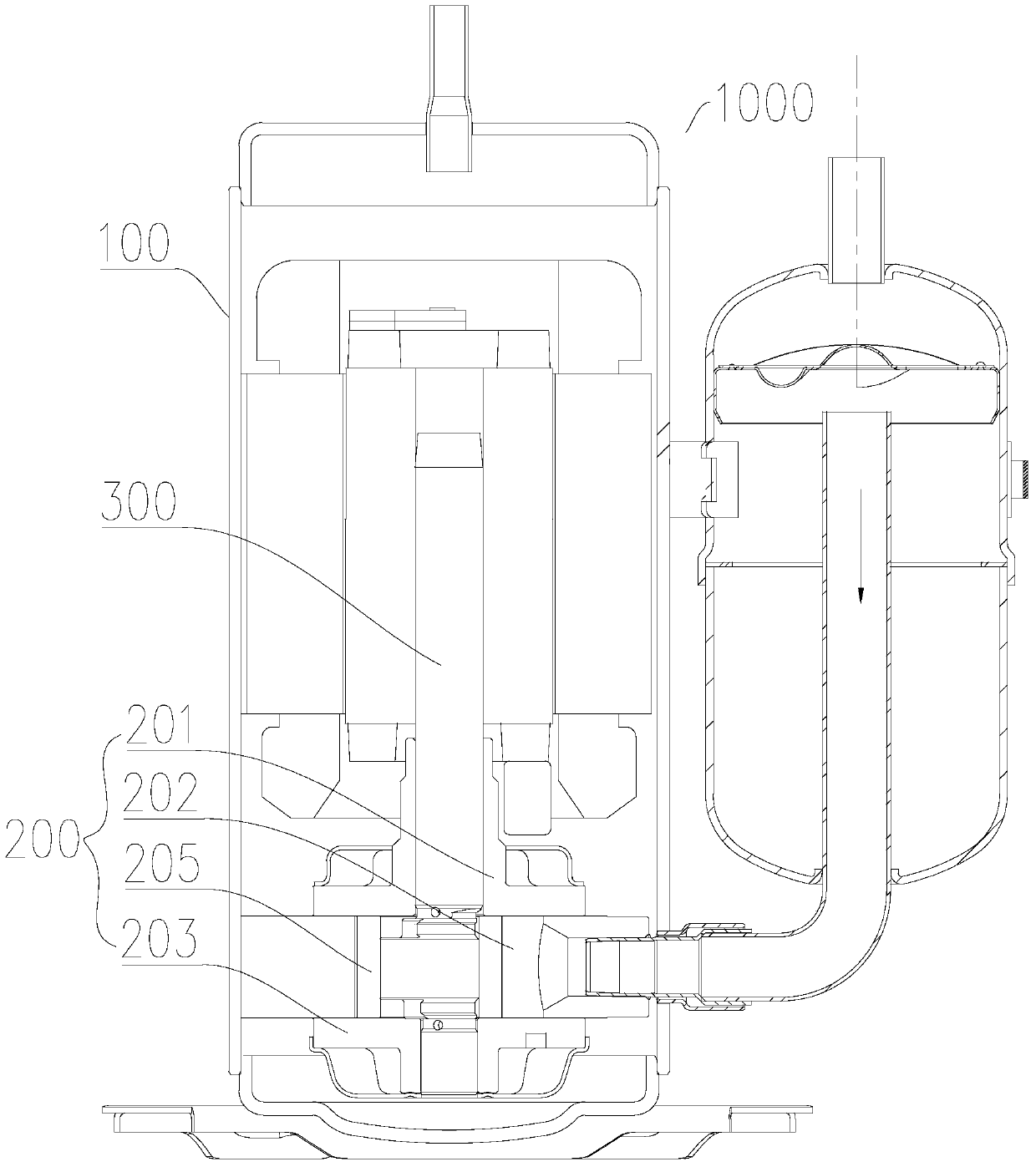

Crankshafts for rotary compressors, rotary compressors and refrigeration cycle devices

A rotary compressor and compression mechanism technology, applied in the field of compressor manufacturing, can solve problems such as poor lubrication, large friction factor, and large contact area, and achieve the effects of solving the problem of jamming, increasing the inlet oil pressure, and improving the lubrication environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

