Patents

Literature

69 results about "Radius part" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

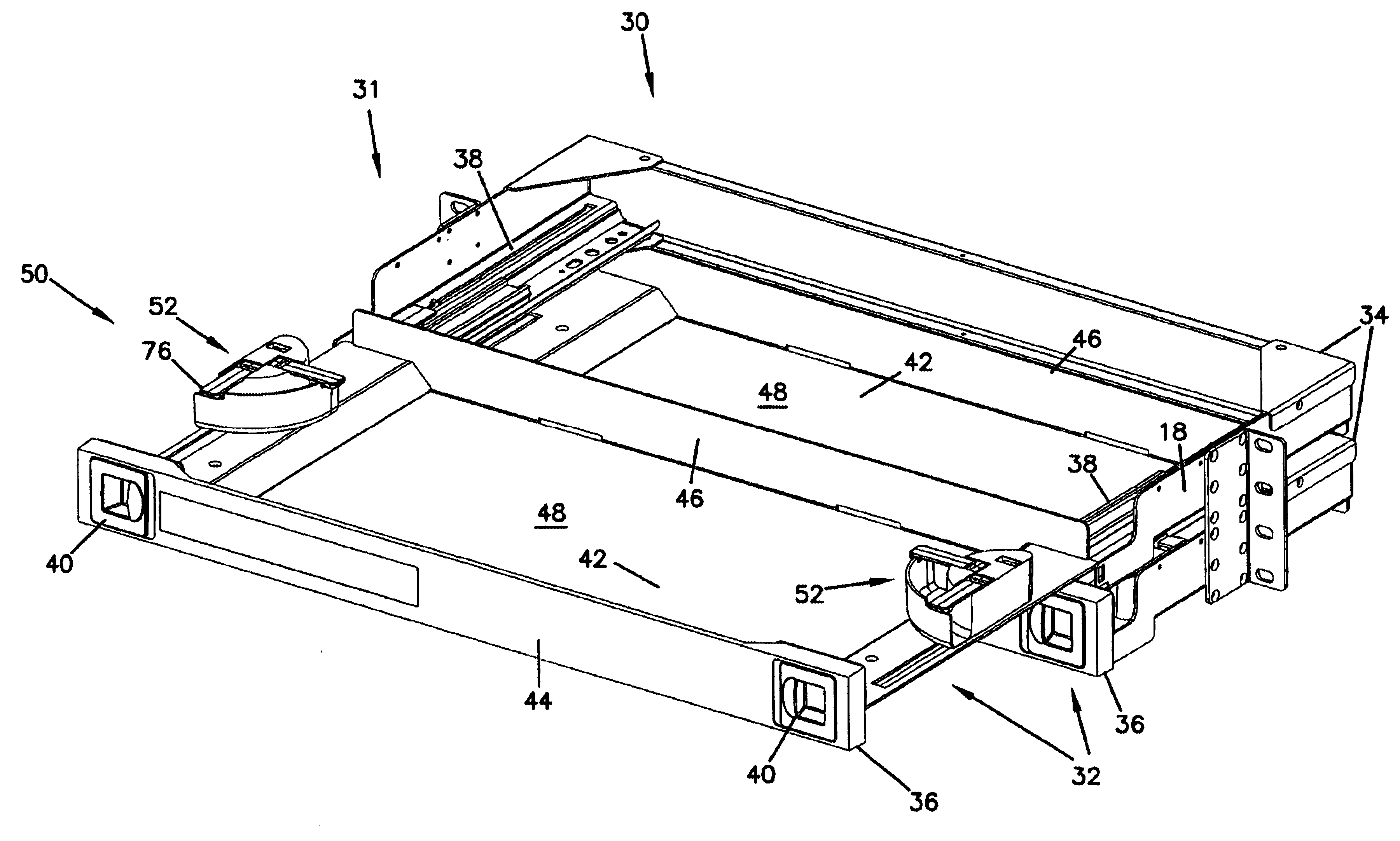

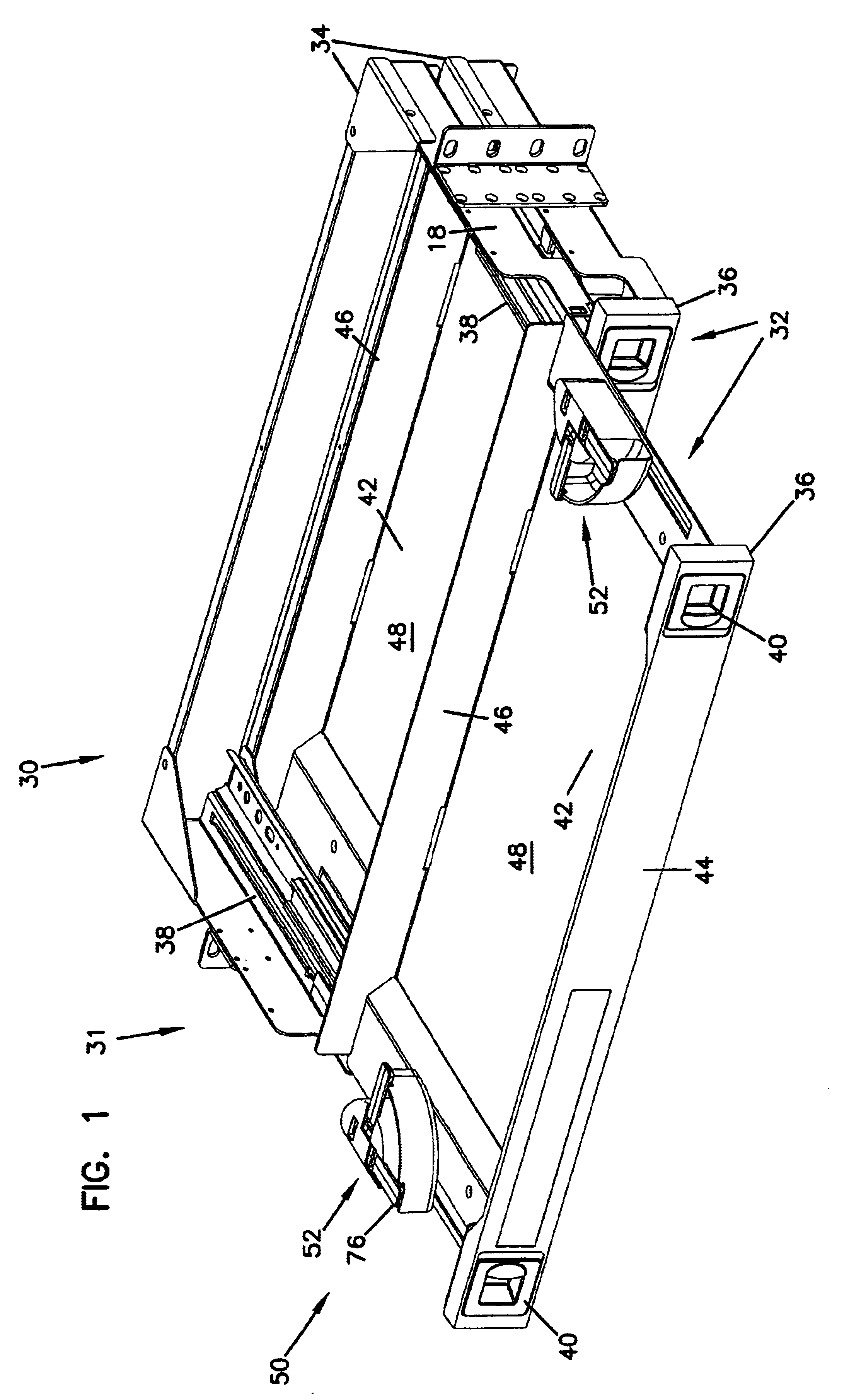

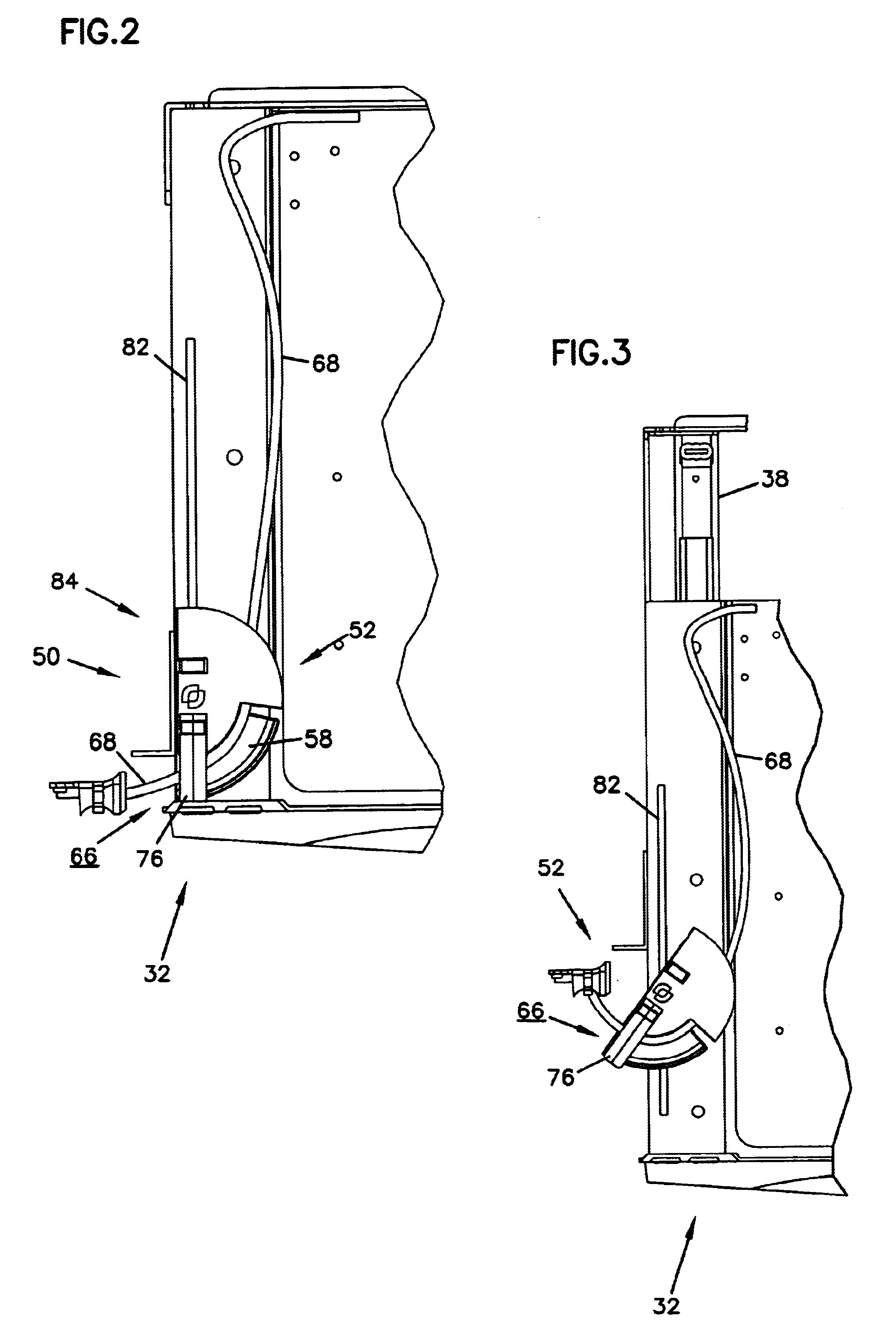

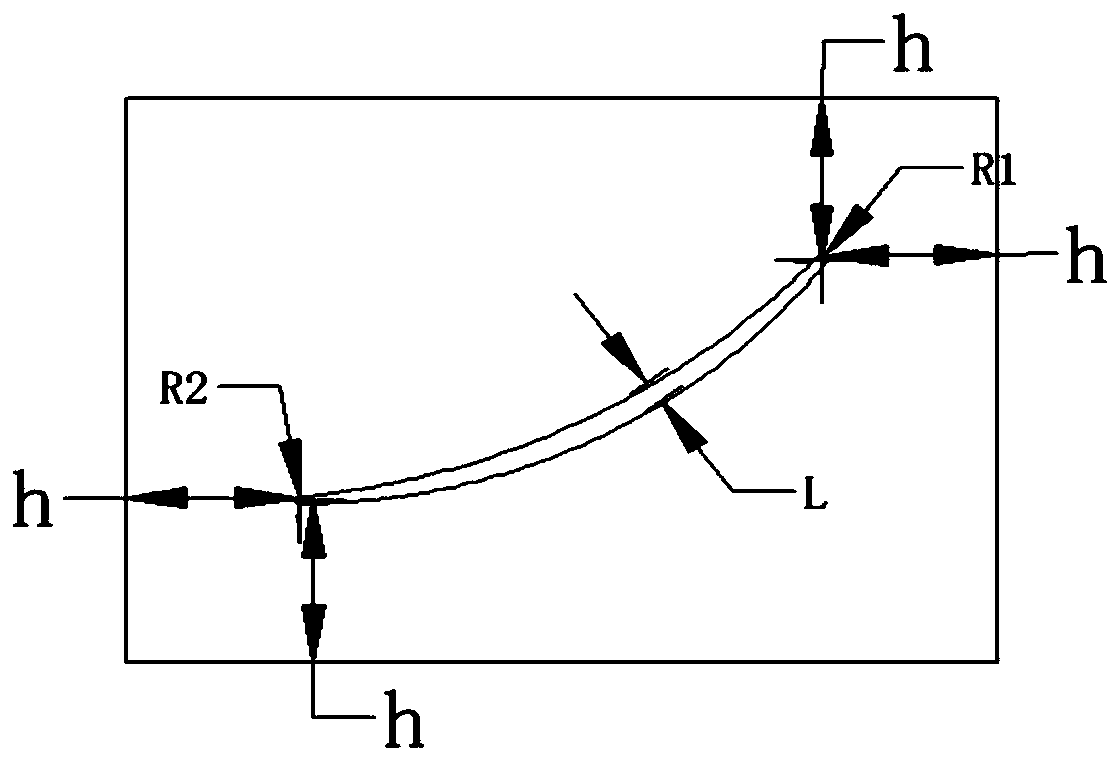

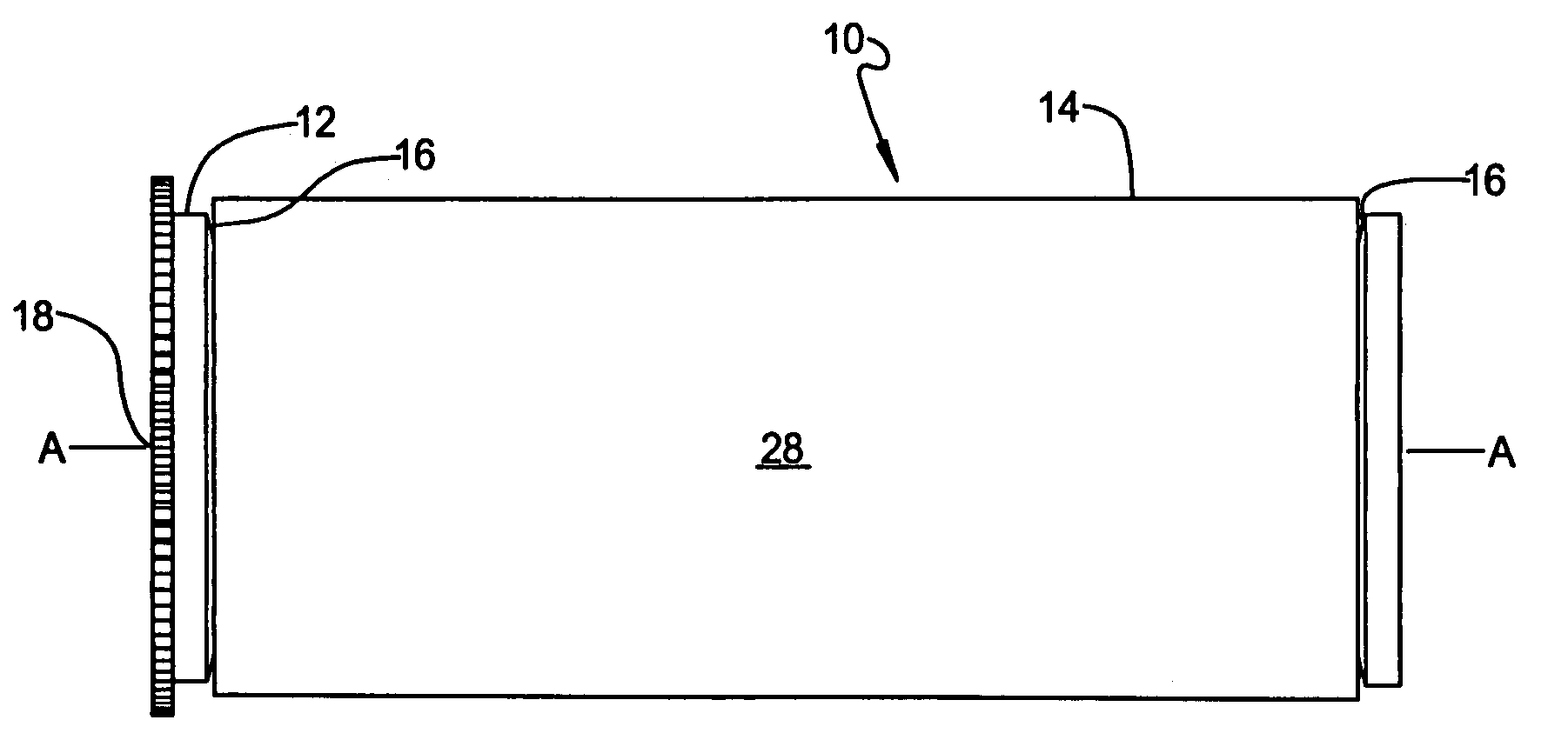

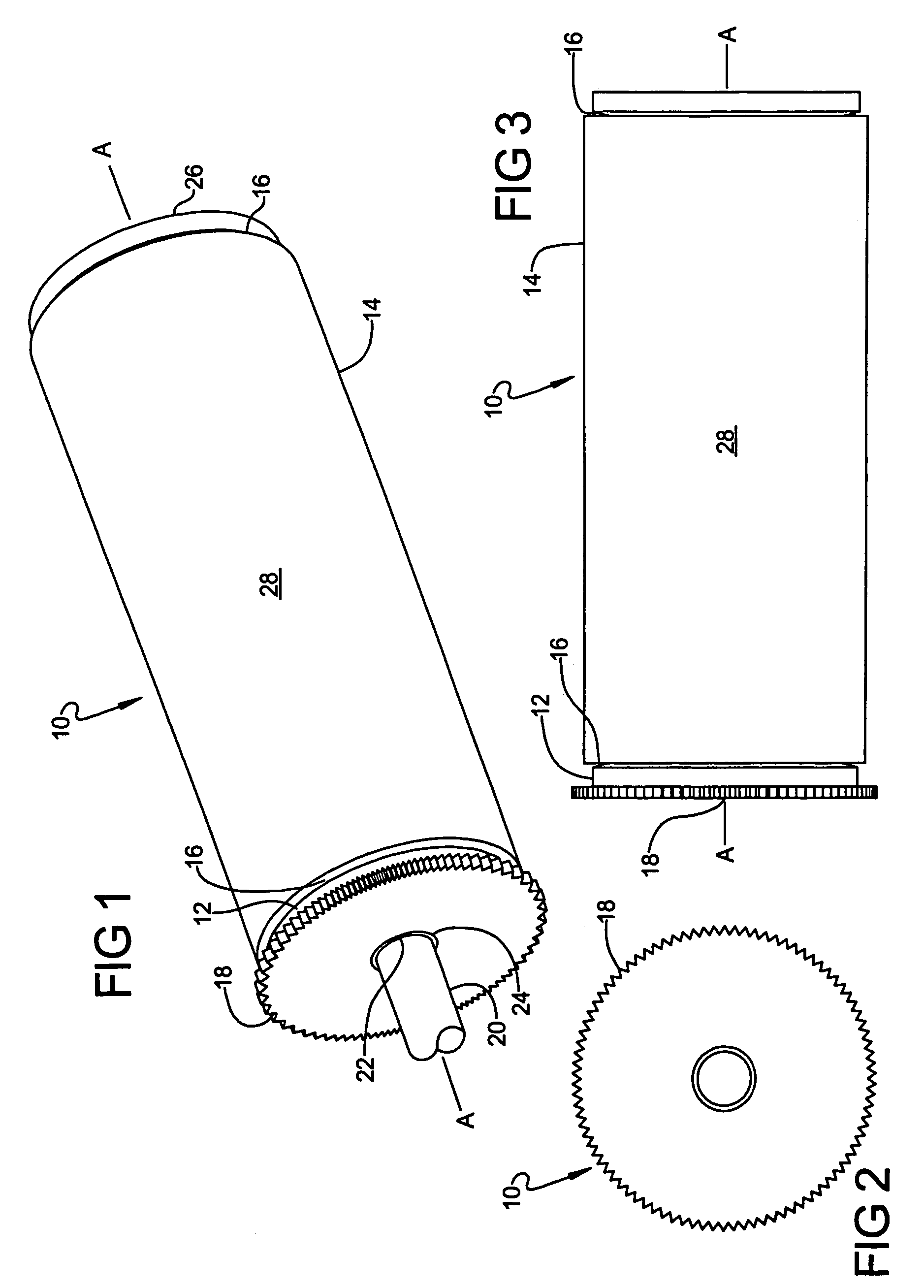

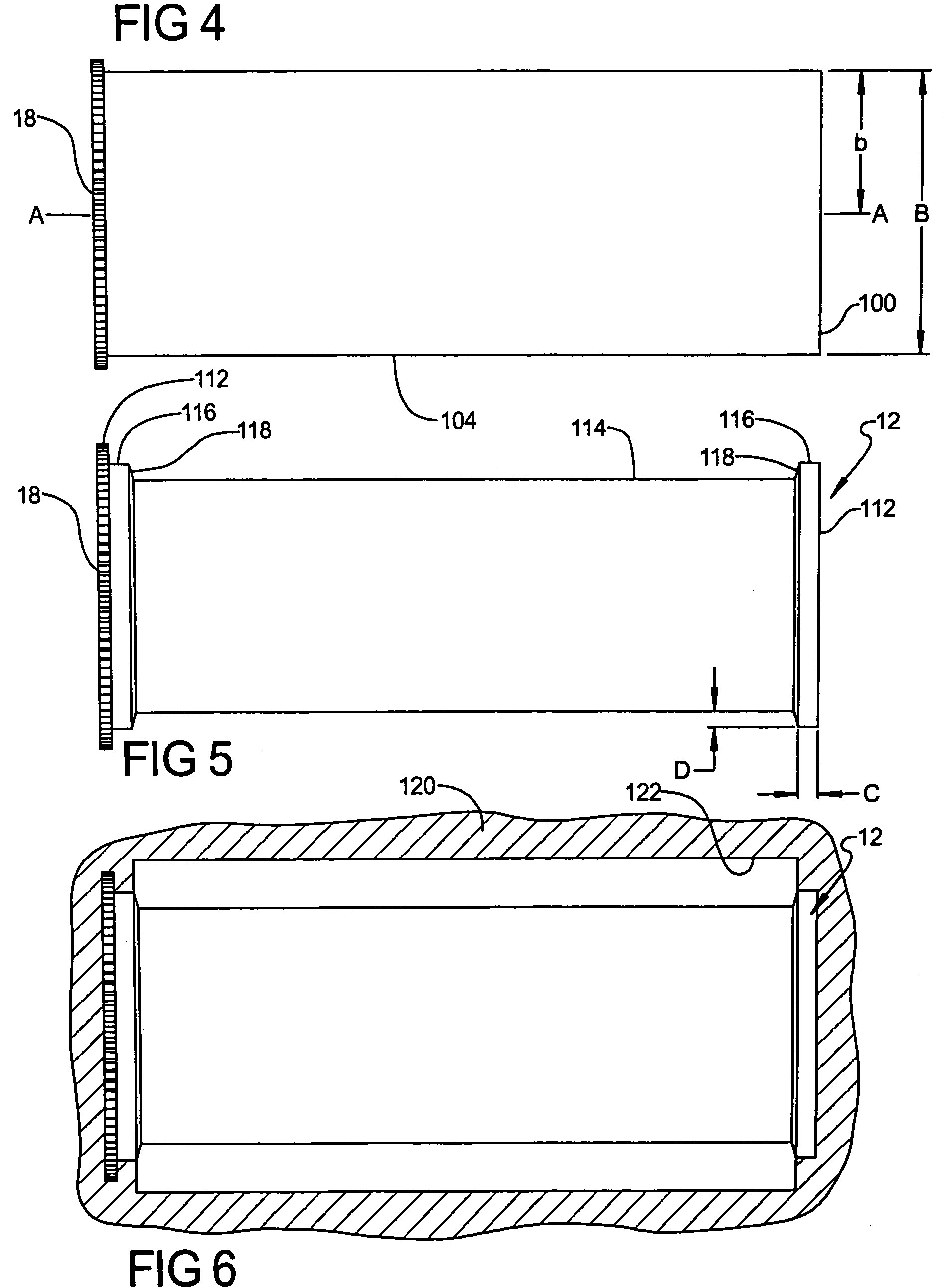

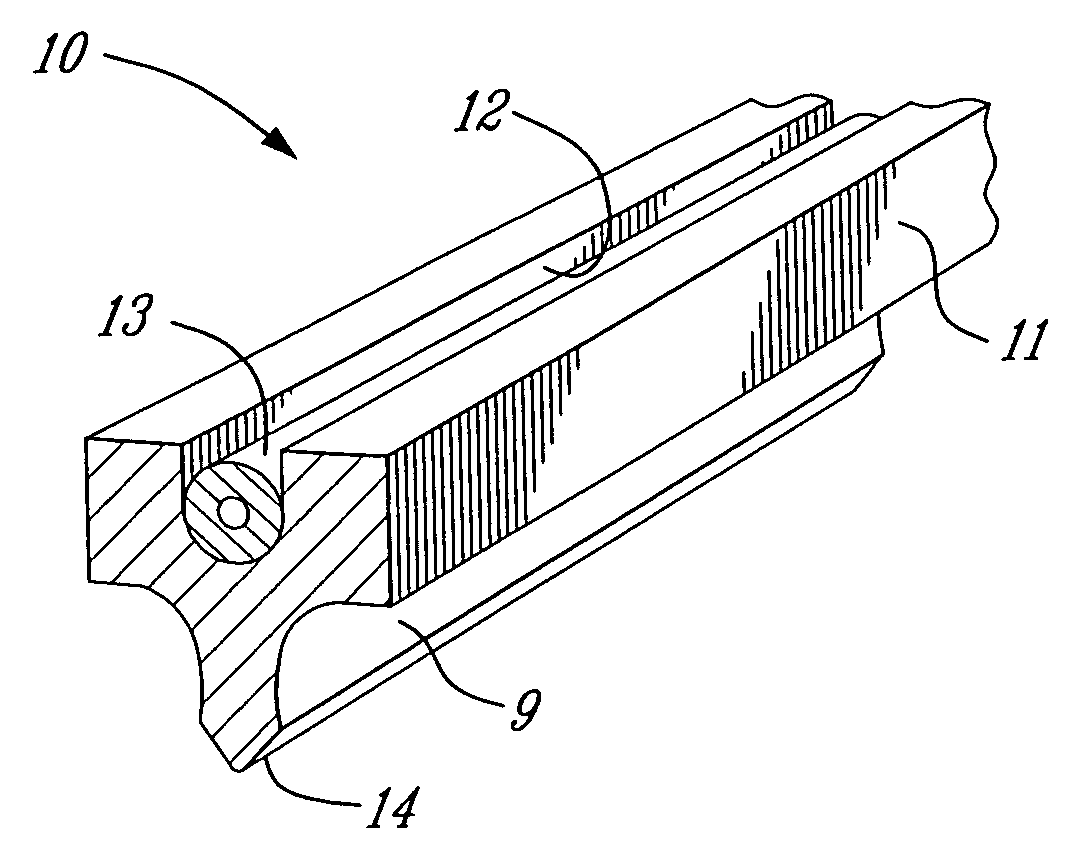

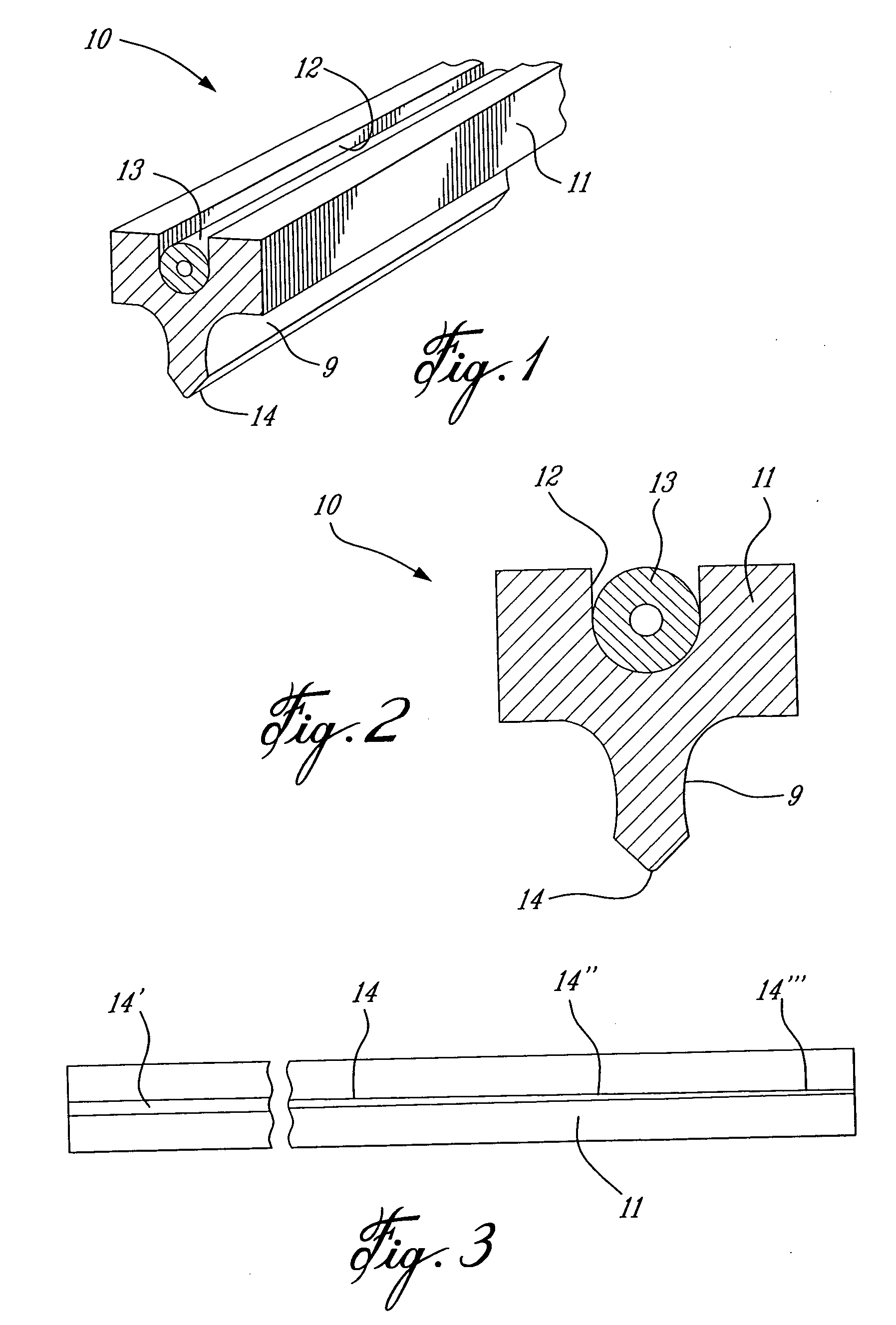

Rotating radius limiter for cable management panel and methods

A rotating radius limiter for an optical fiber cable management panel is provided. The radius limiter includes a radius limiter structure and a bracket that permit relative motion between the structure and the bracket. The structure and bracket are mounted to a sliding cable management panel. The radius limiter structure includes a curved wall, an opening for receiving cables and a trough section for retaining cables about a radius portion.

