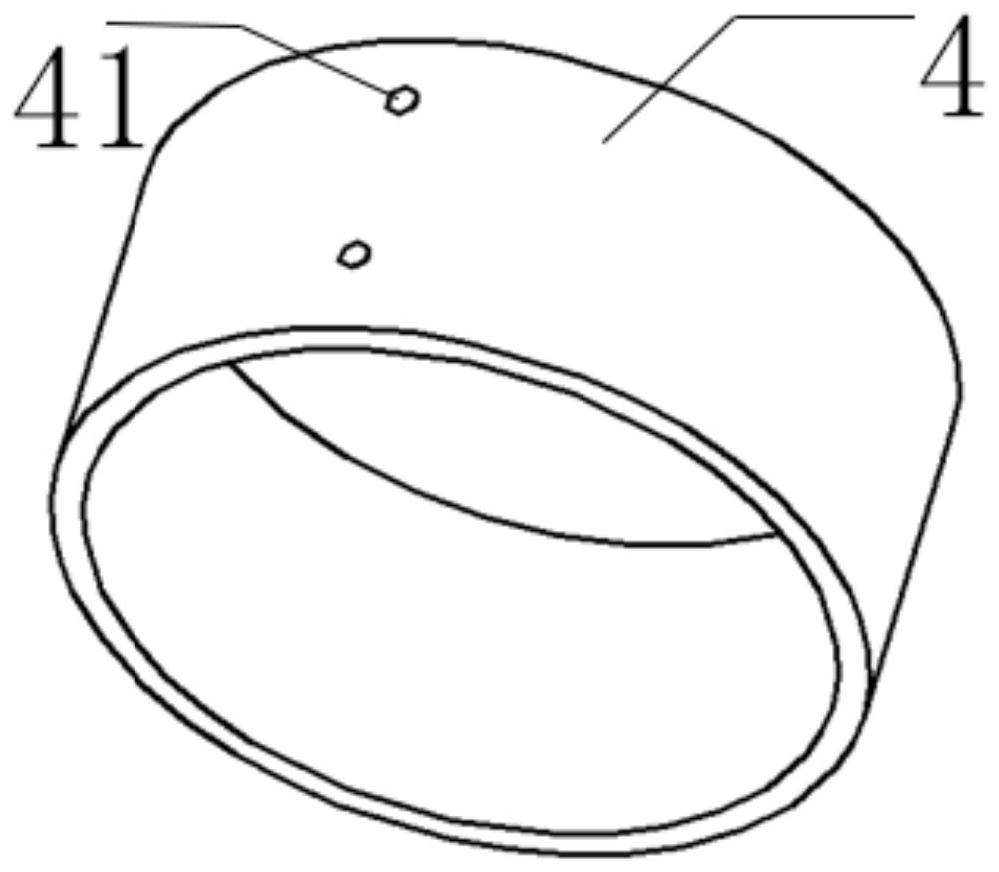

Packing wear condition monitoring device

PendingCN108489839AReduce frictionReduce friction lossBorehole/well accessoriesInvestigating abrasion/wear resistanceEngineeringOil production

The invention belongs to the technical field of oil production well tools, in particular to a packing wear condition monitoring device, which comprises a filling chamber (1), a metering mechanism (4)and a pressure matching cylinder (5), wherein the filling chamber (1) comprises a shell (104), a shield (106), a rubber cylinder (105) and a packing (2); the rubber cylinder (105) and the packing (2)are separately placed in the shell (104); a cursor (3) is located at a middle shaft of the shell (104); the packing (2) and the rubber cylinder (105) are sequentially sleeved with the cursor (3); theend of the shield (106) is fixedly connected with the end of the rubber cylinder (105); a pressure chamber E is defined by the inner wall of the shell (104) and the outer wall of the rubber cylinder (105). The packing wear condition monitoring device can be used to prolong the service life of the packing, provide on-site information and remote information of the working wear condition of the packing, perform real-time control on the sudden increase of pressure underground, reduce the working intensity of oil producing workers and lower the production risk.

Owner:辽宁众森装备制造有限公司

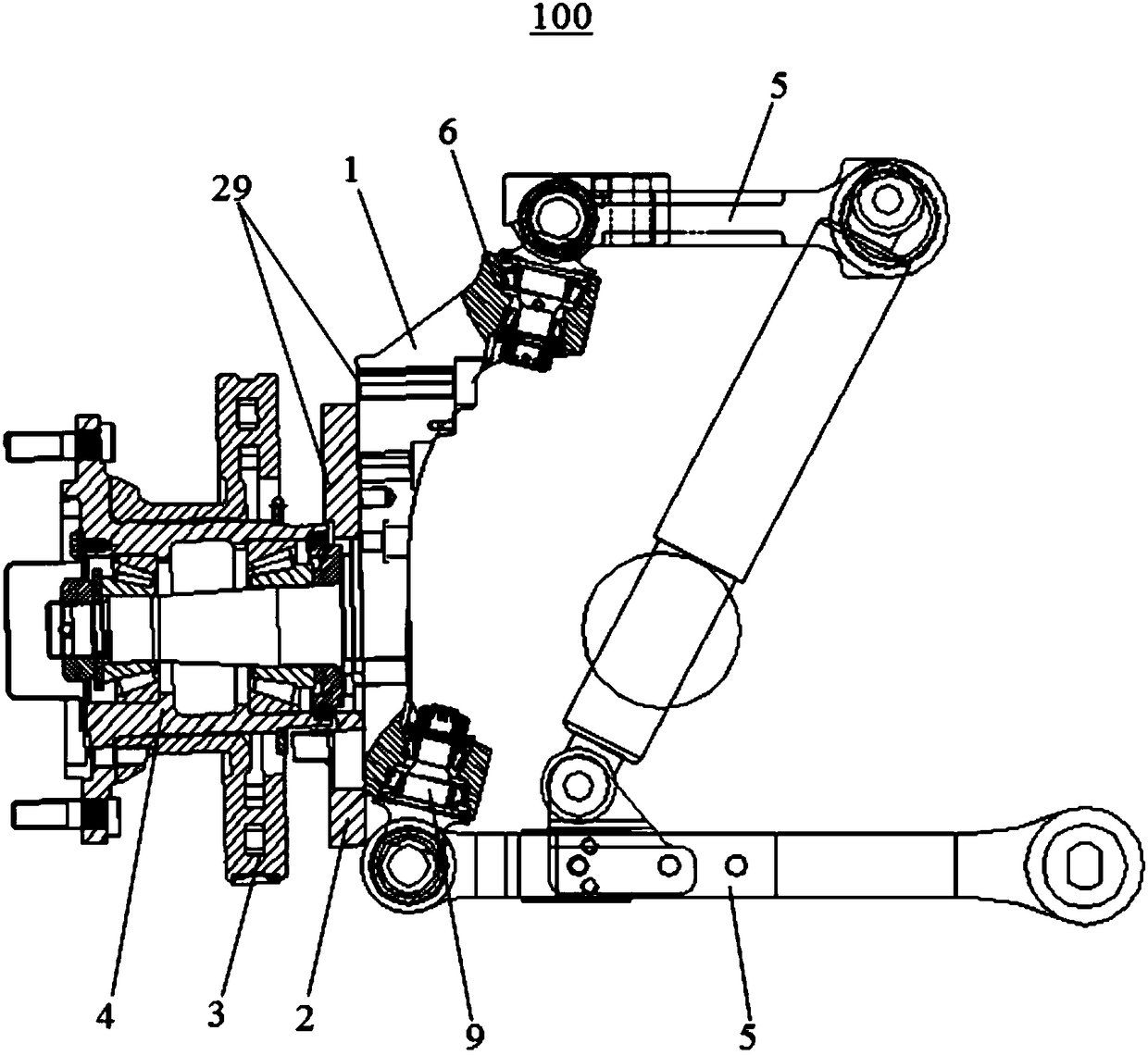

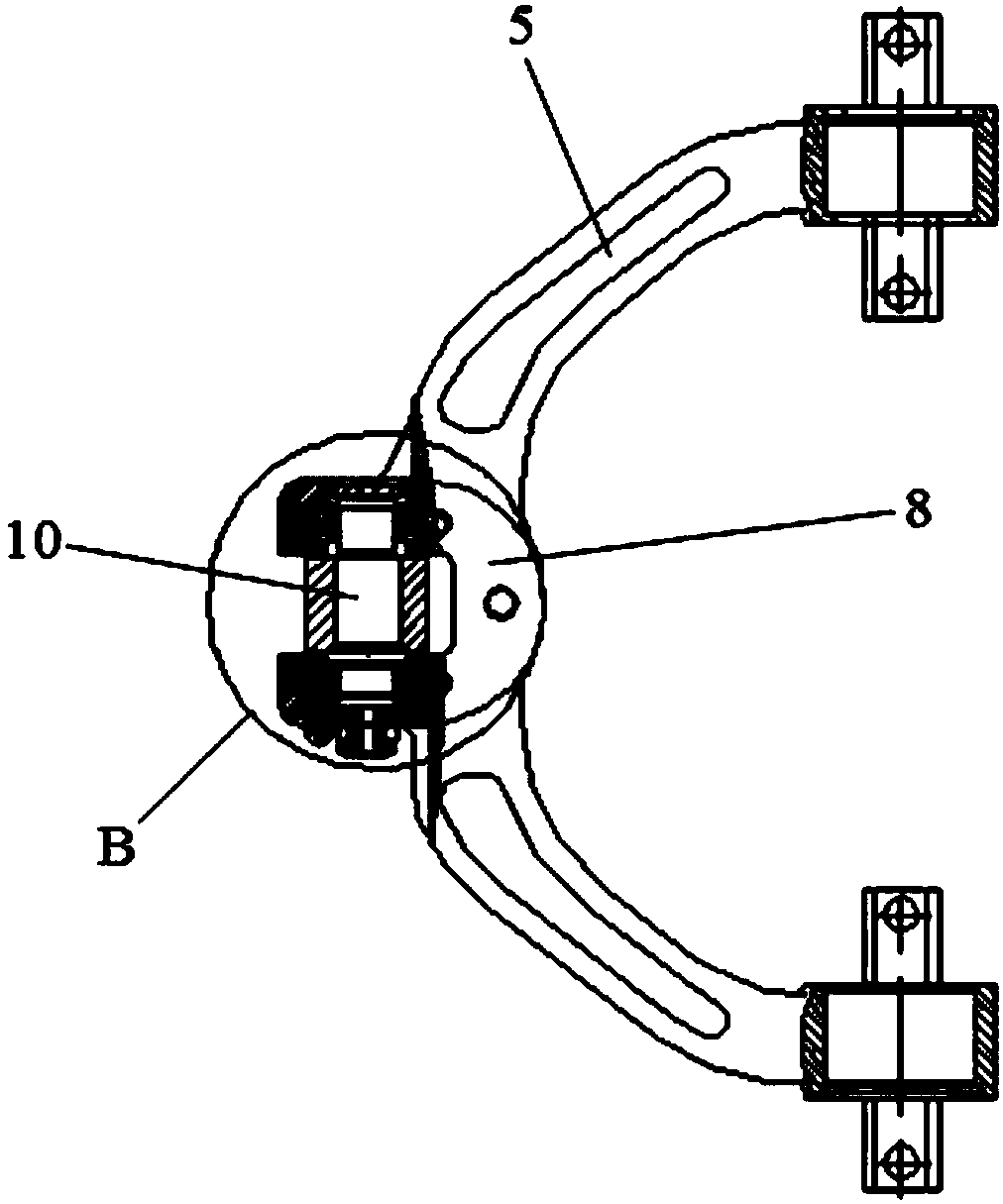

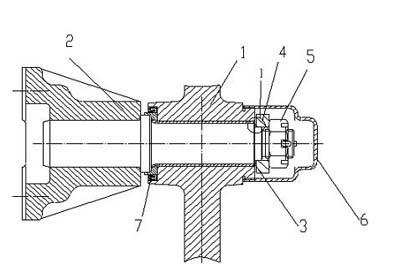

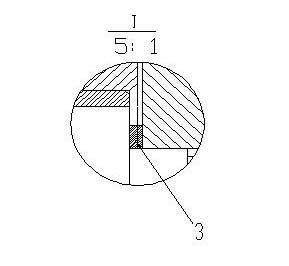

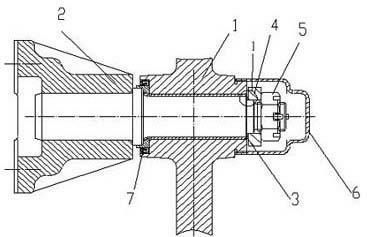

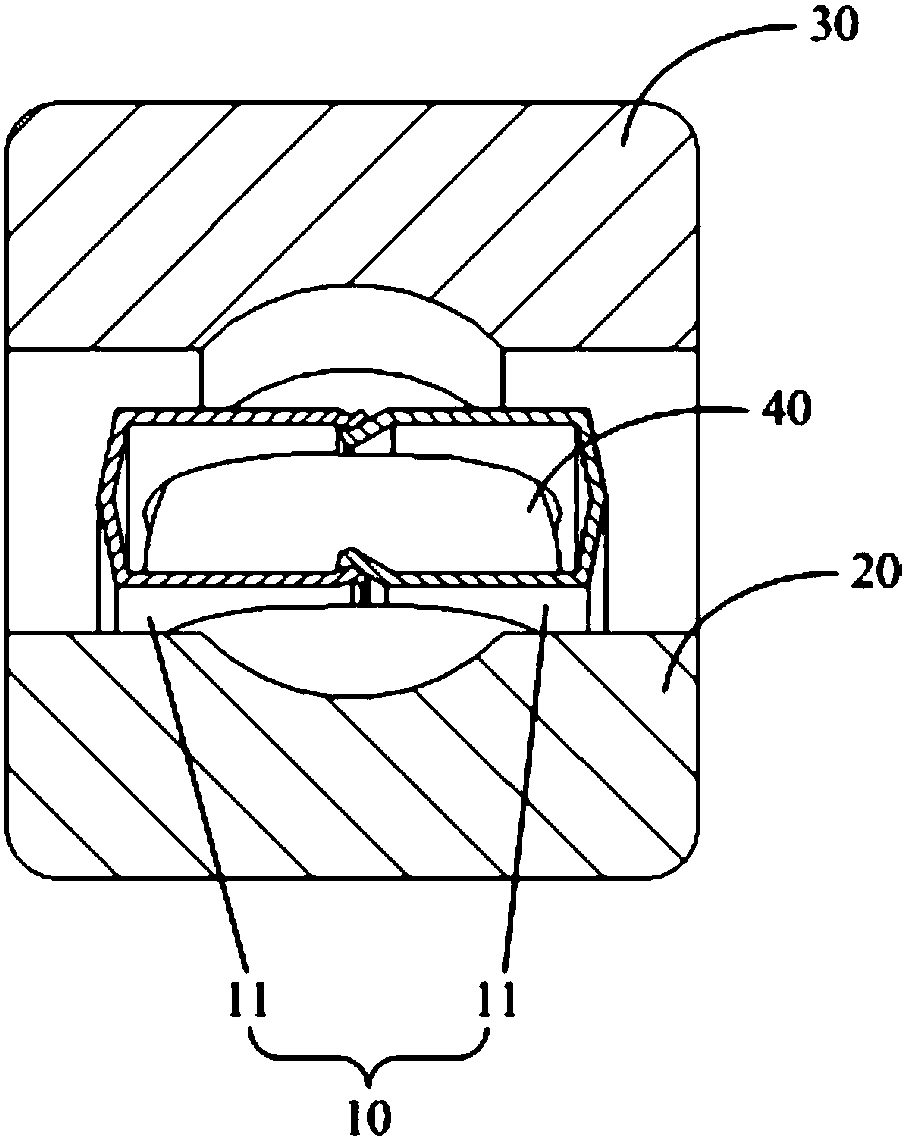

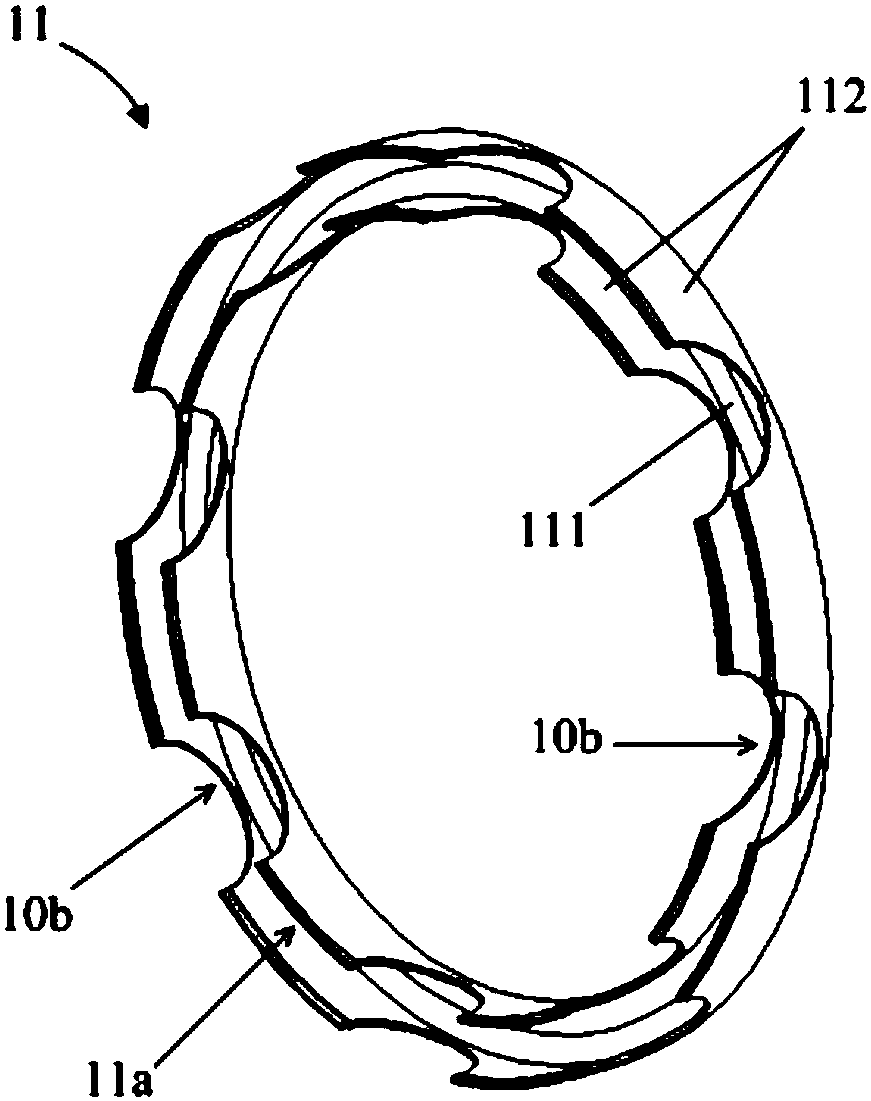

High comfort performance independent suspension for new energy bus

PendingCN108407889AReduce offset distanceRaise the inclinationSteering linkagesPivoted suspension armsNew energyControl arm

The invention discloses a high comfort performance independent suspension for a new energy bus. The high comfort performance independent suspension for the new energy bus comprises a steering knuckleassembly, a mounting plate, a brake disc, a hub assembly and a control arm, wherein the mounting plate, the brake disc and the hub assembly are fixed on the end surface of the steering knuckle assembly; the control arm is connected with the steering knuckle assembly; connecting lug blocks are arranged at the upper and lower ends of the steering knuckle assembly; the control arm is connected with the connecting lug block through a short pin rotating piece in a rotating manner; a step-shaped mounting hole is formed in the connecting lug block; a U-shaped fork is arranged at the end part of the control arm; coaxial mounting holes are formed in the two sides of the U-shaped fork; the short pin rotating piece comprises a short pin connecting piece and a T-shaped knuckle, wherein one end of theshort pin connecting piece is connected with the mounting hole through a bearing, and the two ends of the T-shaped knuckle are erected in the coaxial mounting holes through bearings; and the other endof the short pin connecting piece is fixedly connected with the T-shaped knuckle. According to the high comfort performance independent suspension for the new energy bus, the kingpin offset distanceis reduced, the kingpin inclination angle is increased, and the stability and comfort of the braking of the complete bus are improved.

Owner:方盛车桥(苏州)有限公司

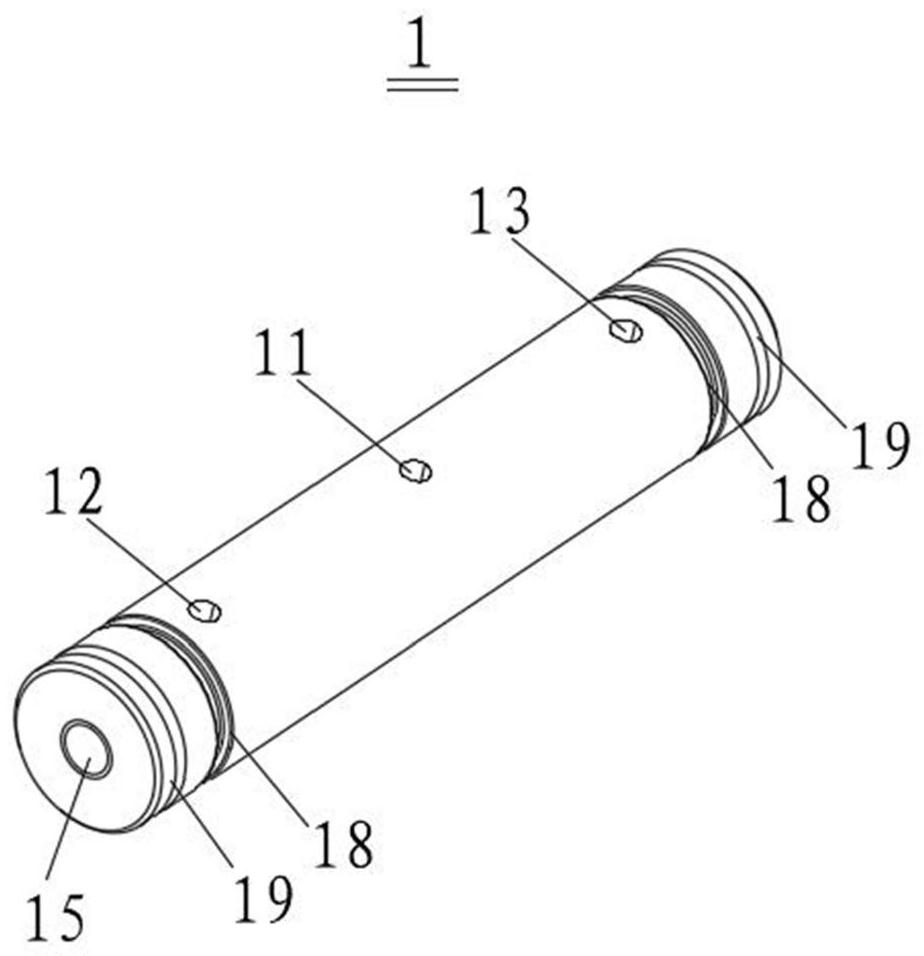

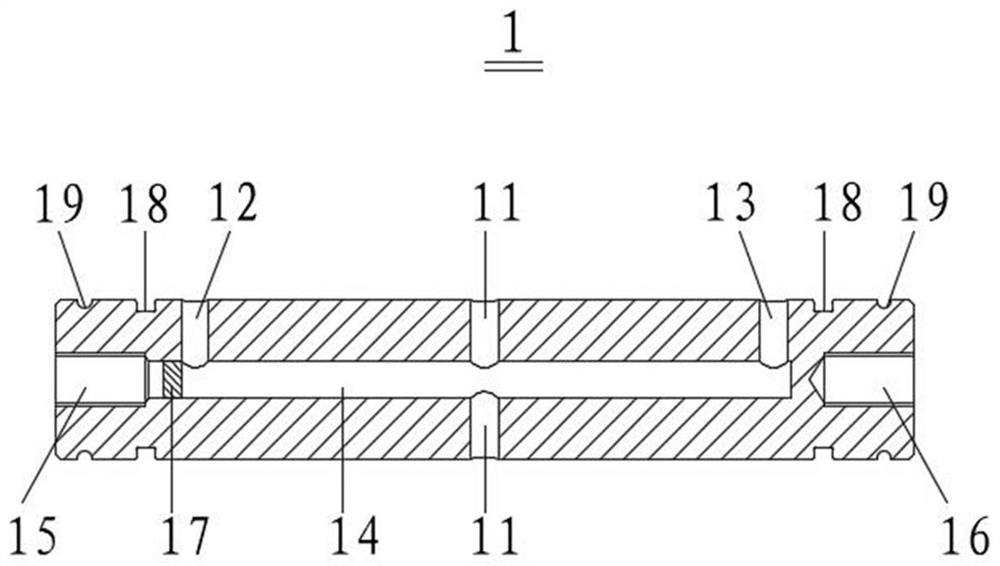

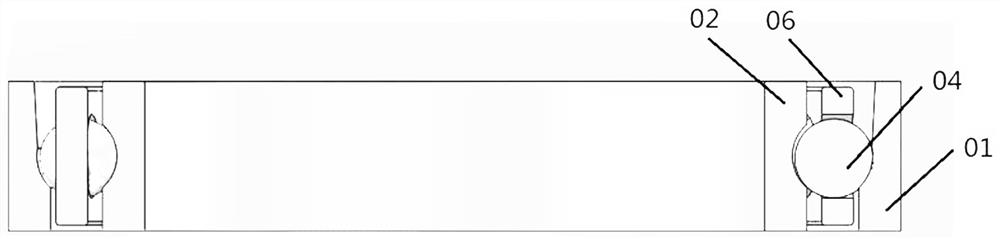

Thrust wheel shaft, thrust wheel and operation machine

ActiveCN112977657AImprove the lubrication effectImprove cooling effectEndless track vehiclesEngine sealsMarine engineeringOil intake

The invention provides a thrust wheel shaft, a thrust wheel and an operation machine. The thrust wheel shaft comprises an oil inlet, a first oil outlet, a second oil outlet and a lubricating oil channel. The oil inlet is formed near the middle part of the thrust wheel shaft and is used for communicating with a first oil storage cavity on a wheel body of the thrust wheel; the first oil outlet is formed in the first end close to the thrust wheel shaft and used for extending to a first floating oil seal on the thrust wheel. The second oil outlet is formed in the second end close to the thrust wheel shaft and is used for extending to a second floating oil seal on the thrust wheel; the lubricating oil channel is arranged in the supporting wheel shaft and extends from the first end of the supporting wheel shaft to the second end of the supporting wheel shaft, and the lubricating oil channel is communicated with the oil inlet, the first oil outlet and the second oil outlet. The lubricating environment of the floating oil seal of the thrust wheel is improved, the situation that the floating oil seal and a lining of the thrust wheel are excessively abraded due to the fact that the lubricating oil amount is reduced is prevented, and the service life of the thrust wheel is guaranteed.