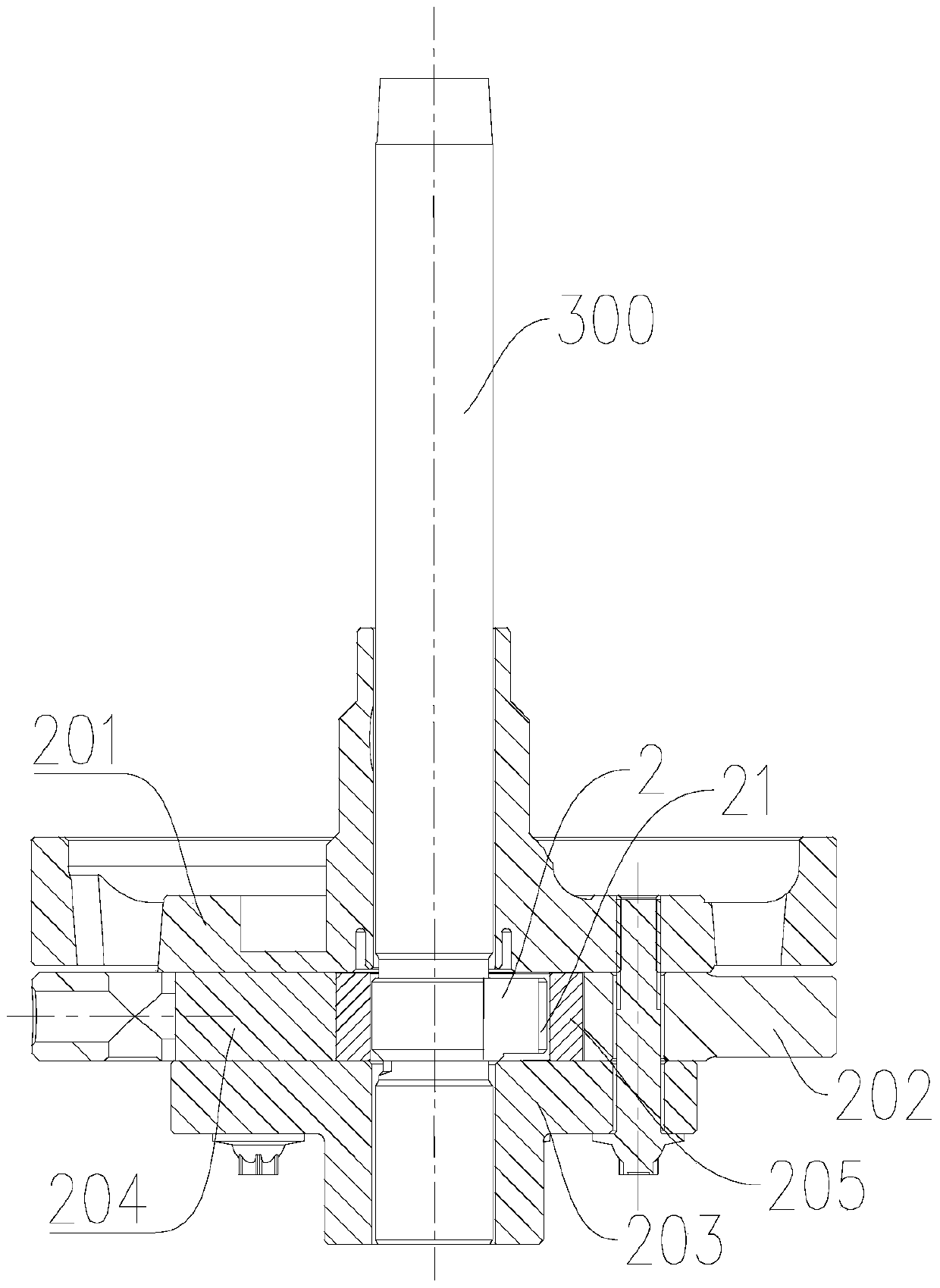

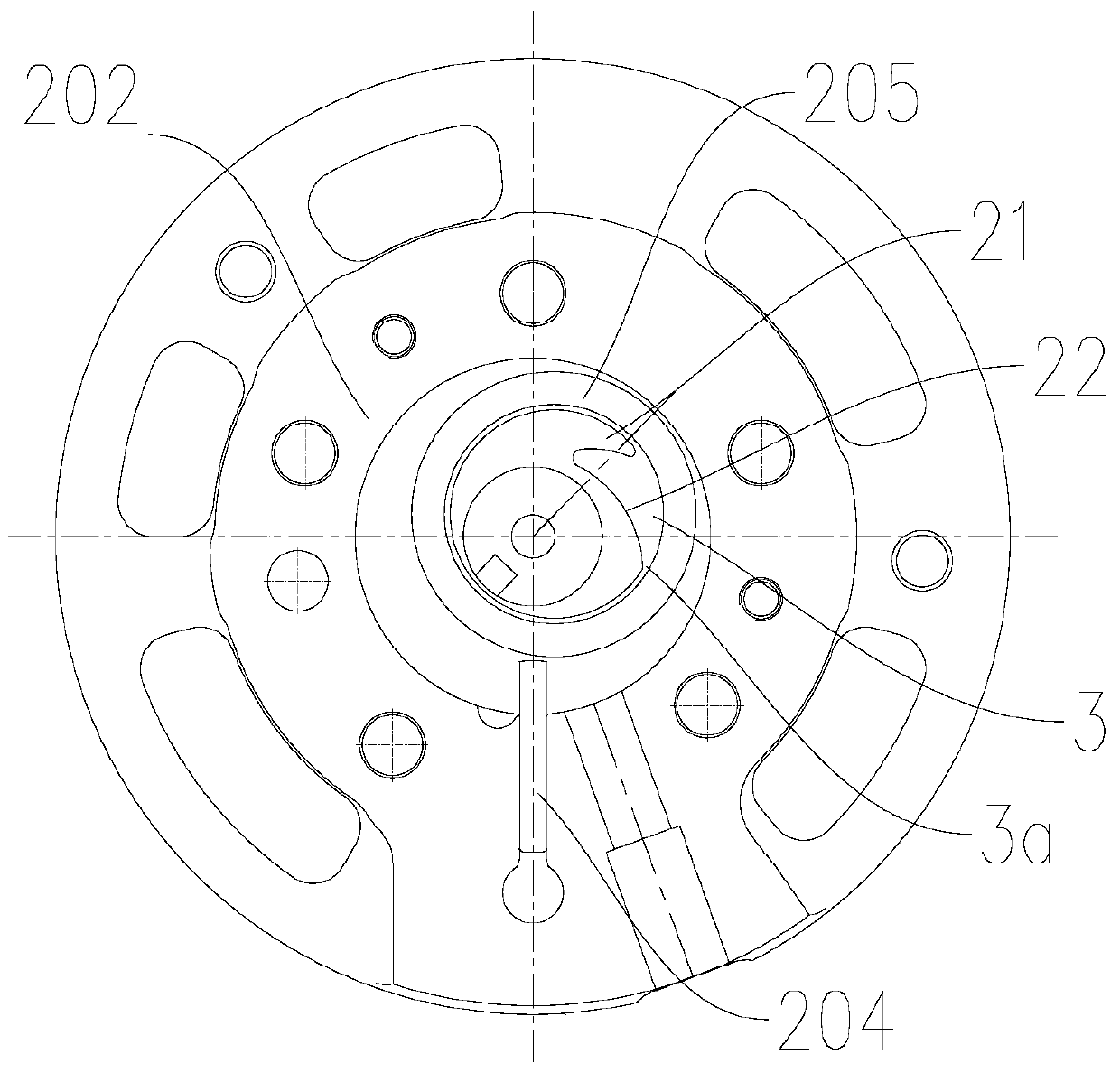

[0064] refer to Figure 7-Figure 10 , the eccentric part 2 is provided with a flexible structure 21, the flexible structure 21 has a first end 211 and a second end 212, the first end 211 of the flexible structure 21 is connected to the side wall of the eccentric part 2, and the second end of the flexible structure 21 212 and the side wall of the eccentric part 2 are spaced apart from each other. Specifically, the first end 211 of the flexible structure 21 is connected to the side wall of the eccentric part 2, and the second end 212 of the flexible structure 21 extends toward a direction away from the side wall of the eccentric part 2, so that when the piston 205 is in abnormal contact with the inner wall of the cylinder 202 At this time, the second end 212 of the flexible structure 21 can be elastically deformed to absorb the abnormal contact force, so as to improve the jamming problem of the rotary compressor 1000, and the flexible structure 21 of this structure makes the ent...

Embodiment 2

[0072] Such as Figure 11 with Figure 12 As shown, the structure of the present embodiment is substantially the same as that of the first embodiment, wherein the same components are designated with the same reference numerals, and the only difference is that no flexible structure 21 is provided on the eccentric part 2 of the third embodiment.

Embodiment 3

[0074] Such as Figure 13 with Figure 14 As shown, the eccentric part 2 is provided with a flexible structure 21, the flexible structure 21 has a first end 211 and a second end 212, and the first end 211 and the second end 212 of the flexible structure 21 are connected to the side wall of the eccentric part 2 , other parts of the flexible structure 21 except the first end 211 and the second end 212 are spaced apart from the sidewall of the eccentric part 2, at this time, a substantially A crescent-shaped cavity, and the cavity can pass through the eccentric part 2 along the axial direction of the body 1 . Thus, when the piston 205 is in abnormal contact with the inner wall of the cylinder 202, the part of the flexible structure 21 except the first end 211 and the second end 212 can be elastically deformed to absorb the contact force. Therefore, the structure of the flexible structure 21 is simple and easy to process, and the connection between the flexible structure 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com