Owner:COMMSCOPE TECH LLC

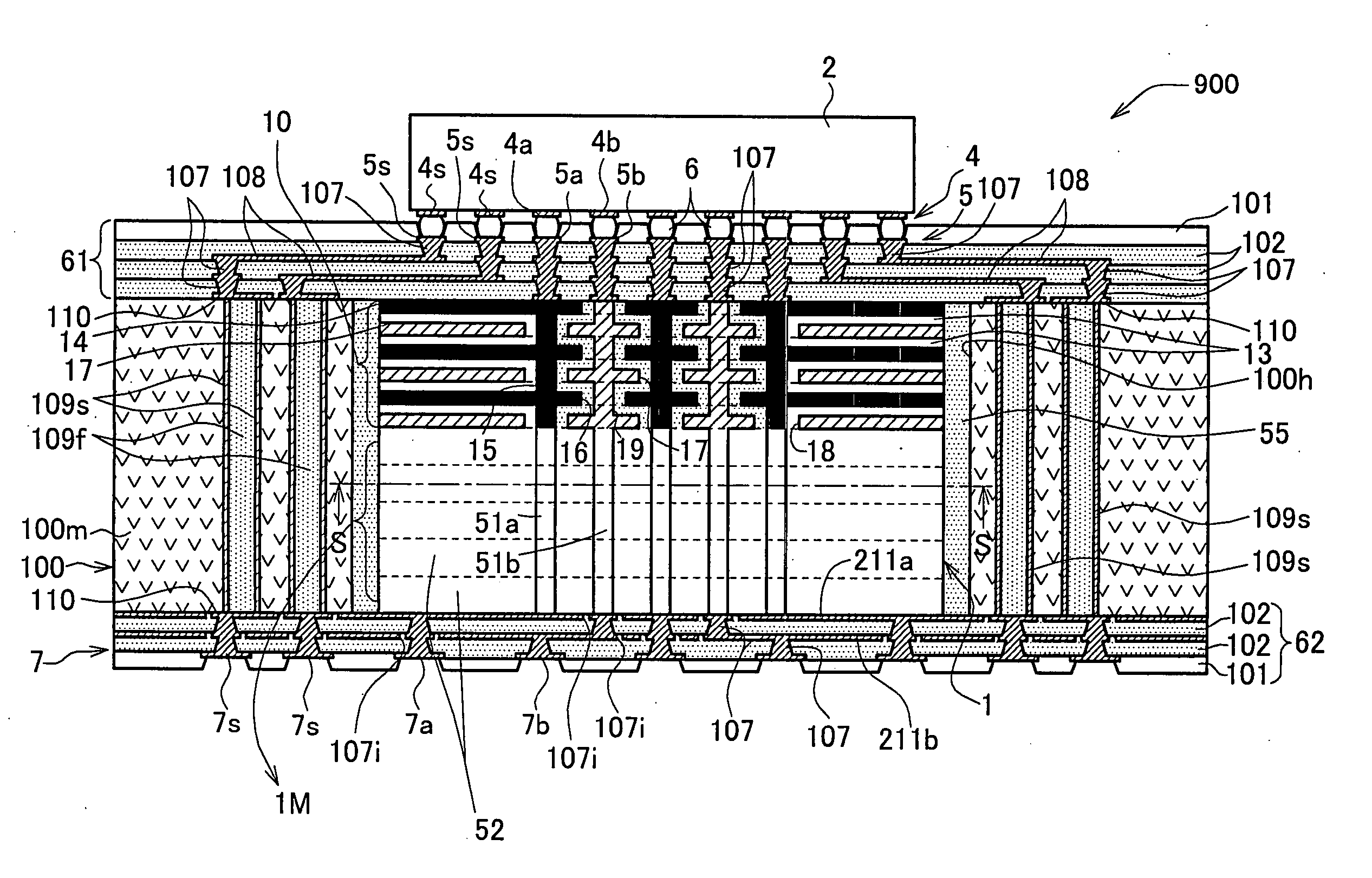

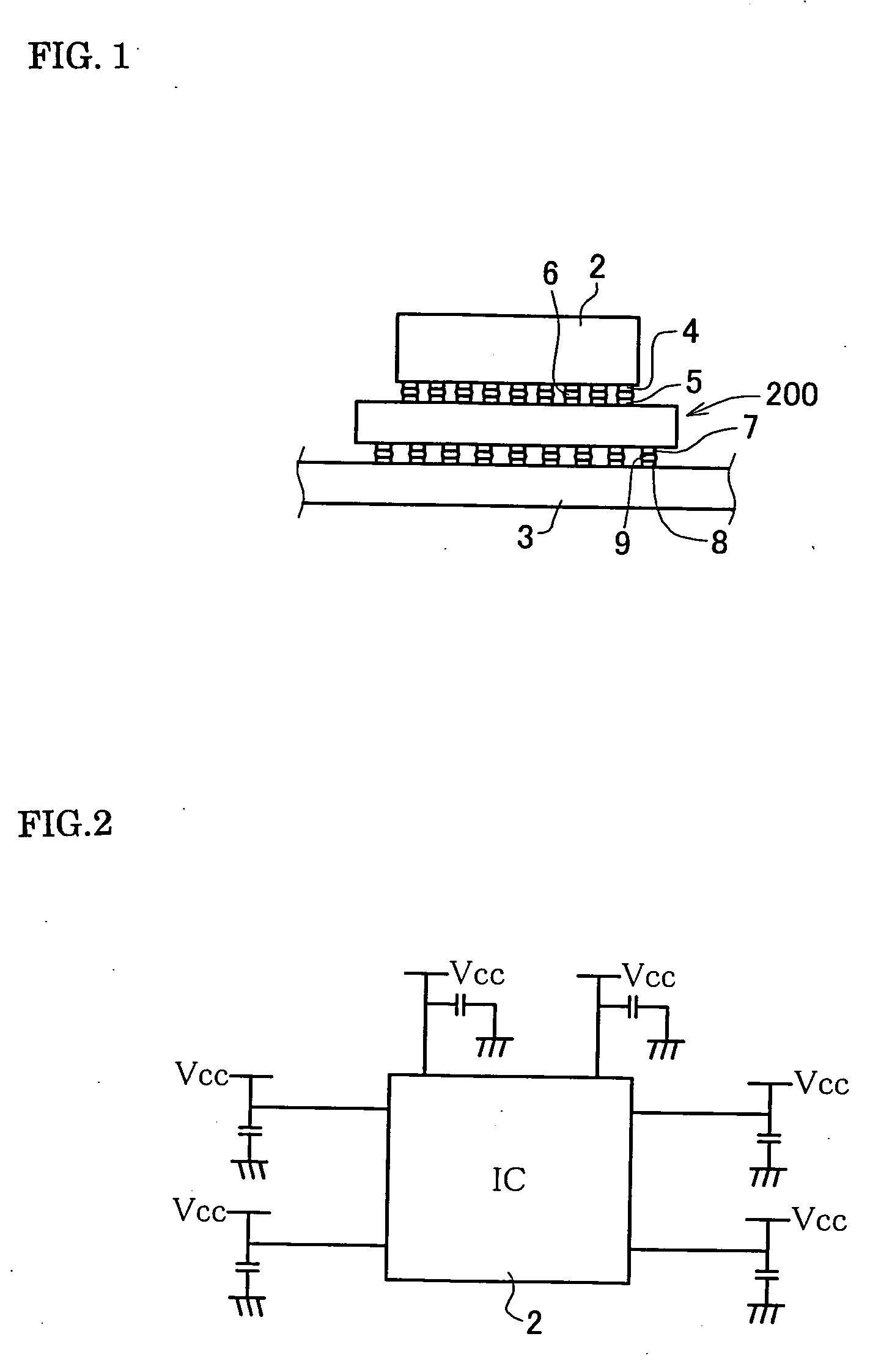

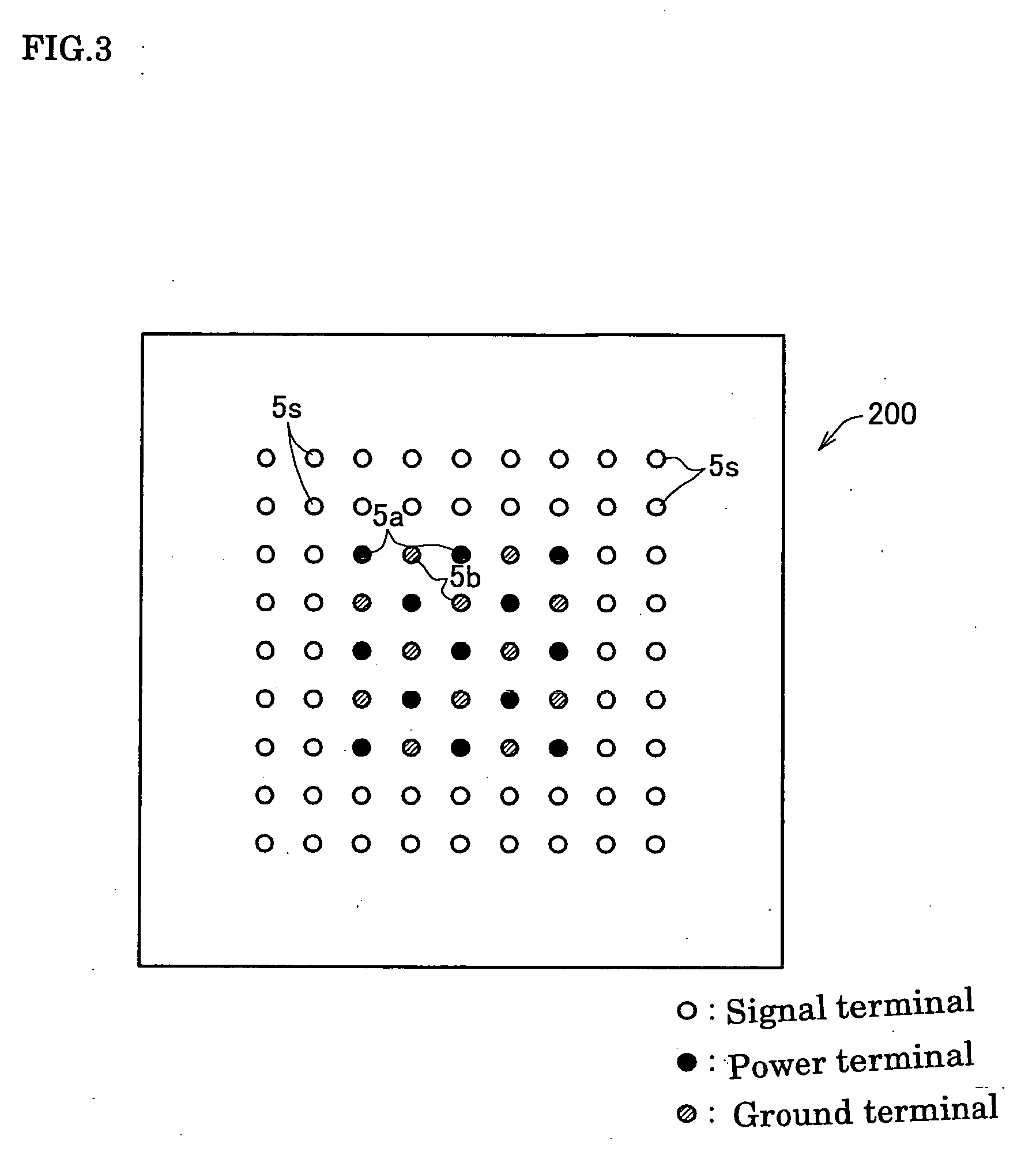

Wiring board and capacitor to be built into wiring board

ActiveUS20060175083A1Reduce the overall heightReduce in quantityCross-talk/noise/interference reductionSemiconductor/solid-state device detailsDielectricElectrical conductor

An intermediate board has a board core formed by a main core body and a sub-core portion. The main core body has a plate-like shape and includes an open sub-core housing portion in which the sub-core portion is housed. A first terminal array of the board core has an area that overlaps an orthogonal projection of the sub-core portion. The latter incorporates a laminated ceramic capacitor formed by first and second conductor layers with a ceramic (dielectric) layer therebetween. The first layer is connected to first and second side terminals of a first type while the second layer is connected to first and second side terminals of a second type. The housing portion has an inner edge which, in cross section, is of a quadrate shape, and a radius portion is formed at each corner having a dimension of between 0.1 and 2 mm.

Owner:NGK SPARK PLUG CO LTD

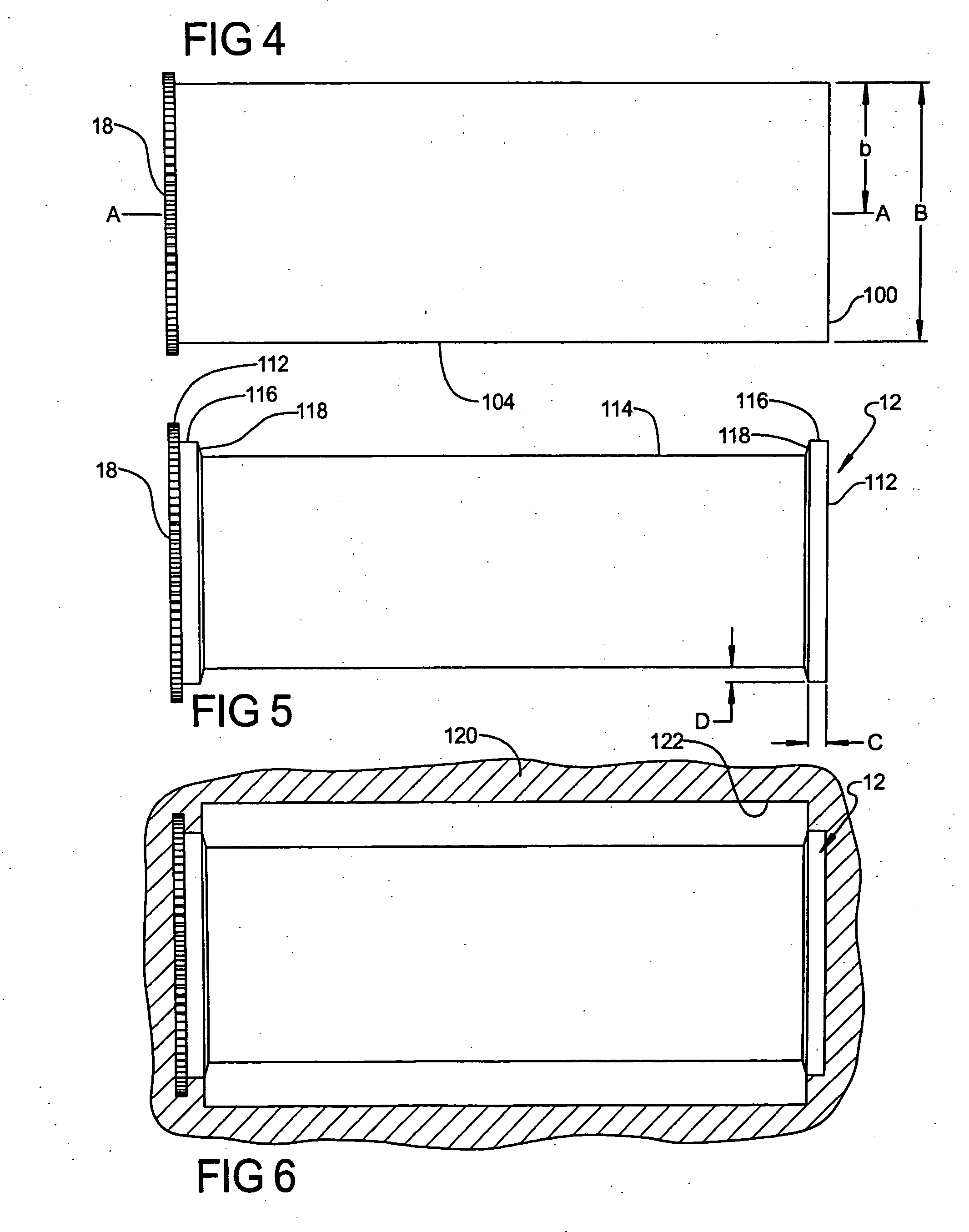

Hydraulic forming press system and press method thereof

A hydraulic pressing system for forming a workpiece and its pressing method are disclosed. The part A to be expanded maximally and a part B linked to said part A and to be bent are first expanded and said part B is then bent inward by upper and lower dies to obtain the beautiful contour with minimal curvature radius.