Owner:SANY HEAVY MACHINERY

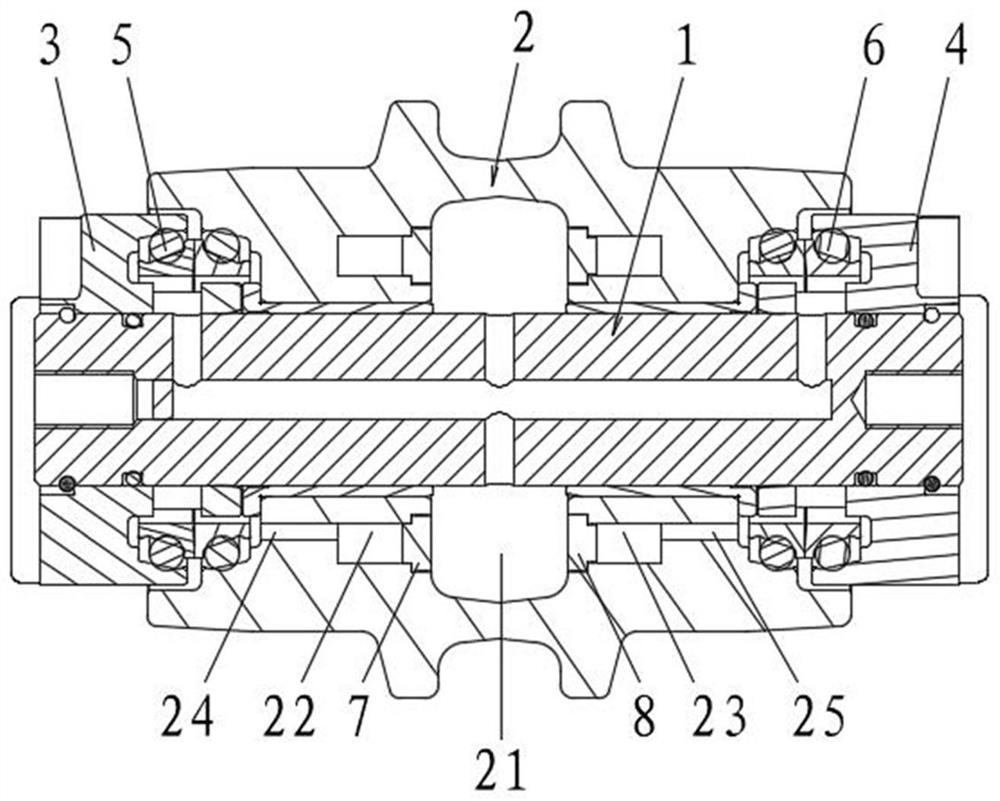

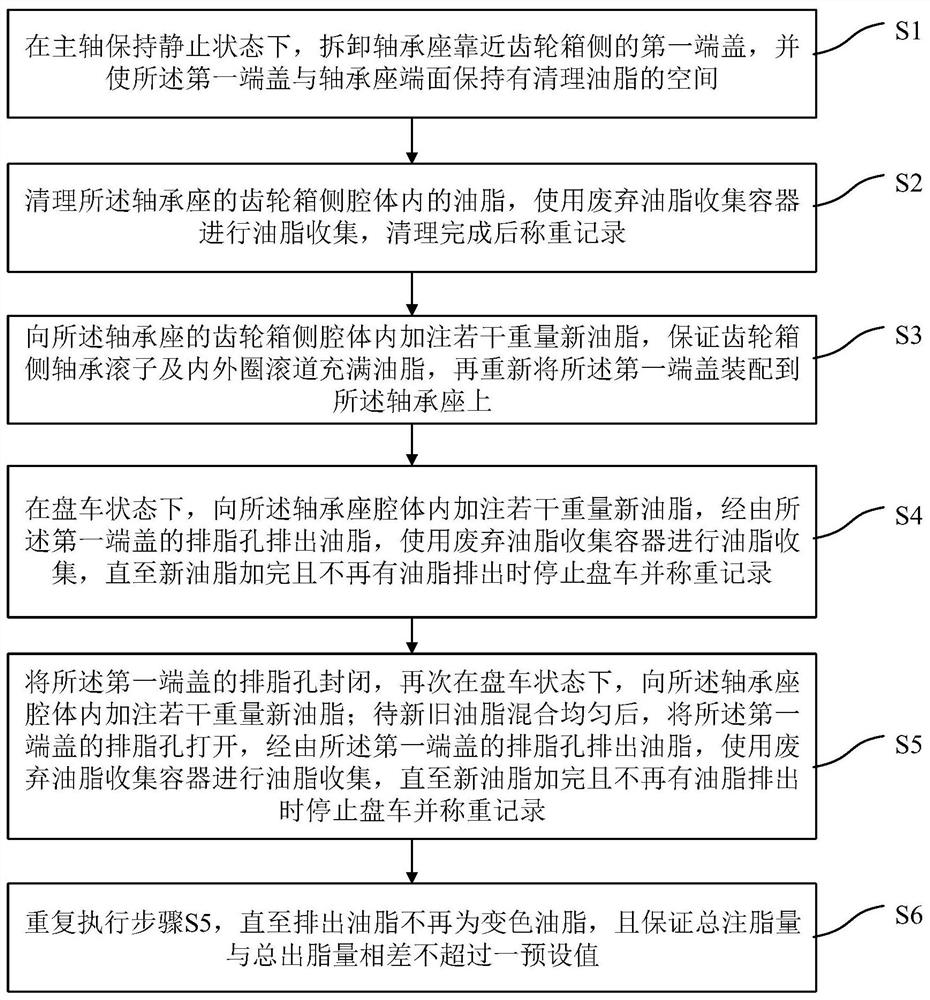

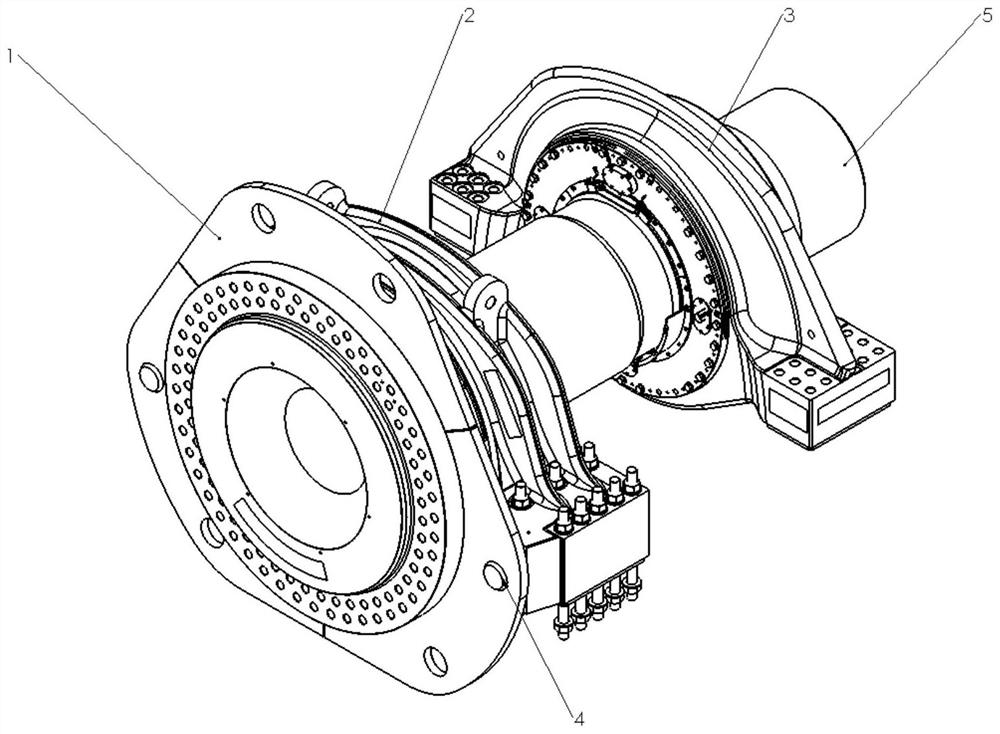

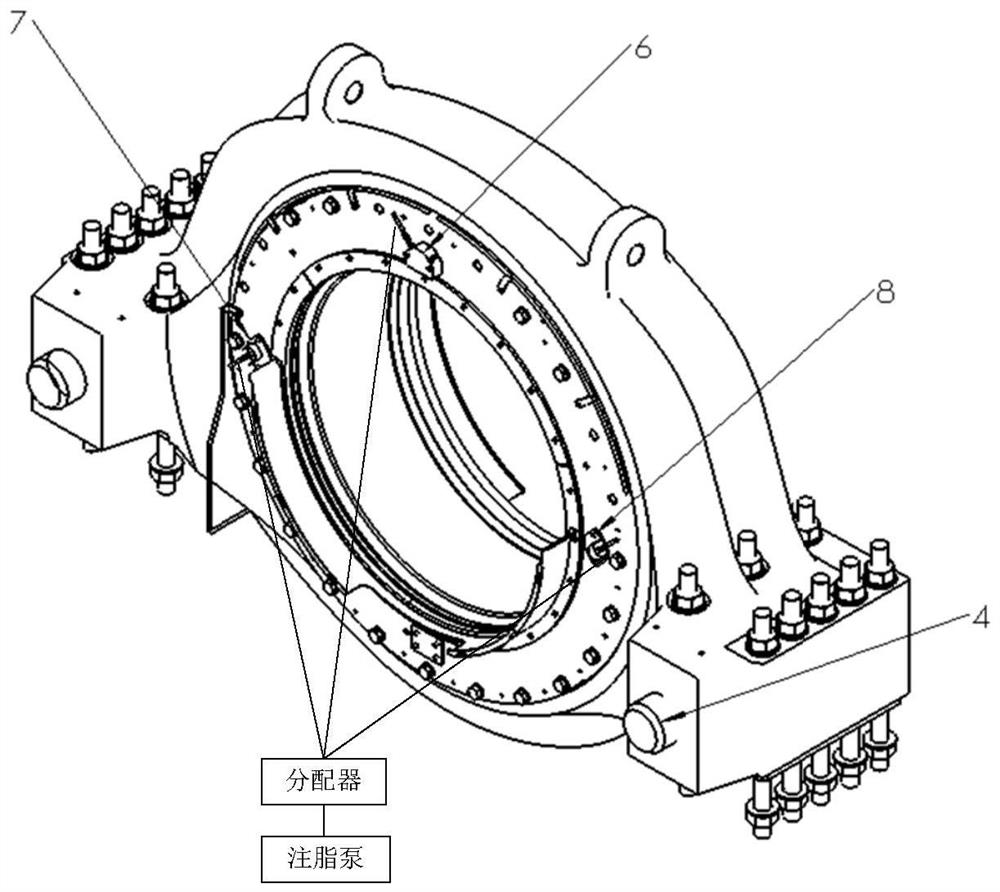

Main bearing grease replacement method for fan driving chain

ActiveCN113137349AImprove lubrication environmentIncreased operating lifeMachines/enginesWind energy generationOil and greaseProcess engineering

The invention provides a main bearing grease replacement method for a fan driving chain. The method comprises the following steps that old grease in a cavity on the side, close to a gear box, of a bearing seat is cleaned up at first, new grease is poured into the cavity on the side of the gear box, then new grease is poured into the cavity of the bearing seat in a turning state, and the new grease and the old grease in the cavity on the side, far away from the gear box, of the bearing seat are mixed; and meanwhile, most of the new and old mixed grease in the cavity on the side far away from the gear box is washed away through the poured-in new grease, then the new grease is injected again in the turning state, the new grease and the old grease can be evenly mixed and then discharged, then the new grease is injected multiple times, evenly mixed and then discharged, finally, the discharged grease does not change color, and cleaning of the old grease is completed. The discharged old grease needs to be weighed in the whole process, so that it is guaranteed that the total grease injection amount and the total grease discharging amount are almost the same. The grease of a main bearing can be replaced through grease injection and grease discharging methods, damage of a bearing oil film can be reduced to the maximum extent, the lubricating environment of the main bearing is improved, and the service life of the main bearing is prolonged.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

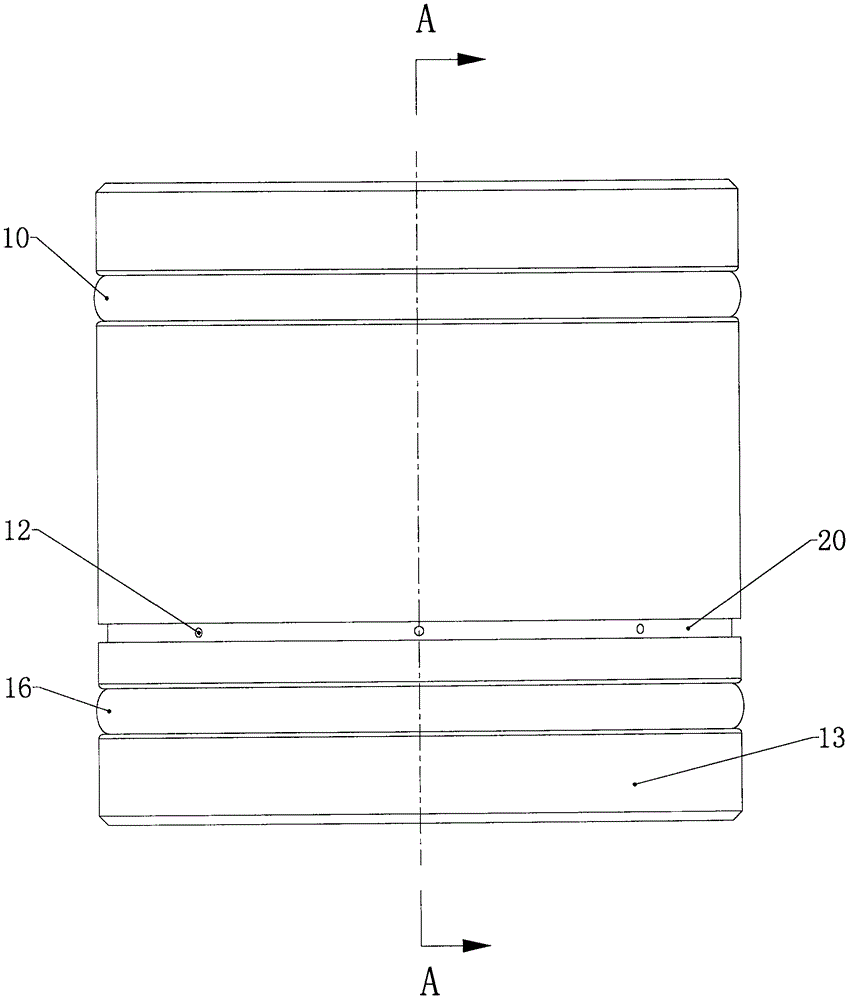

Split type tri-cone drill

PendingCN108442886AImprove scraping efficiencyImprove lubrication environmentDrill bitsSpray nozzleEngineering

The invention relates to a split type tri-cone drill which is mainly composed of a first cone set, a second cone set, a third cone set, teeth, bit legs, an oil storage compensation pressure balance system and a spraying nozzle. The three bit legs are separately connected to three cone lower bodies through biased bit-leg journals at the lower ends of the three bit legs. Three cone upper bodies areseparately installed on journals of the three cone lower bodies. During operation, the three cone lower bodies separately orbit with a drill body and rotate around the bit-leg journals; and the threecone upper bodies separately orbit with the drill body and rotate around journals of the three cone lower bodies, the task of scraping and crushing rocks is achieved, so that the tooth scraping efficiency of a small end tooth ring and a middle tooth ring is improved, and the rock crushing efficiency of the drill is improved.

Owner:SOUTHWEST PETROLEUM UNIV

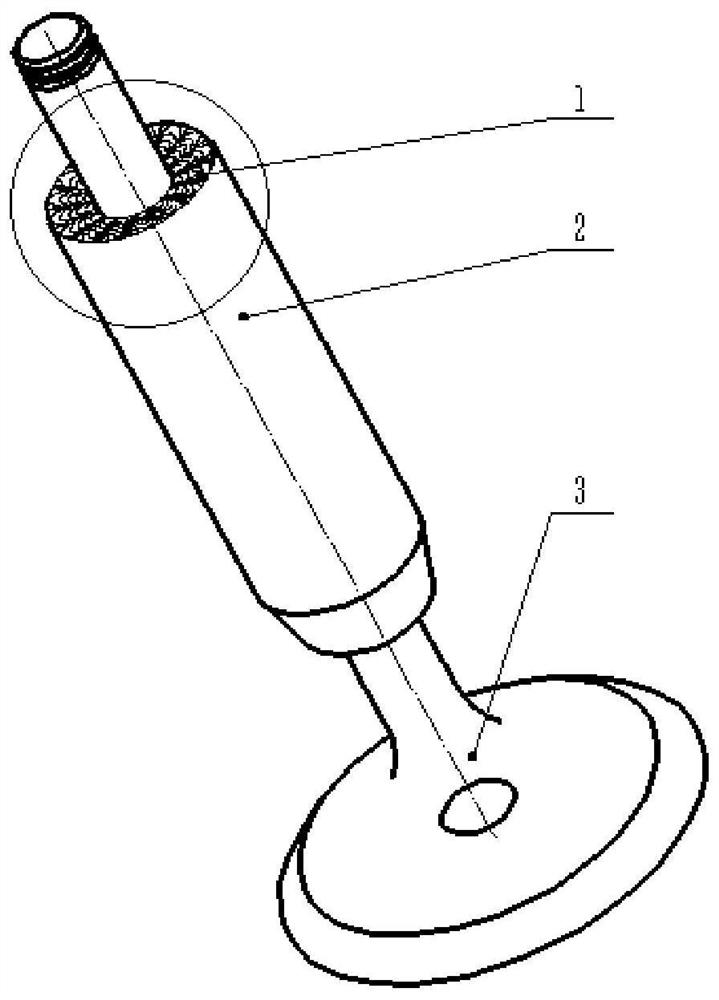

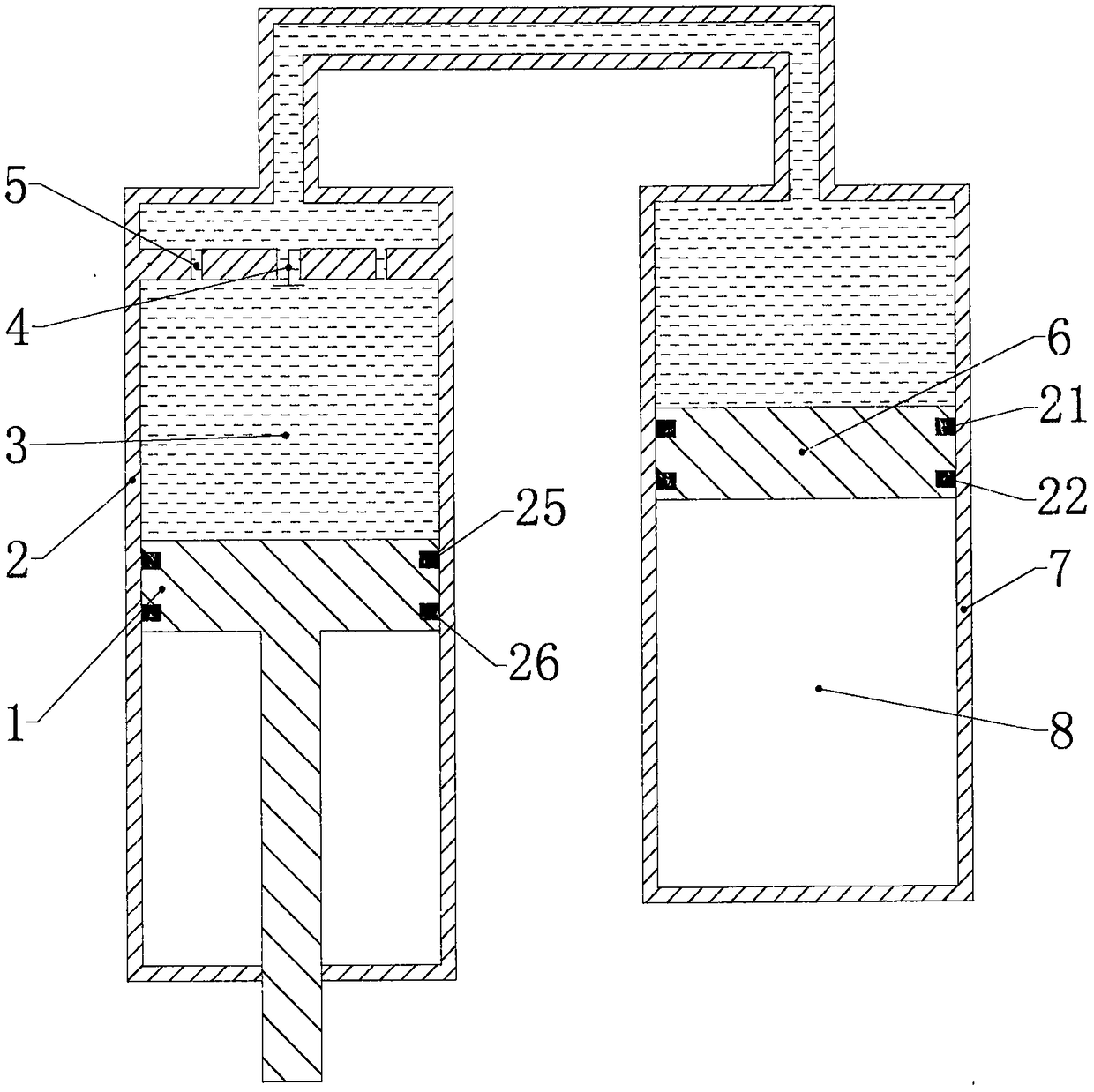

Oil and gas spring type self-lubricating compensation floating piston

ActiveCN106838096AReduce frictionImprove lubrication environmentSpringsGas and liquid based dampersGas springEngineering

The invention aims at providing an oil and gas spring type self-lubricating compensation floating piston. The oil and gas spring type self-lubricating compensation floating piston comprises a small piston, an automatic lubricating floating piston, a small piston sealing ring and a clamp spring, wherein the small piston is sheathed in a center weight reducing groove of the automatic lubricating floating piston; lubricating oil or lubricating grease is arranged into an oil storage cavity surrounded by the small piston and the automatic lubricating floating piston; the small piston sealing ring is arranged in the small piston in the radial direction, and is matched with the inner wall of a weight reducing hole to form radial sealing; the clamp spring is arranged at the upper end of the weight reducing hole, so as to prevent the small piston from falling down from the automatic lubricating floating piston during high-speed movement; the side surface of the automatic lubricating floating piston is processed with a radial lubricating oil passage and a peripheral lubricating oil passage, a lubricating oil groove is arranged between a sealing ring at the oil side and a sealing ring at the gas side, and the lubricating oil passage is used for guiding the lubricating oil in the oil storage cavity into the lubricating oil tank and a radial gap between the automatic lubricating floating piston and a cylinder body.

