Wire separating type wire drawing combined die

A combined die and separate technology, used in wire drawing dies and other directions, can solve the problems of poor lubrication conditions and poor heat dissipation capacity, and achieve the effects of stable working environment, avoidance of explosion and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

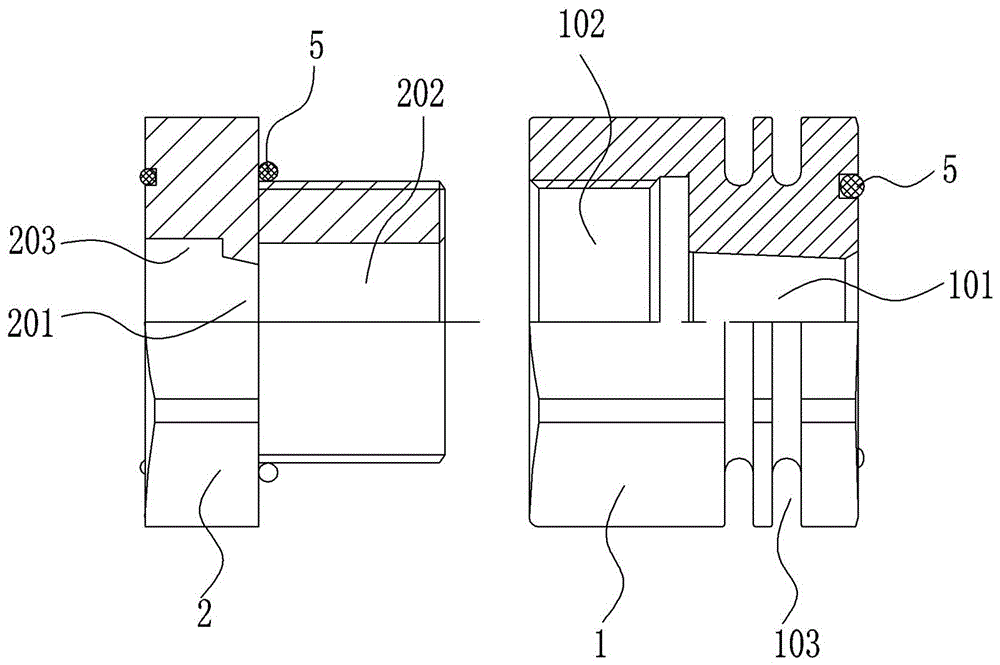

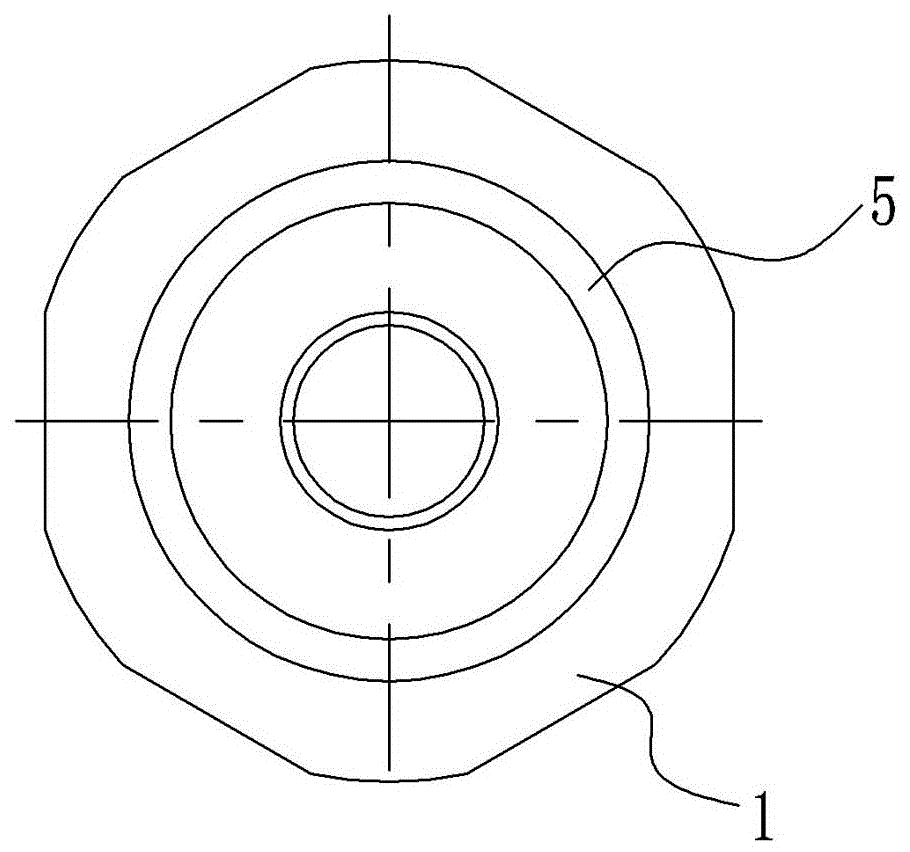

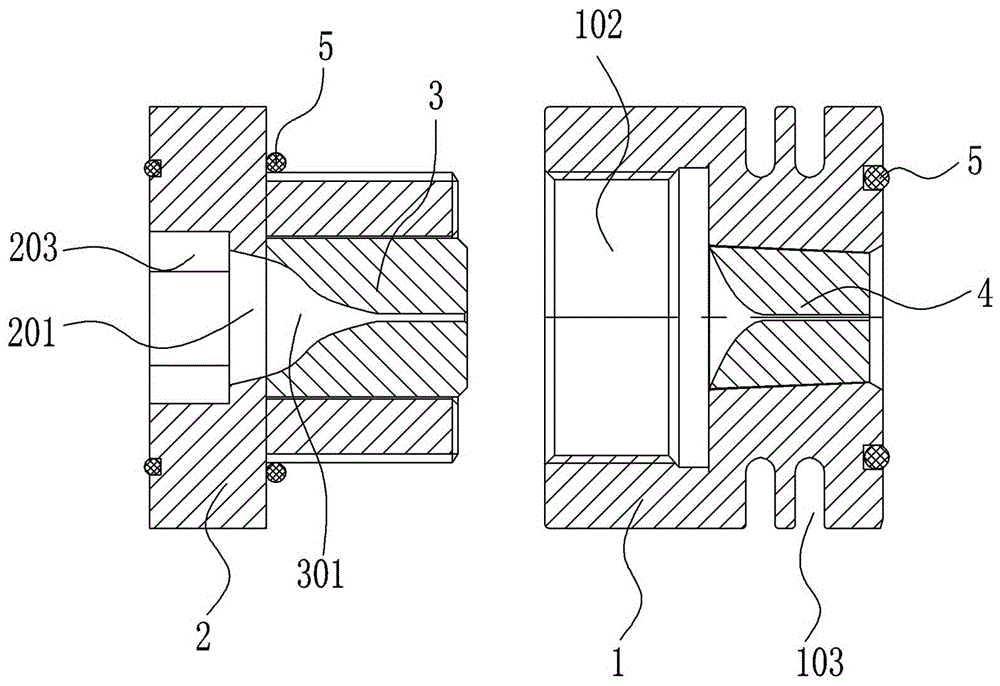

[0018] The wire separation type wire drawing combination die of the present invention comprises a mold body 1 and a mold cover 2, the mold body 1 is in the shape of a hollow cylinder, the cross-section of the mold body 1 and the mold cover 2 is a regular hexagon with rounded corners, The cylindrical inner surface of the mold body 1 is provided with an internal thread, and the outer diameter of the mold cover 2 is provided with an external thread, and the internal thread of the mold body 1 is installed in cooperation with the external thread of the mold cover 2; the mold cover 2 includes a uniform No taper lubricating powder cavity 201 and front core cavity 202, the front core cavity 202 is located at the end of the external thread of the mold cover 2, the lubricating powder cavity 201 is located at the opposite end of the external thread of the mold cover 2, and the The front core cavity 202 and the lubricating powder cavity 201 are arranged concentrically, and the front core c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com