Owner:SUNG WOO HITECH

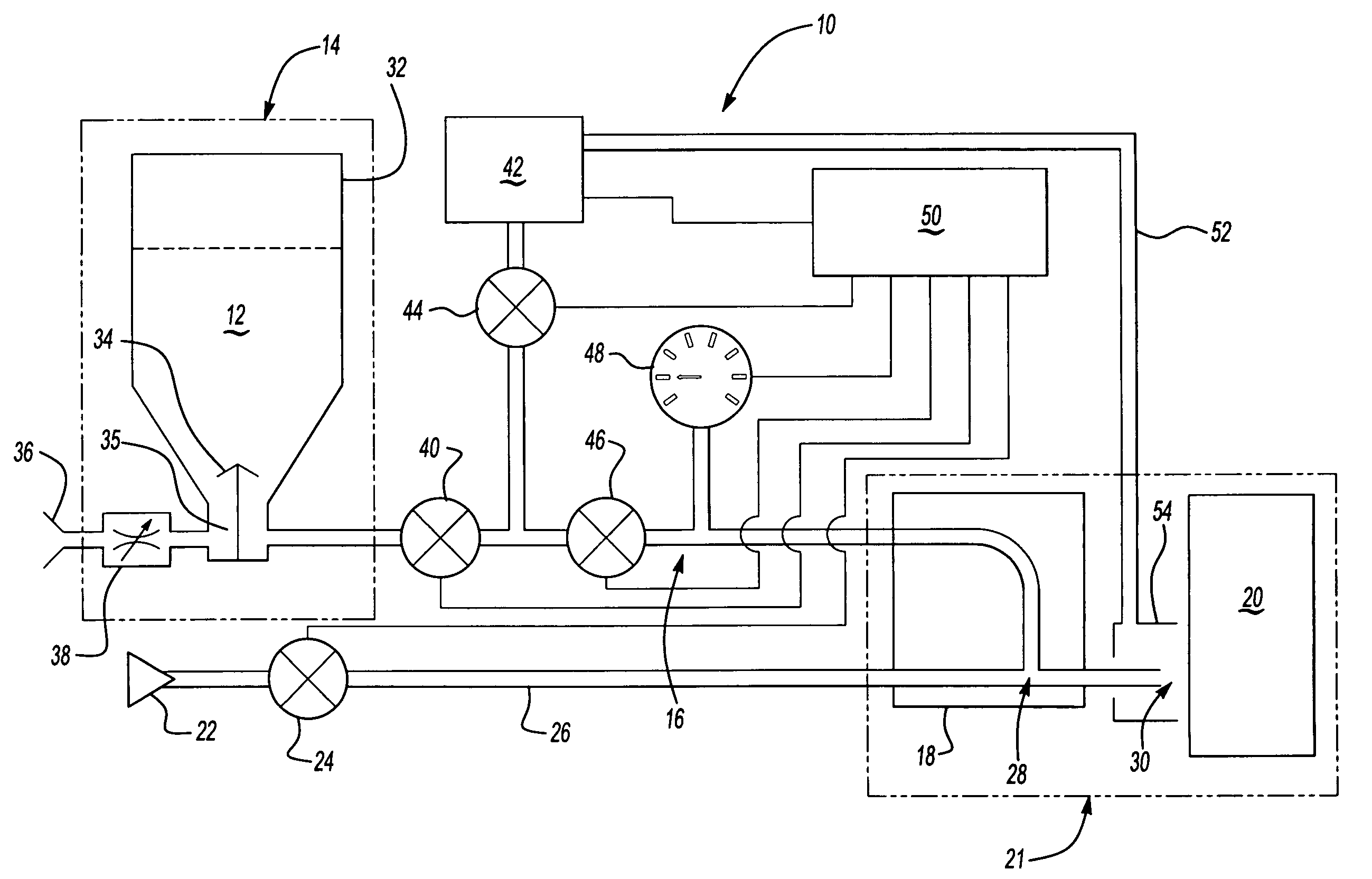

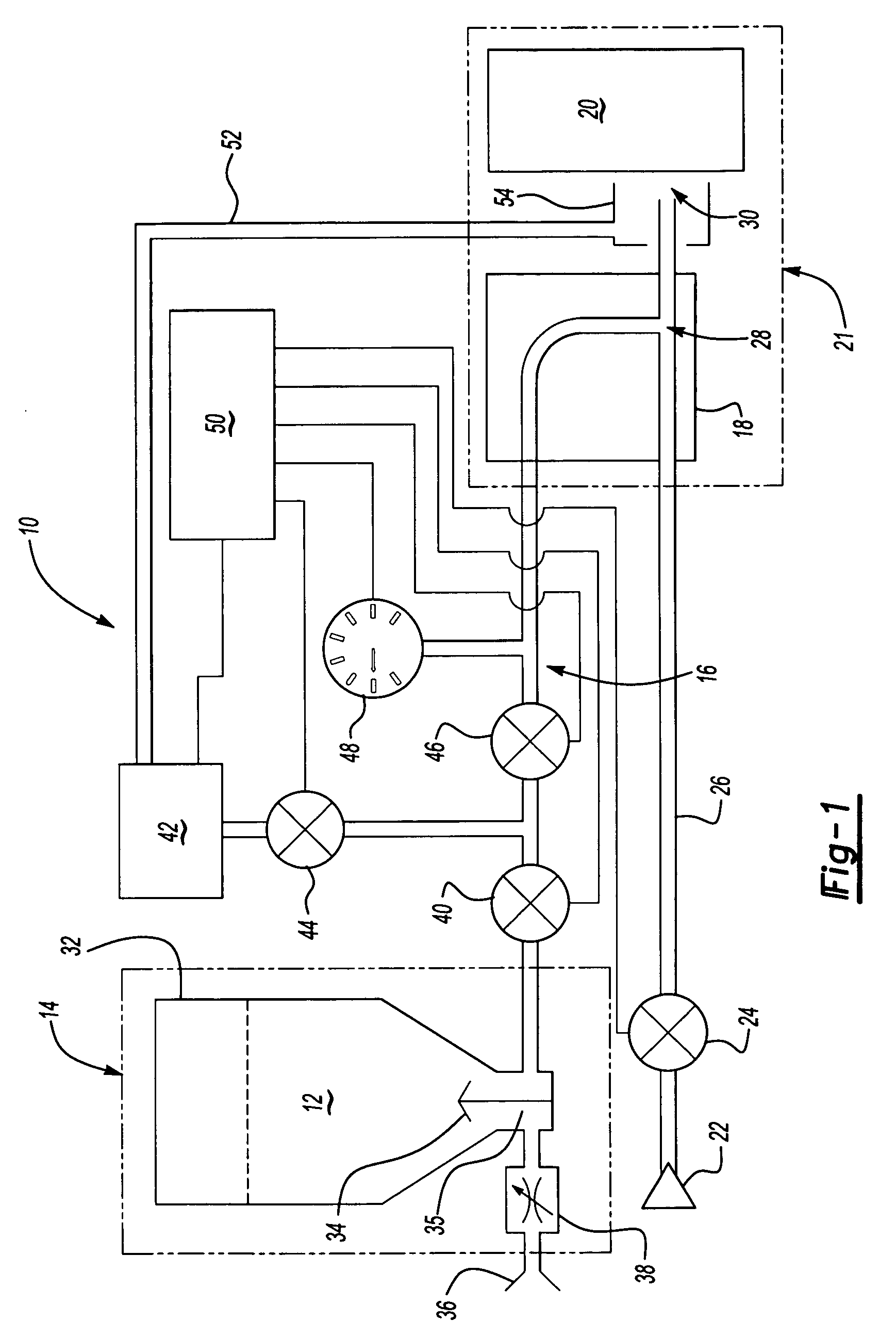

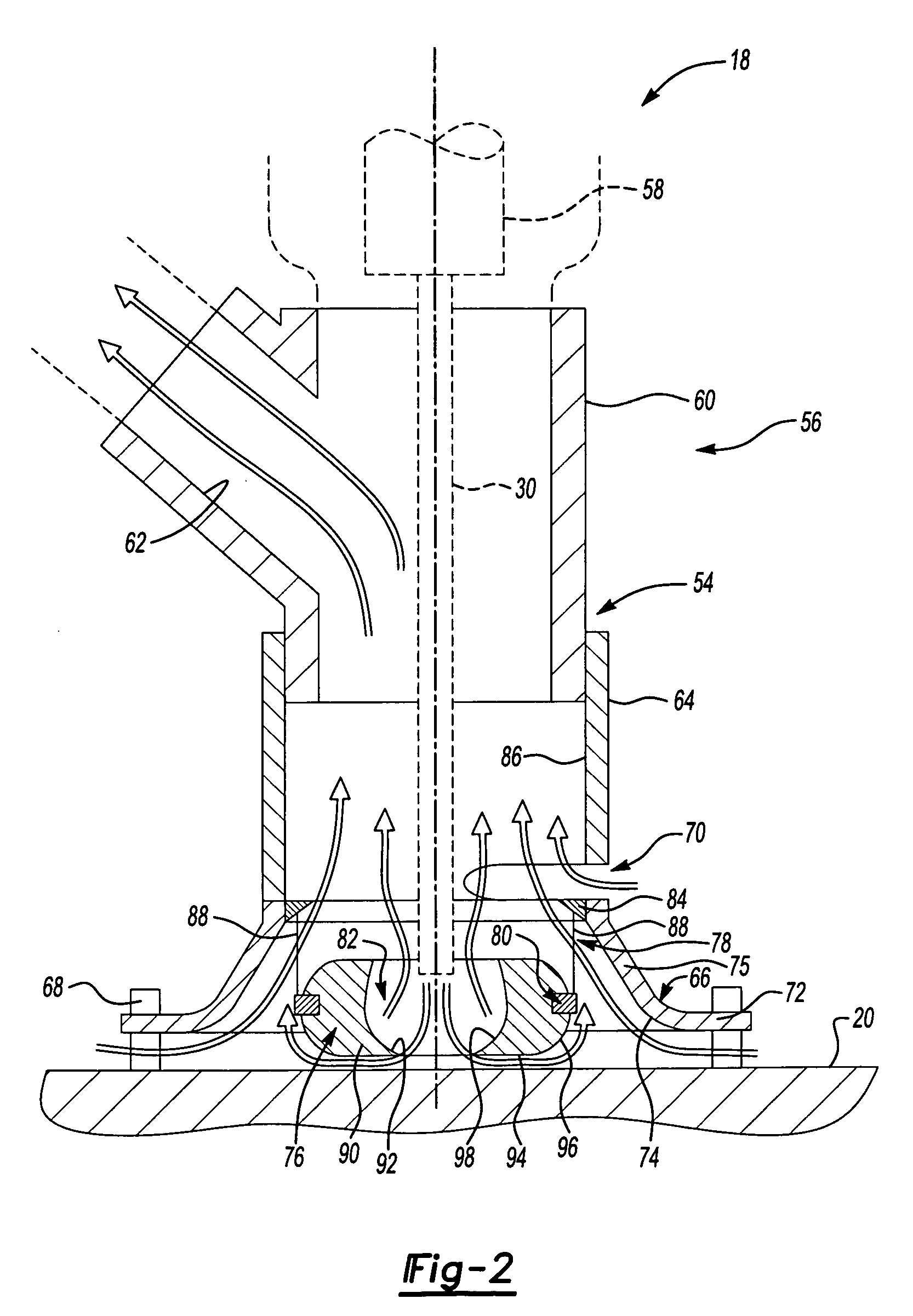

Vacuum nozzle for spray system

InactiveUS20060081174A1Efficient drawingMinimizing turbulent flowLiquid surface applicatorsVacuum evaporation coatingVisibilityEngineering

A cold spray system includes a spray nozzle for depositing material onto a substrate. A collection assembly at least partially surrounds the spray nozzle for vacuuming undepositive material and gases in the work area. The collection assembly includes a transparent collection tube at an end portion of the collection assembly to provide visibility to the work area. The collection assembly includes a shield having a flange that extends radially outwardly from the collection assembly and is generally parallel to a substrate. An angled portion of the shield extends from the collection assembly. A radius portion adjoins the flange and the angled portion. A ring is spaced between the spray nozzle and the shield. An inner surface of the ring deflects material that typically would otherwise not become adhered to the substrate back into the collection assembly to minimize the material that must be vacuumed at the substrate. A curved surface of the ring extends from a surface spaced from the substrate toward the shield to provide a smooth transition for materials flowing along the substrate back into the collection assembly.