Owner:CHINA NORTH VEHICLE RES INST

Shaft end gas sealing device

The invention discloses a shaft end gas sealing device. The shaft end gas sealing device comprises a sealing base fixed on a plastifying device, wherein a transmission shaft is inserted in the sealing base, and is rotationally supported through a bearing base fixed on the plastifying device; step holes for inserting through the transmission shaft are formed in the sealing base, and consist of a small hole, a middle hole and a large hole arranged from inside to outside in sequence; two annular grooves are formed in the inner wall of the small hole; a skeleton oil seal component consisting of at least one skeleton oil seal is arranged between the large hole and the transmission shaft; and an annular space between the middle hole and the transmission shaft is communicated with the external through an air inlet way and an air outlet way arranged in the sealing base. The two annular grooves formed in the inner wall of the small hole have an effect of dust accumulation; along with the increment of the dust accumulation, larger dust particles in the plastifying device can be stopped from entering the middle hole from the small hole; and the dust entering the middle hole can be brought outside the sealing base for separate treatment through gas sealing, so that the problem of environment pollution caused by the dust leakage of the plastifying device is effectively solved.

Owner:常州协昌橡塑有限公司

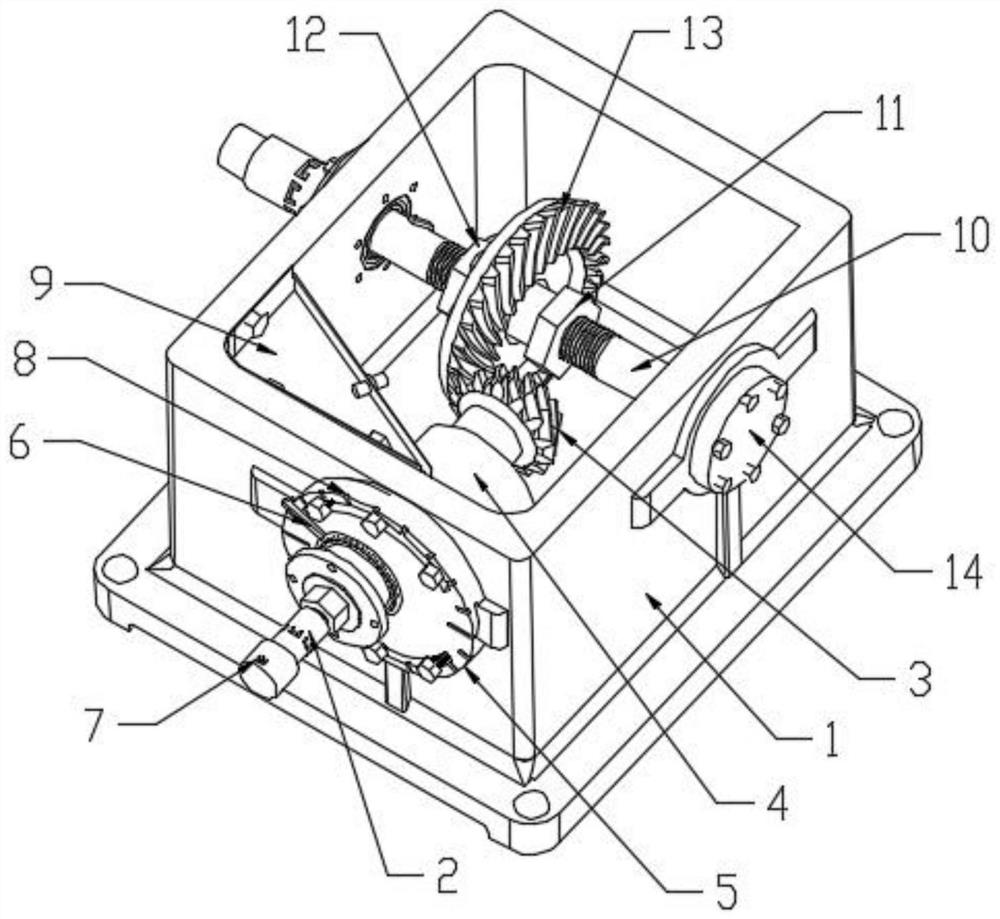

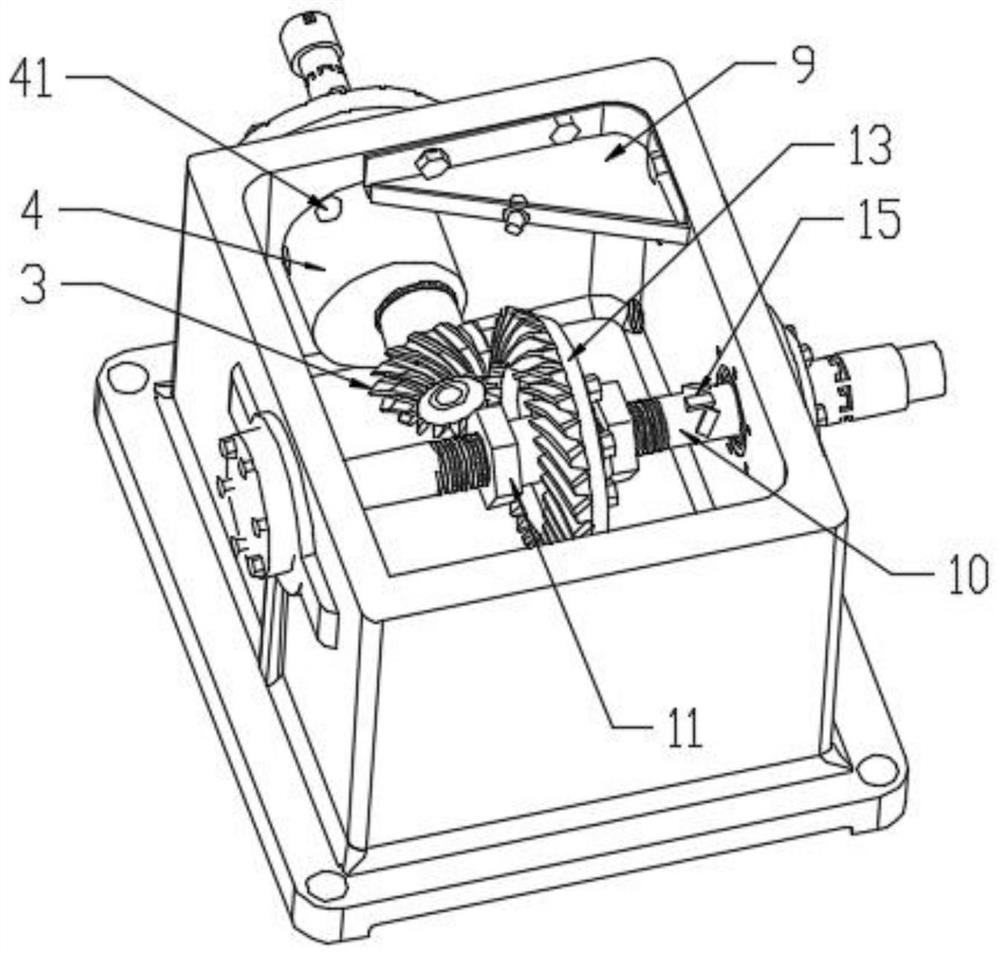

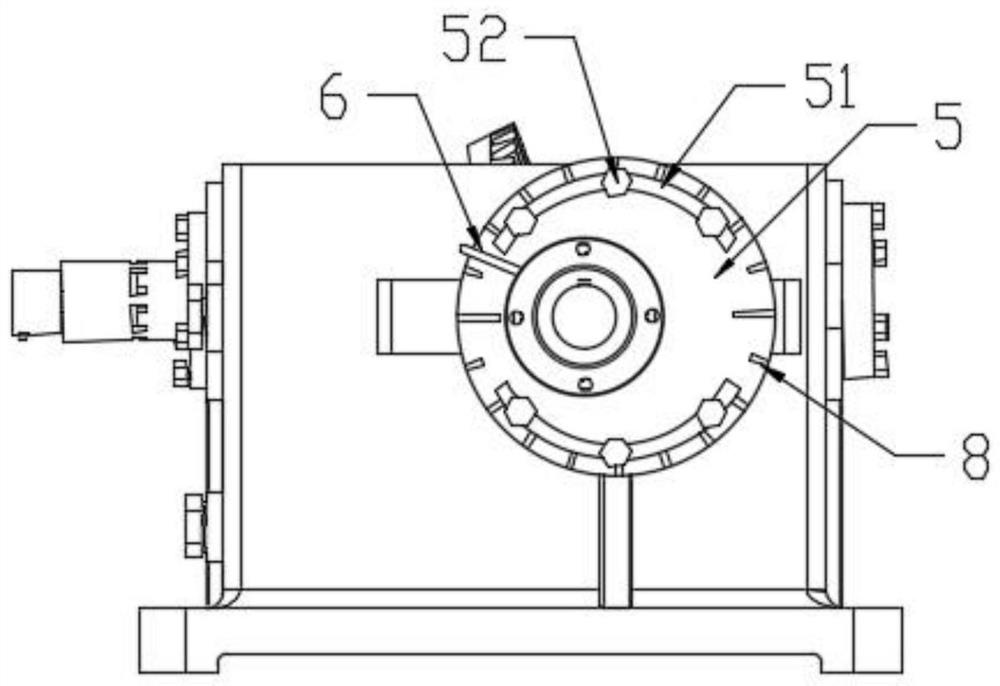

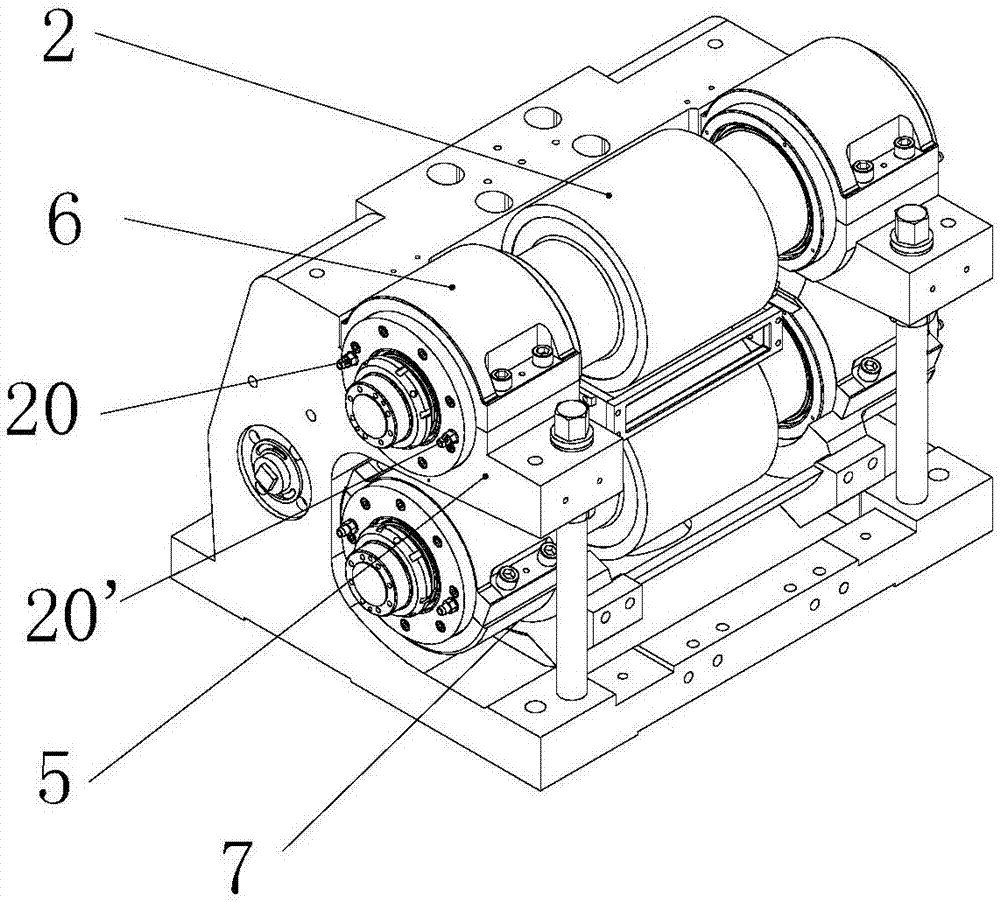

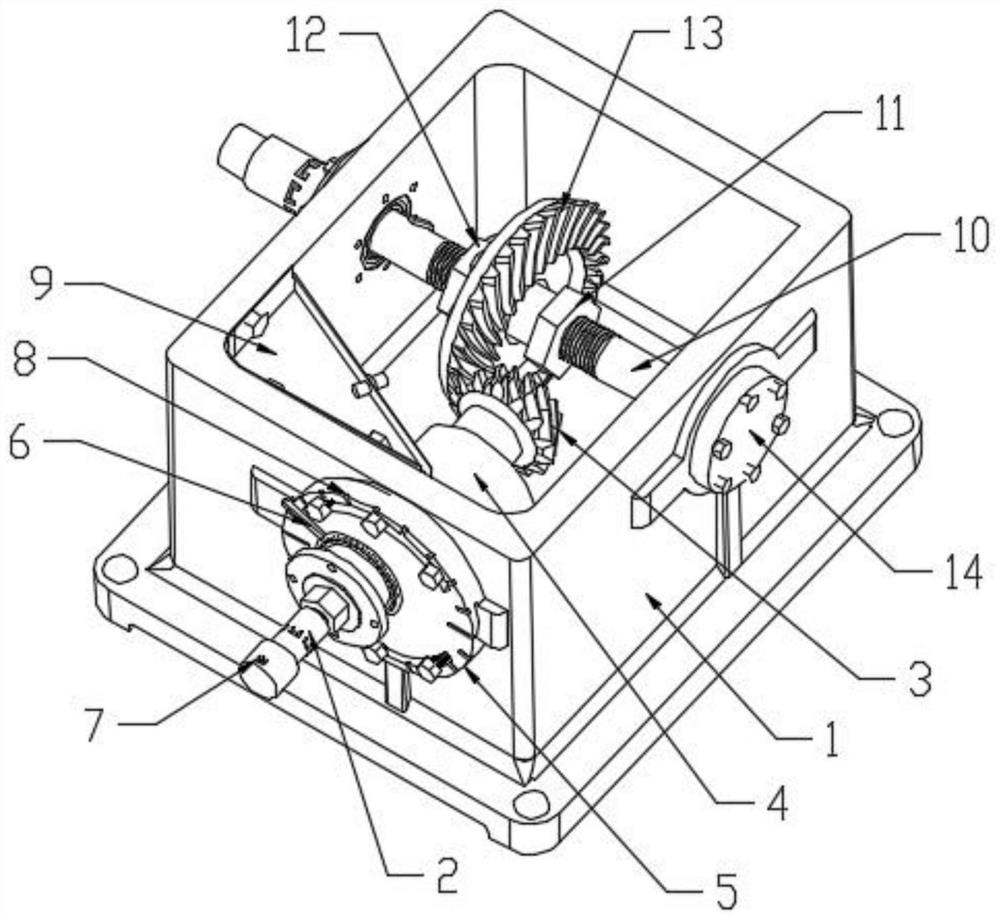

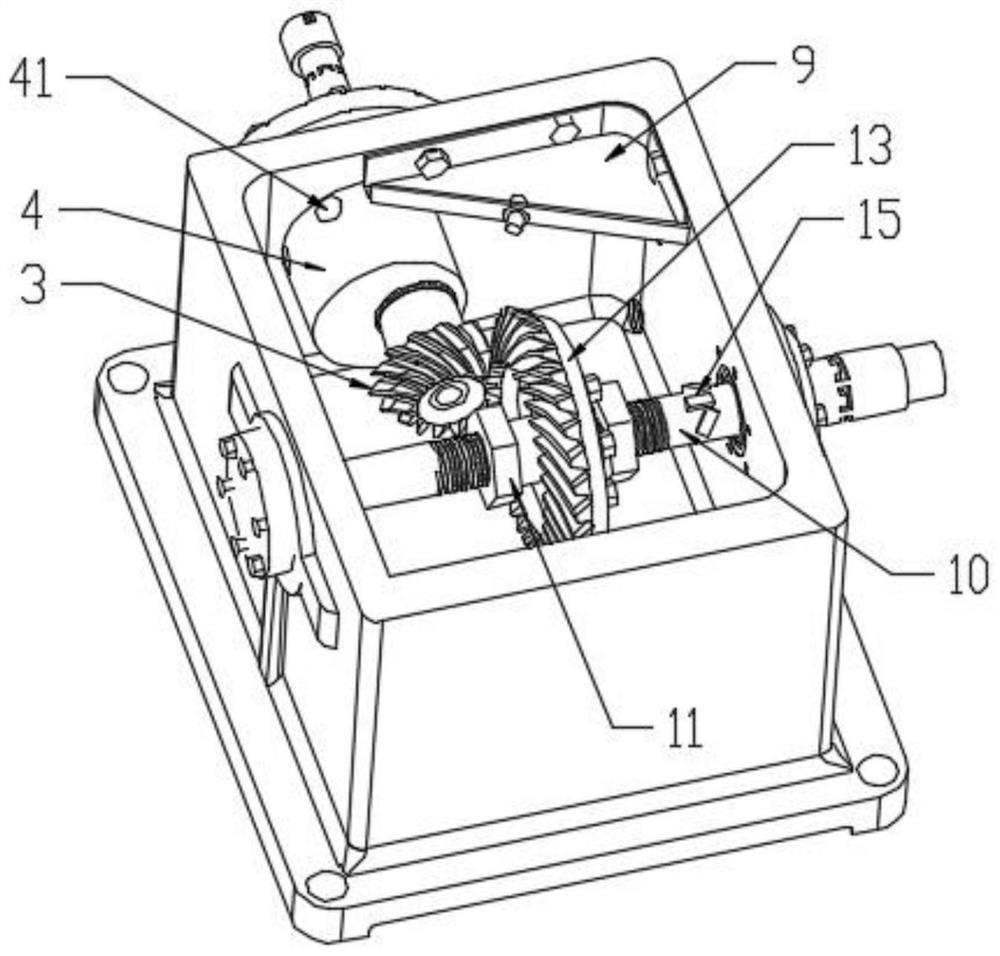

Self-adjusting bevel gear test box with adjustable offset distance

The invention discloses a self-adjusting bevel gear test box with an adjustable offset distance, and belongs to the technical field of mechanical design. The self-adjusting bevel gear test box comprises a box body; two mutually vertical wheel shafts are horizontally arranged in the box body; a bevel pinion is arranged on a pinion shaft; a shaft sleeve is arranged on a bull gear shaft; a rotatablebevel gear wheel is arranged on the shaft sleeve; fixing nuts are arranged at two ends of the shaft sleeve; a compression spring is arranged between the fixing nuts and the shaft sleeve; the pinion shaft is rotatably arranged in an eccentric shaft seat; the eccentric shaft seat is connected with an adjusting disc; a bull gear is arranged on the eccentric shaft seat; a worm and worm wheel mechanismis arranged in the box body and comprises a worm and a worm wheel arranged on the bull gear shaft; the pinion on the worm is meshed with the bull gear; and the worm wheel is connected with the fixingnuts through a spline sleeve mechanism. Various dynamic performance tests and analysis can be carried out on bevel gears with different offset distances and installation distances through one gear box, and the positions of the bevel gears can be changed automatically and adaptively according to adjustment of the offset distances in the test process.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

