Active vibration isolation shafting assembly with long life and high precision for space

An active vibration isolation and long-life technology, which is applied in the direction of shock absorber-spring combination, shock absorber, vibration suppression adjustment, etc., can solve the design life and reliability that cannot meet the demand, unstable friction torque, abnormal speed response, etc. problems, achieve good lubrication characteristics and running stability, prevent vibration interference, and improve the effect of lubricating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical content, structural features, achieved goals and effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

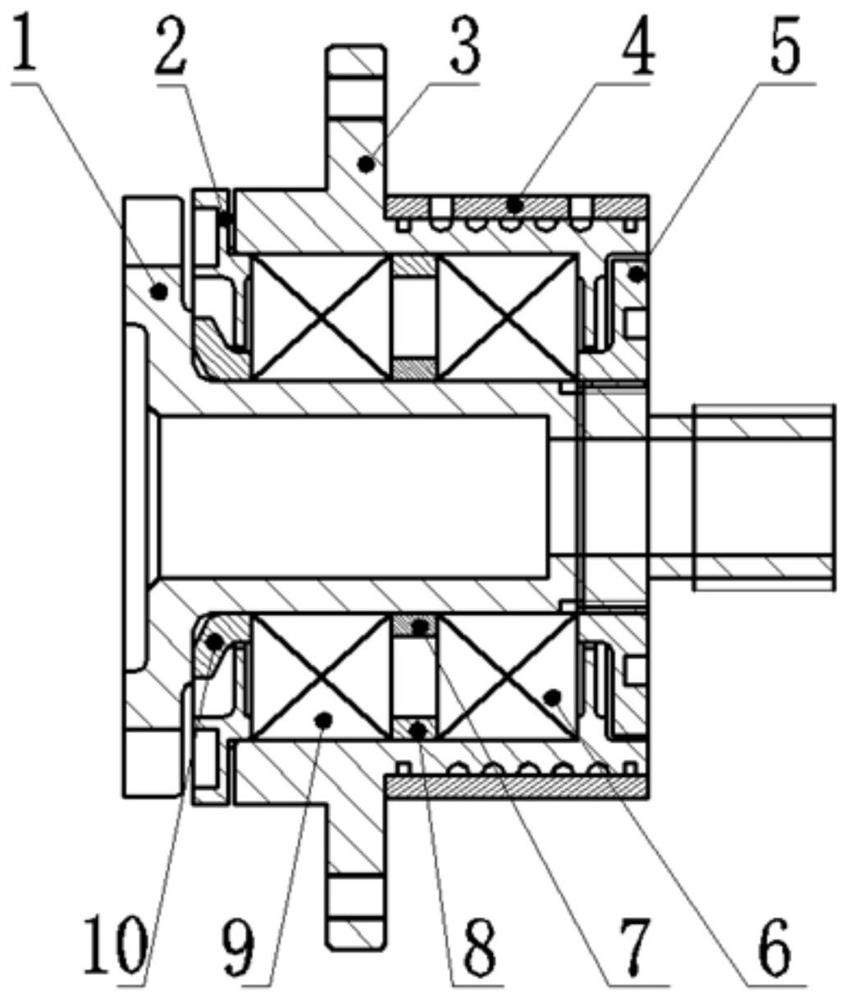

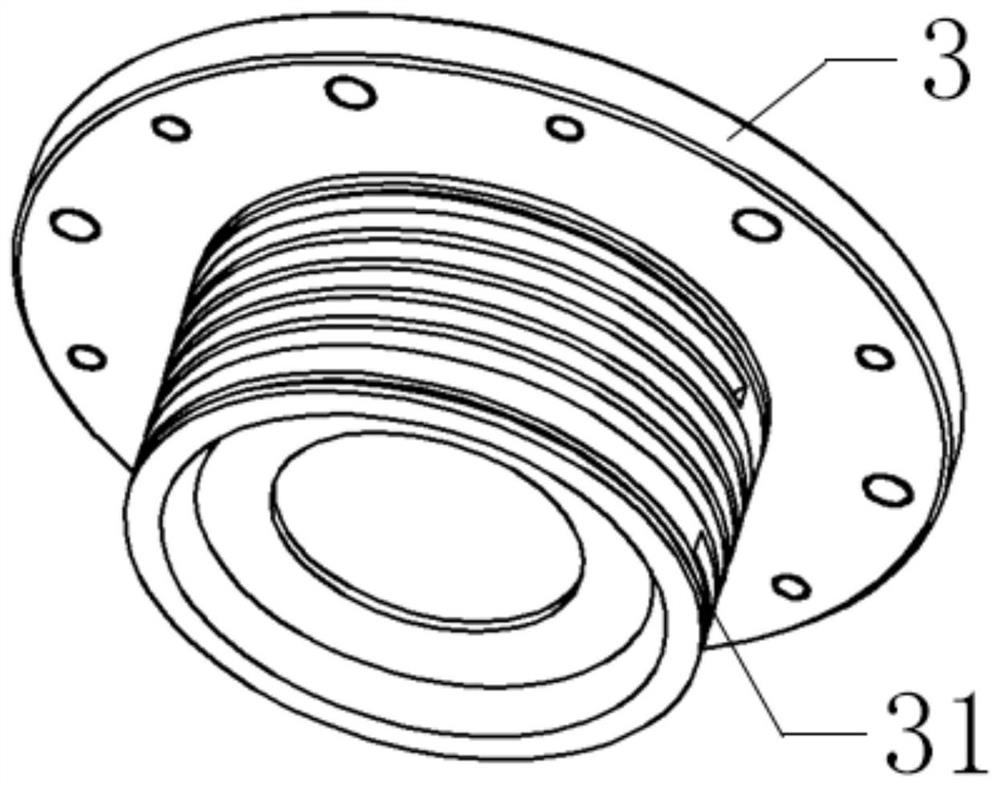

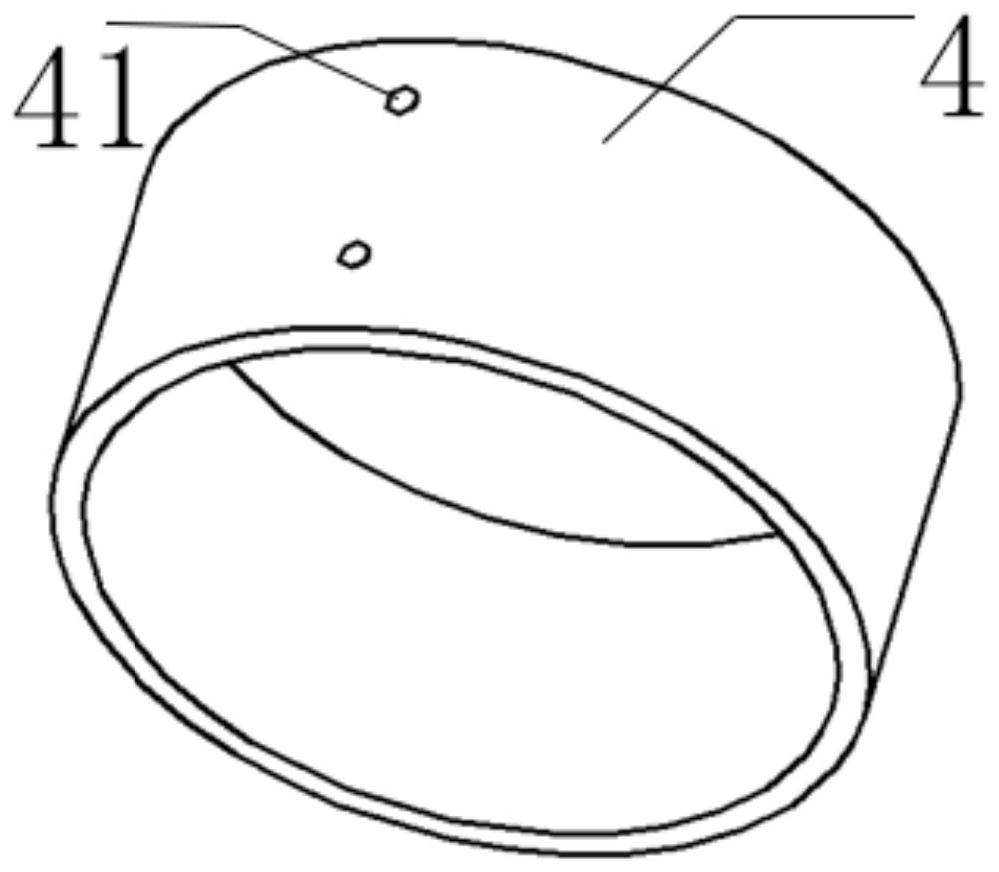

[0024] Such as figure 1 As shown, a long-life and high-precision active vibration isolation shaft assembly for space provided by the present invention includes: a support shaft 1, a labyrinth sealing gland 2, a bearing seat 3, an outer sleeve 4, a lock nut 5, an upper Bearing 6, inner spacer ring 7, outer spacer ring 8, lower bearing 9 and disc spring 10.

[0025] The upper bearing 6 and the lower bearing 9 both adopt angular contact ball bearings; the upper bearing 6 and the lower bearing 9 are set on the support shaft 1 in a back-to-back installation mode, and the bearing seat 3 is set on the upper bearing 6 and the The outside of the lower bearing 9; wherein, since the upper bearing 6 and the lower bearing 9 are installed in a back-to-back manner, the bearing span can be effectively increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com