Owner:DOBEN LTD

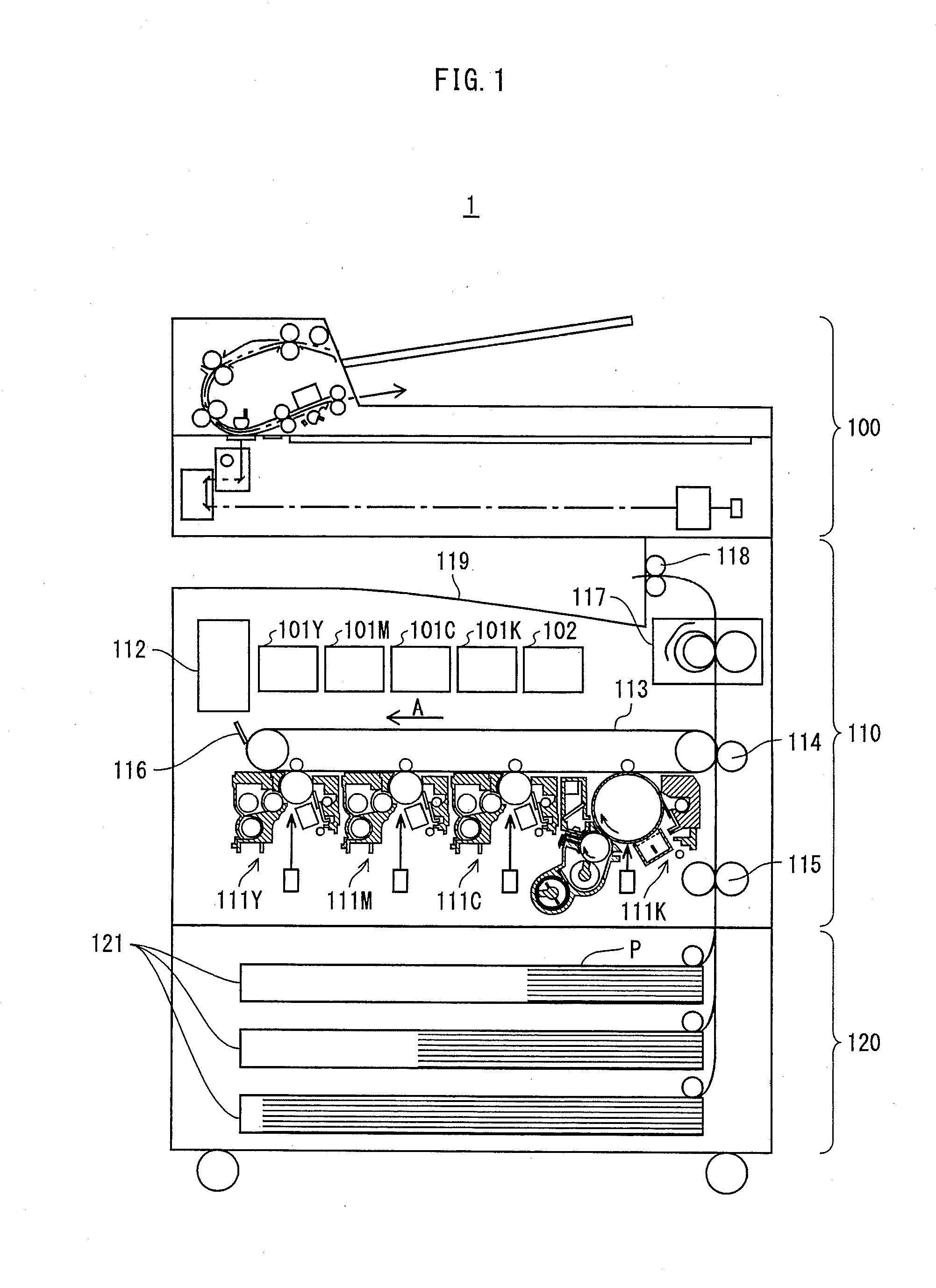

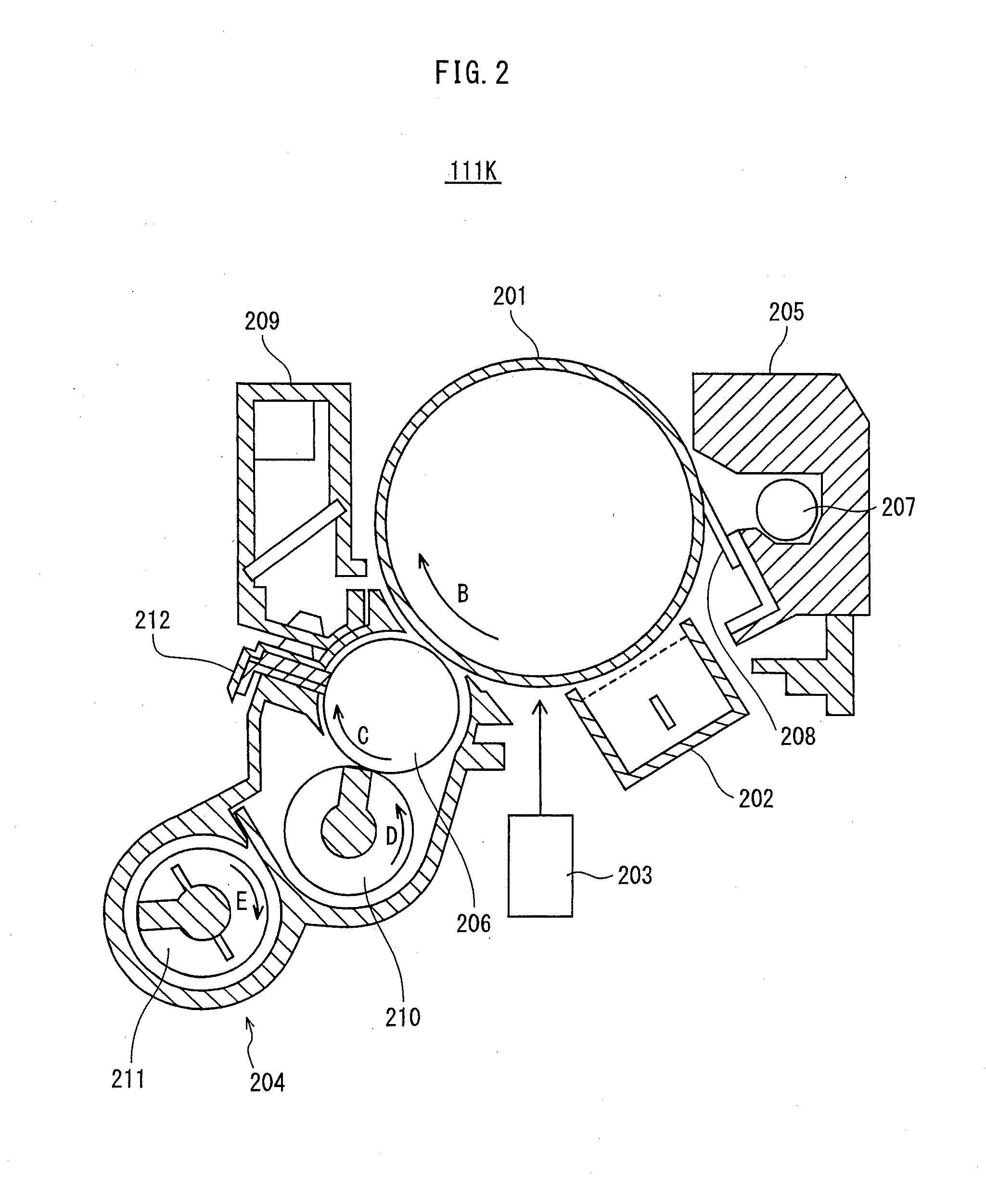

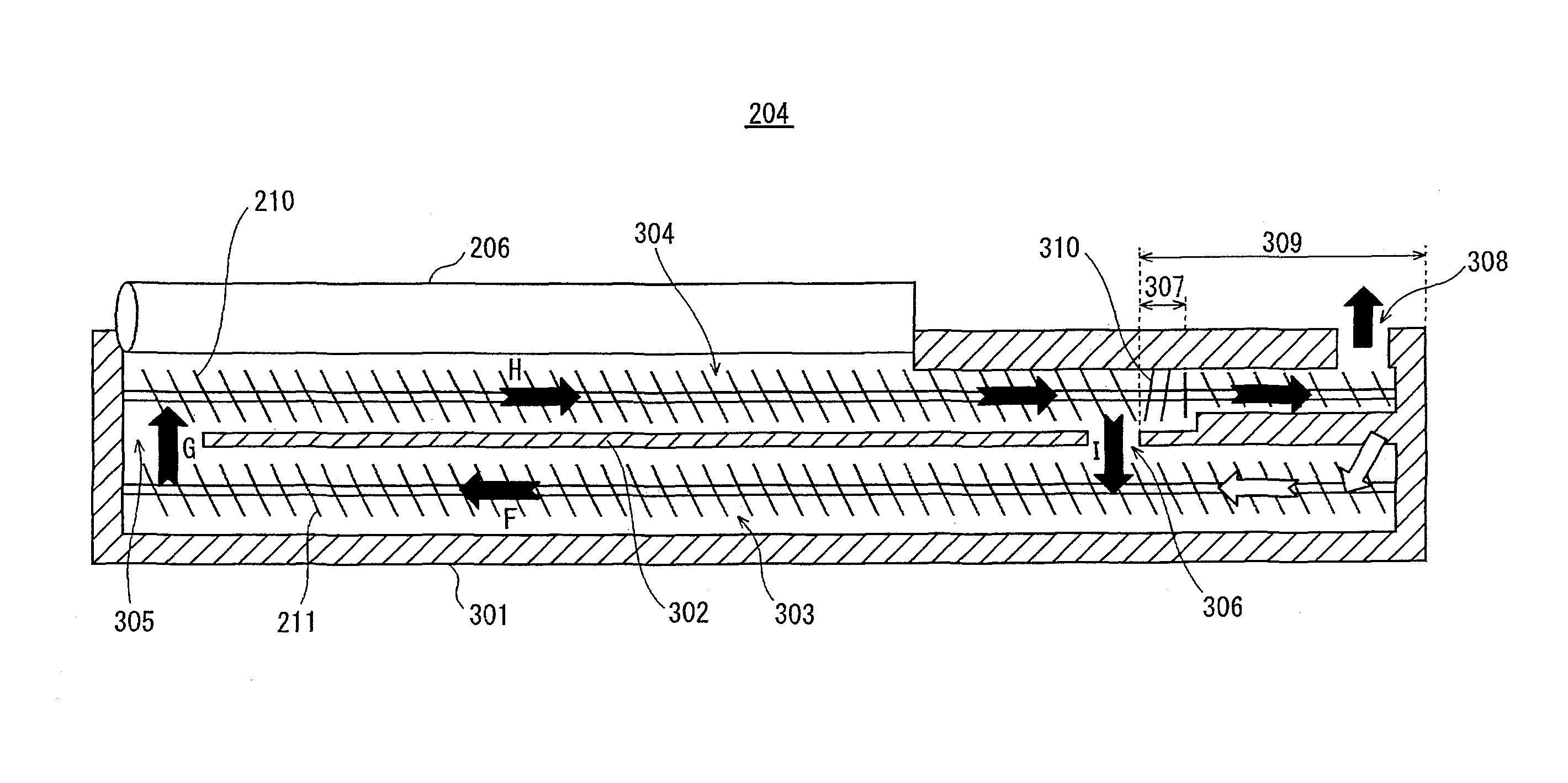

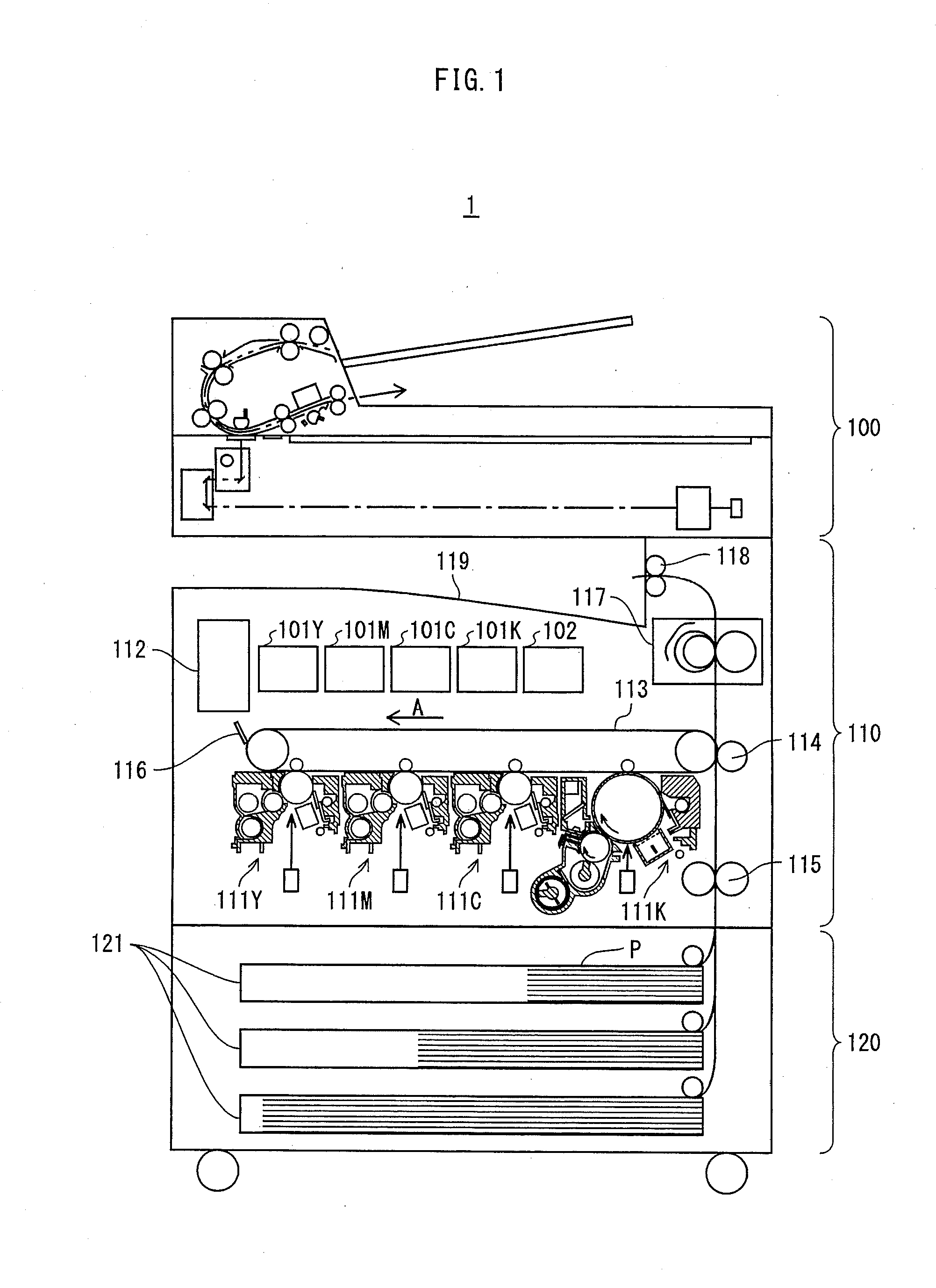

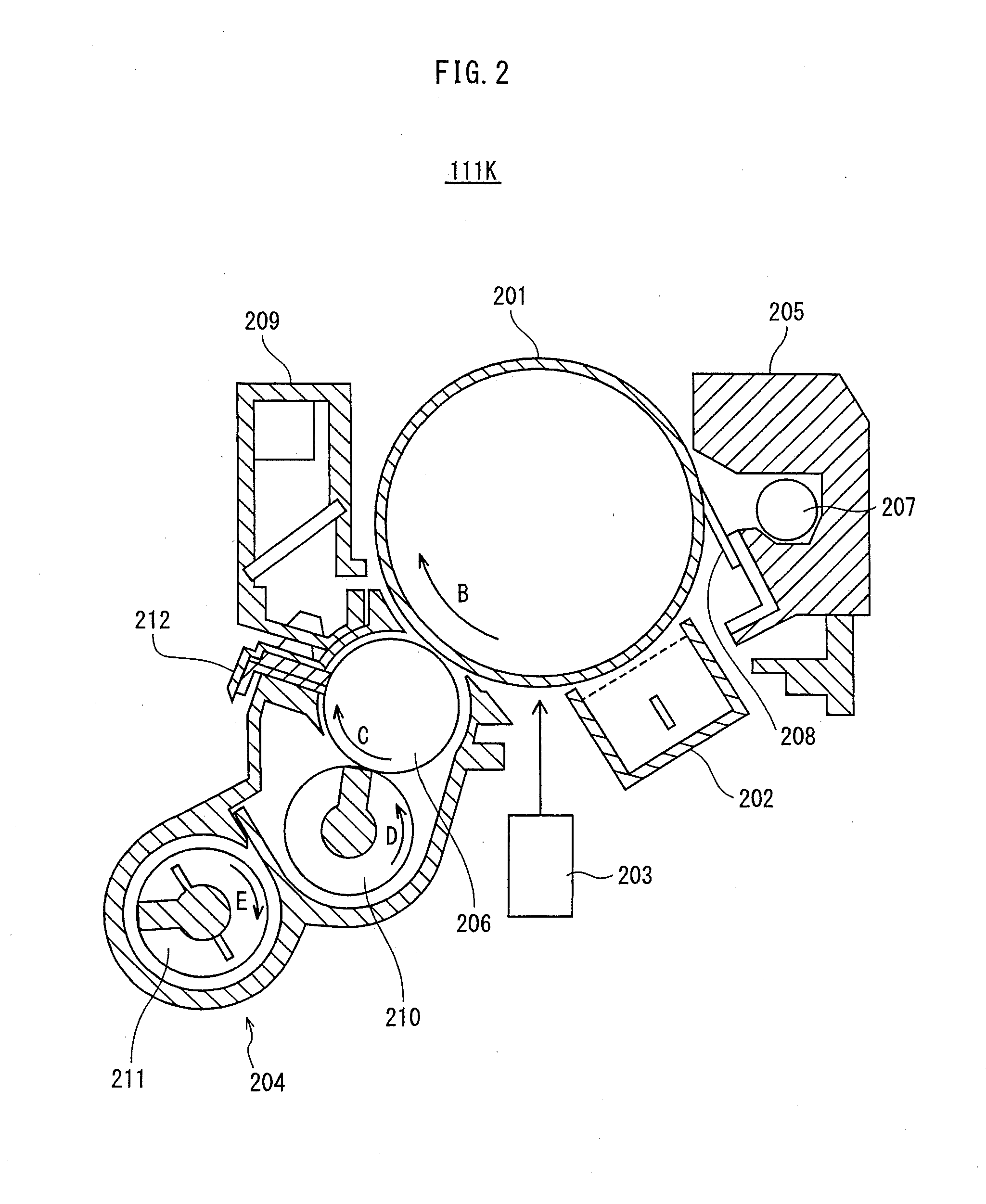

Developing device and image forming apparatus

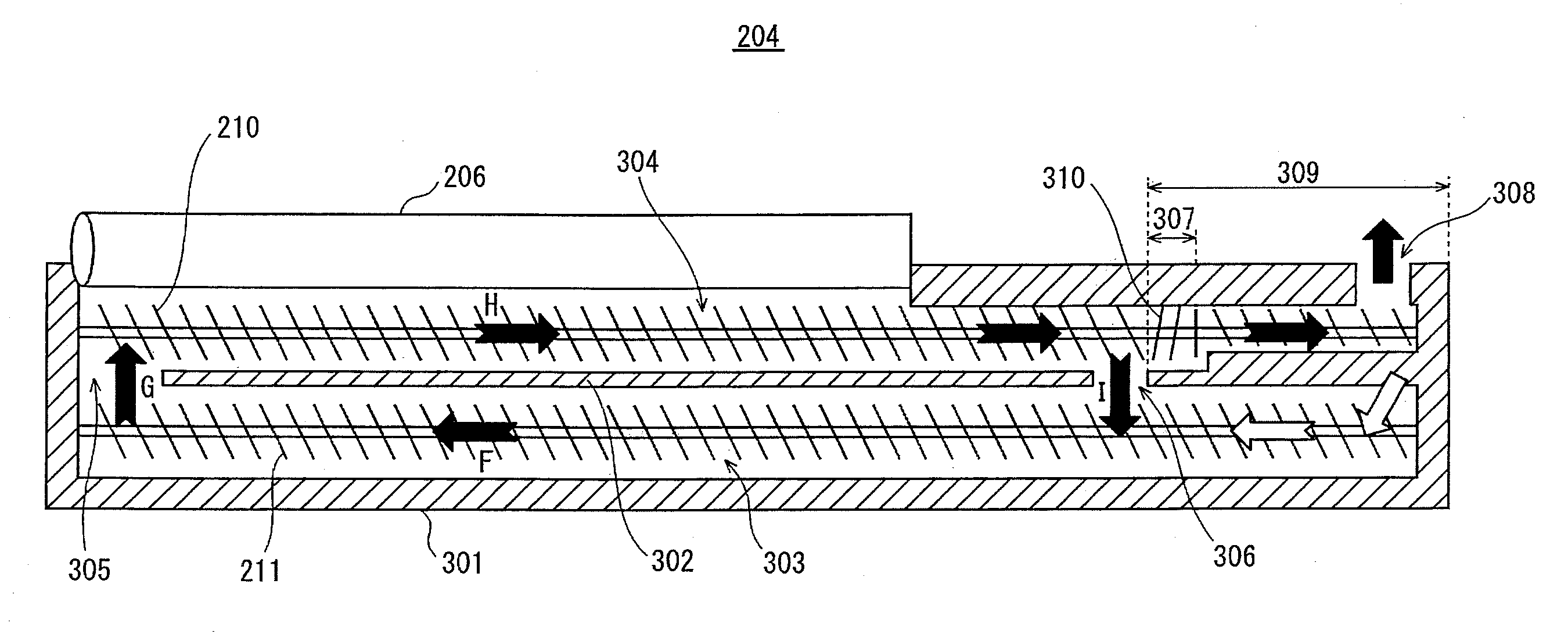

A trickle-type developing device comprising: a stirring and conveying tank provided with stirring and conveying screws that circulate the developer; a discharge member via which a part of the developer is conveyed from the tank to a discharge opening through which the developer is discharged, the discharge opening being provided in the discharge member; and a reverse flow generating screw provided inside a portion of the discharge member, sharing one of rotation shafts of the stirring and conveying screws, and pushing back a part of the developer, wherein the portion has a reduced-radius part and in a cross section thereof perpendicular to an axial direction of the one of rotation shafts, an inner radius of the portion is smaller in the reduced-radius part than in the remaining part, the reduced-radius part being located in a lower part of the portion with respect to a vertical direction of the portion.