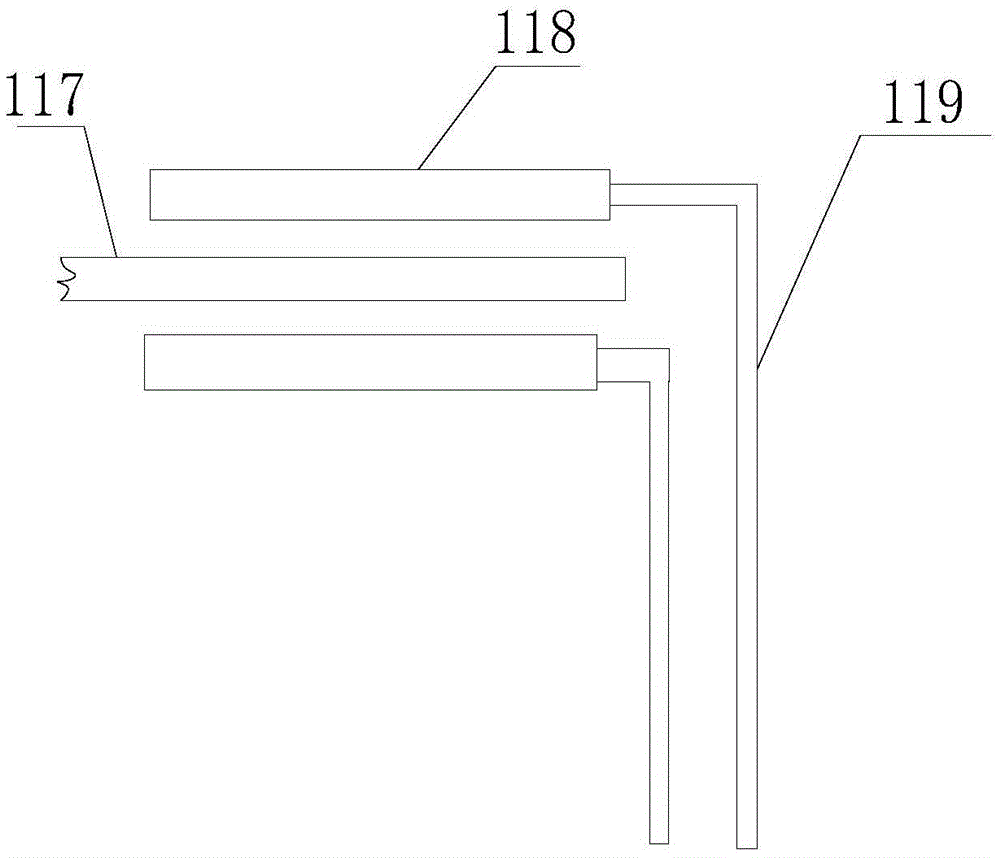

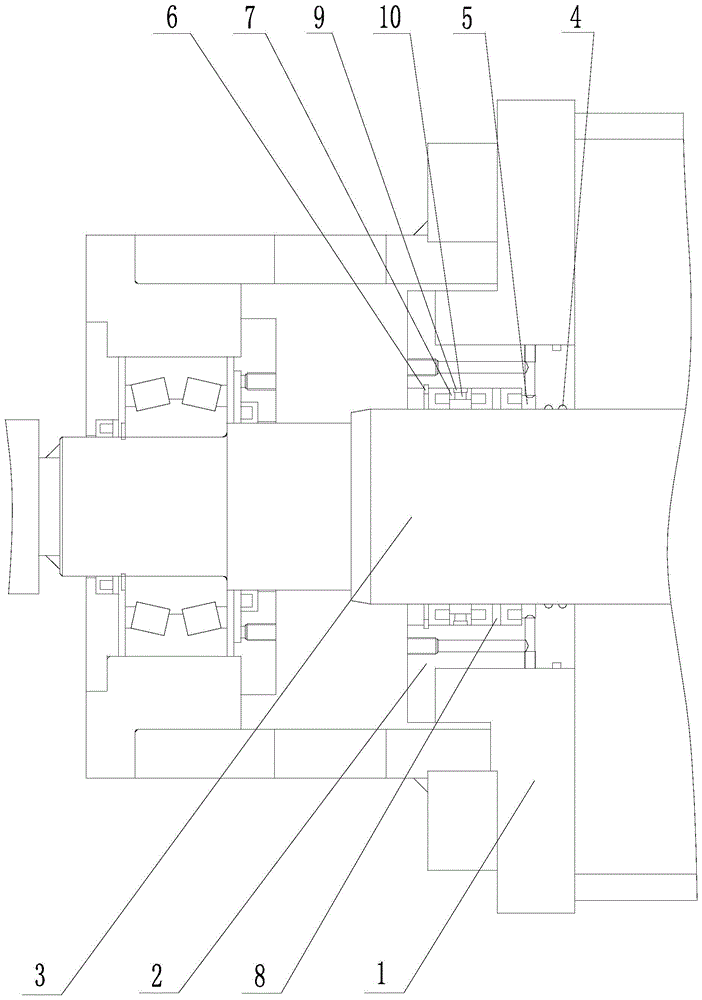

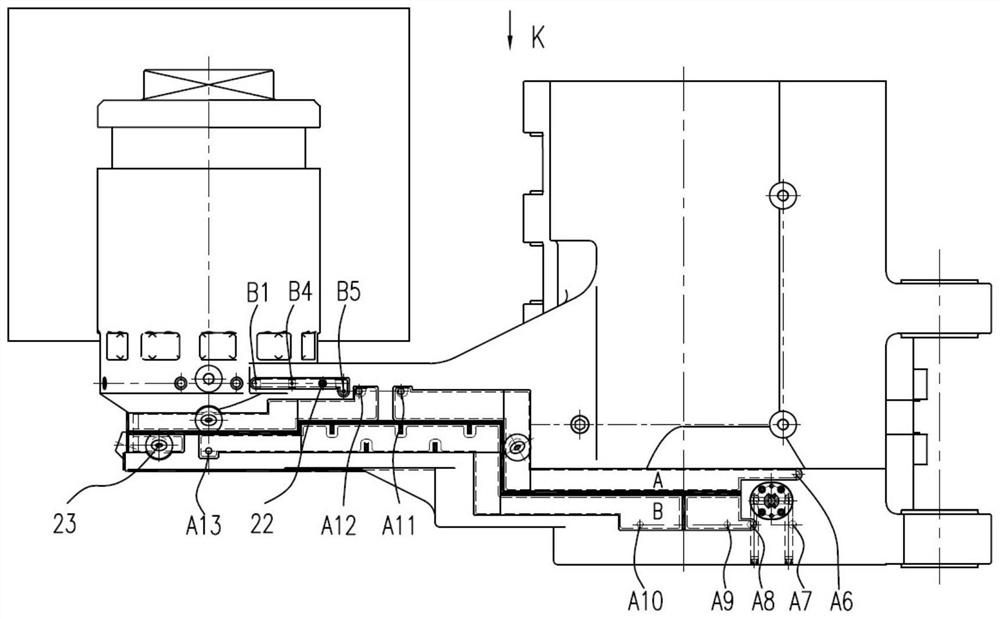

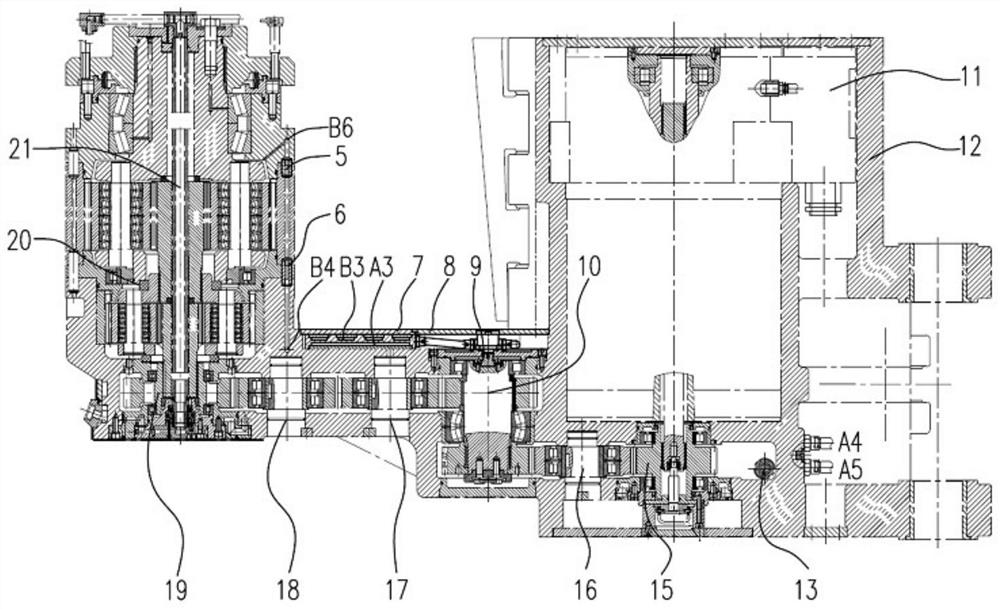

External circulating lubricating and cooling system for coal mining machine and coal mining machine cutting device

PendingCN113216957ALower operating temperatureImprove lubrication environmentLighting and heating apparatusGear lubrication/coolingCoal miningSuction tubing

The invention relates to an external circulating lubricating and cooling system for a coal mining machine and a coal mining machine cutting device. The external circulating lubricating and cooling system comprises a plate cooler, a cycloid lubricating pump and an oil suction filter, and the oil suction filter is installed at the inlet end of an oil suction pipe of the cycloid lubricating pump and located at the bottom of an oil pool of the cutting device; an outlet end of an oil return pipe of the cycloid lubricating pump is connected with an oil duct inlet of the plate cooler, an oil duct outlet of the plate cooler is connected with the oil pool of the cutting device, and an inlet and an outlet of a water channel of the plate cooler are correspondingly connected with an outlet and an inlet of a cooling water jacket of a box body of the cutting device; and the cutting device comprises the lubricating and cooling system, the plate cooler is fixed to the outer side face of the coal wall side in the middle of the box body of the cutting device, the cycloid lubricating pump is installed on the box body of the cutting device, and a main shaft of the cycloid lubricating pump is coaxially connected with a third gear shaft set in the box body. The problems that a high-power-density cutting device is high in operation temperature and a transmission system is poor in lubrication can be solved, and the requirements for efficient lubrication and continuous cooling are met.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

