Oil and gas spring type self-lubricating compensation floating piston

A floating piston, oil-gas spring technology, applied in the direction of spring, spring/shock absorber, gas-hydraulic shock absorber, etc., can solve the problems of reducing the reliability of oil-gas springs, shortening service life, poor lubrication environment of sealing rings, etc., to achieve good Lubricates the environment, prolongs the service life, and reduces friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawings and examples.

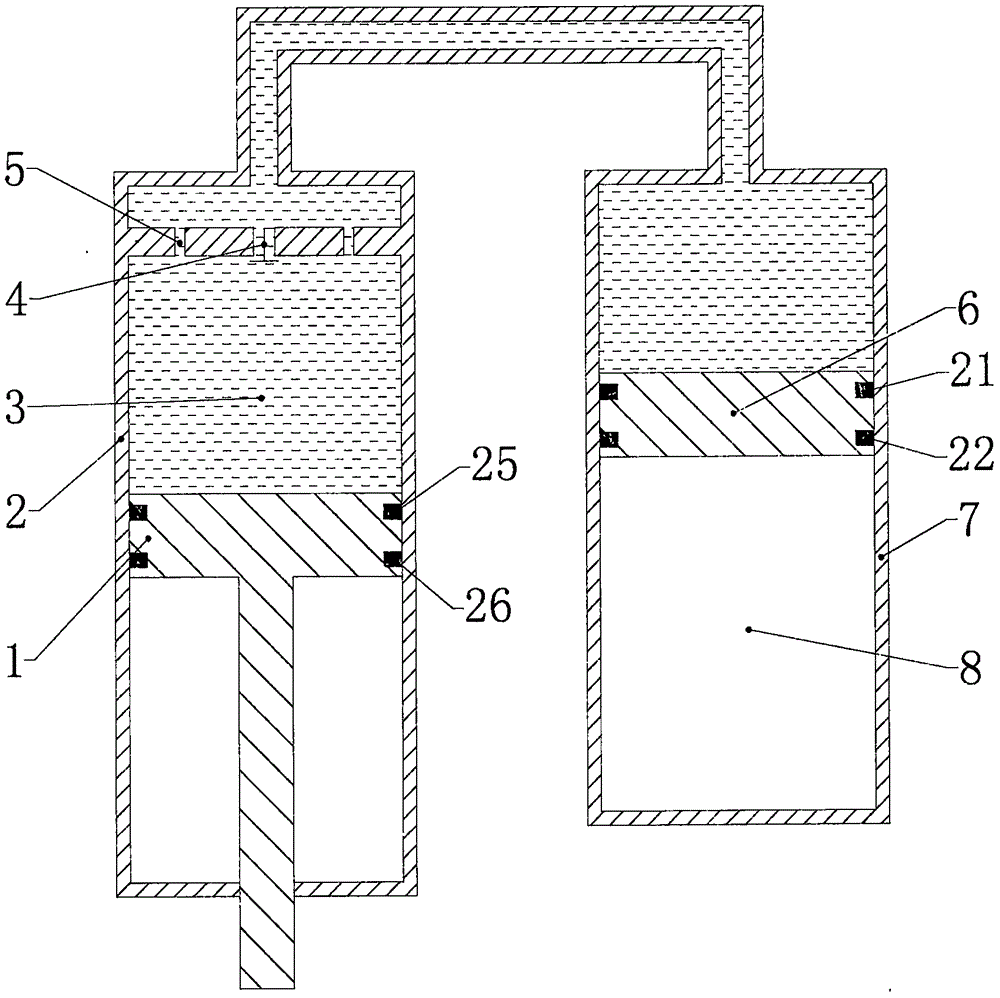

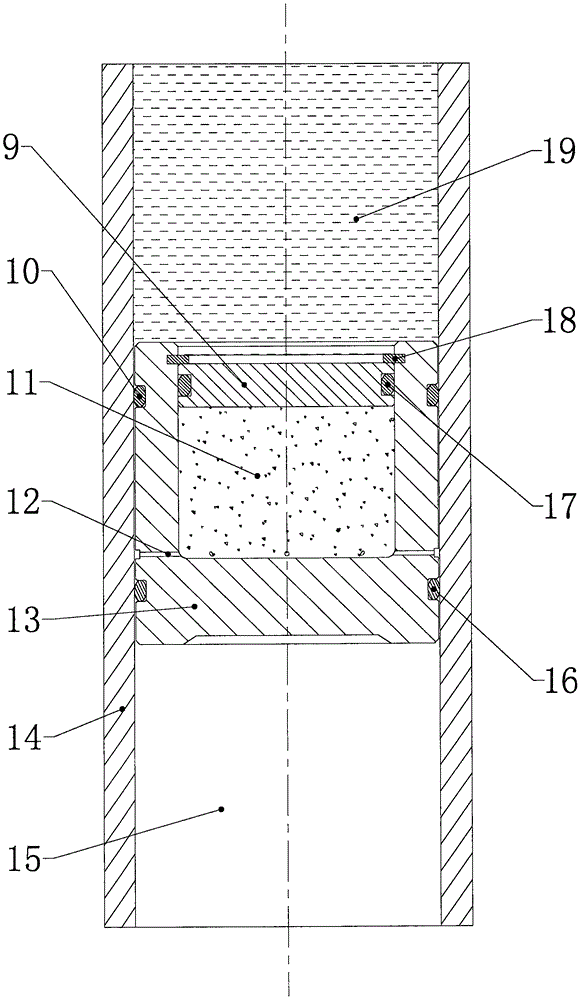

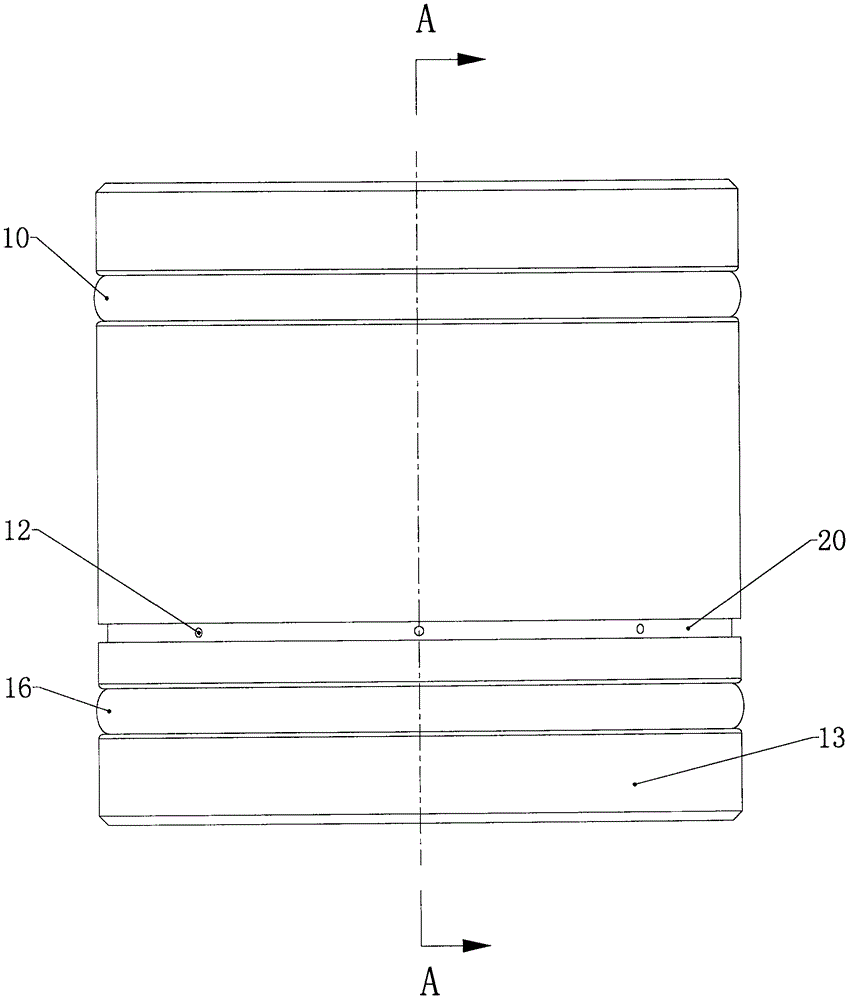

[0013] figure 1 It is a diagram of the working principle of the oil-gas spring. The inner cavities of the oil cylinder 2 and the cylinder 7 are connected together through the oil passage. The damping valve 4 and the main piston 1 are installed in the oil cylinder 2. A high-pressure combined oil seal is arranged on the main piston 1 for Seal the high-pressure oil 3 in the inner cavity, specific plan 1: a combination of two seals, in which the Ster seal is used as the first oil seal 25, which is arranged on the side close to the hydraulic oil, has a one-way sealing capability, and the sealing direction faces the oil side, the second oil seal 26 close to the side of the oil-gas spring annular chamber can use a gray ring, which has two-way sealing ability, and can also use a step seal with one-way sealing ability, and the sealing direction is towards the oil side....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com