Owner:KONICA MINOLTA BUSINESS TECH INC

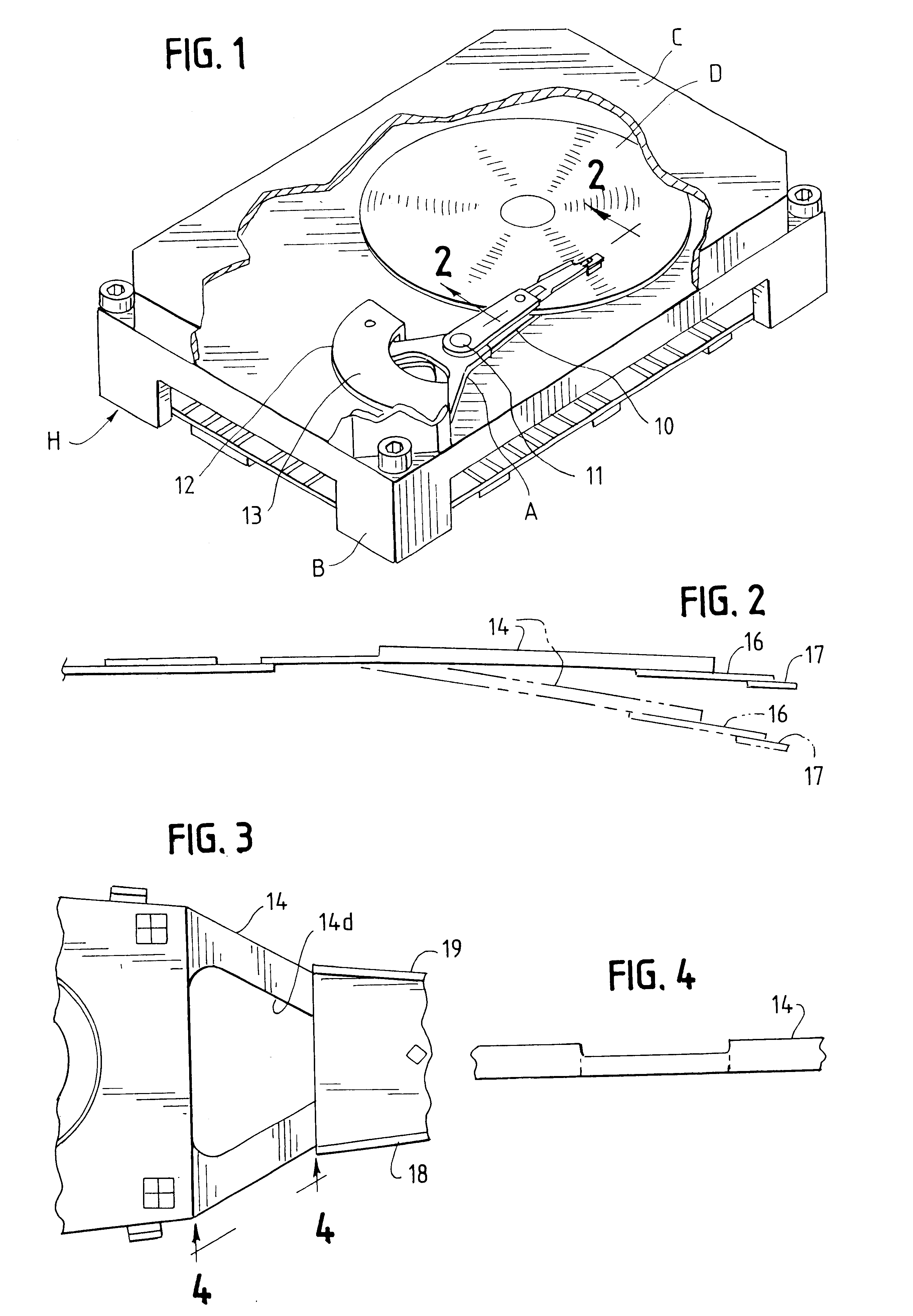

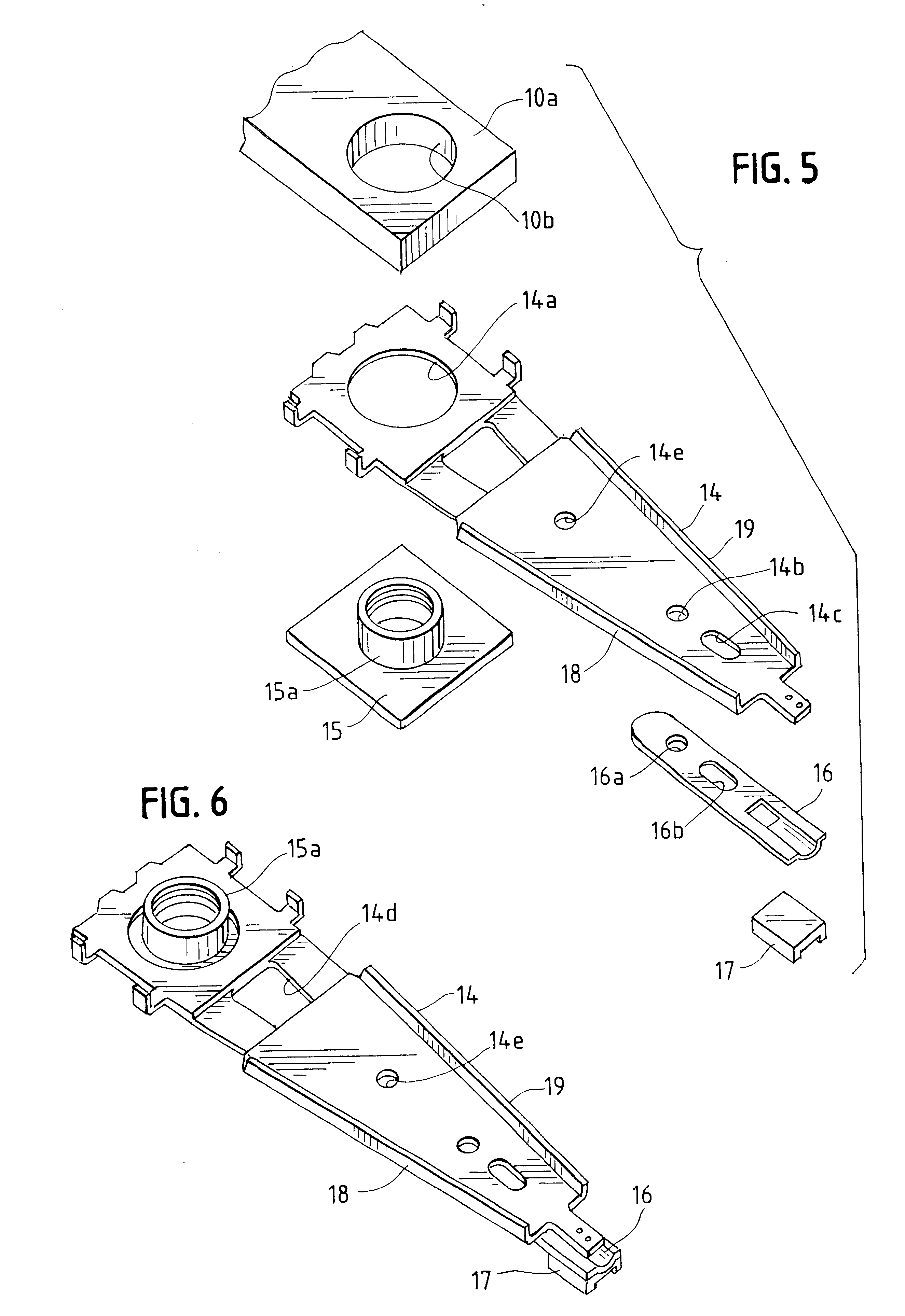

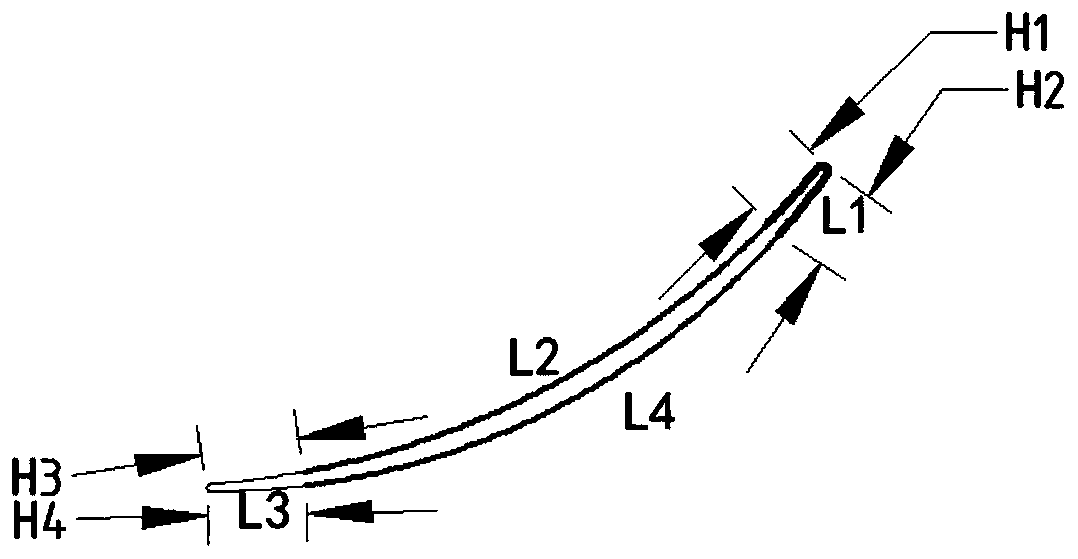

Suspension load beam for disk drive actuator with notch for reducing spring rate

A suspension load beam for an actuator assembly of a disk drive includes a bend radius portion with a spring rate that is less than 18 Newtons per meter, a first bending mode that is greater than 3,500 Hertz, and a first torsion mode that is greater than 5,300 Hertz. The method of making this suspension load beam includes cutting a sheet of material to form a flat suspension load beam including a bend radius portion, removing material in the bend radius portion from full thickness, inspecting the bend radius portion to determine its thickness, and removing material from the bend radius portion and / or from the main body of the suspension load beam to compromise the performance difference due to thickness variation in bend radius portion.