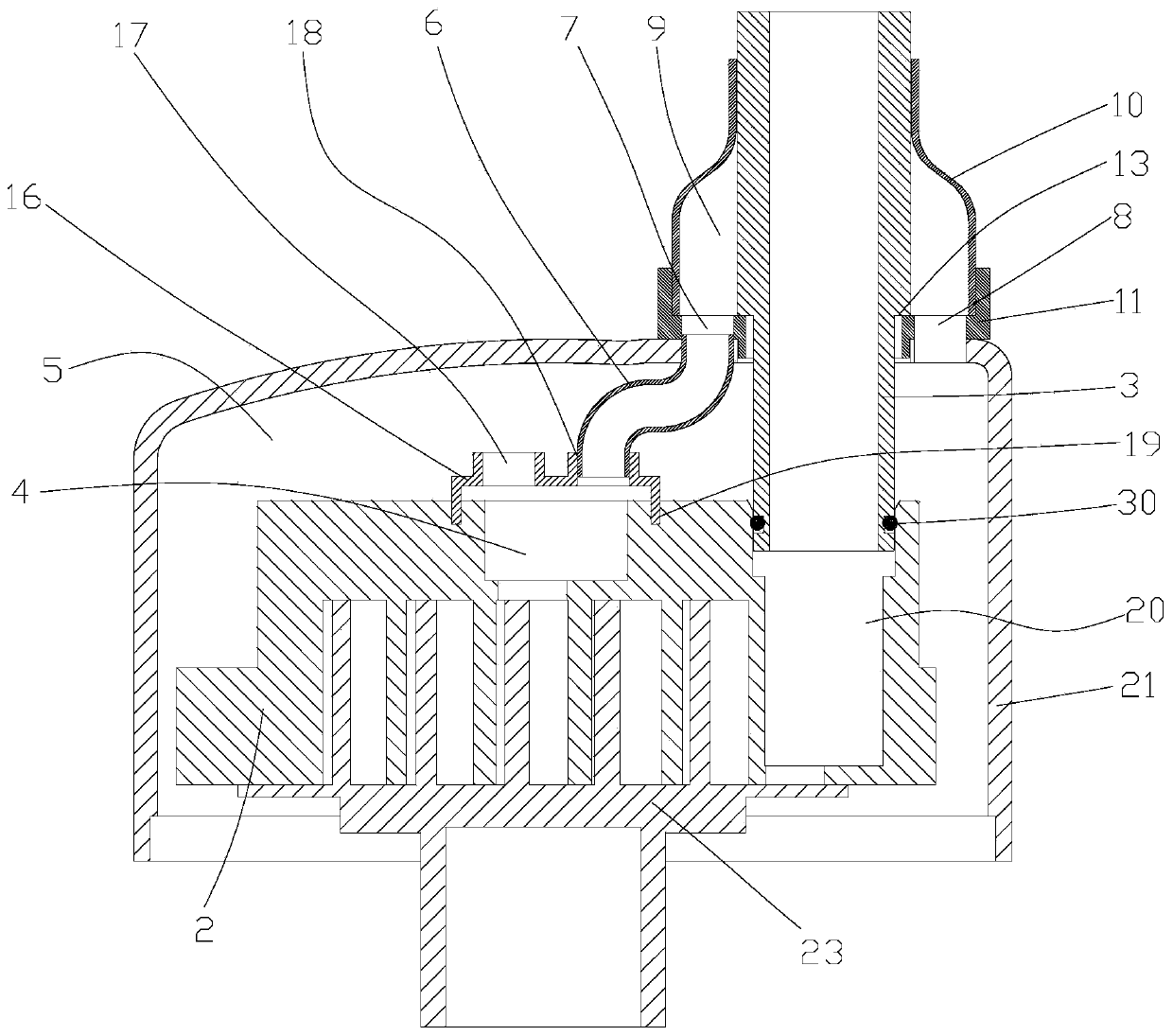

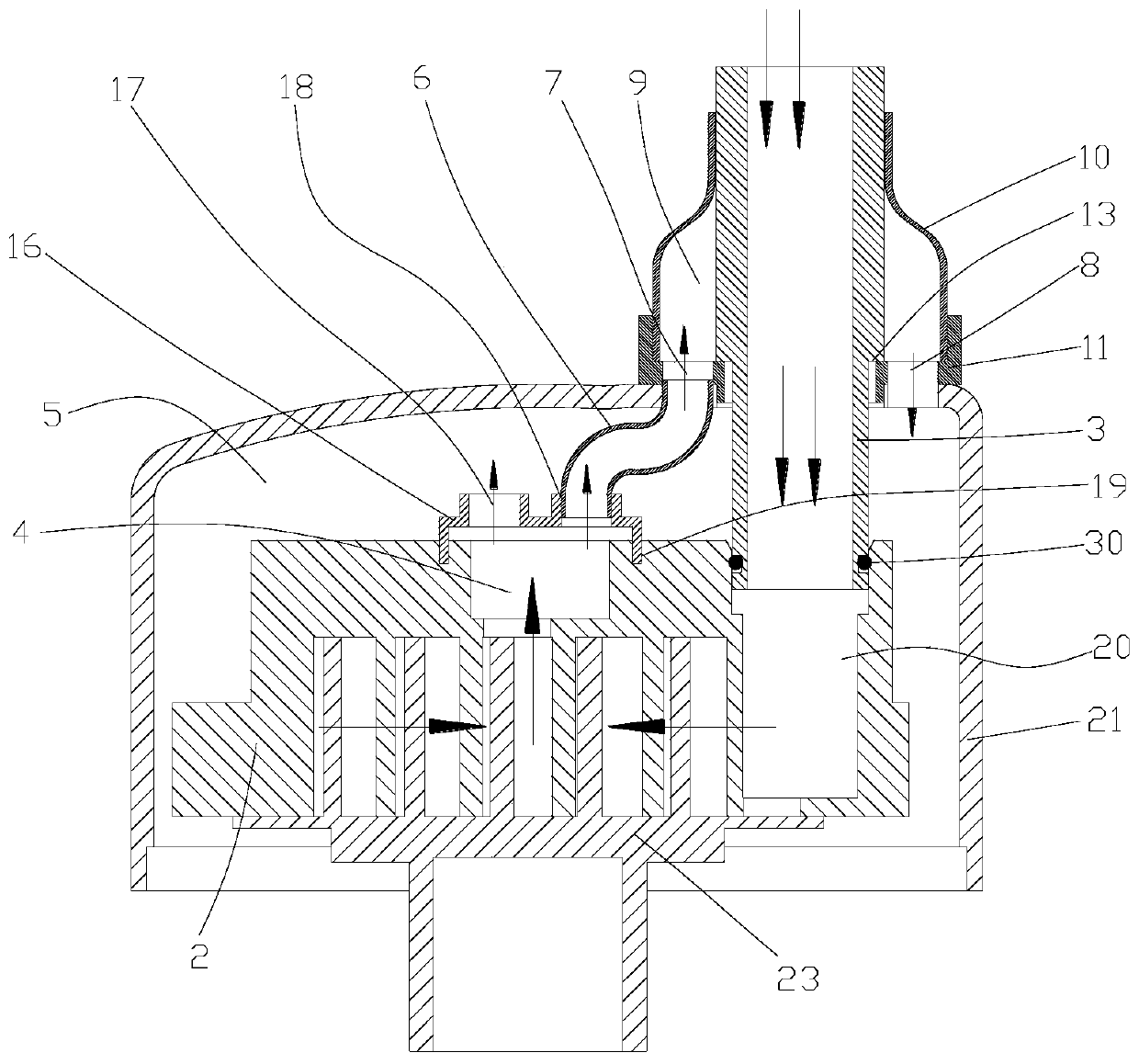

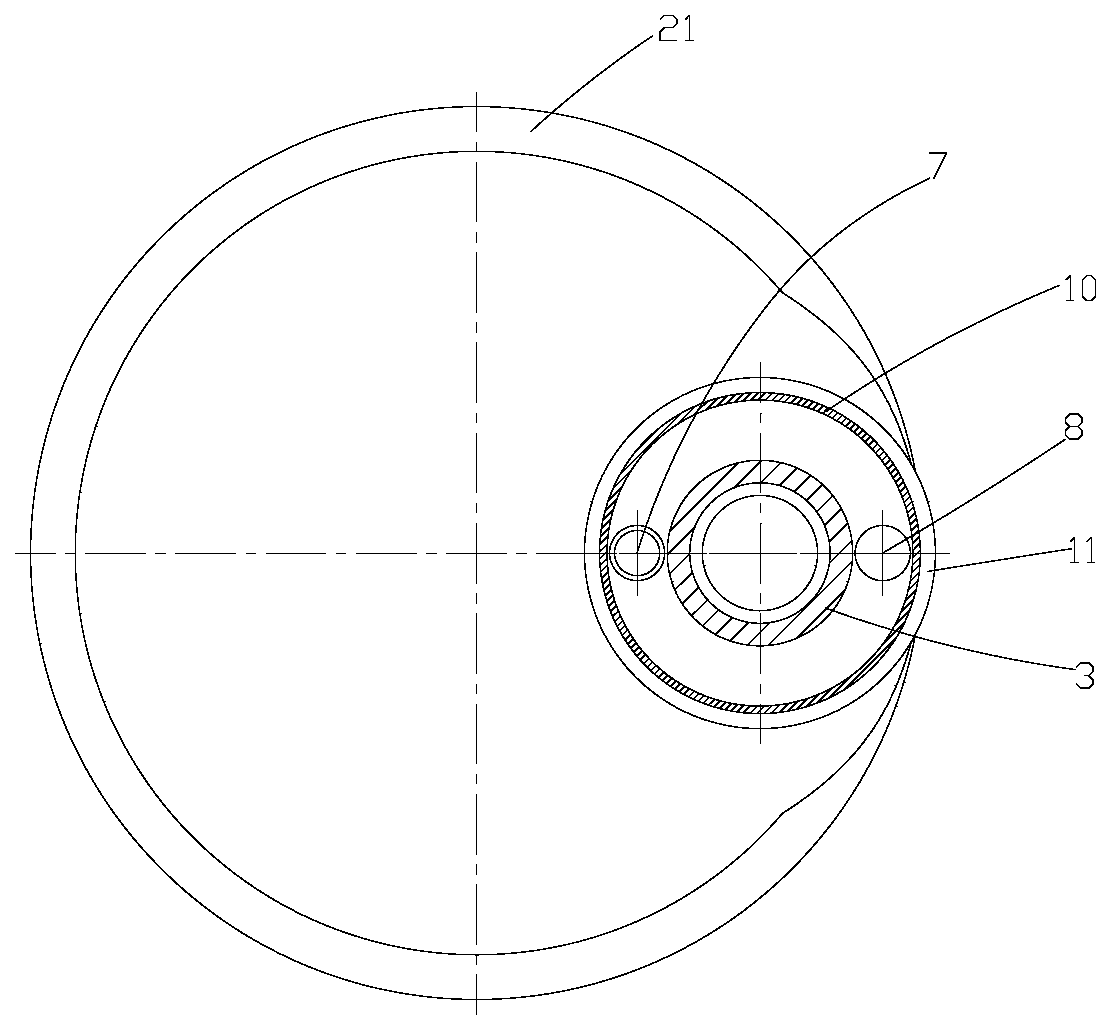

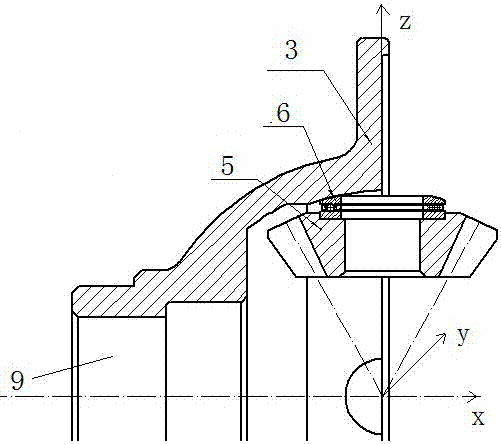

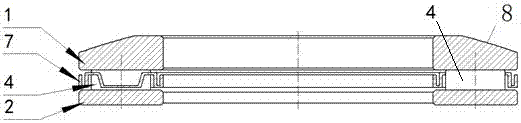

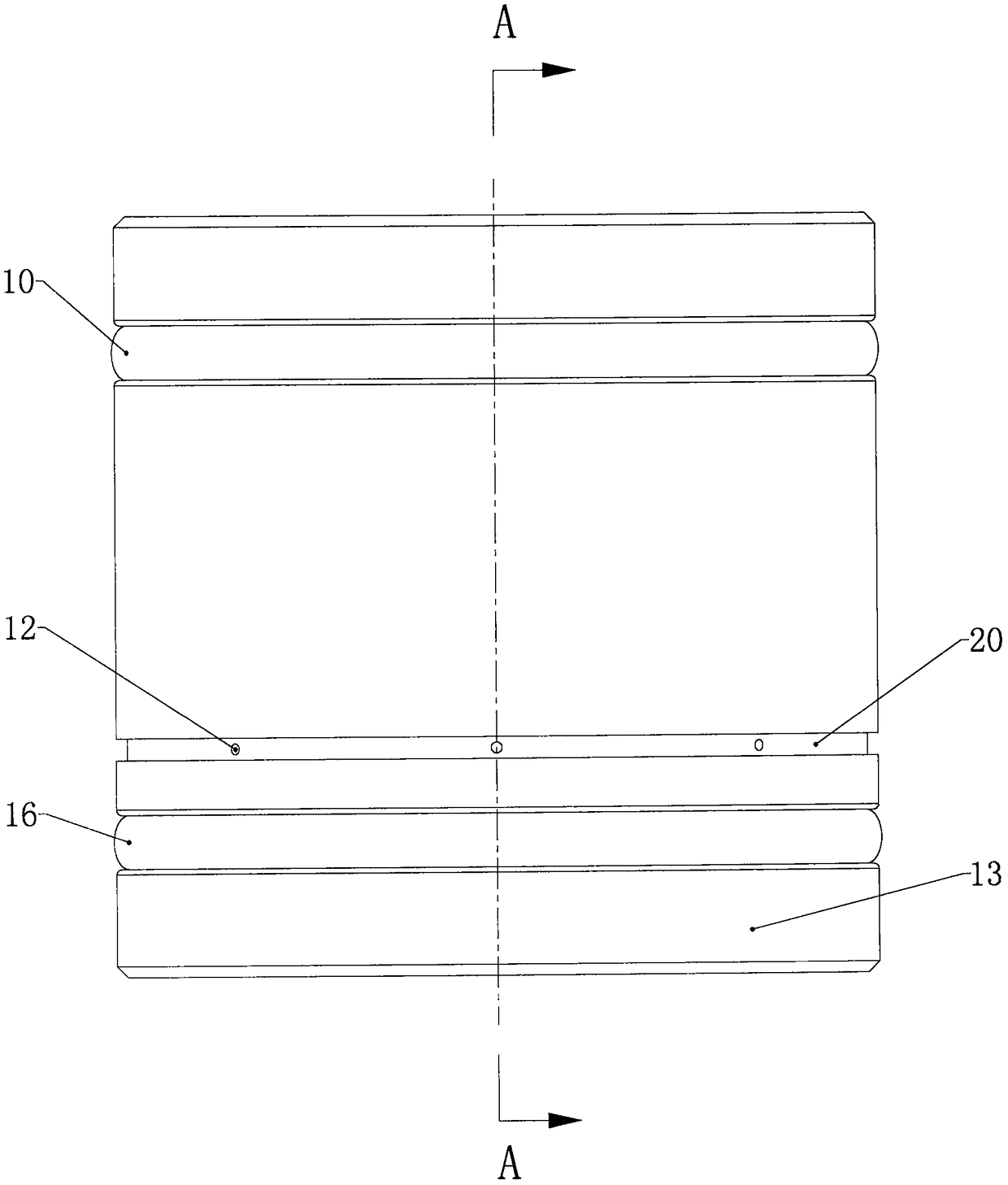

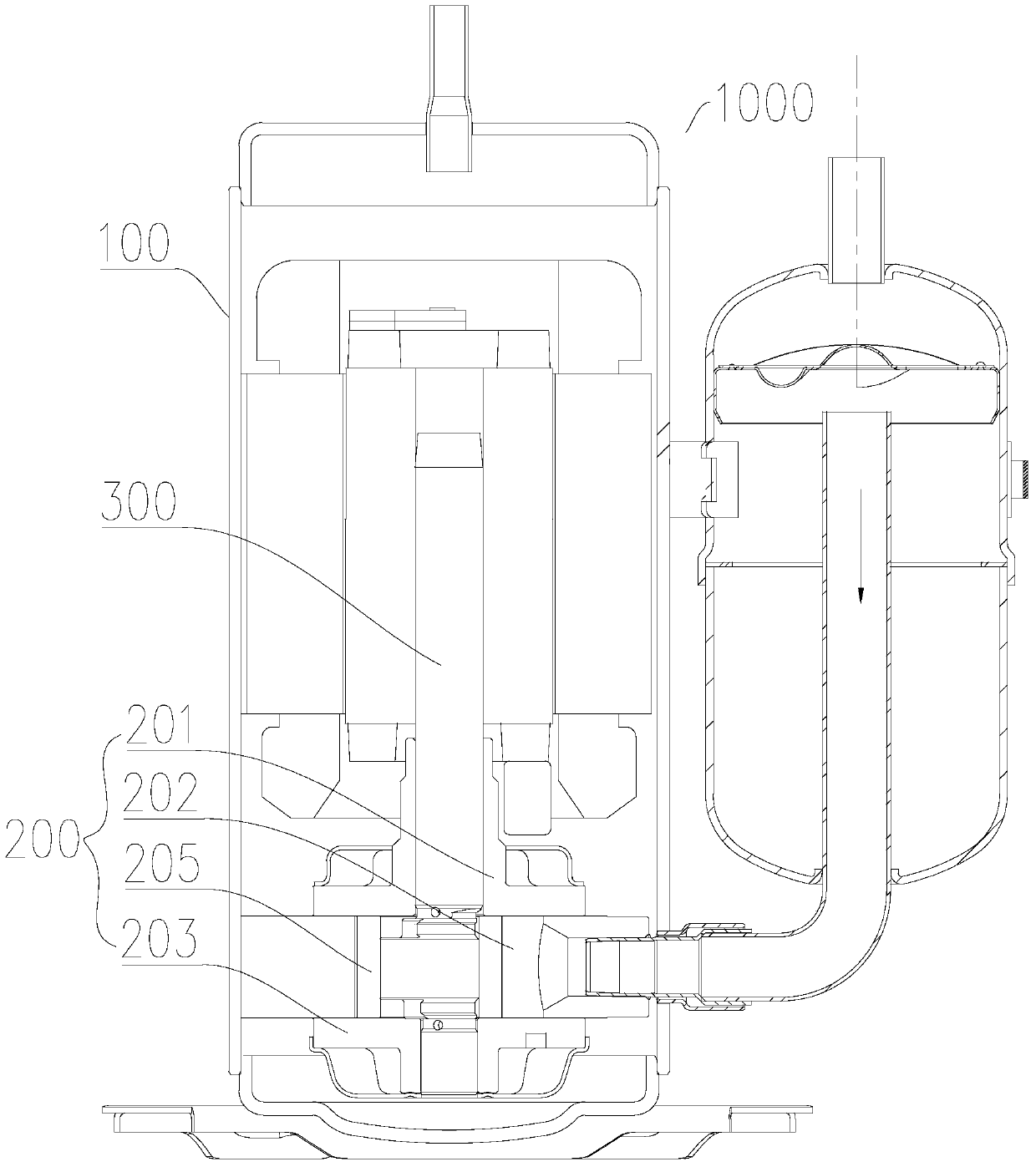

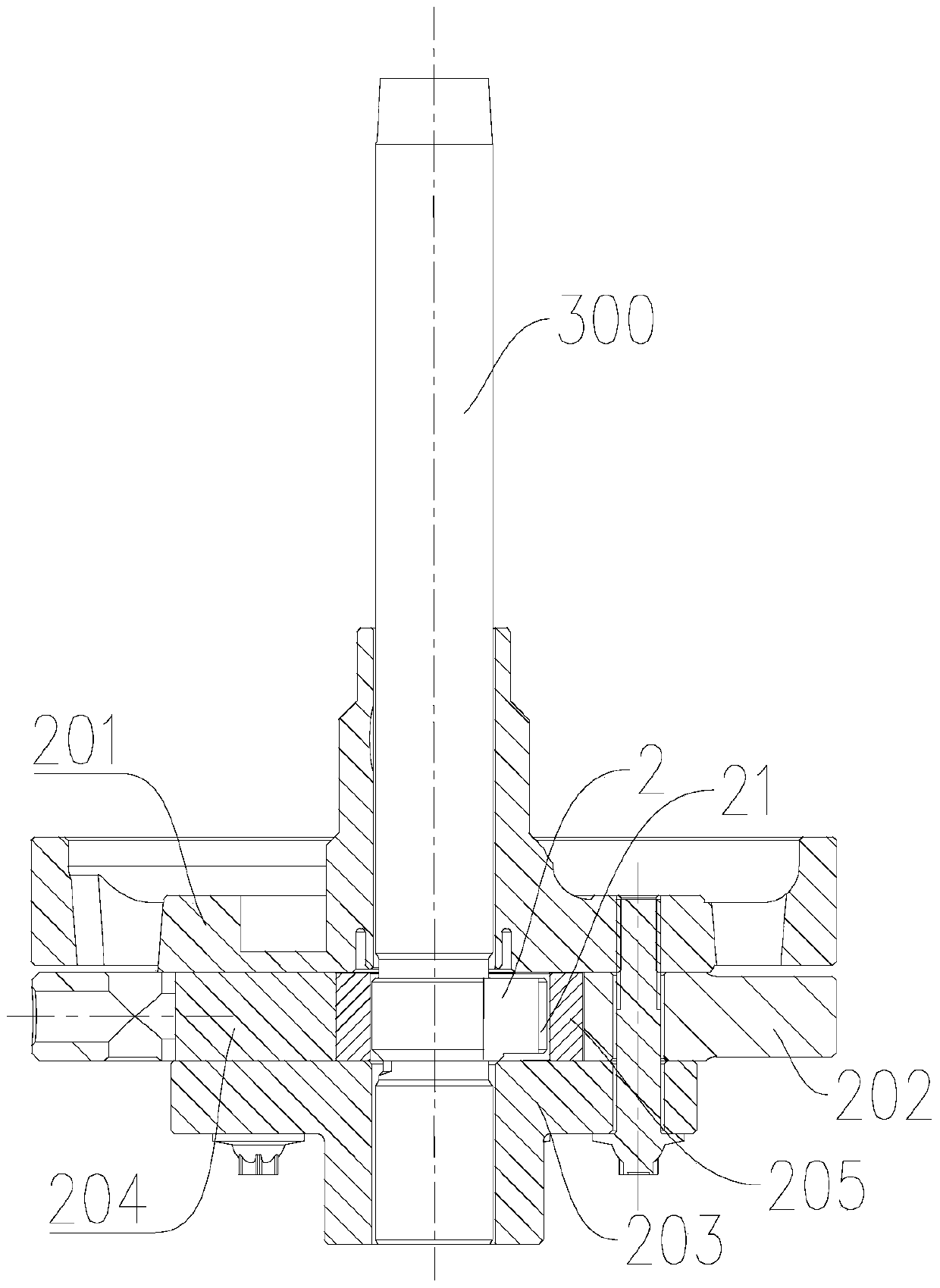

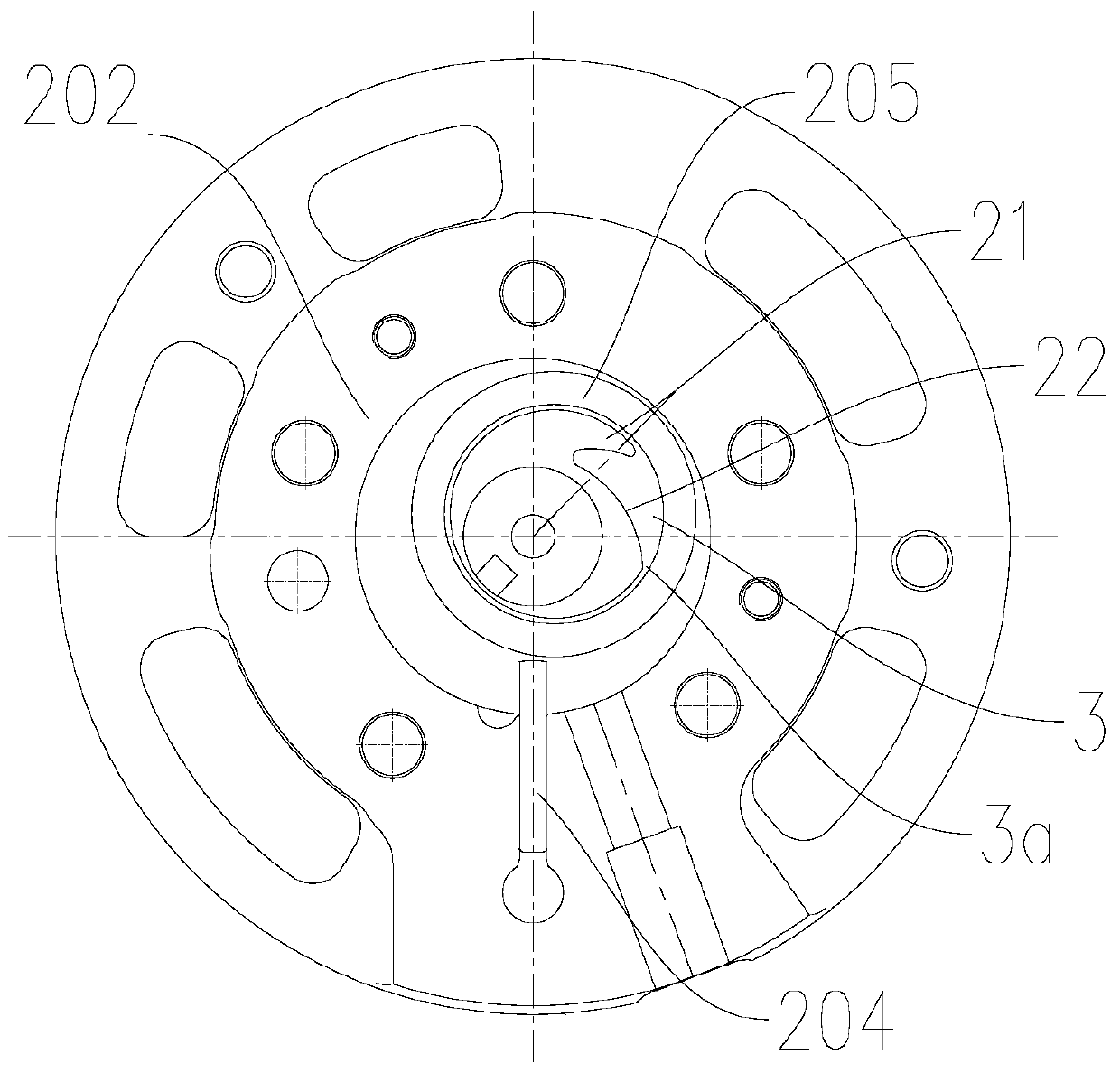

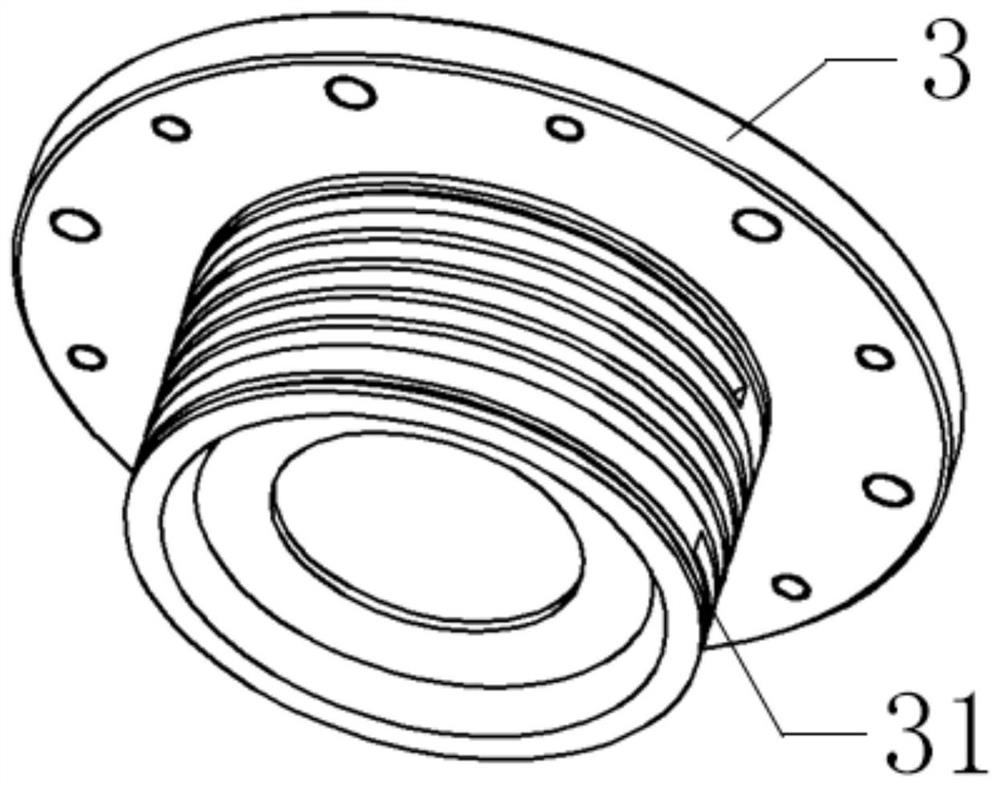

Scroll compressor and heat pump system

ActiveCN110345075AGuaranteed uptimeImprove operational reliabilityHeat pumpsRotary piston pumpsHeat pumpWaste management

The invention provides a scroll compressor and a heat pump system. The scroll compressor comprises a casing (1), a fixed scroll plate (2) and an air suction pipe (3); the air suction pipe (3) is arranged on the casing (1); the fixed scroll plate (2) is provided with an exhaust port (4); the scroll compressor further comprises an air suction reheating assembly; the air suction reheating assembly isin heat exchange contact with the air suction pipe (3); an air inlet of the air suction reheating assembly communicates with the exhaust port (4); an air outlet of the air suction reheating assemblycommunicates with an exhaust cavity (5) of the casing (1); and at least part of a refrigerant discharged from the exhaust port (4) flows through the air suction reheating assembly and flows to the exhaust cavity (5) after being subjected to heat exchange with a refrigerant flowing through the air suction pipe (3). According to the scroll compressor, the phenomenon that liquid is carried due to airsuction can be effectively avoided, and the operation reliability of the scroll compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Motor tricycle engine crankshaft roller pin lubricating structure

InactiveCN106121766ALow failure rateImprove lubrication environmentMachines/enginesLubricant mounting/connectionEngineeringCrankshaft

The invention discloses a motor tricycle engine crankshaft roller pin lubricating structure. The motor tricycle engine crankshaft roller pin lubricating structure comprises a left crank, a right crank and a connecting rod. A crank pin is connected between the left crank and the right crank. The end portion of the connecting rod is sleeved with the crank pin. A crankshaft roller pin is arranged between the end portion of the connecting rod and the crank pin. The right crank is provided with a crank lubricating oil way. The crank pin is provided with a crank pin lubricating oil way communicating with the crank lubricating oil way through an oil supply hole. The opening end of the crank pin lubricating oil way is sealed through a first oil way plug. An oil way hole for supplying lubricating oil to the crankshaft roller pin is formed in the crank pin lubricating oil way. A second oil way plug is arranged in the part, between the oil supply hole and the oil way hole, of the crank pin lubricating oil way and provided with a lubricating oil passing hole. According to the motor tricycle engine crankshaft roller pin lubricating structure, lubricating oil about to enter the crankshaft roller pin can be filtered again, particle impurities in the lubricating oil are prevented from flowing into the crankshaft roller pin, the lubricating environment of the crankshaft roller pin is greatly improved, and the fault rate of a motor tricycle engine is effectively reduced.

Owner:力帆科技(集团)股份有限公司

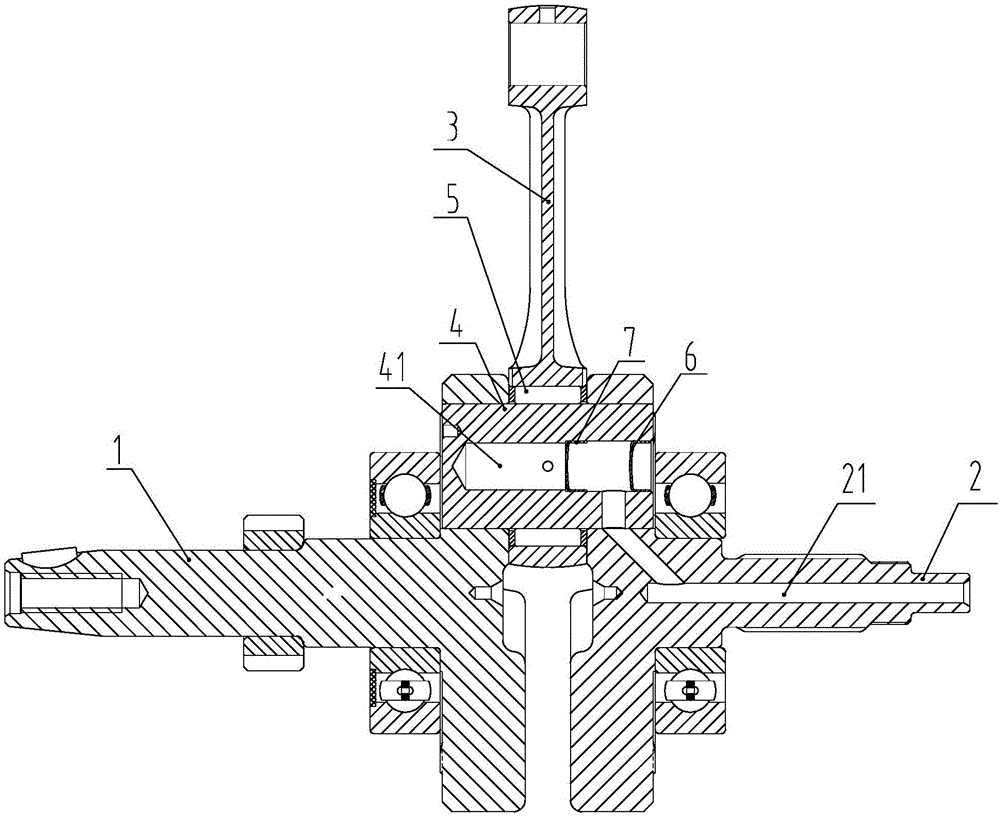

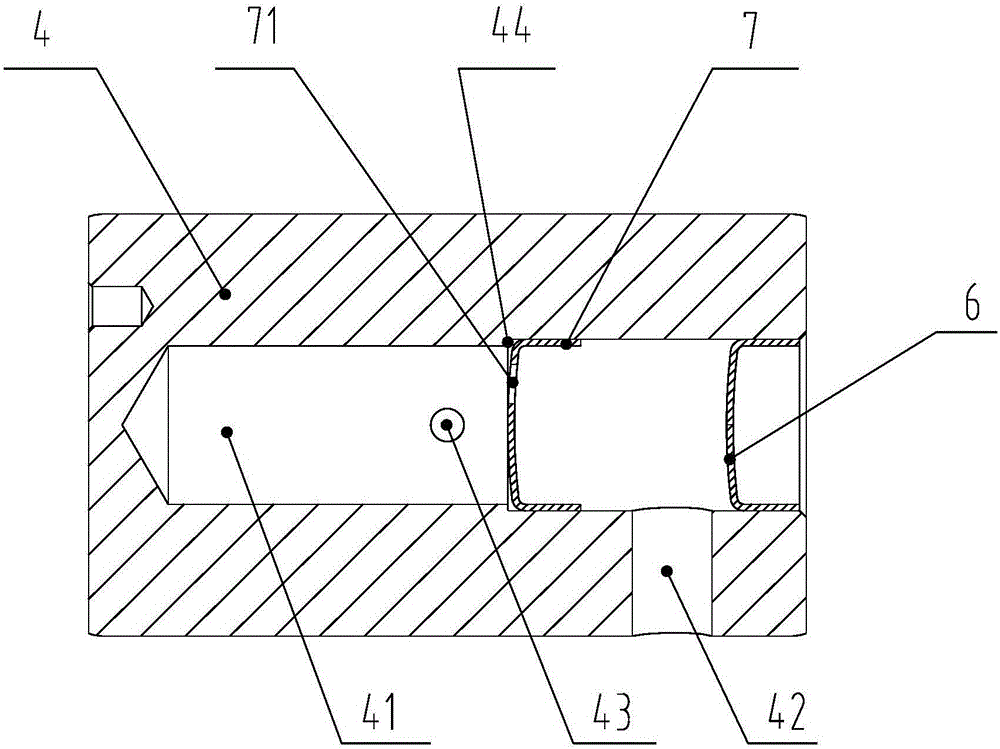

Automobile differential mechanism and bearing combination structure

PendingCN106870684AAvoid early failureExtended service lifeDifferential gearingsNeedle roller bearingThrust bearing

The invention discloses an automobile differential mechanism and bearing combination structure. The combination structure is characterized in that a thrust bearing is clamped between a differential case and the top ends of planetary gears, and the thrust bearing and the planetary gears are arranged on a same shaft together in a sleeving mode. Contact surfaces of the thrust bearing and the differential case are spherical surfaces corresponding to each other, and the contact surface on the thrust bearing is a static surface. The combination structure has the beneficial effects that roller pin bearings rotate along with rolling of the planetary gears, grinding scrap iron is reduced, the internal lubrication environment is improved, the faults of the automobile differential mechanism are reduced, and the overall service life of the differential mechanism is prolonged.

