Feeding mechanical arm of meter lathe

A technology for instrument lathes and manipulators, applied in the field of instrument lathe feeding and feeding manipulators, can solve problems such as difficulty in improving processing efficiency and quality, machine jamming, and difficult positioning, and achieves overcoming the problem of inertial force oscillations, accurate return positioning, and improving processing efficiency and processing quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

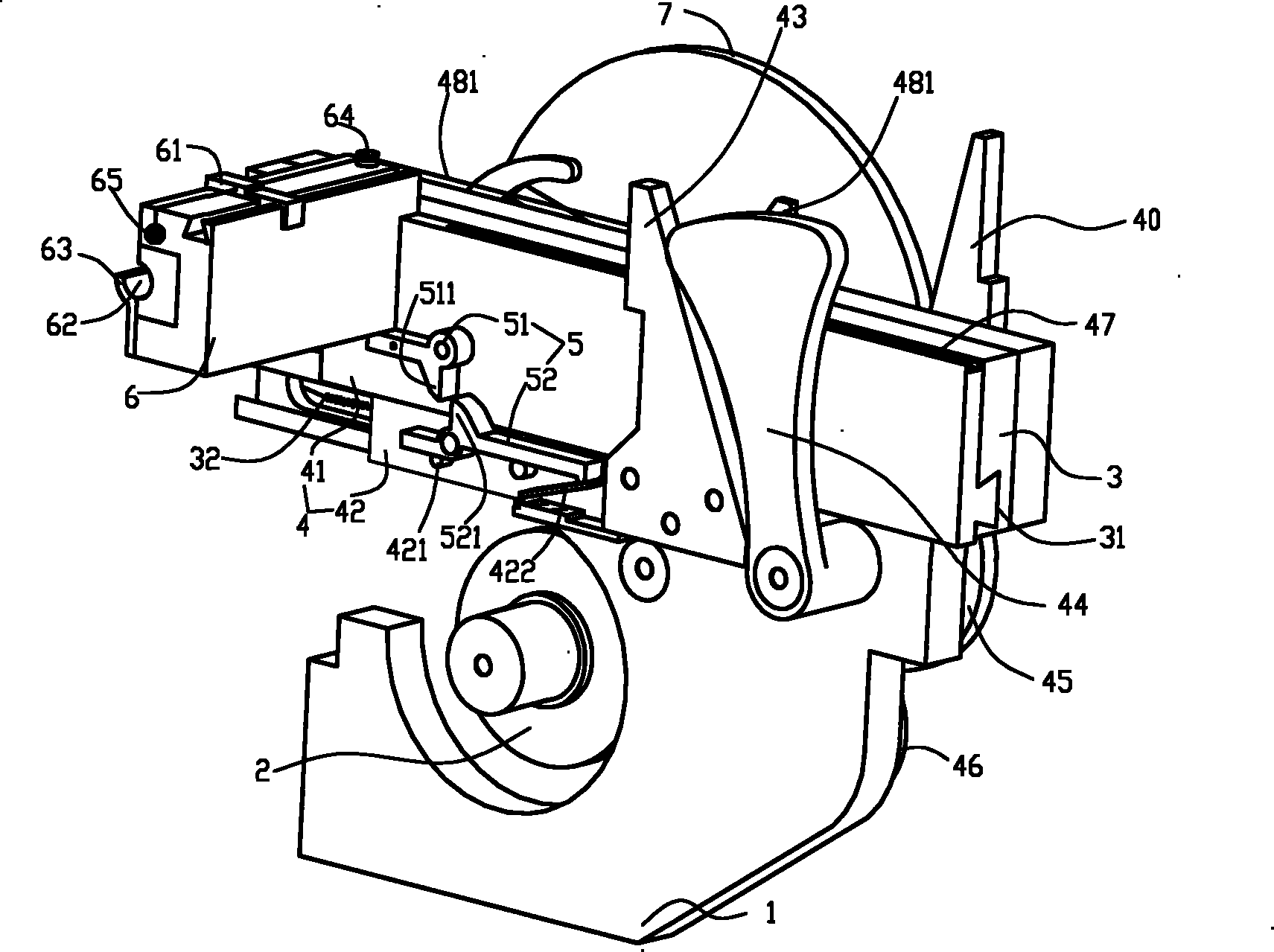