Owner:MAXTOR

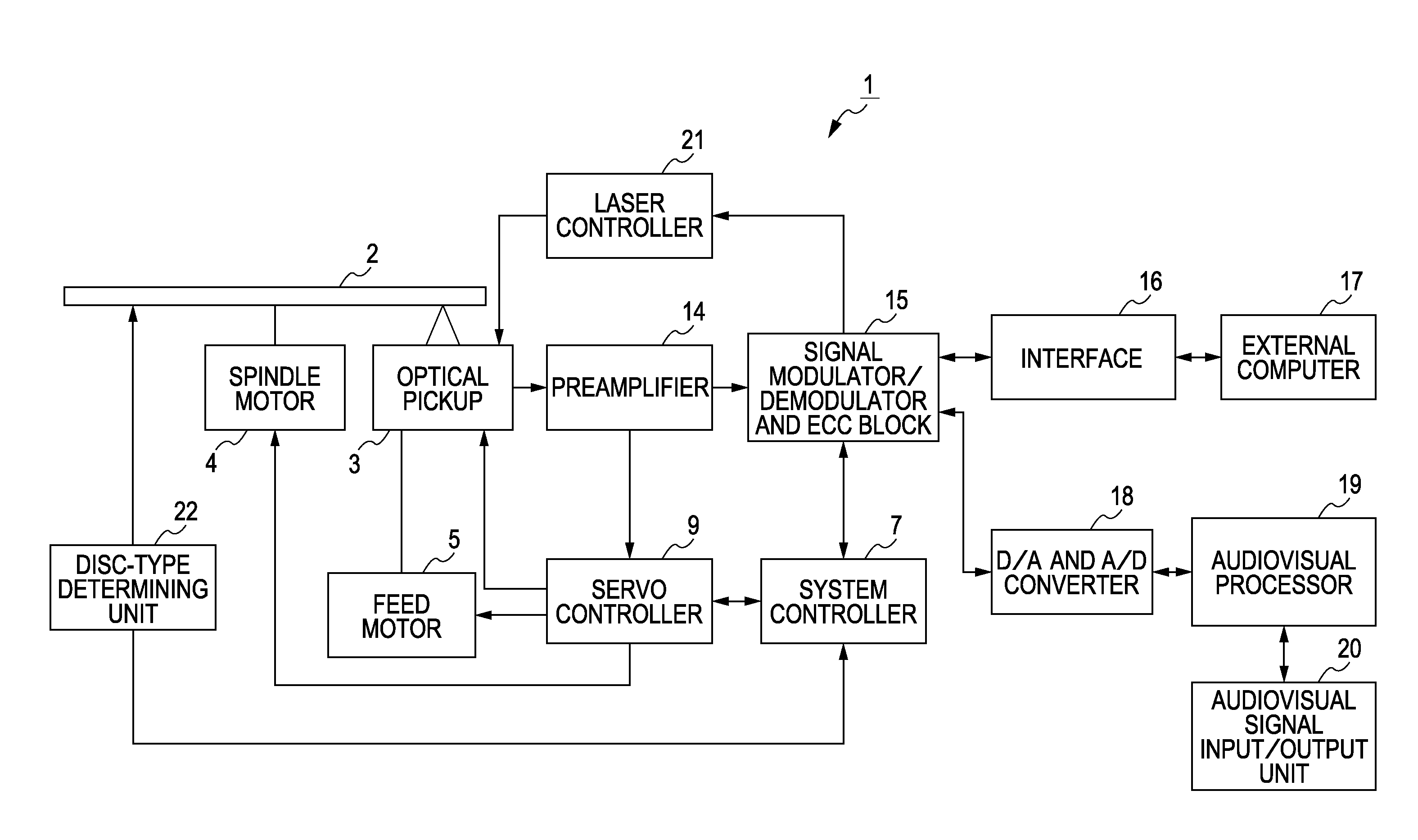

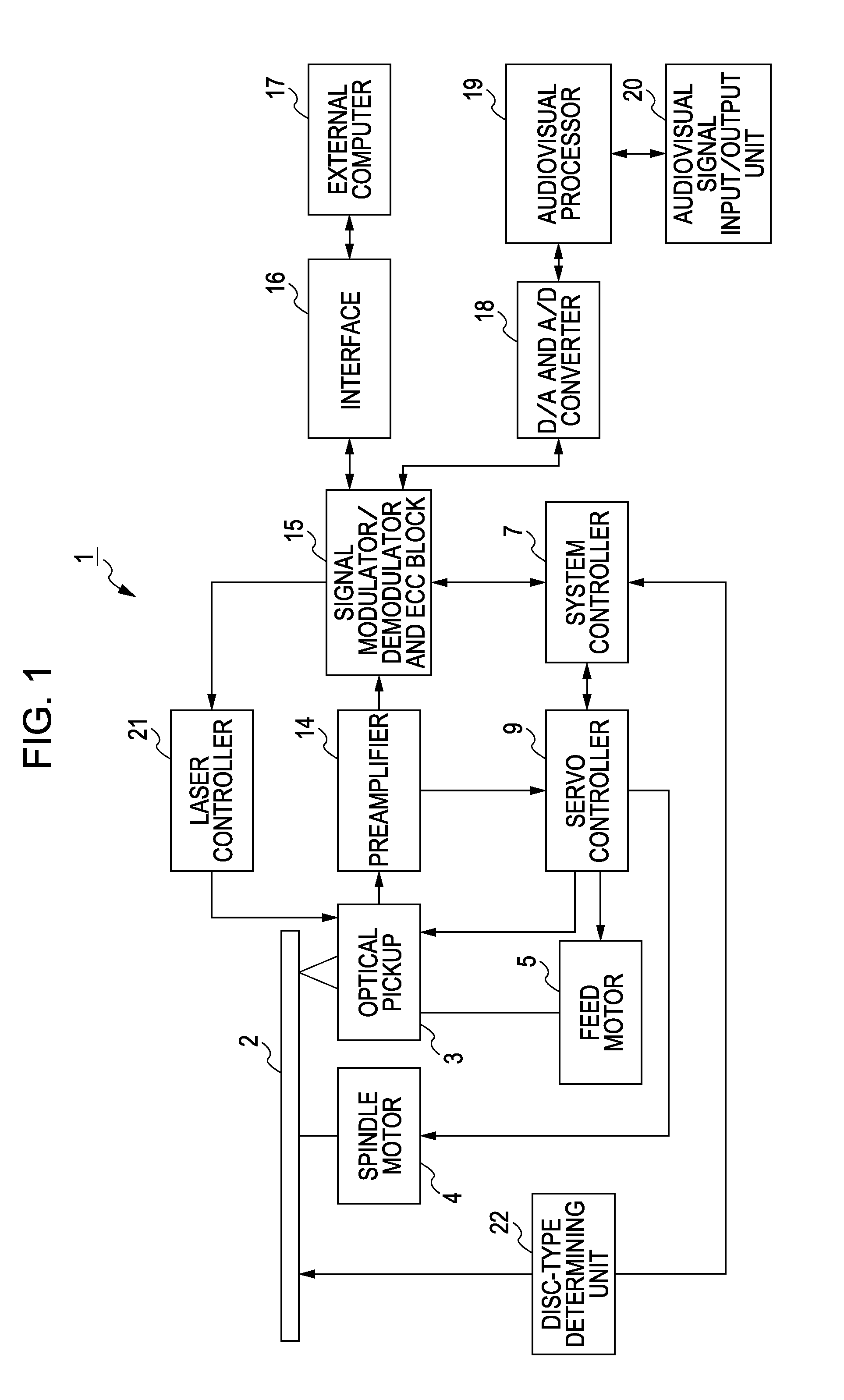

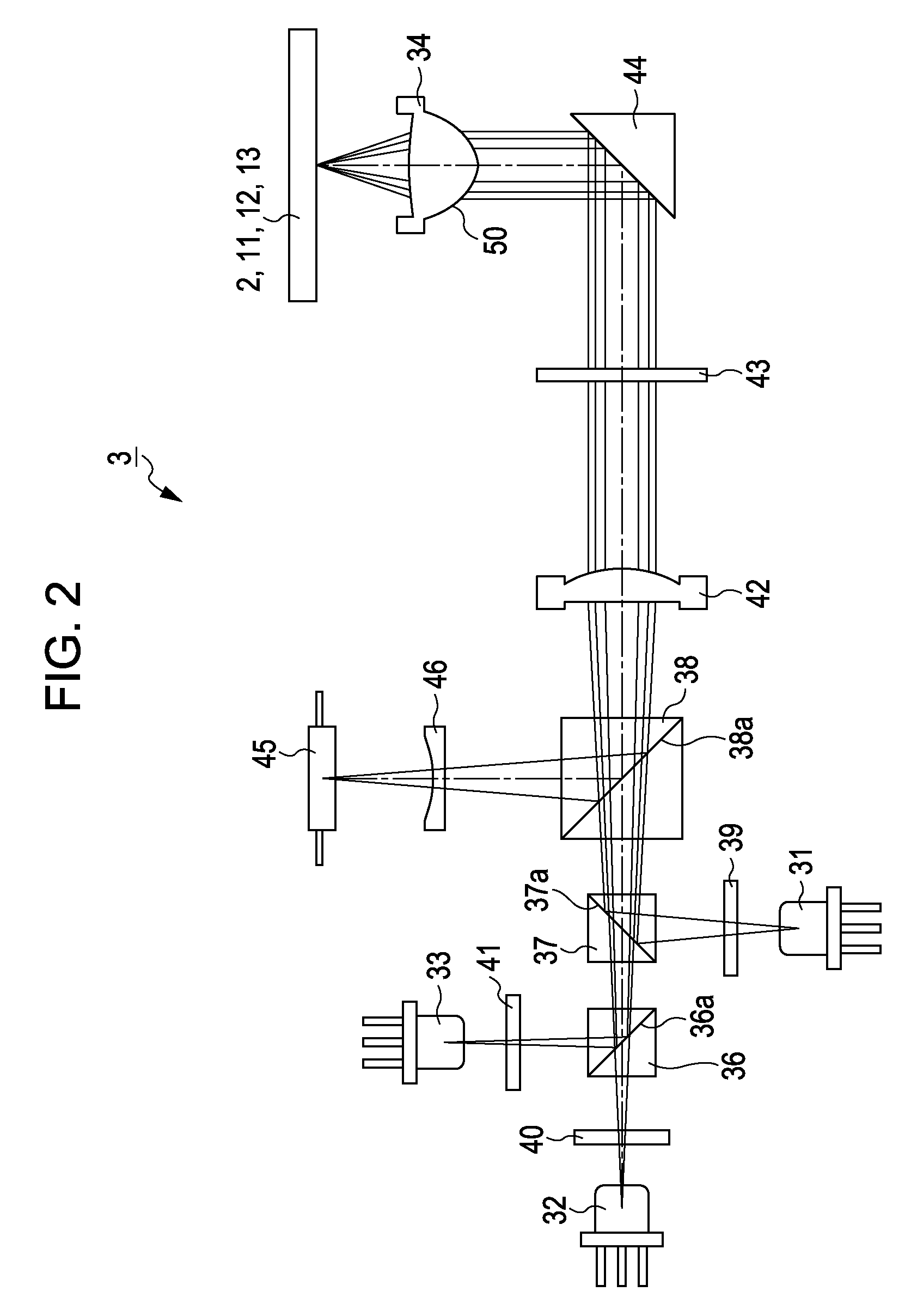

Objective lens, optical pickup, and optical disc apparatus

ActiveUS20100322059A1Servo control is prevented from becoming unstableEasy to recordRecord information storageOptical beam guiding meansOptical pickupLight beam

Provided is an objective lens for selectively focusing each of light beams having three wavelengths λ1, λ2, and λ3 on a signal recording surface of a corresponding optical disc, the wavelengths λ1, λ2, and λ3 satisfying at least a relationship λ1<λ2<λ3, the objective lens including a diffraction section disposed on an entry-side surface thereof, the diffraction section including a first region disposed in an innermost radius portion, a second region disposed outside the first region, and a third region disposed outside the second region, the first to third regions being formed so that an aperture of the light beams are appropriately limited, the first region including a staircase-like diffractive structure having a certain number of levels configured so that diffracted light of a predetermined order has the highest diffraction efficiency and optical-path-difference phase amounts for the levels of the diffractive structure has a certain relationship.