Owner:SHANDONG HUXIWANG GRP

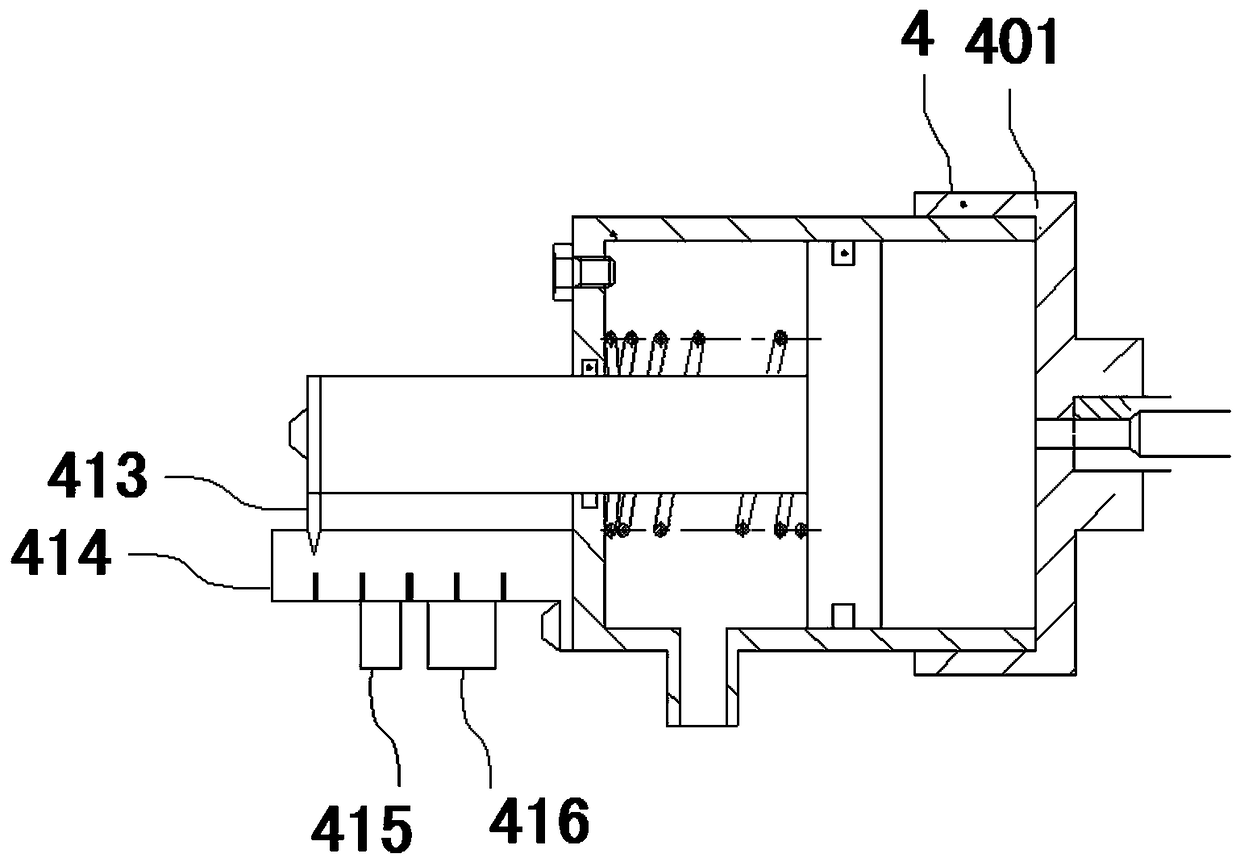

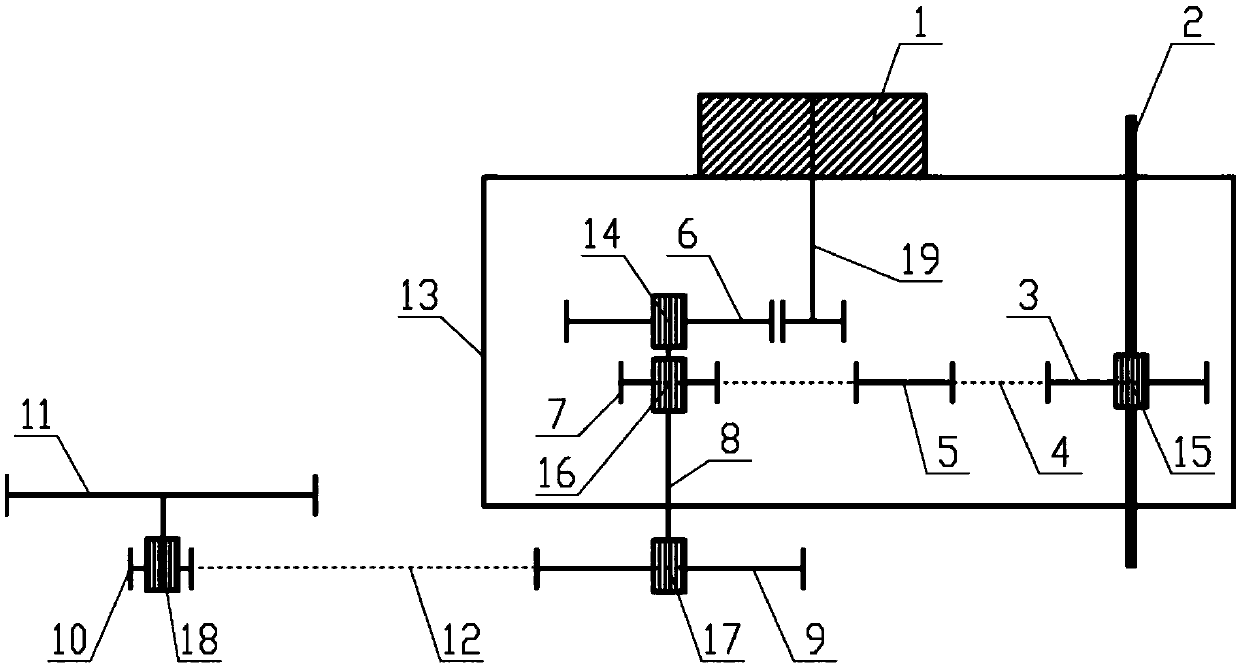

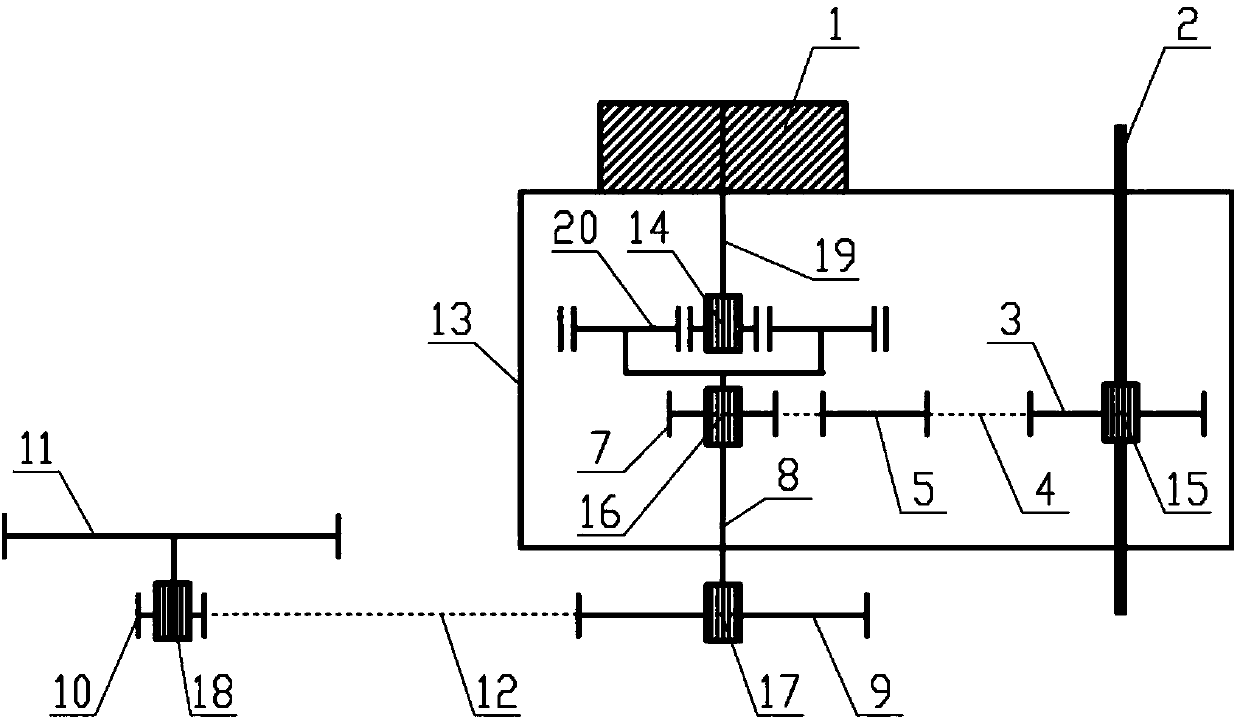

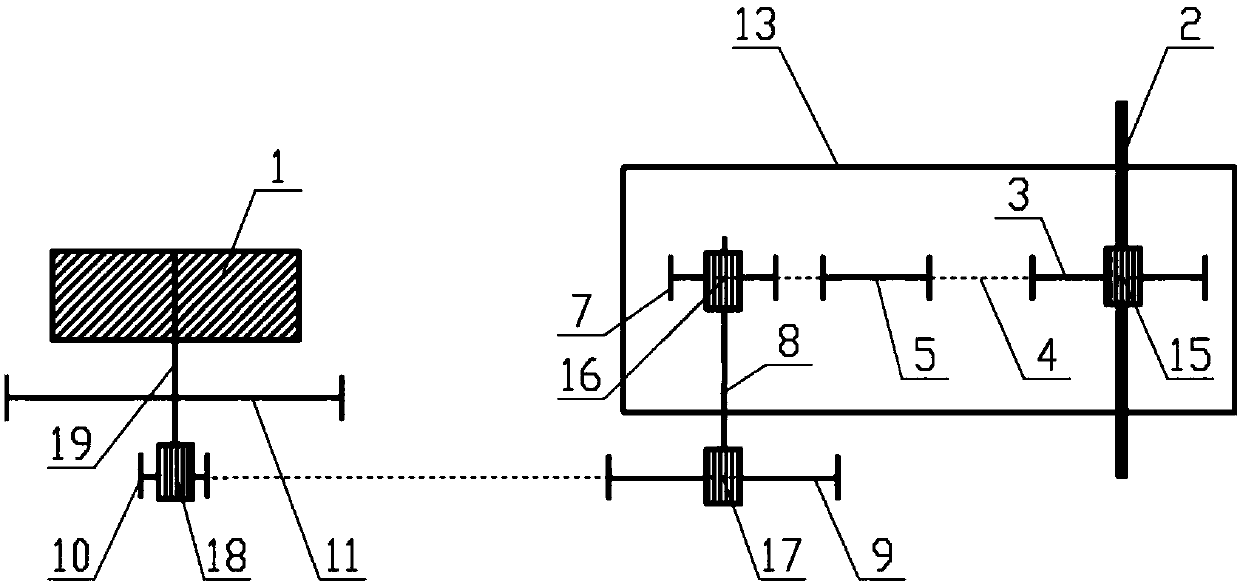

Power assisting device and power assisting bicycle

PendingCN109677557AEfficient storageNoise shieldingChain/belt transmissionRider propulsionDrive wheelDrive shaft

The invention discloses a power assisting device and a power assisting bicycle. The power assisting device comprises a motor, a crank-set, a drive shaft, a flywheel, a first drive wheel, a second drive wheel and a pedaling force measuring device; a motor controller of the motor controls output of a torque; a transmission connection is established between the crank-set and the first drive wheel through a first chain or a first belt; the transmission connection is established between the second drive wheel and the flywheel through a second chain or a second belt; the first drive wheel and the second drive wheel are installed on the drive shaft; the torque on the first drive wheel can be transmitted to the second drive wheel; the pedaling force measuring device includes a swing arm which swings under the tension of the first chain or the first belt, and a sensor for detecting a rotation angle or a displacement distance of the swing arm; the sensor sends a detected electrical signal to themotor controller; and the motor controller controls the motor to output the corresponding torque. With the power assisting device and the power assisting bicycle disclosed by invention, effective accommodation and sealing for related components can be implemented, thereby improving the reliability of the device.

Owner:南京奥特博机电科技有限公司

Down-press crimping machine for staple fiber production line

ActiveCN106087155BExtended service lifeGuaranteed accuracyNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveProduction lineFiber

Owner:SUZHOU HUIFENG CHEM FIBER MACHINERY

Wire separating type wire drawing combined die

InactiveCN105710148AQuick and easy disassemblyStable working environmentDrawing diesWorking environmentMaterials science

The invention relates to the technical field of metal wire production, in particular to a wire-separated wire drawing combination die, which includes a die body and a die cover. The die cover includes a lubricating powder cavity and a front core cavity without taper. The core cavity and the lubricating powder cavity pass through the center of the mold cover; the mold body includes a tapered rear core cavity and a non-tapered matching cavity, and the rear core cavity and the matching cavity pass through the center of the mold body; the front mold A cylindrical pressure mold core and a tapered finished mold core are installed in the core cavity and the rear core cavity respectively; the inlet end of the pressure mold core is provided with a groove with powder, and the wire separation type wire drawing combination of the present invention The mold adopts the double-core separation design, which has good sealing performance, stable working environment of the mold, and a good lubricating environment. The quality of the finished wire rod is significantly improved. In addition, there are heat dissipation grooves on the periphery of the rear core cavity on the mold body to avoid mold bursting.

Owner:HENAN HENGXING SCIENCE & TECHNOLOGY CO LTD

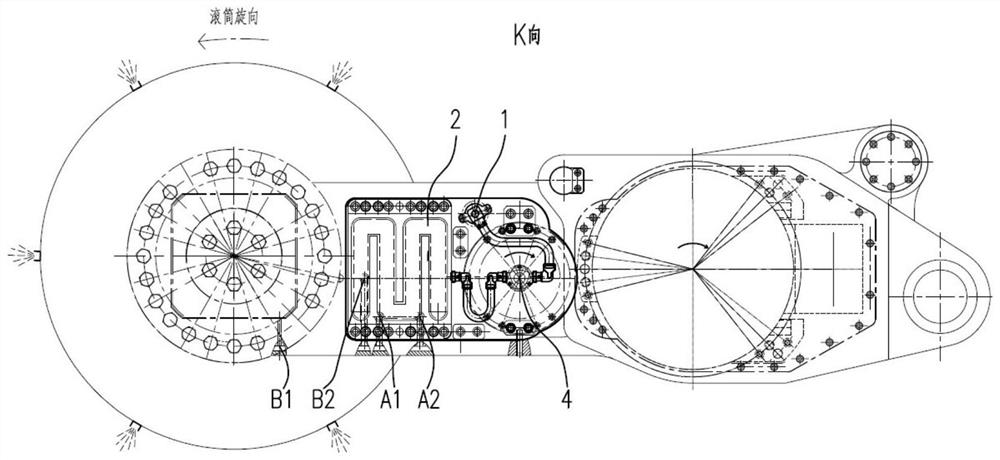

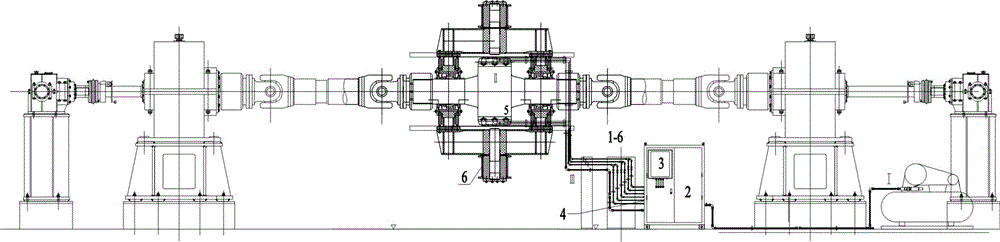

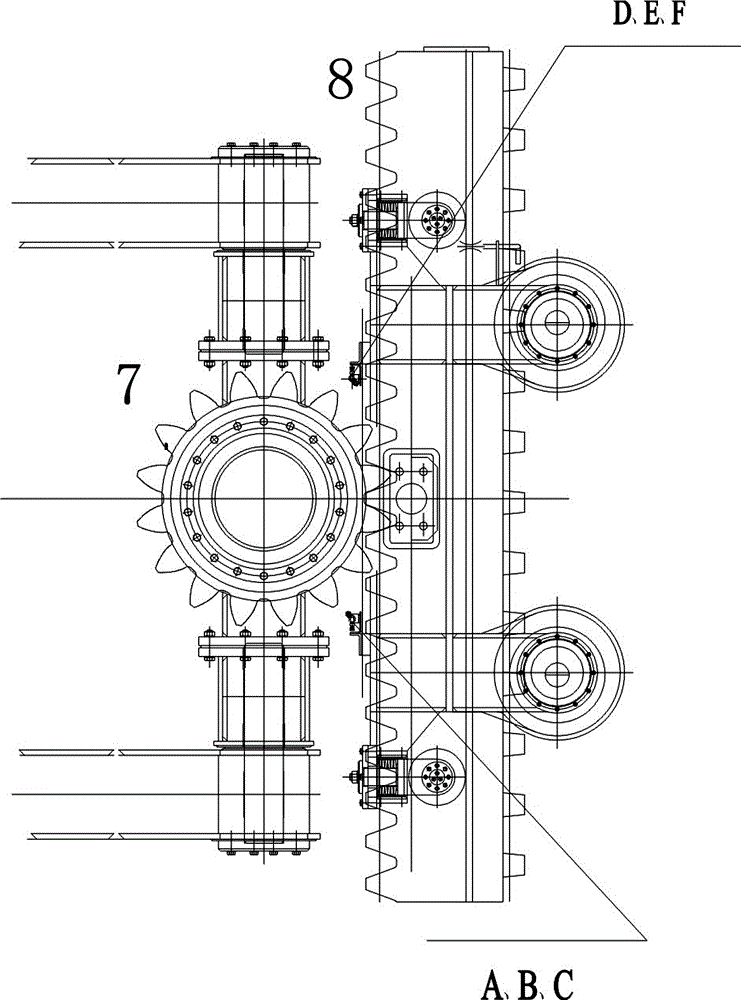

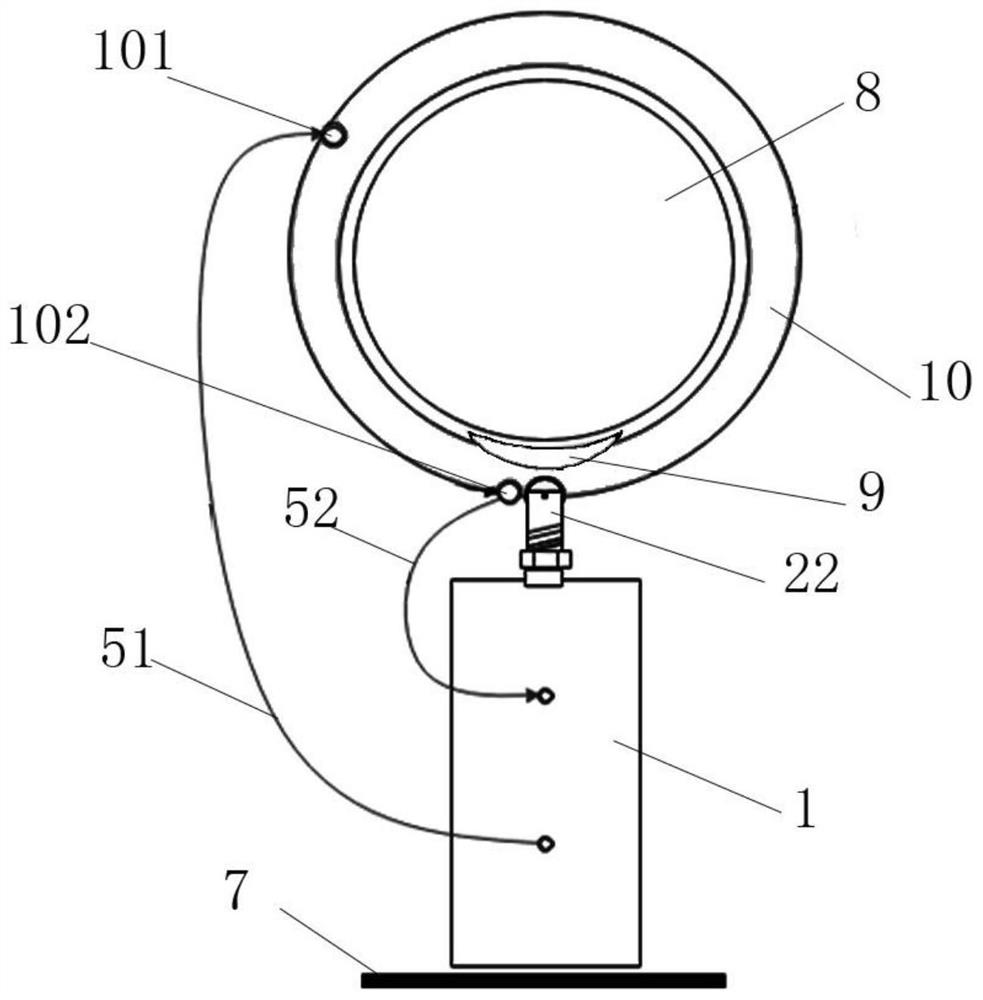

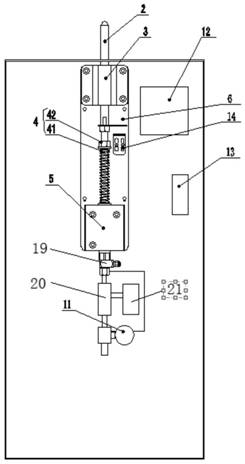

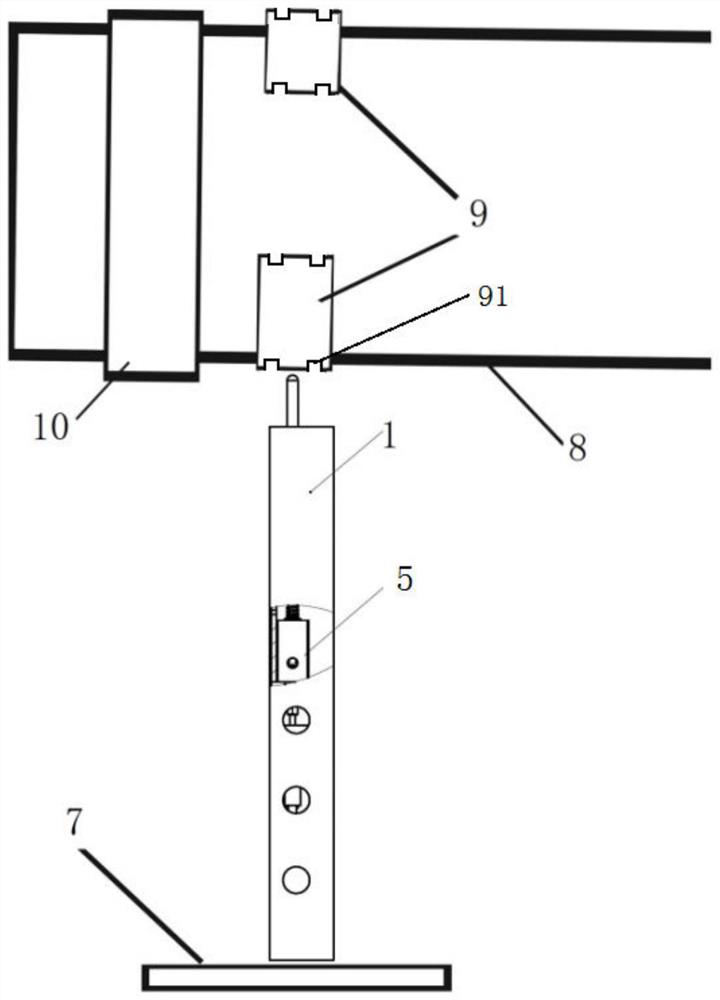

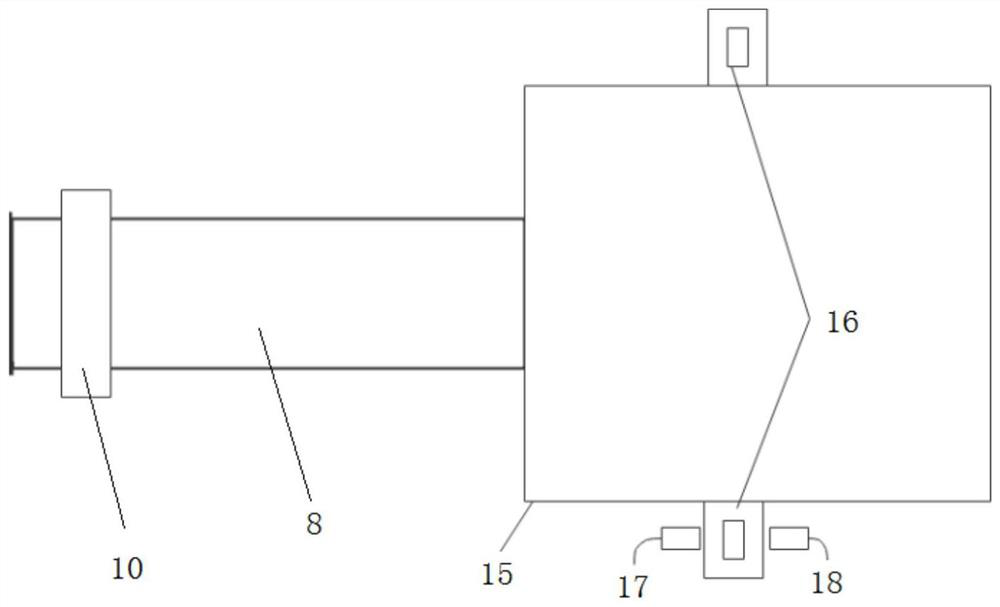

Periodic gear wheel spraying lubrication device and method with adaptability to displacement

ActiveCN105485321AImprove lubrication environmentContinuous and stable automatic lubricationGear lubrication/coolingSpray nozzleLubrication

The invention discloses a periodic gear wheel spraying lubrication device and method with adaptability to displacement. The periodic gear wheel spraying lubrication device comprises an air compressor air supply system, a fixed lubrication pump station, an increment type two-line distributor, lubricating oil nozzles and a pinion bracket mechanism, wherein the air compressor air supply system is connected to the fixed lubrication pump station through a first pipeline and then divided into two return pipelines; the first return pipeline is connected onto a pneumatic triplet, compressed air enters a pneumatic pump to enable the pneumatic pump to work after the compressed air is processed by the pneumatic triplet, and lubricating oil is output from an oil outlet of the pneumatic pump, reaches a hydraulic directional control valve after passing through a filter and is then connected to the lubricating oil nozzles through the increment type two-line distributor; the second return pipeline enters a third pipeline through the pneumatic pump and is then connected onto the lubricating oil nozzles through the increment type two-line distributor. According to the periodic gear wheel spraying lubrication device and method with adaptability to displacement, the problems of failure of tooth profile surface, reduction of transmission efficiency, reduction of driving performance and the like of gear driving due to oil shortage are solved.