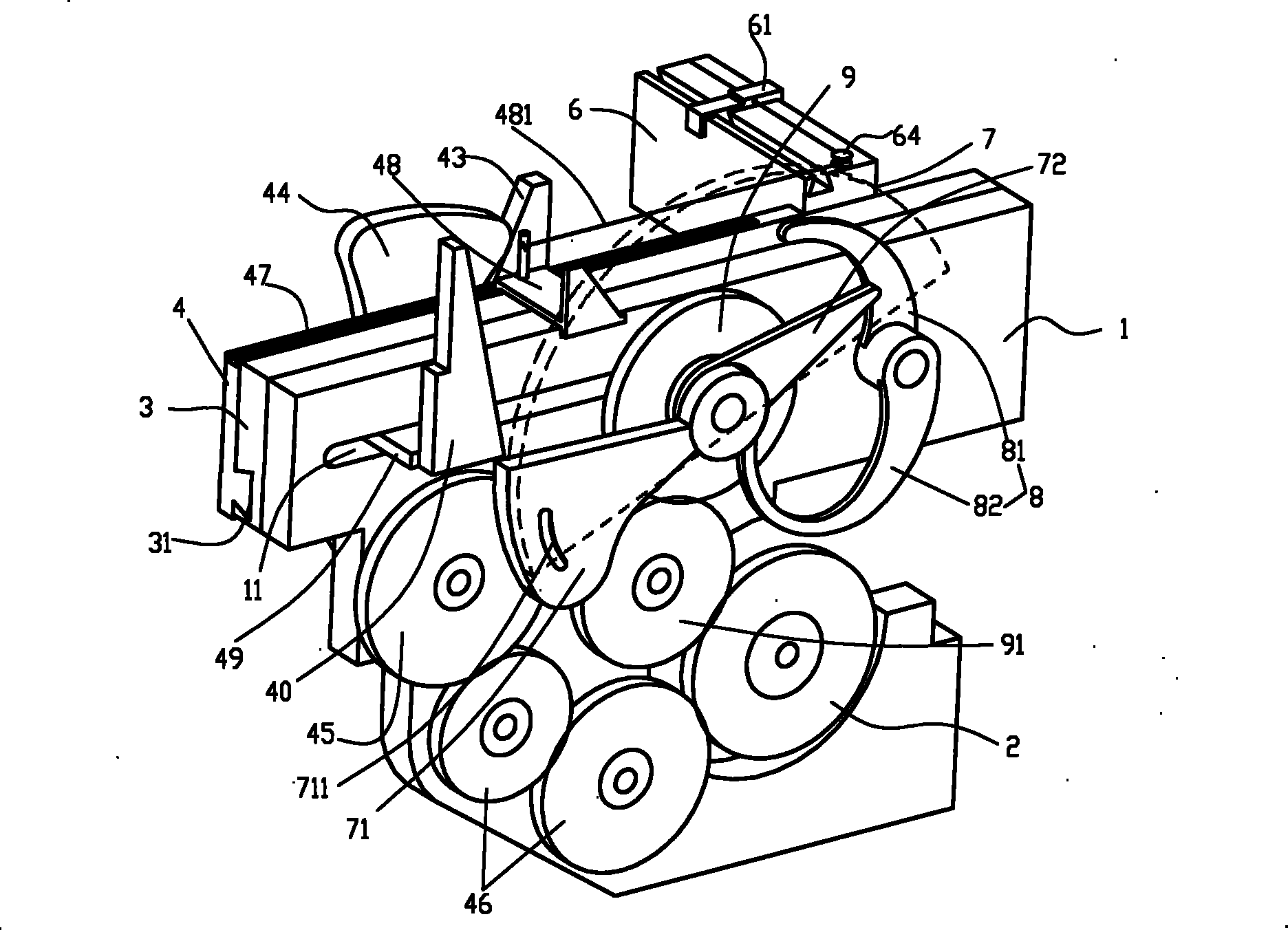

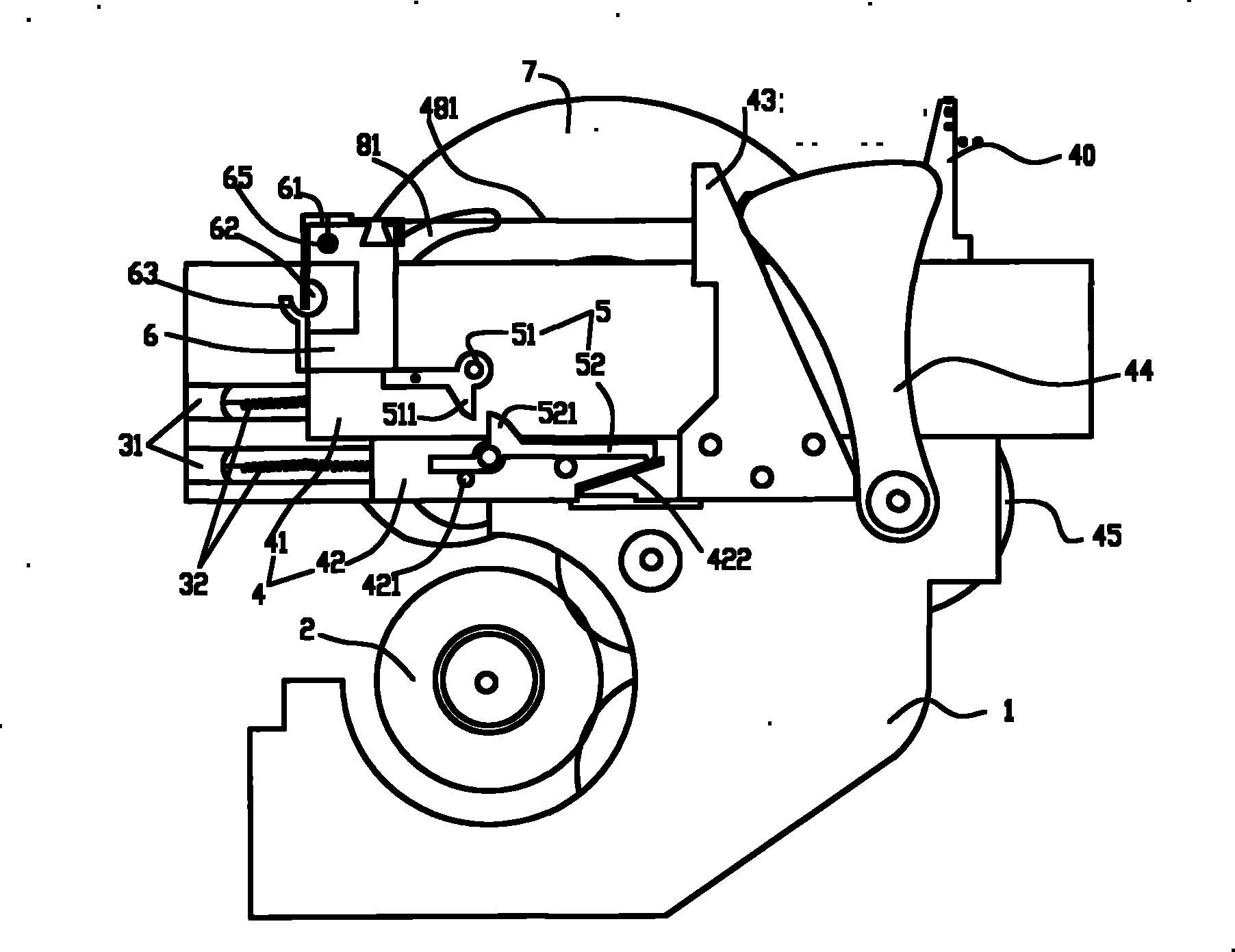

[0019] Such as figure 1 , 2 , 3 and 4, a feeding and feeding manipulator for an instrument lathe, including a bracket 1, a driving gear 2 is hollowed out in the middle of the bracket 1 for connecting an external motor, and a carriage 3 is fixedly installed on one side of the upper part of the bracket, while the upper part of the bracket The rear end is provided with an eccentric wheel 44 on the carriage side. A transverse through hole 11 is correspondingly provided on the mobilizer 3 and the bracket 1 , and a slider 4 that can slide along a dovetail groove 31 thereon is provided on the outer side of the moratorium 3 .

[0020] The sliding plate 4 is divided into an upper sliding plate 41 and a lower sliding plate 42, both of which are movably connected with the carriage 3 through a dovetail groove 31 and a return spring 32 respectively, and a linkage structure 5 is arranged at the joint of the two. The linkage structure 5 is composed of an upper slide plate part and a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com