Owner:SONY CORP

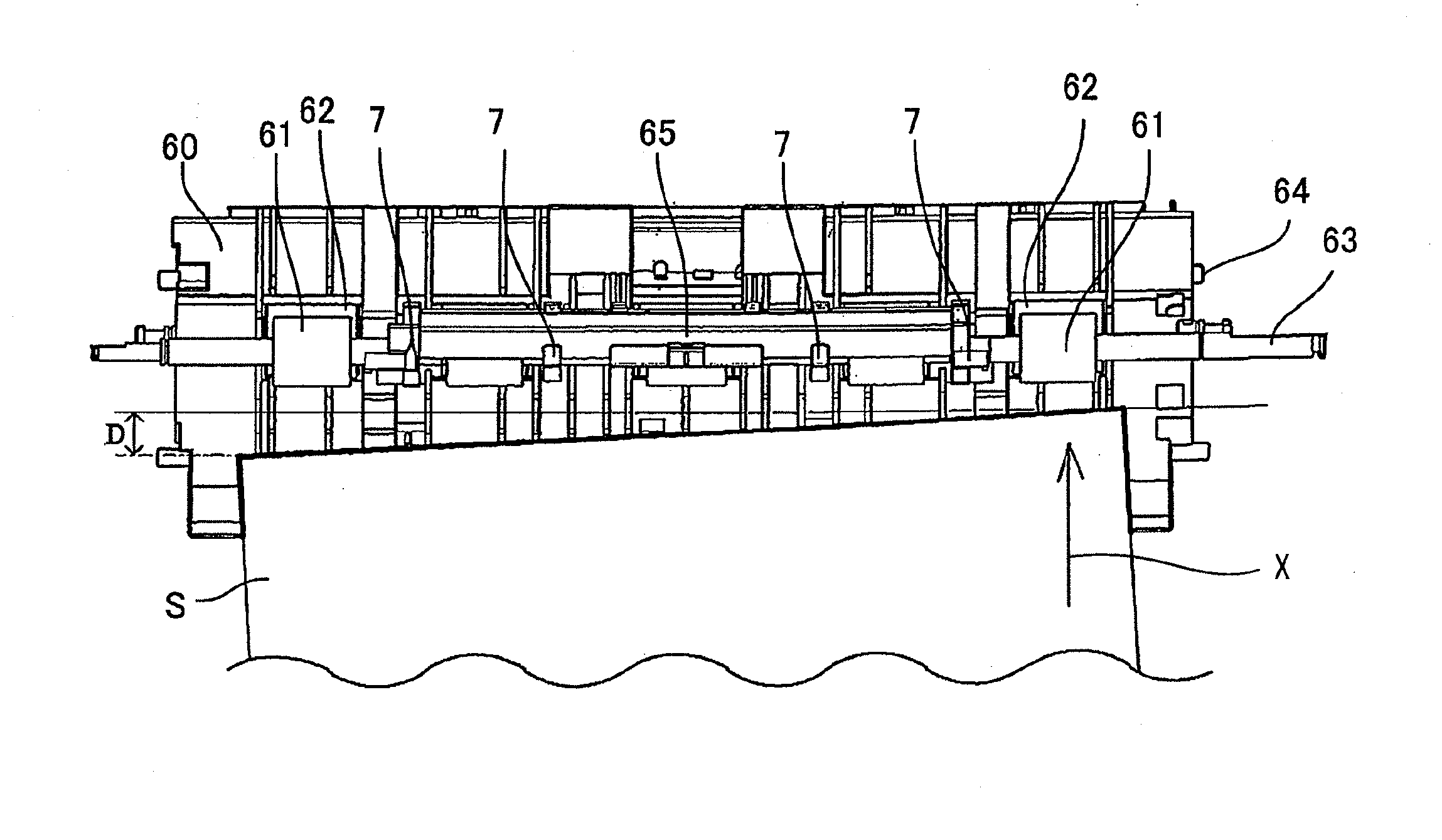

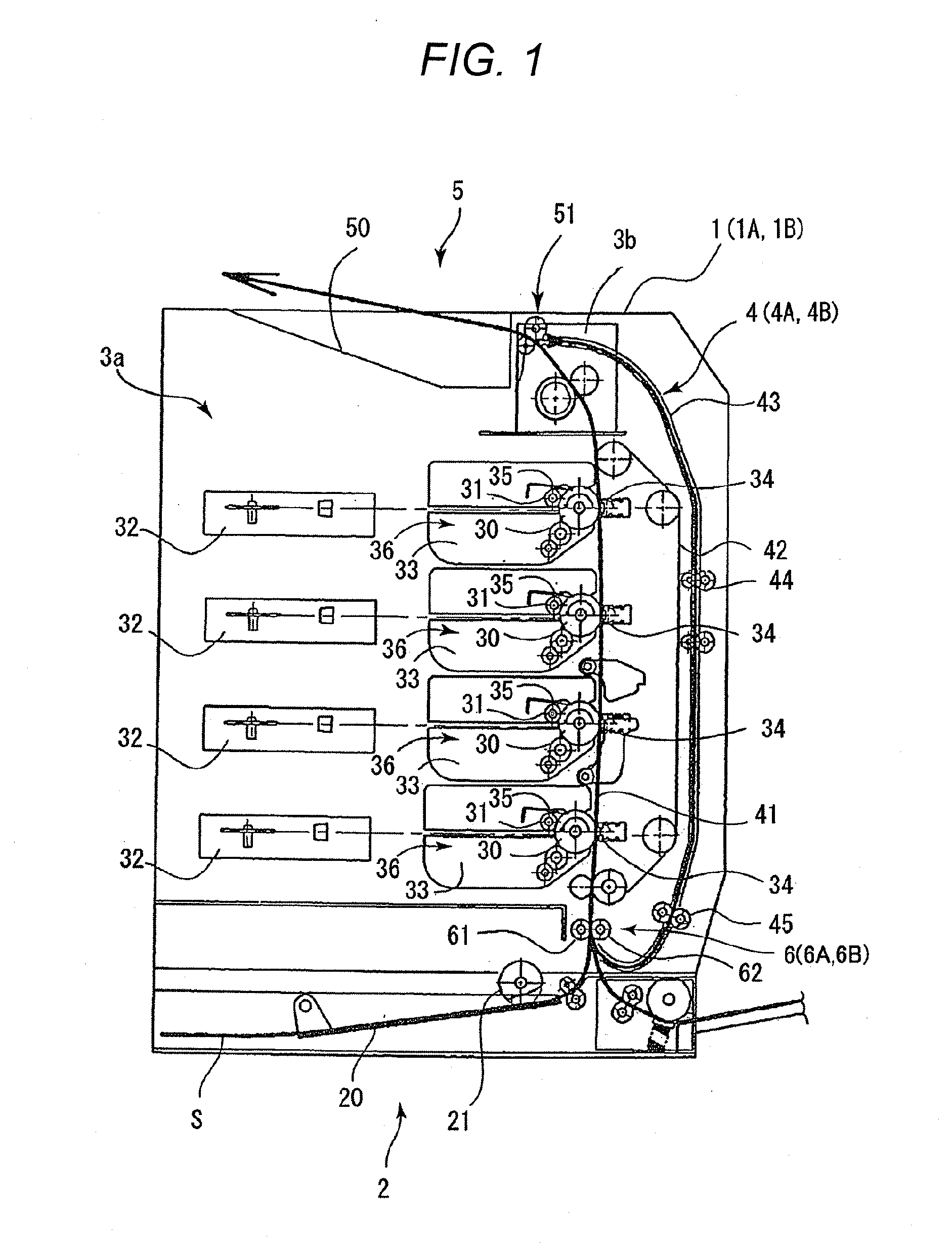

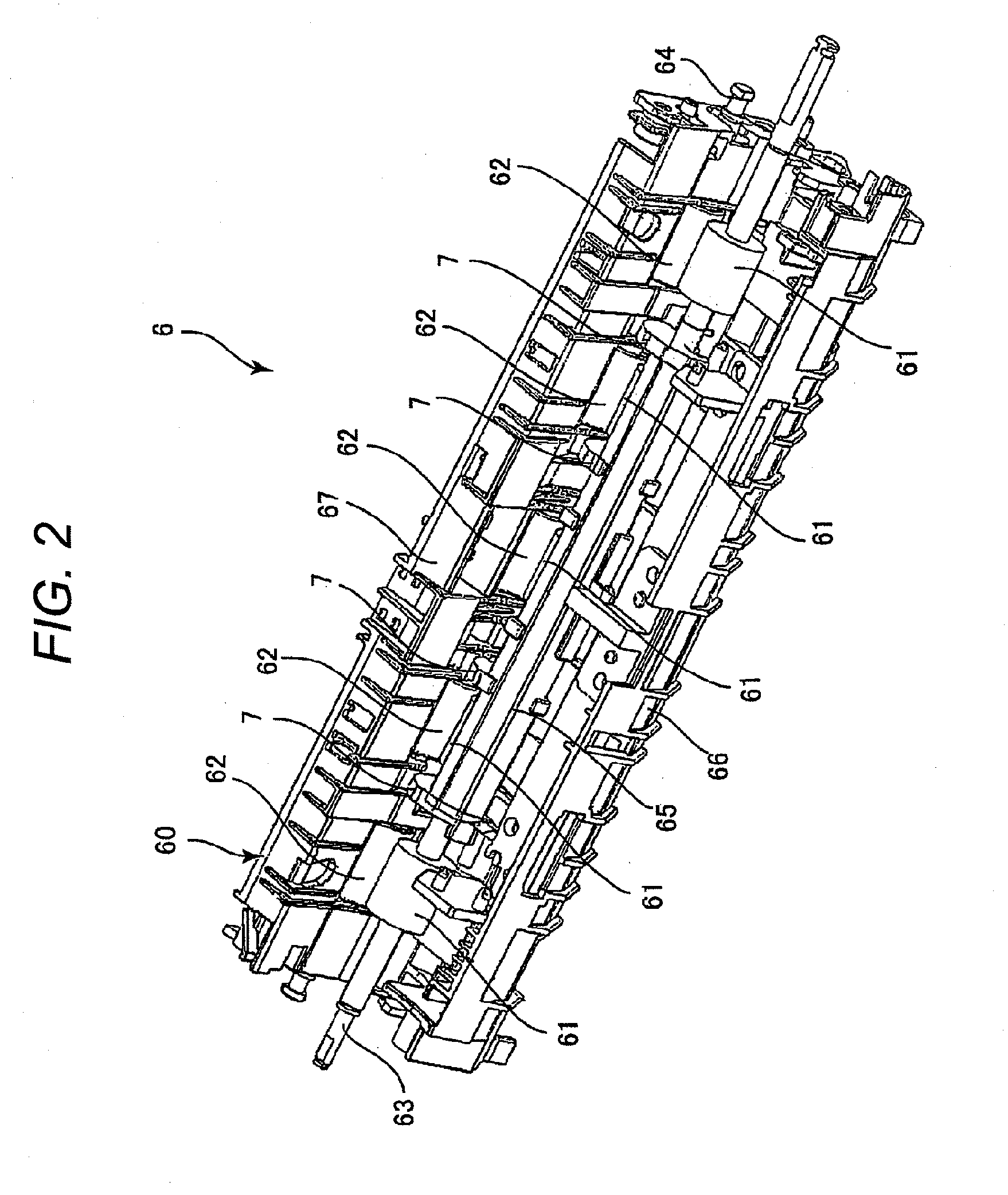

Sheet conveying apparatus and image forming apparatus

ActiveUS20120080838A1InhibitionCorrect skewRegistering devicesArticle feedersSheet materialRadius part

A sheet conveying apparatus including: a conveying roller pair conveying a sheet by a nip portion; a shutter portion which is rotatably supported on a rotary shaft of the first conveying roller; a same radius portion, provided in the shutter portion, which is formed to have substantially the same radius as a radius of the first conveying roller; an abutment portion, provided in the shutter portion, and against which the leading edge of the sheet is abutted; and a boundary portion, provided in a boundary of the abutment portion and the same radius portion, which guides the leading edge of the sheet to the nip portion when the shutter portion is rotated by abutting the leading edge of the sheet against the boundary portion.

