Novel transition arm structure

A transition arm, a new type of technology, applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of loose transition arm, aggravated wear, high maintenance cost, reduce wear, improve life, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

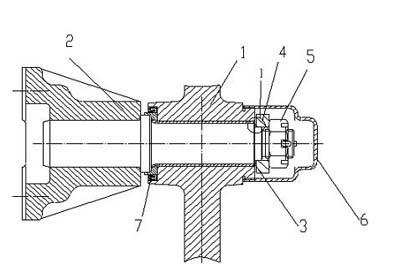

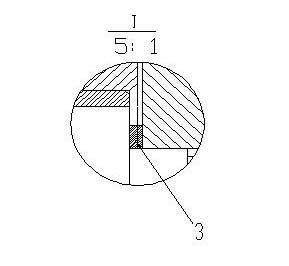

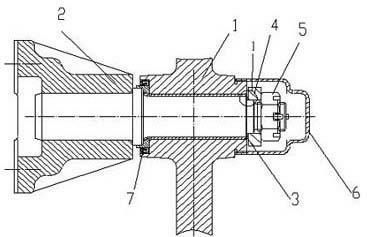

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, a new transition arm structure is composed of transition arm and bushing assembly 1, transition arm bracket and shaft assembly 2, adjusting gasket 3, steering intermediate arm shaft retaining ring 4, and lock nut 5. The transition arm The bracket and the shaft are welded to form the transition arm bracket and shaft assembly 2. The transition arm and bushing assembly 1 and the transition arm bracket and shaft assembly 2 are assembled through the cooperation of the shaft and the bushing. The lock nut 5 is used to fix the gap between the transition arm and bushing assembly 1 and the end face of the transition arm bracket and shaft assembly 2 by adjusting the spacer 3; the two sides of the transition arm and bushing assembly 1 are equipped with oil seals 7 and Dust cover6.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com