Owner:CHINA GEZHOUBA GRP THREE GORGES CONSTR ENG CO LTD

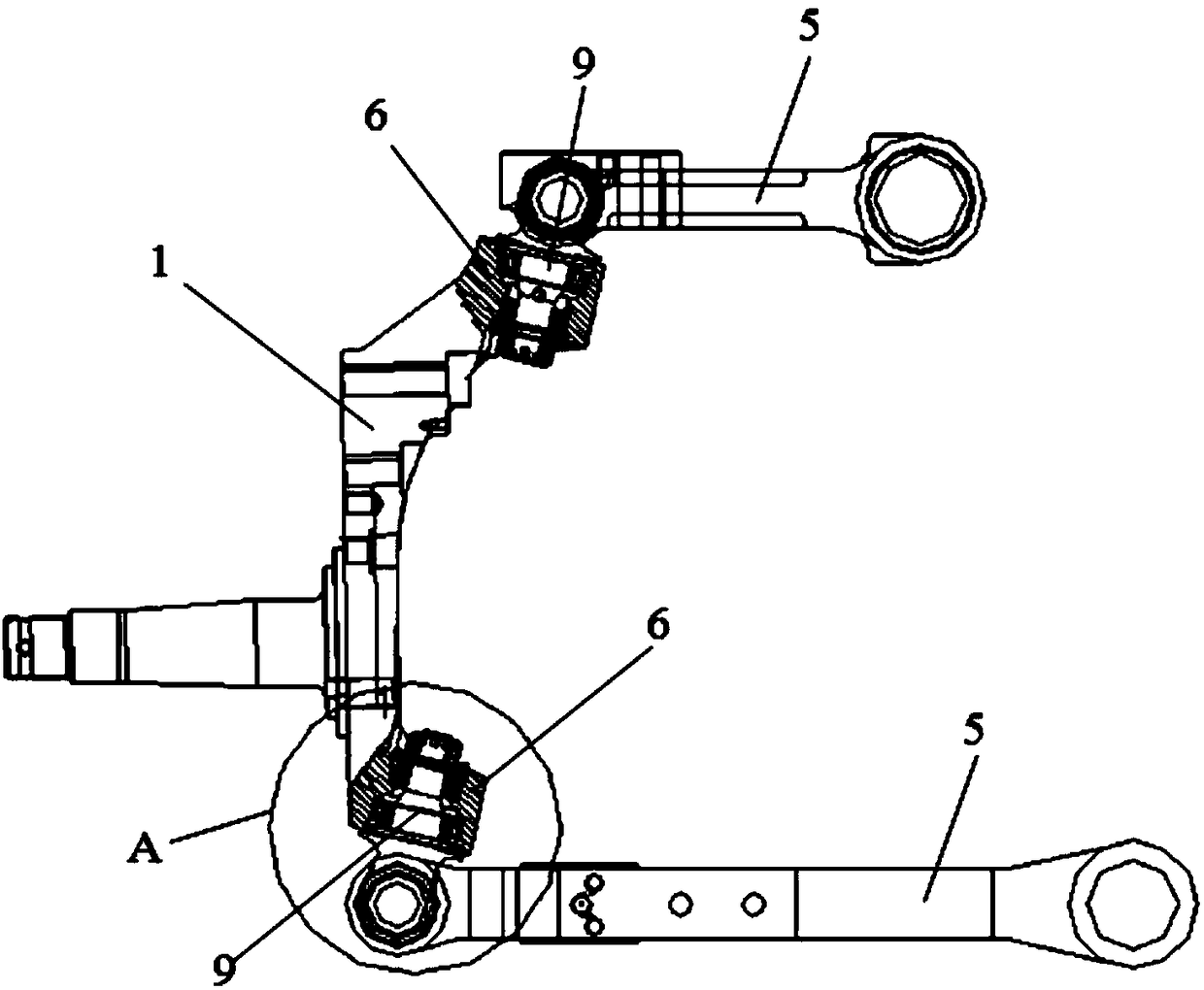

Novel transition arm structure

InactiveCN102452289AImprove lubrication environmentReduce wearPivoted suspension armsEngineeringRetaining ring

The invention relates to a novel transition arm structure which comprises a transition arm and bushing assembly, a transition arm bracket and shaft assembly, adjusting gaskets, a steering middle arm shaft retaining ring and locking nuts. A transition arm bracket and a shaft are welded together to form the transition arm bracket and shaft assembly; the transition arm and bushing assembly and the transition arm bracket and shaft assembly are assembled through the match of a bushing and the shaft and fixed through the steering middle arm shaft retaining ring and the locking nuts; the gap between the end surfaces of the transition arm and bushing assembly and the transition arm bracket and shaft assembly is adjusted by using the adjusting gaskets; in addition, two sides of the transition arm and bushing assembly are provided with an oil seal and a dustproof cover respectively; the adjusting gaskets can not cause abrasion to the components; if a transition arm is abraded, the matching gap can be reset by dismounting part of the adjusting gaskets; and moreover, the matching surfaces are fully sealed so that good lubricating environment can be ensured. Due to the characteristics, the abrasion of the transition arm can be greatly reduced, the service life can be prolonged, and the maintenance cost can be lowered.

Owner:FAW GROUP

Lubricating process suitable for spaceflight low-speed bearing

PendingCN114876962AImprove lubrication environmentExtend your lifeMachine bearings testingLubricant transferThermodynamicsSpaceflight

According to the lubricating technology suitable for the spaceflight low-speed bearing, a novel composite lubricating mode of lubricating oil and lubricating grease is adopted in the lubricating technology method, an early-stage grease filling test is carried out according to the structure and the size of the bearing, and the filling amount of the lubricating grease is obtained through a test result; the filling amount and the mixing ratio of the lubricating oil and the lubricating grease are reasonably distributed, so that the lubricating environment in a raceway of the bearing under the low-rotating-speed working condition is improved, and the effect of prolonging the service life of the bearing is achieved; moreover, a reasonable lubricating grease filling process is formulated, the bearings are screened through a running-in test, the filling amount of the lubricating grease is reasonably distributed according to the areas of inner and outer ring raceways of the bearings, and the filling amount and the filling uniformity of the lubricating grease on the inner and outer raceways of the bearings are ensured through weighing of a precision balance and filling of a special grease filling worker. The grease filling process and running-in screening of the bearing are necessary verifications for ensuring flexible operation and reasonable scheme of the bearing under the condition of adopting the novel composite lubrication mode.

Owner:LUOYANG BEARING RES INST CO LTD

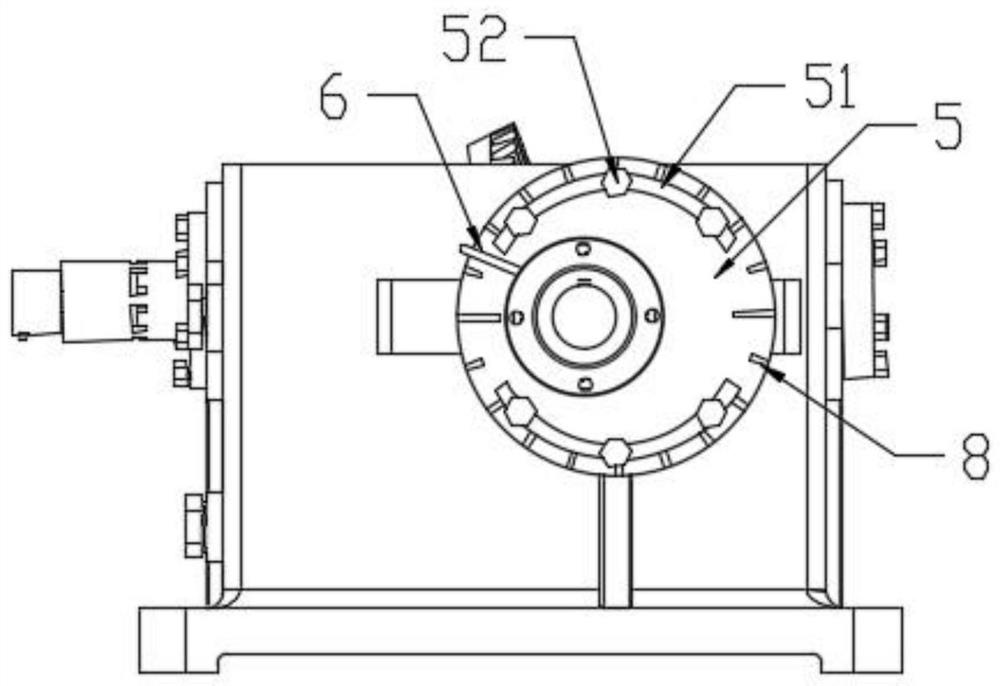

Lubricating oil circulating system for heavy load bearing of wind generating set

PendingCN114646013AExtended service lifeExtended use timeMeasurement devicesConduits/junctionsOil and greaseReciprocating motion

The invention belongs to the technical field of fans, and particularly relates to a lubricating oil circulating system for a heavy-load bearing of a wind generating set. Comprising a spindle, a main bearing, a circulation triggering device, a piston rod and a grease circulation device. A main bearing is arranged on the main shaft, and an oil injection hole and an oil discharge hole are formed in the main bearing; an oil injection pipe of the grease circulating device is connected with the oil injection hole, and an oil suction pipe of the grease circulating device is connected with the oil discharge hole; a circulating trigger device is arranged on the periphery of the main shaft; the grease circulating device is connected with one end of the piston rod; a bull eye wheel is arranged at the other end of the piston rod and is used for being in contact triggering with a circulating triggering device; the piston rod is driven to reciprocate through rotation of the main shaft and contact of the piston rod and the circulation triggering device, the grease circulation device sucks lubricating oil flowing out of the main bearing, and the lubricating oil flows back to a main bearing oil injection hole after being filtered to supplement lubrication. Main shaft displacement sensors are arranged on the upper side and the lower side of the main shaft. Circulating flow lubrication of the bearing can be achieved, and the service life of the main bearing is prolonged.

Owner:沈阳锐源创能源科技有限公司

A self-adjusting bevel gear test box with adjustable offset distance

The invention discloses a self-adjusting bevel gear test box with adjustable offset distance, which belongs to the technical field of mechanical design and includes a box body. Two mutually perpendicular wheel shafts are horizontally arranged in the box body, and a small cone is arranged on the pinion shaft. Gear, the large gear shaft is provided with a shaft sleeve, and the shaft sleeve is provided with a rotatable large bevel gear; the two ends of the shaft sleeve are provided with fixed nuts; a compression spring is arranged between the fixed nut and the shaft sleeve; the pinion shaft is rotatable Set in the eccentric shaft seat; the eccentric shaft seat is connected with the adjustment disc; the eccentric shaft seat is provided with a large gear; the box is provided with a worm gear mechanism, which includes a worm and a worm gear arranged on the shaft of the large gear; the small gear on the worm The gear meshes with the bull gear; the worm gear is connected with the fixed nut through a spline sleeve mechanism. The present invention can test and analyze various dynamic performances of bevel gears with different offset distances and installation distances through a gear box, and can automatically adapt and change the position of the bevel gears according to the adjustment of the offset distance during the test process.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

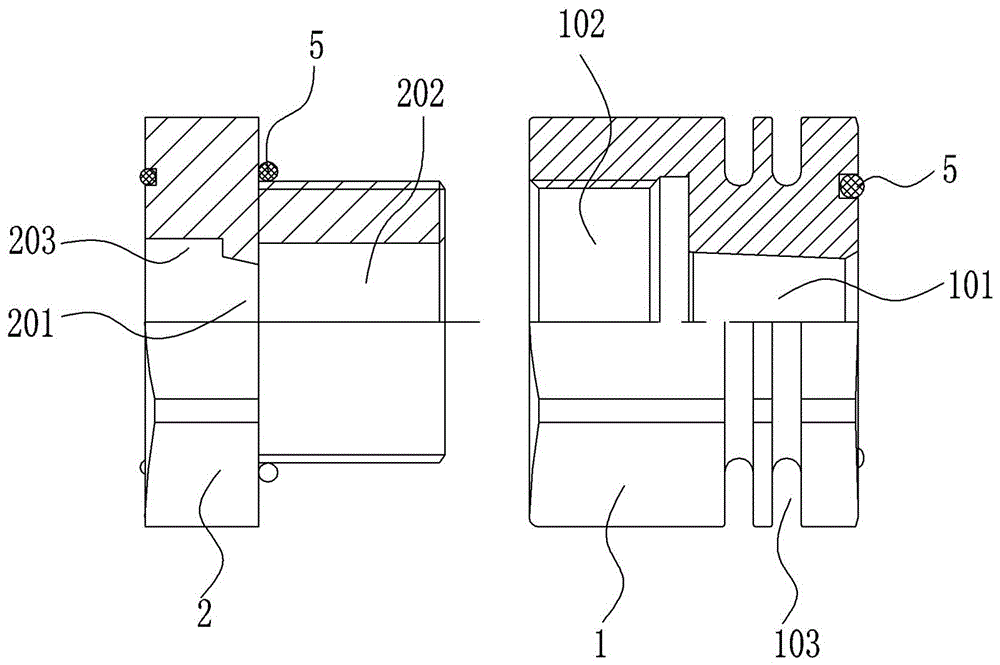

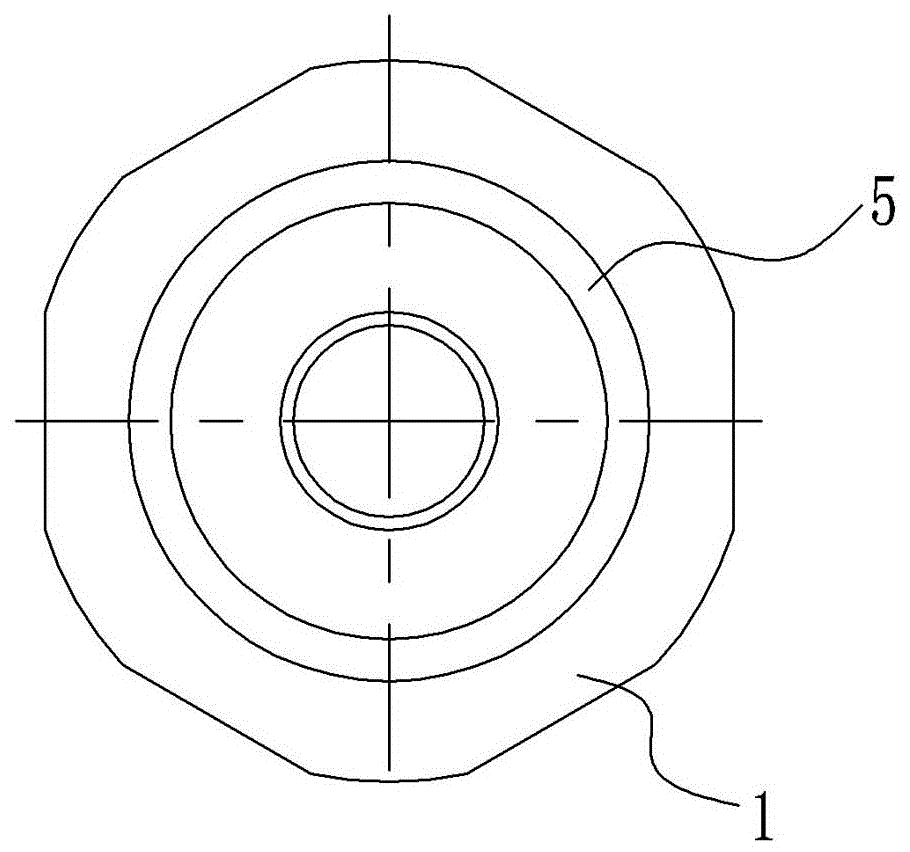

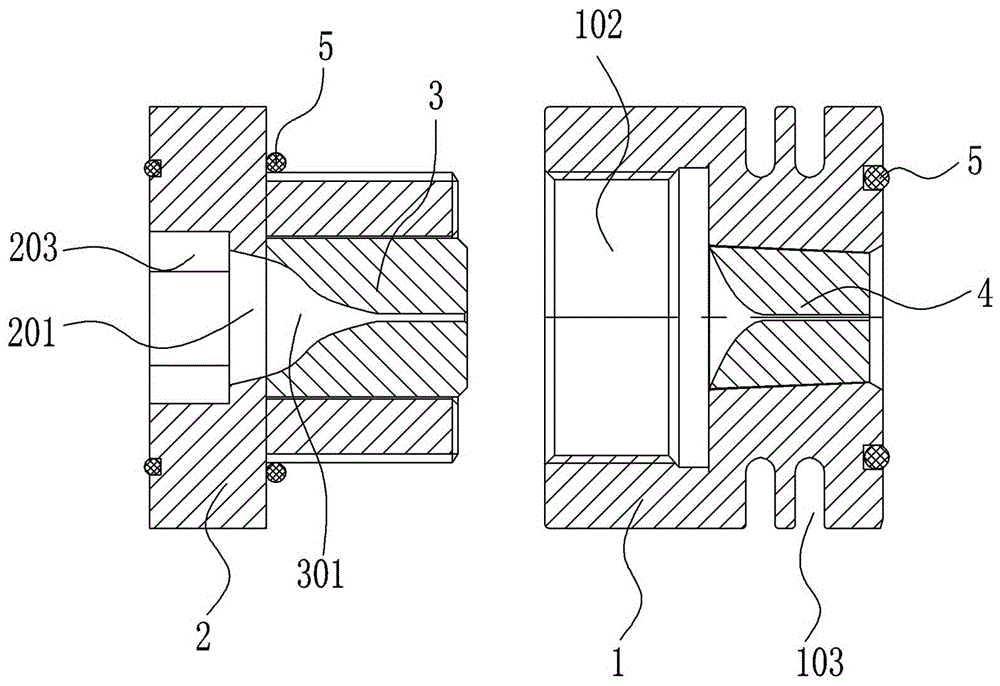

a valve guide

ActiveCN106703926BPrevent inflowPrevent outflowLubrication of auxillariesMachines/enginesEngineeringValve guide

The invention discloses a valve guide. The upper end surface of the valve guide body (2) is a slope inclined from the outer edge to the center, and the slope surface has a plurality of lines starting from the center of the valve guide body (2). The secondary grooves (1) radiating outward in an array and adjacent to each other are distributed in each of the secondary grooves (1) starting from the center of the valve guide body (2). A plurality of wedge-shaped blind holes that radiate outward in a uniform distribution in an array structure and are distributed in a gradient stack to form a wedge-shaped included angle, the wedge-shaped edge (5) of each of the wedge-shaped blind holes is arched, and the edge is sharp, and its opening is along the The secondary groove (1) faces the inner center of the valve guide body (2); the upper end face of the valve guide body (2) is provided with an arched boss (6) on the circumferential edge. The invention is a valve guide which can realize continuous unidirectional spreading and conveying of fluid without external power, thereby improving lubricating environment.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Intelligent lubrication system for heavy-duty bearings of wind turbines

An intelligent lubricating system for a heavy-duty bearing of a wind power generating set belongs to the technical field of wind turbines. Installed on the base of the engine room, it includes a trigger device and an oil suction and injection pipeline connected to the main bearing. The trigger device includes an action connecting rod and a trigger block. The trigger block is arranged on the outer periphery of the main shaft. One end of the action link is a free end for It is triggered by contact with the trigger block, and the other end is connected to the oil injector. The oil suction and oil injection pipeline includes an oil suction pump, an oil suction filter, a grease storage tank, an oil injector and an oil injection filter connected in sequence. The oil suction pump is connected to the main bearing on the main shaft Oil outlet, the oil outlet pipe of the oil injection filter is connected to the oil injection port of the main bearing to form a lubricating oil circulation; through the rotation of the main shaft, the action connecting rod contacts the trigger block, driving the action connecting rod to reciprocate, and the oil suction pump sucks the lubricating oil flowing out of the main bearing , After being filtered by the oil suction filter, it is stored in the grease storage tank, and then filtered by the oil injector and the oil injection filter, and then returned to the oil injection port of the main bearing for supplementary lubrication. The invention can realize the circulation lubrication of the bearing and improve the service life of the main bearing.

Owner:沈阳依纳科技有限公司

Oil-pneumatic spring self-lubricating compensating floating piston

ActiveCN106838096BReduce frictionImprove lubrication environmentSpringsGas and liquid based dampersGas springEngineering

The invention aims at providing an oil and gas spring type self-lubricating compensation floating piston. The oil and gas spring type self-lubricating compensation floating piston comprises a small piston, an automatic lubricating floating piston, a small piston sealing ring and a clamp spring, wherein the small piston is sheathed in a center weight reducing groove of the automatic lubricating floating piston; lubricating oil or lubricating grease is arranged into an oil storage cavity surrounded by the small piston and the automatic lubricating floating piston; the small piston sealing ring is arranged in the small piston in the radial direction, and is matched with the inner wall of a weight reducing hole to form radial sealing; the clamp spring is arranged at the upper end of the weight reducing hole, so as to prevent the small piston from falling down from the automatic lubricating floating piston during high-speed movement; the side surface of the automatic lubricating floating piston is processed with a radial lubricating oil passage and a peripheral lubricating oil passage, a lubricating oil groove is arranged between a sealing ring at the oil side and a sealing ring at the gas side, and the lubricating oil passage is used for guiding the lubricating oil in the oil storage cavity into the lubricating oil tank and a radial gap between the automatic lubricating floating piston and a cylinder body.

Owner:CHINA NORTH VEHICLE RES INST

Crankshafts for rotary compressors, rotary compressors and refrigeration cycle devices

ActiveCN104819155BSolve the card machine problemImprove lubrication environmentRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention discloses a crankshaft for a rotary compressor, a rotary compressor and a refrigeration cycle device. The crankshaft comprises: a body and an eccentric part, the eccentric part is sheathed on the body, and a flexible structure is arranged on the eccentric part and at least one of the oil pressure surfaces, the flexible structure is configured to deform inwardly when subjected to an external force in an inward direction, and the oil pressure surface is configured to rotate around the rotation center axis of the crankshaft. The distance between the central axes of the parts is smaller than the distance between the tail end of the hydraulic surface and the central axis of the eccentric part. According to the crankshaft for a rotary compressor of the present invention, when the eccentric part is provided with the flexible structure of the above-mentioned structural features, it can effectively solve the problem of the rotary compressor jamming caused by the abnormal contact between the piston and the cylinder; when the eccentric When the oil pressure surface with the above-mentioned structural features is provided on the upper part, a high-pressure oil wedge can be formed at the end of the oil chamber, thereby increasing the inlet oil pressure and improving the lubrication environment between the eccentric part and the piston.

Owner:GUANGDONG MEIZHI COMPRESSOR

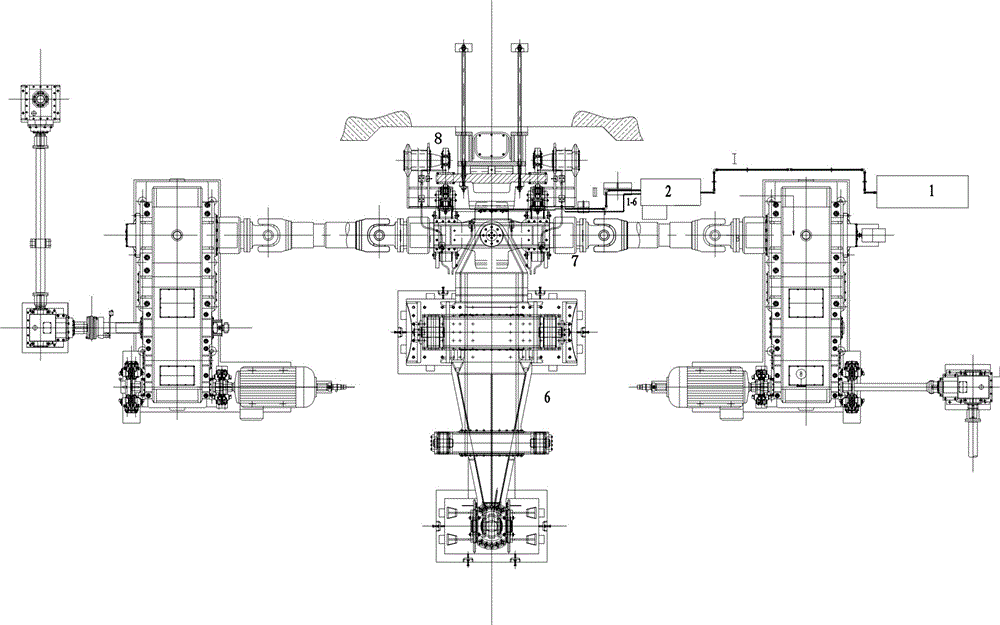

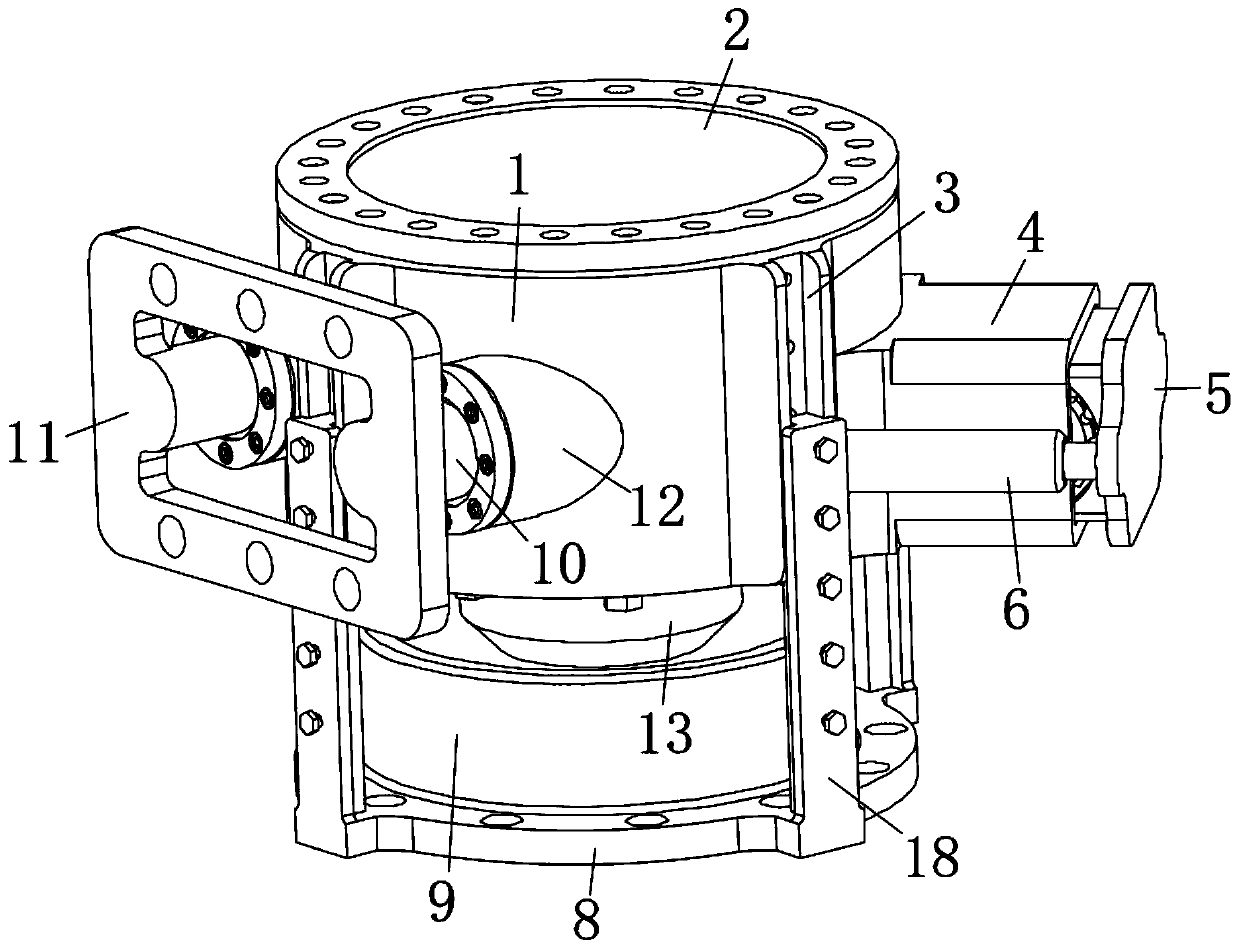

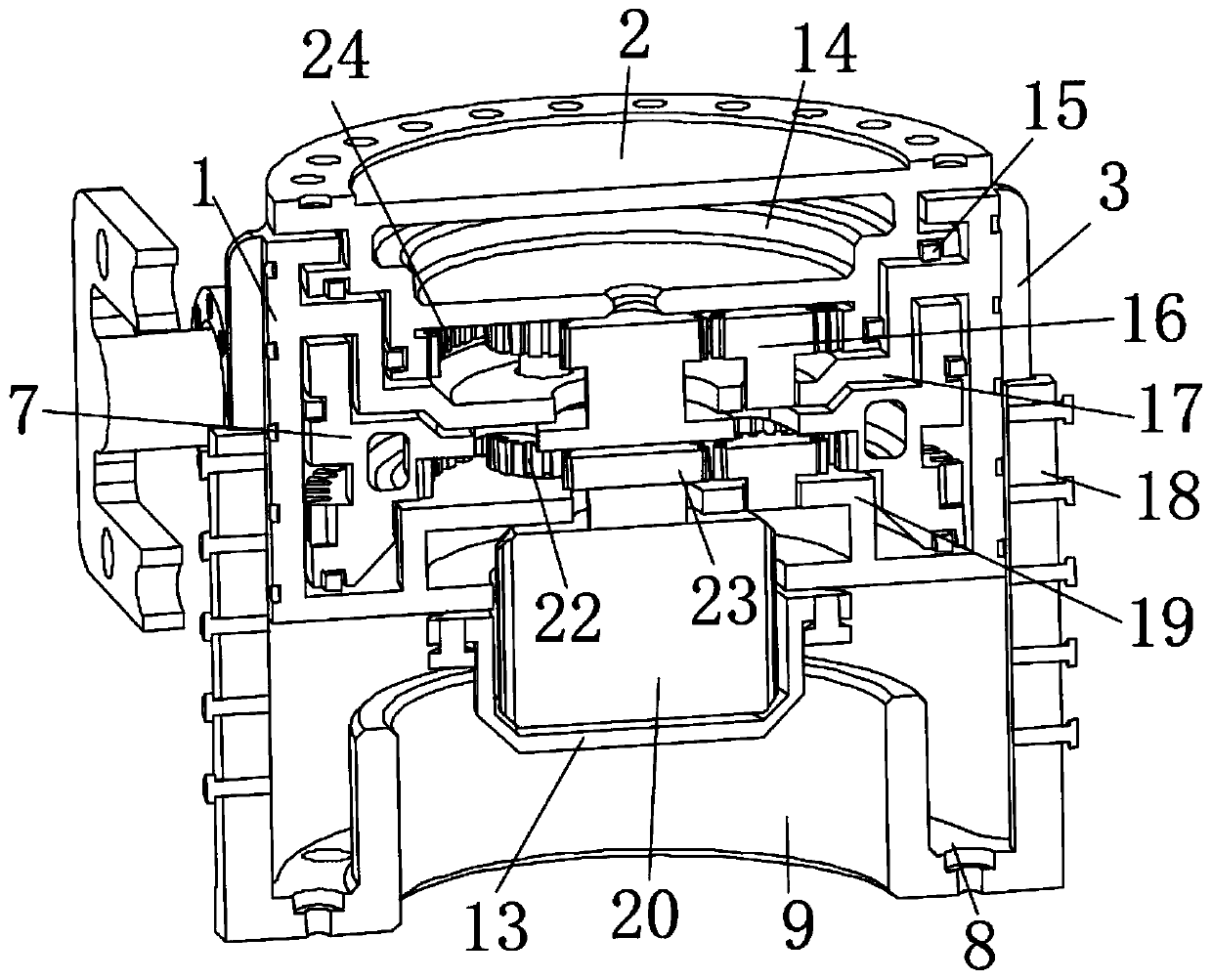

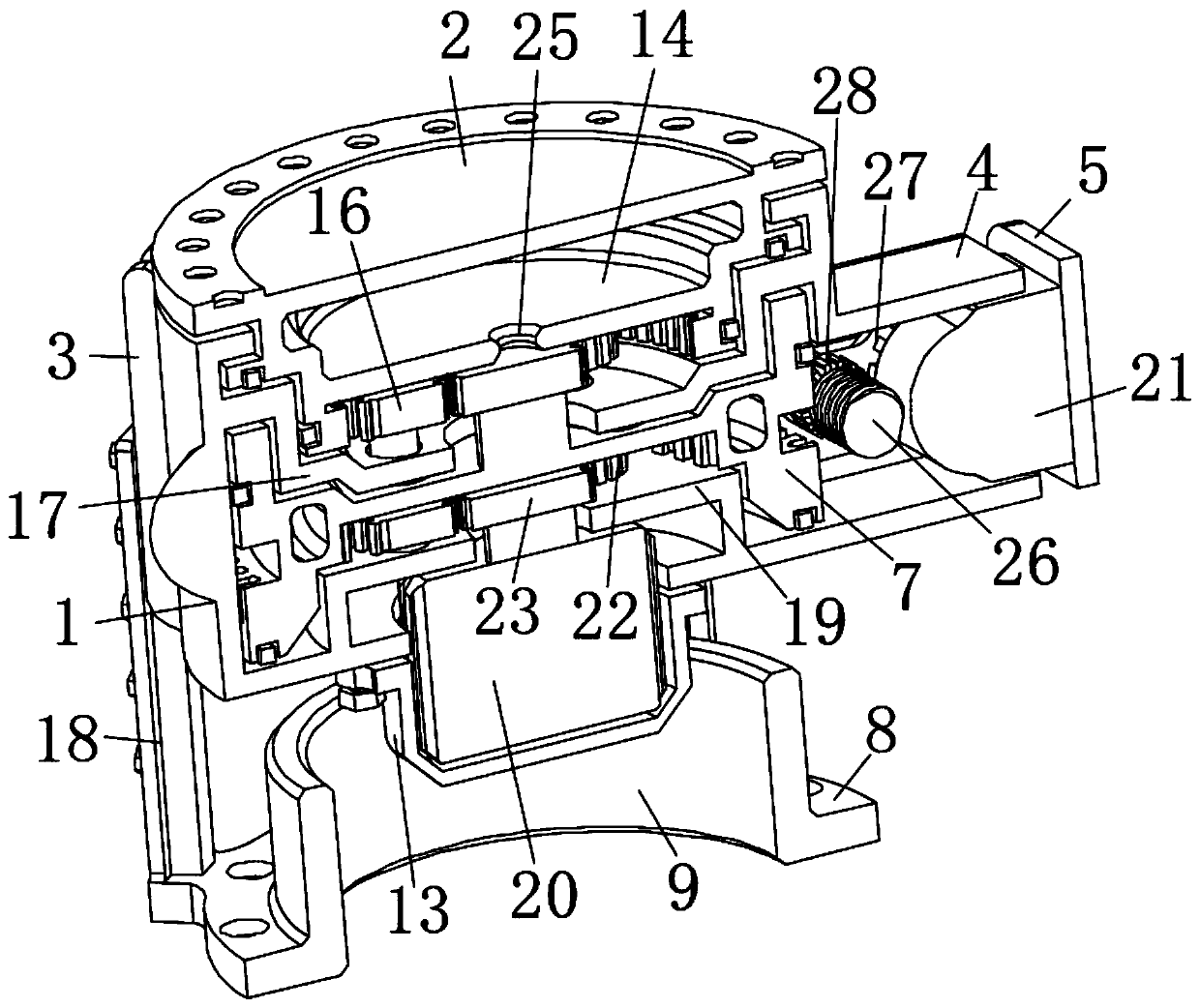

Gear type rotating driving device

InactiveCN110206857AIncrease profitHighly integratedGear lubrication/coolingToothed gearingsReducerMechanical equipment

The invention relates to the technical field of mechanical equipment design, and discloses a gear type rotating driving device. The gear type rotating driving device comprises an outer shell body, a lower fixing plate is fixedly arranged at the bottom of the outer shell body, moreover, a main motor is fixedly arranged on the lower fixing plate, and a protective cover which sleeves the outer side of the main motor is fixedly arranged at the bottom of the outer shell body through bolts. According to the gear type rotating driving device, switchable dual-power-source drive is adopted, the main motor is used for providing conventional rapid rotating drive, an auxiliary motor finely adjusts a pressure-bearing seat through cooperation between a worm and an outer gear ring and provides a self-locking function, two stages of planetary gear reducers are further designed inside the gear type rotating driving device, so that a reducer is not required to be externally connected, the utilization rate of the internal space is increased, the integration level is higher, moreover, the interior is provided with a better lubricating environment, the running abrasion is effectively reduced, moreover,the structure is easy to detach, and the maintenance is convenient.

Owner:嘉兴砺安贸易有限公司

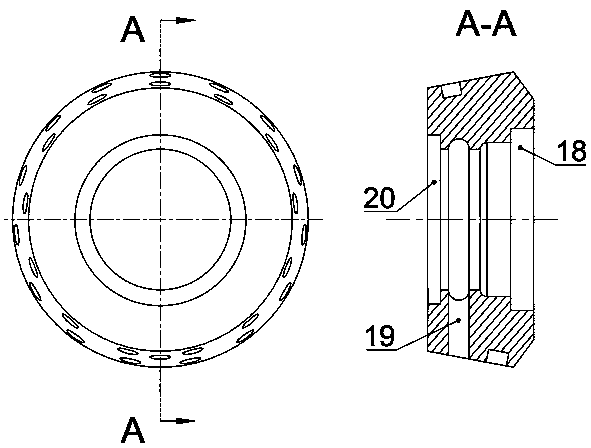

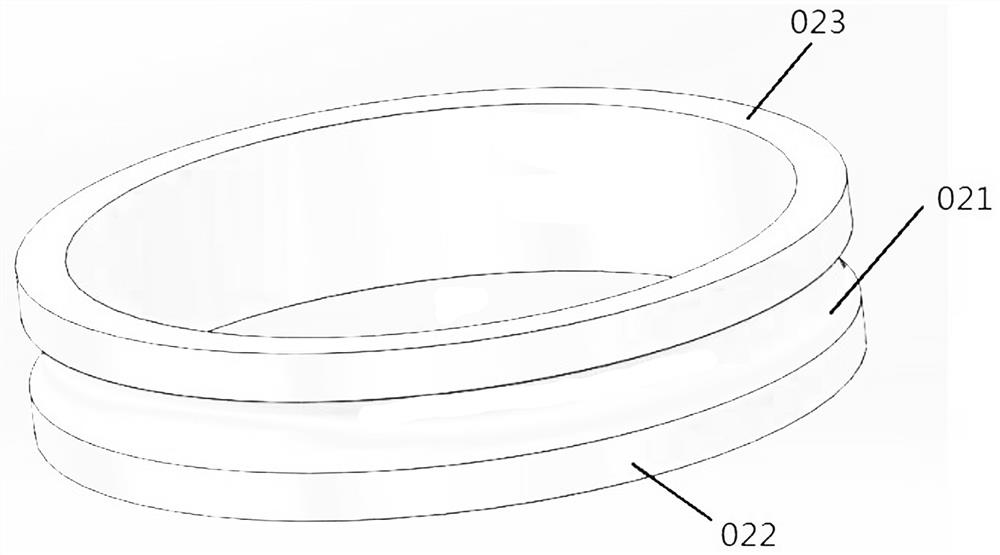

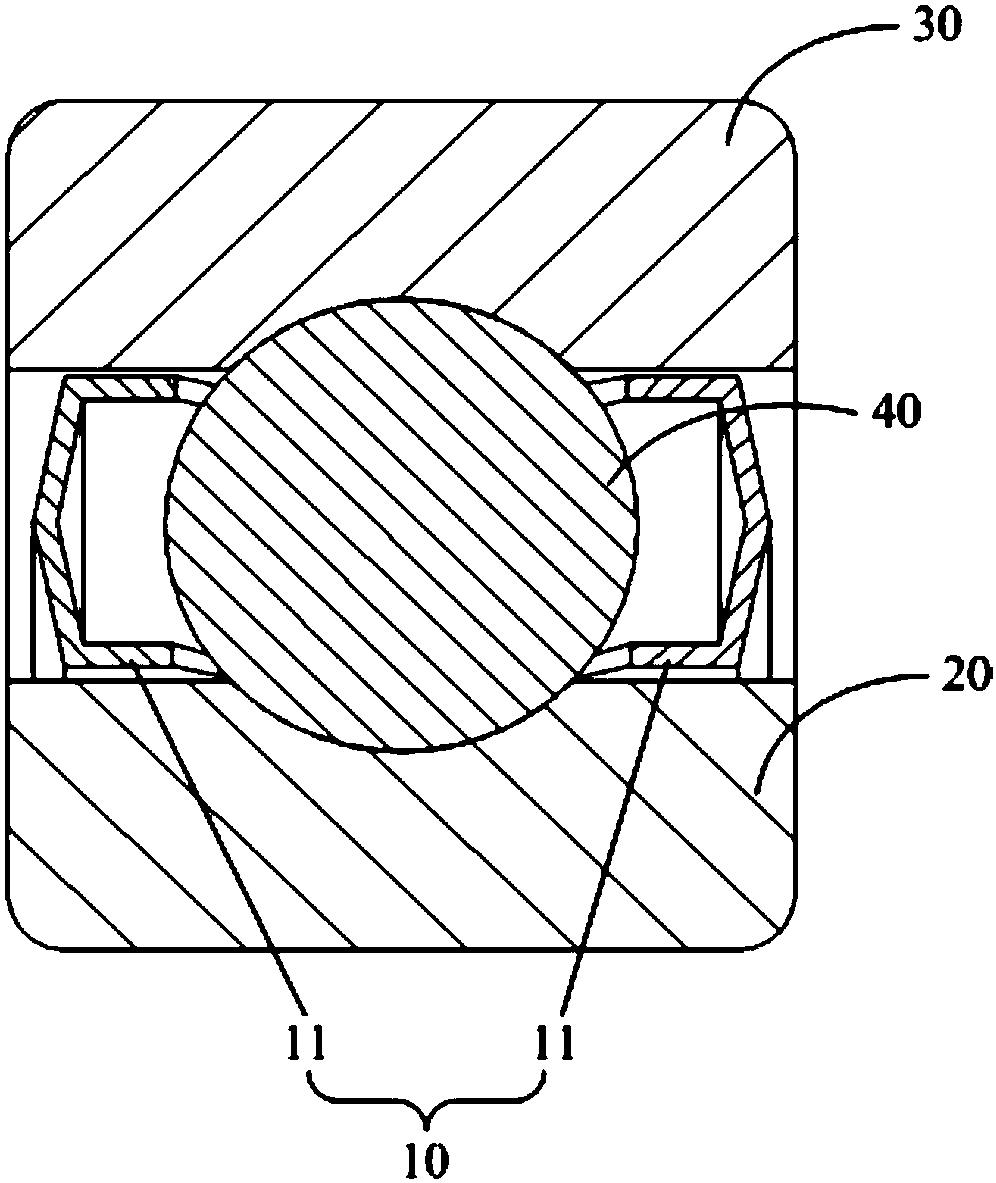

Bearing and cage thereof

InactiveCN108131396AImprove lubrication environmentBearing componentsLubricationMechanical engineering

The invention provides a bearing and a cage thereof. The cage of the bearing comprises support rings which are coaxial and arranged face to face, wherein an annular groove opening to the other supportring is formed coaxially in each support ring; each support ring comprises a bottom for forming the bottom wall of the corresponding annular groove as well as side parts located on two sides in the radial direction of the bottom to form side walls of the corresponding annular groove, and a plurality of pockets are distributed in the circumferential direction of the side parts, so that a ball canbe arranged axially in a pocket manner; the pockets in the side parts of the two sides in the radial direction of each bottom are in one-to-one correspondence for pocket arrangement of one ball. The lubrication environment between the cage and the ball can be improved effectively.

Owner:SCHAEFFLER TECH AG & CO KG

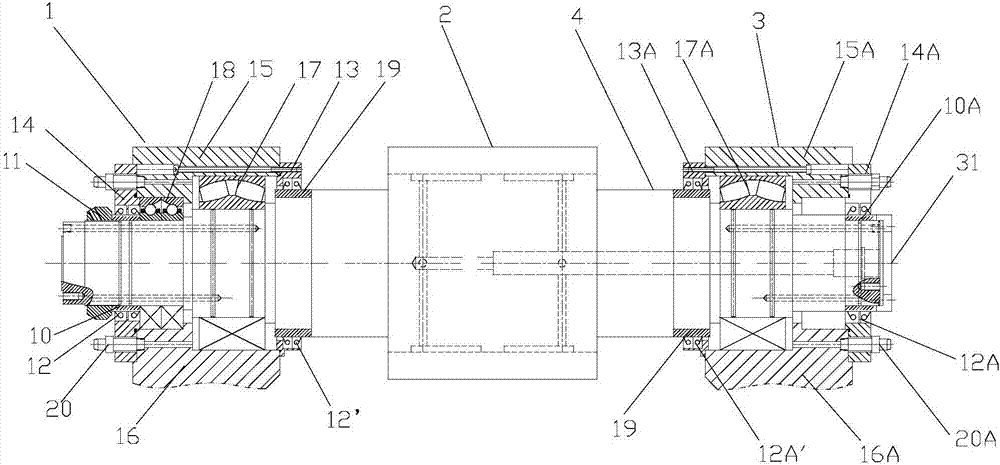

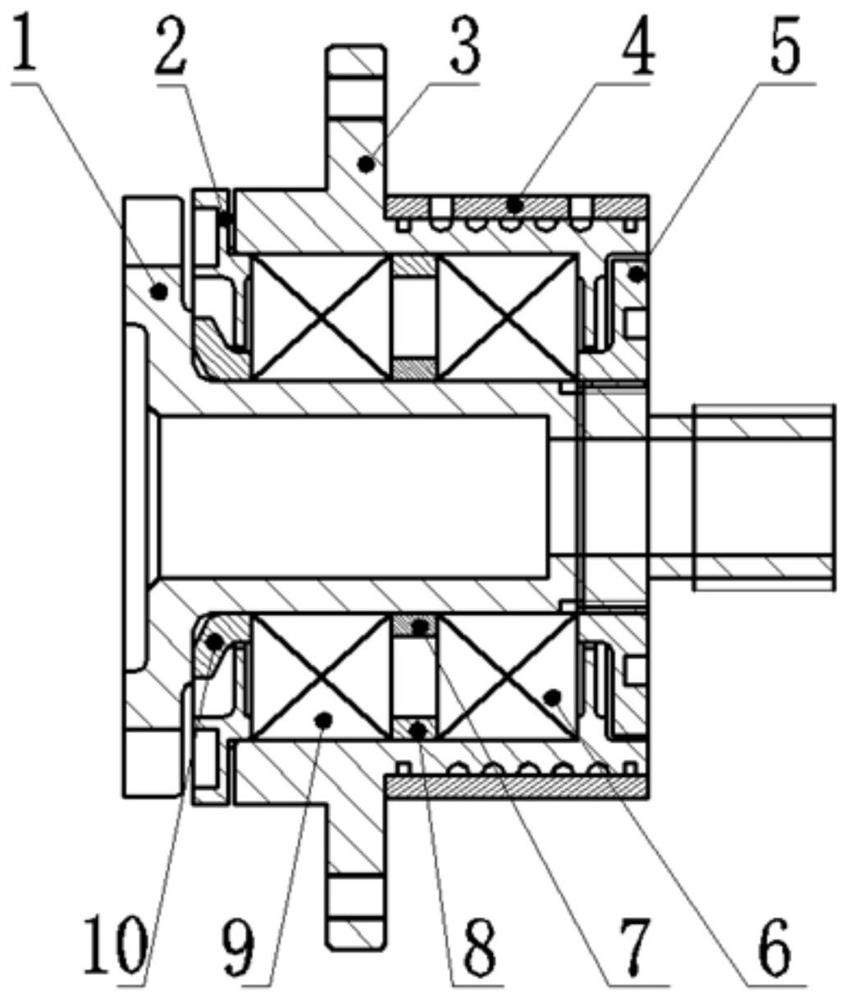

Active vibration isolation shafting assembly with long life and high precision for space

InactiveCN112460186AImprove featuresImprove running smoothnessSpringsNon-rotating vibration suppressionBall bearingVibration isolation

The invention discloses an active vibration isolation shafting assembly with long life and high precision for space. The active vibration isolation shafting assembly comprises an upper bearing, a lower bearing, a labyrinth seal gland, a supporting shaft, a bearing seat and an outer sleeve, wherein the upper bearing and the lower bearing are a pair of angular contact ball bearings and are arrangedon the supporting shaft in a sleeving manner in a back-to-back mounting manner; the bearing seat is arranged outside the upper bearing and the lower bearing in a sleeving manner; a spiral channel is formed in the surface of the bearing seat; the labyrinth seal gland is arranged on the outer end surface of the bearing seat and is used for axially positioning the upper bearing and the lower bearing;the outer sleeve is arranged outside the bearing seat, and a closed cavity is formed between the outer sleeve and the spiral channel of the bearing seat; and the cavity is filled with an electrorheological fluid damping material. The service life of the bearings is greatly prolonged, active vibration isolation is achieved, and the rotating precision and the control precision of the shafting assembly are improved.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com