Owner:CANON KK

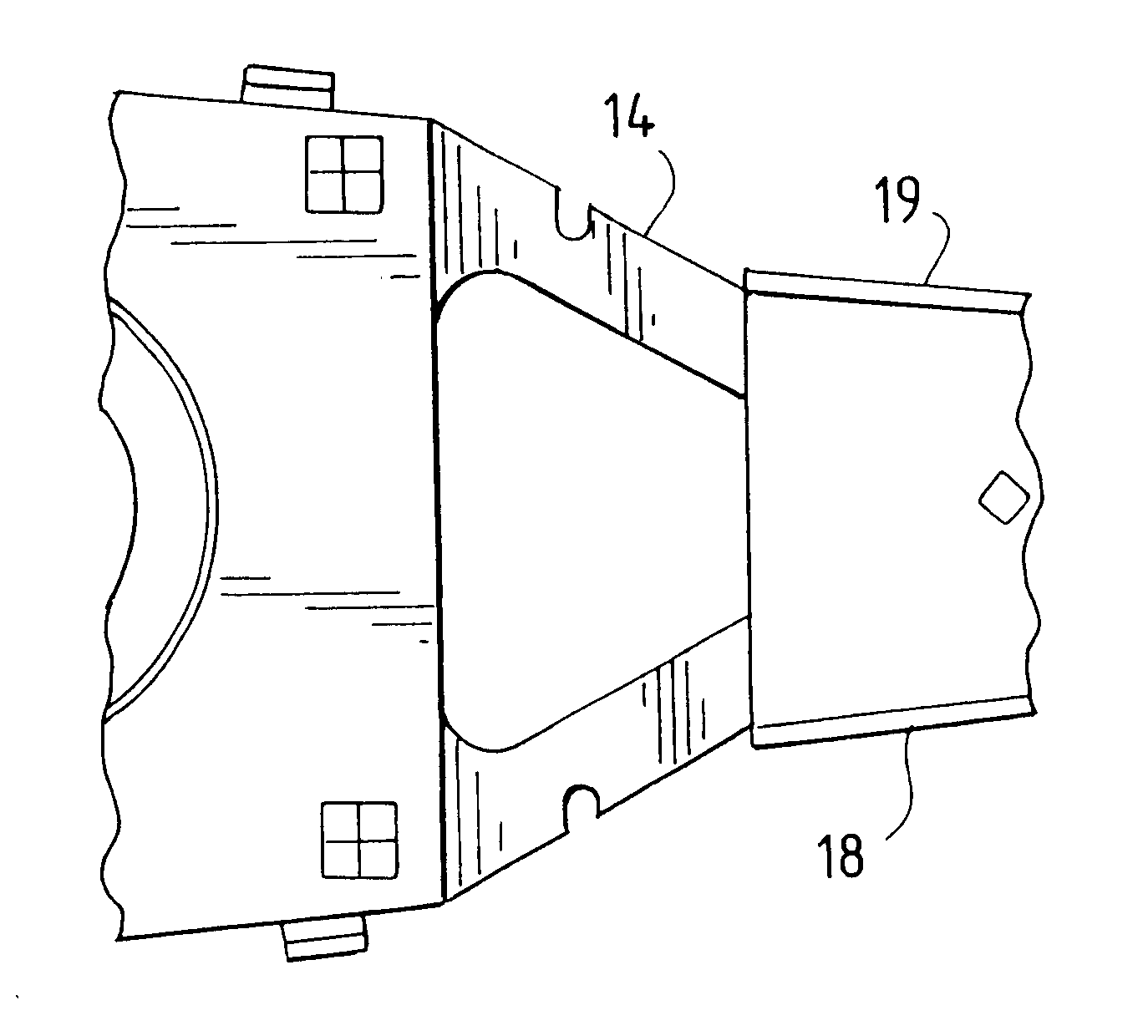

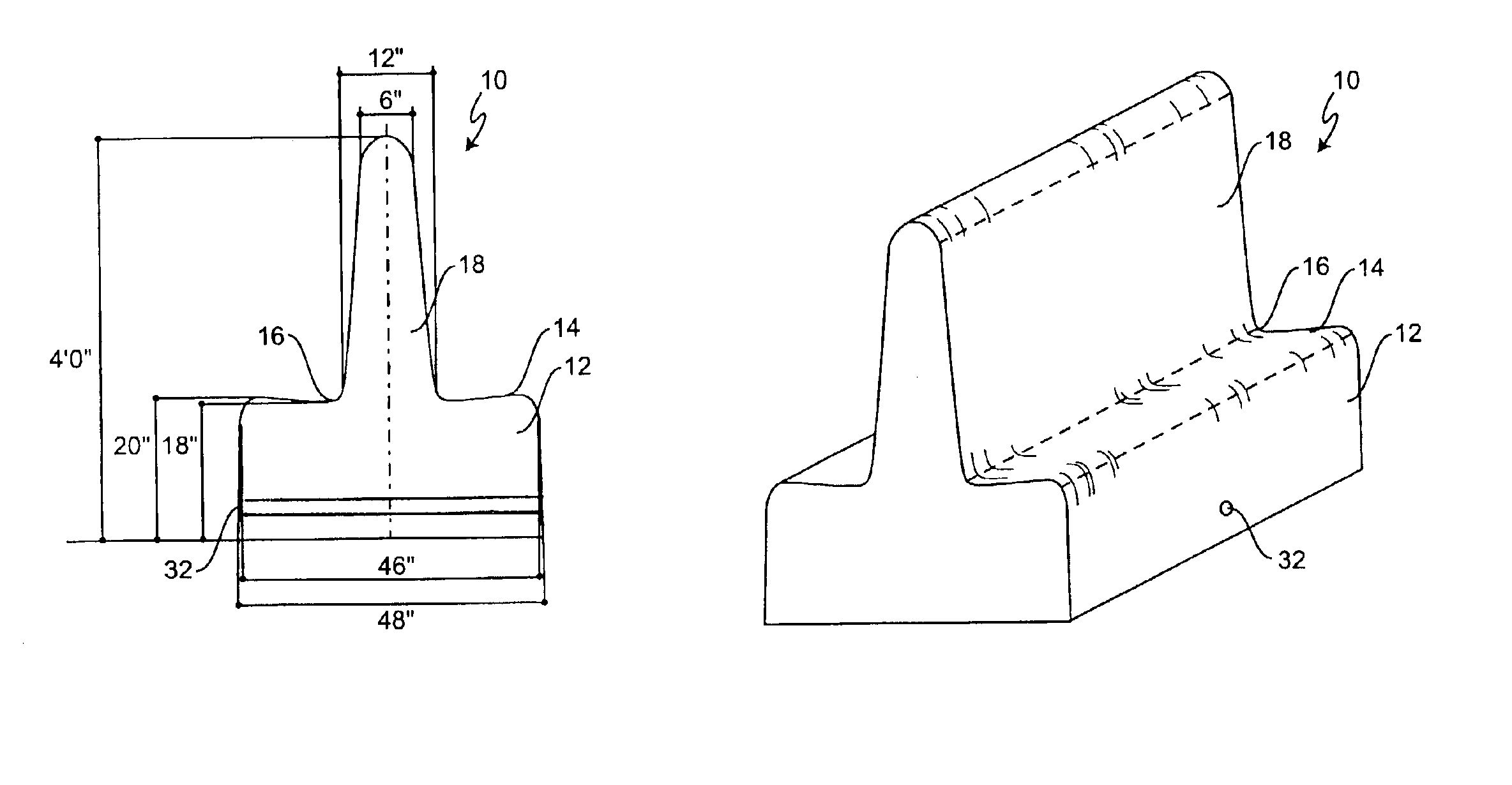

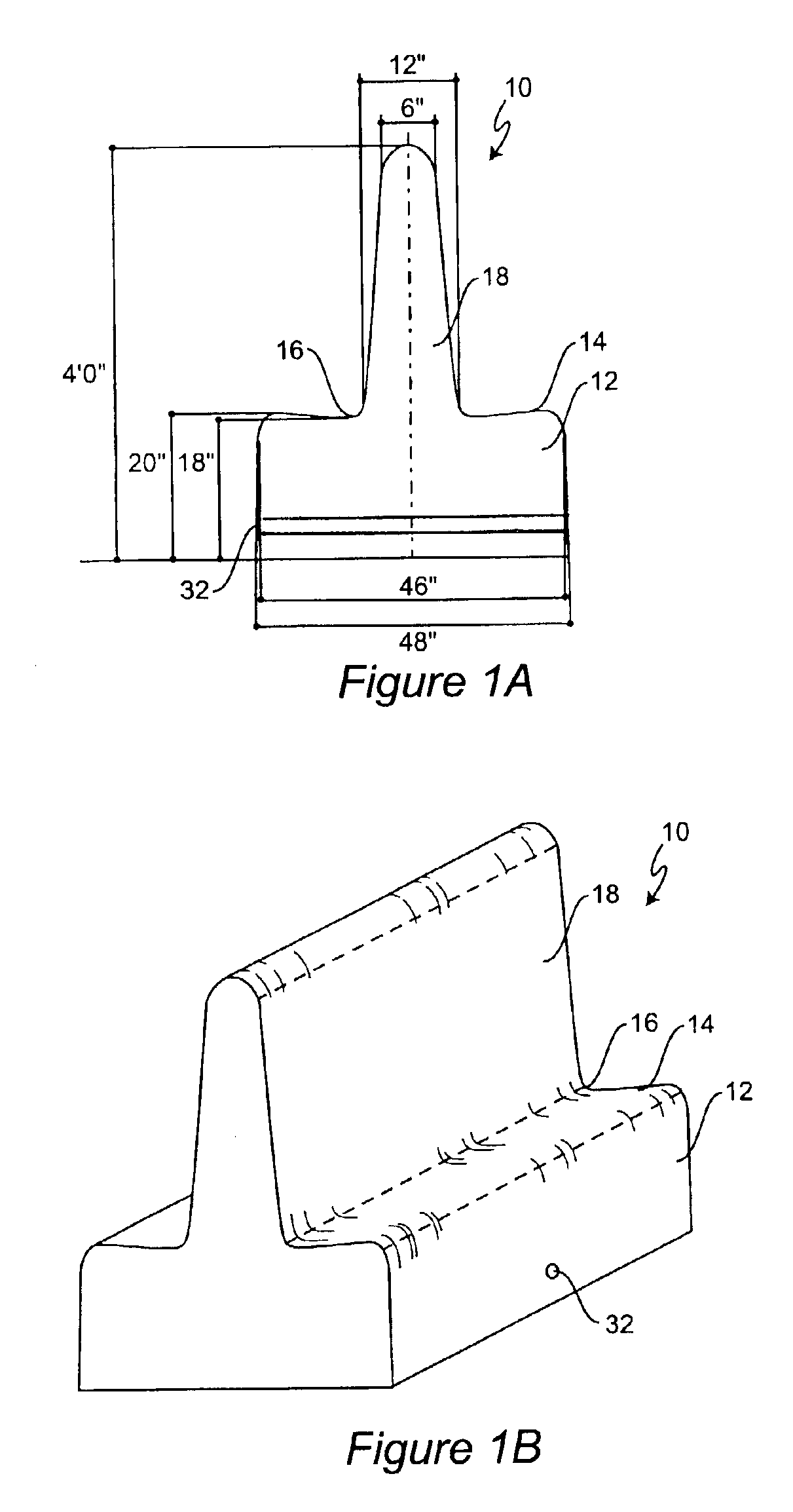

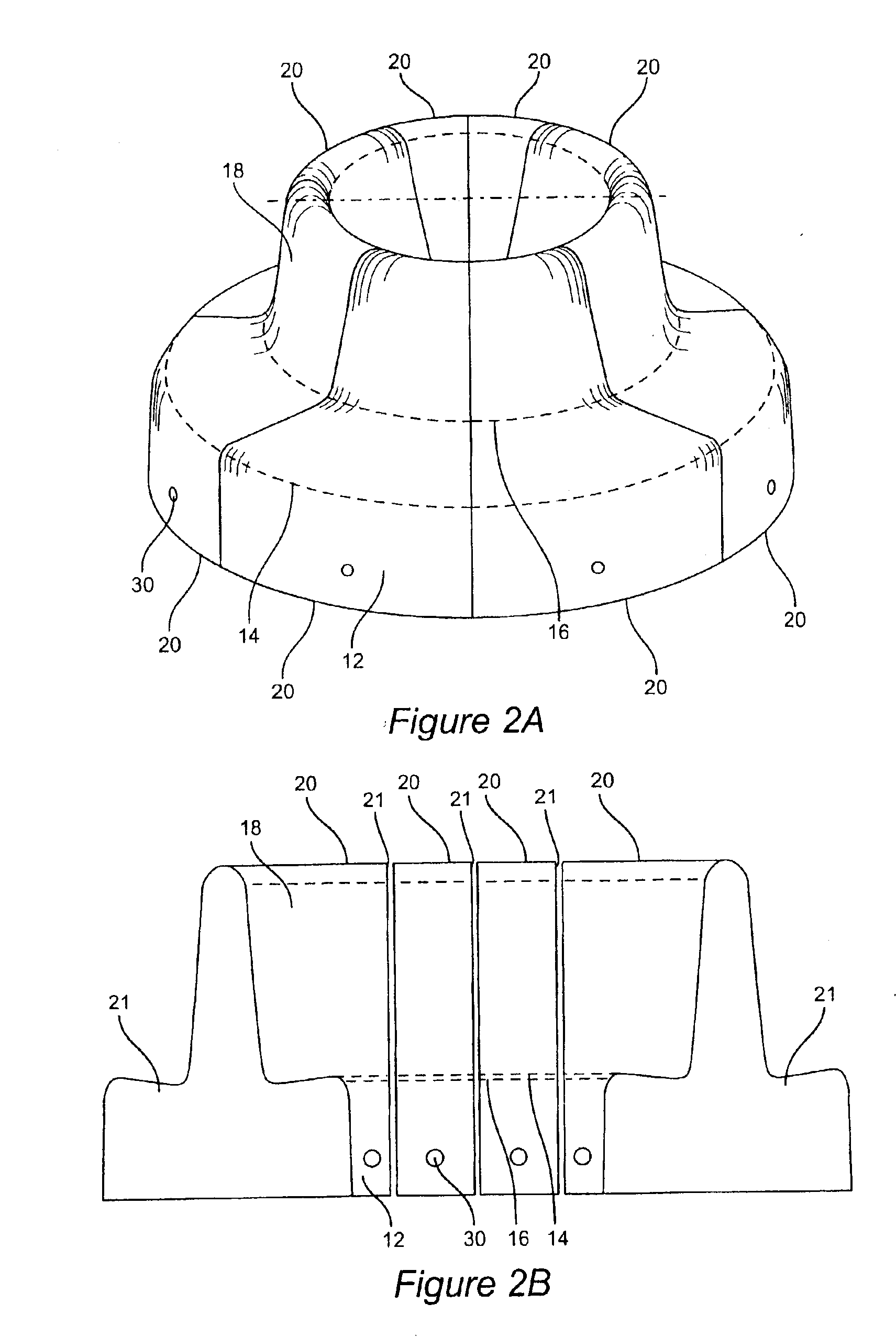

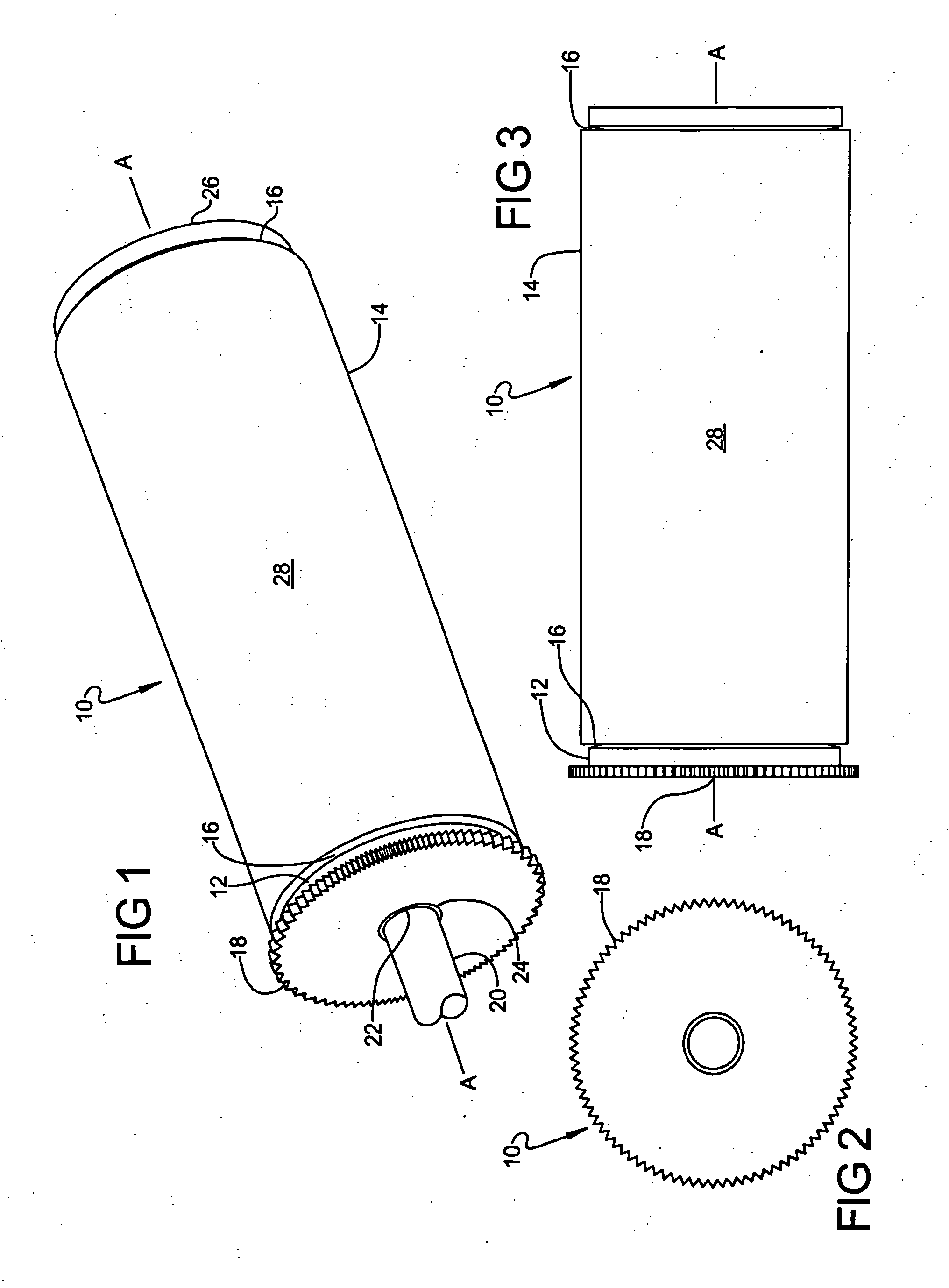

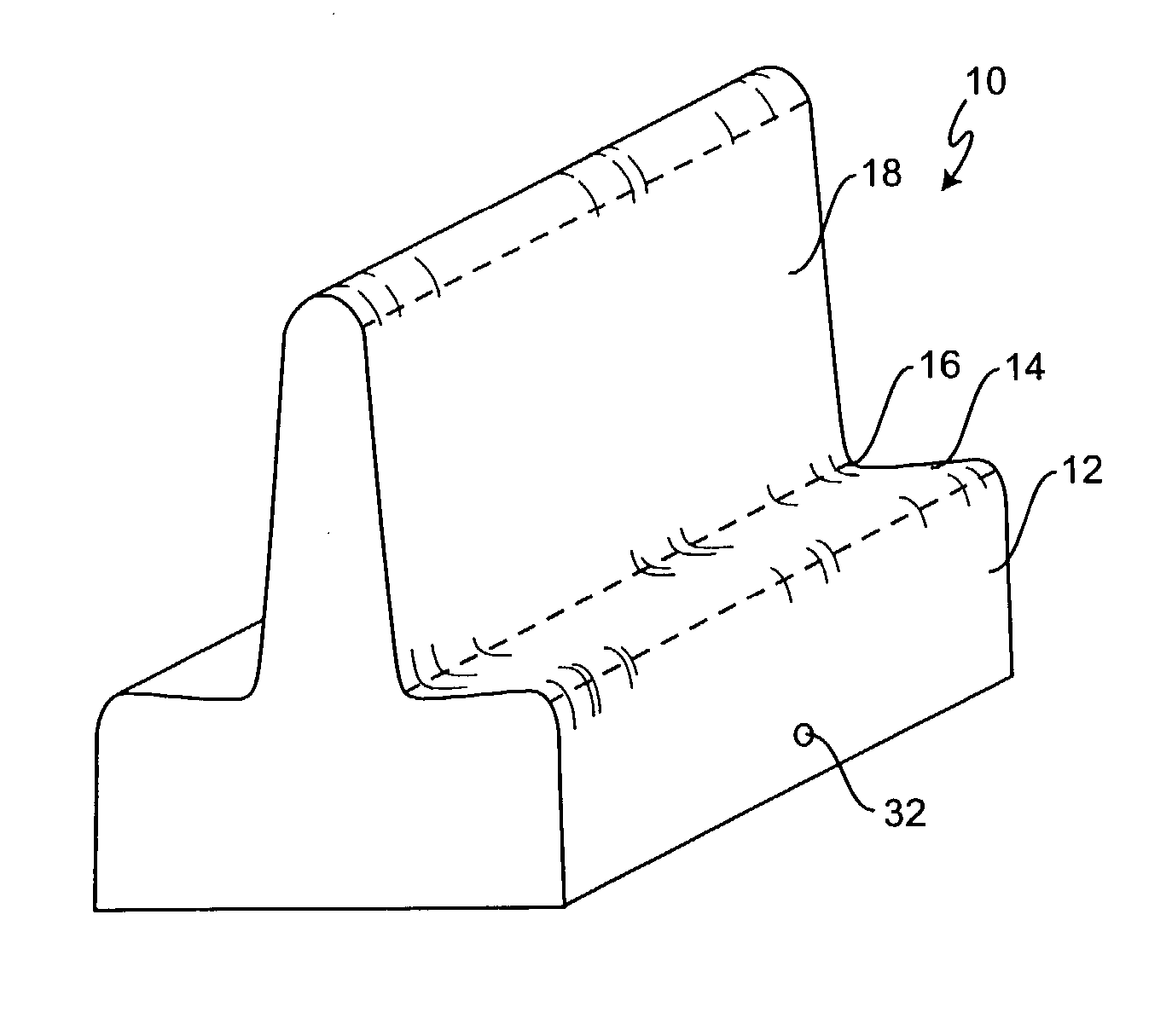

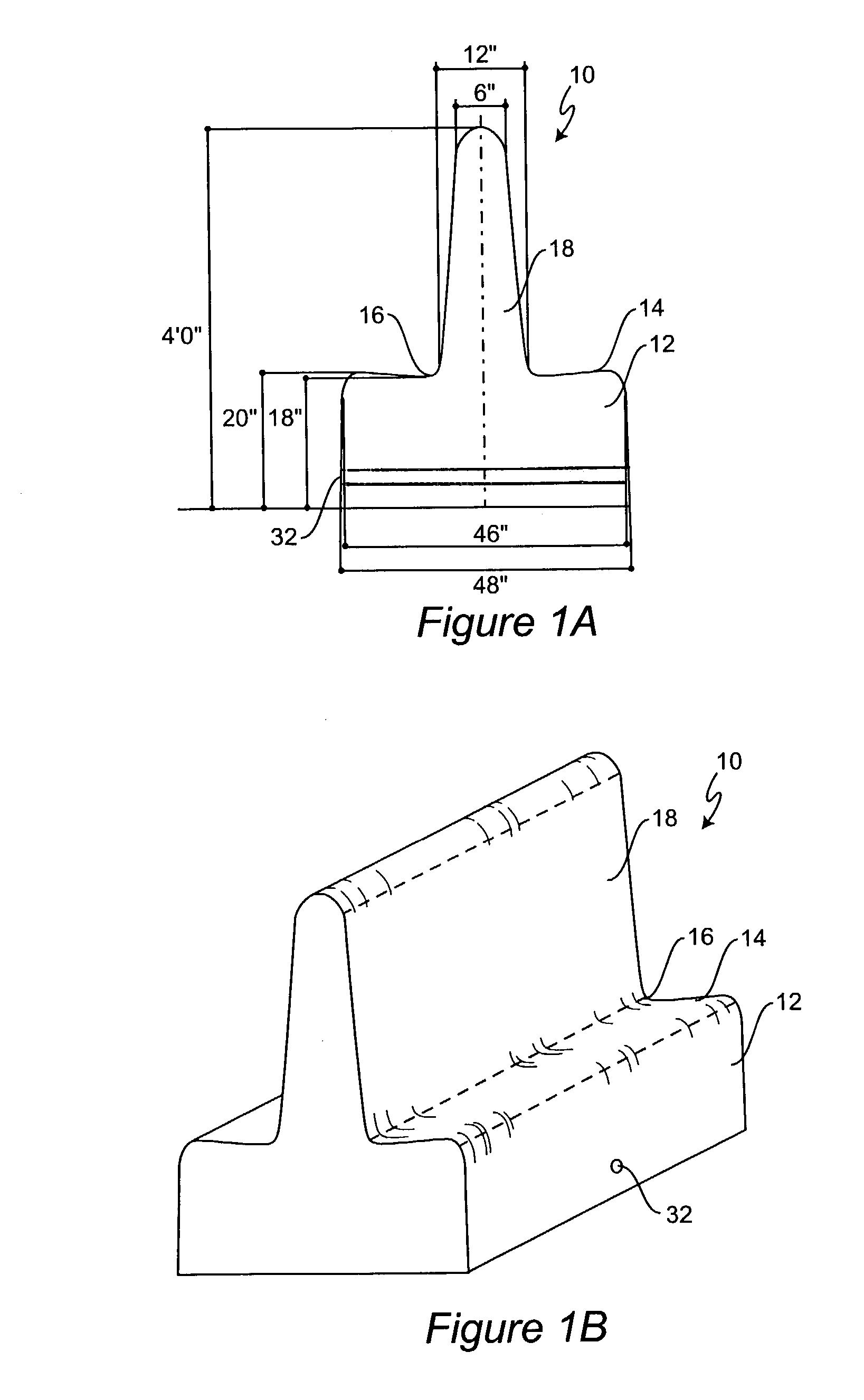

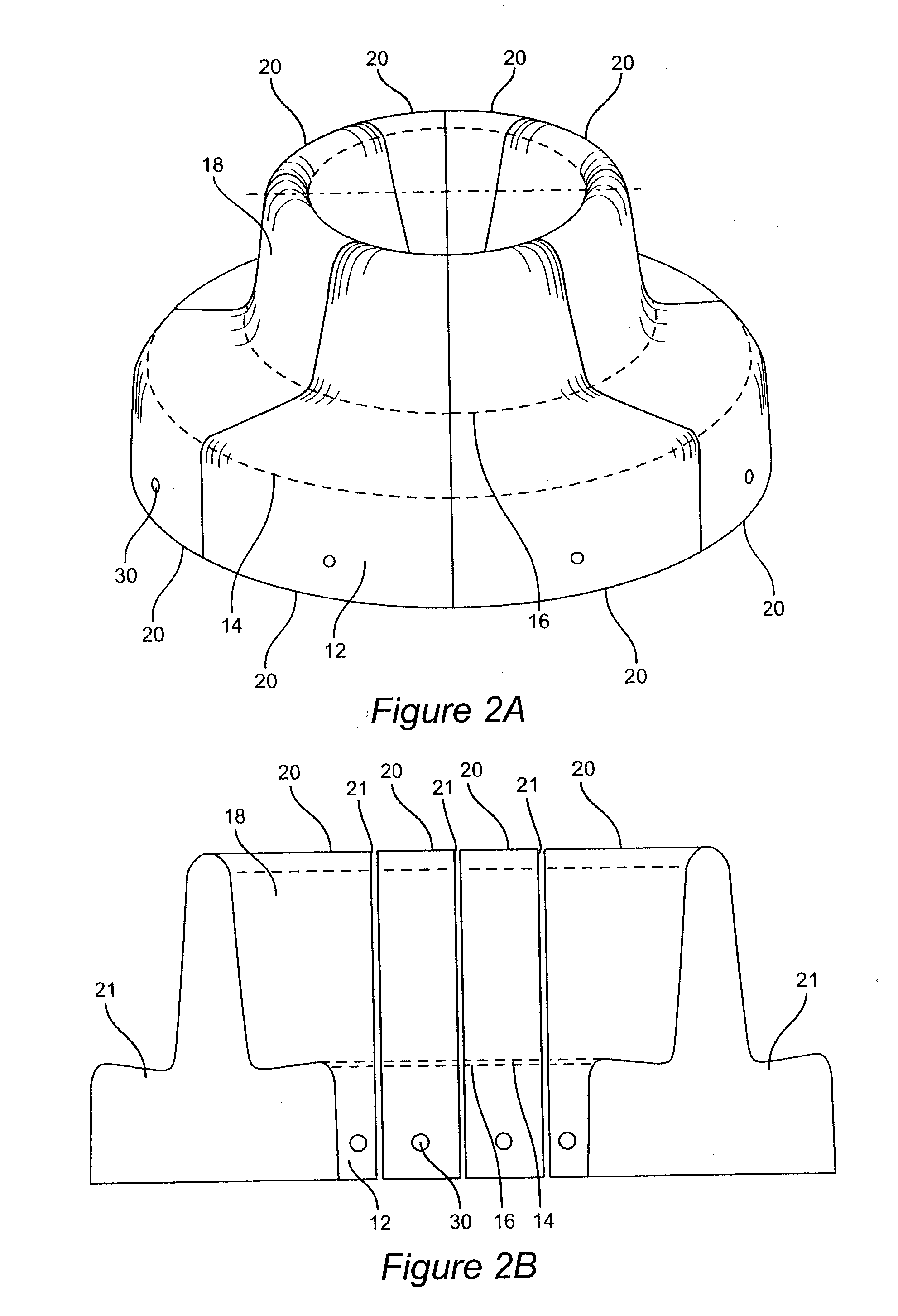

Decorative bench barrier

InactiveUS6887010B2Easy to placeEasy to transportTraffic restrictionsRoadway safety arrangementsEngineeringBack rests

A decorative bench barrier serves the function of providing security for buildings, memorials, and people, while at the same time providing aesthetically pleasing seating suitable for long term use on city streets, in parks, and in other areas. The decorative bench barrier is constructed from one or more reinforced precast concrete elements which include a wide base, a central seating region, and a top back rest. The reinforced precast concrete elements are made in straight sections and radius sections. The radius sections are preferably either 45° or 90°. The sections are interconnectable so that a circular, square, serpentine or other suitable configuration for the bench barrier can be assembled on site.

Owner:MAYER RODIS NANCY J

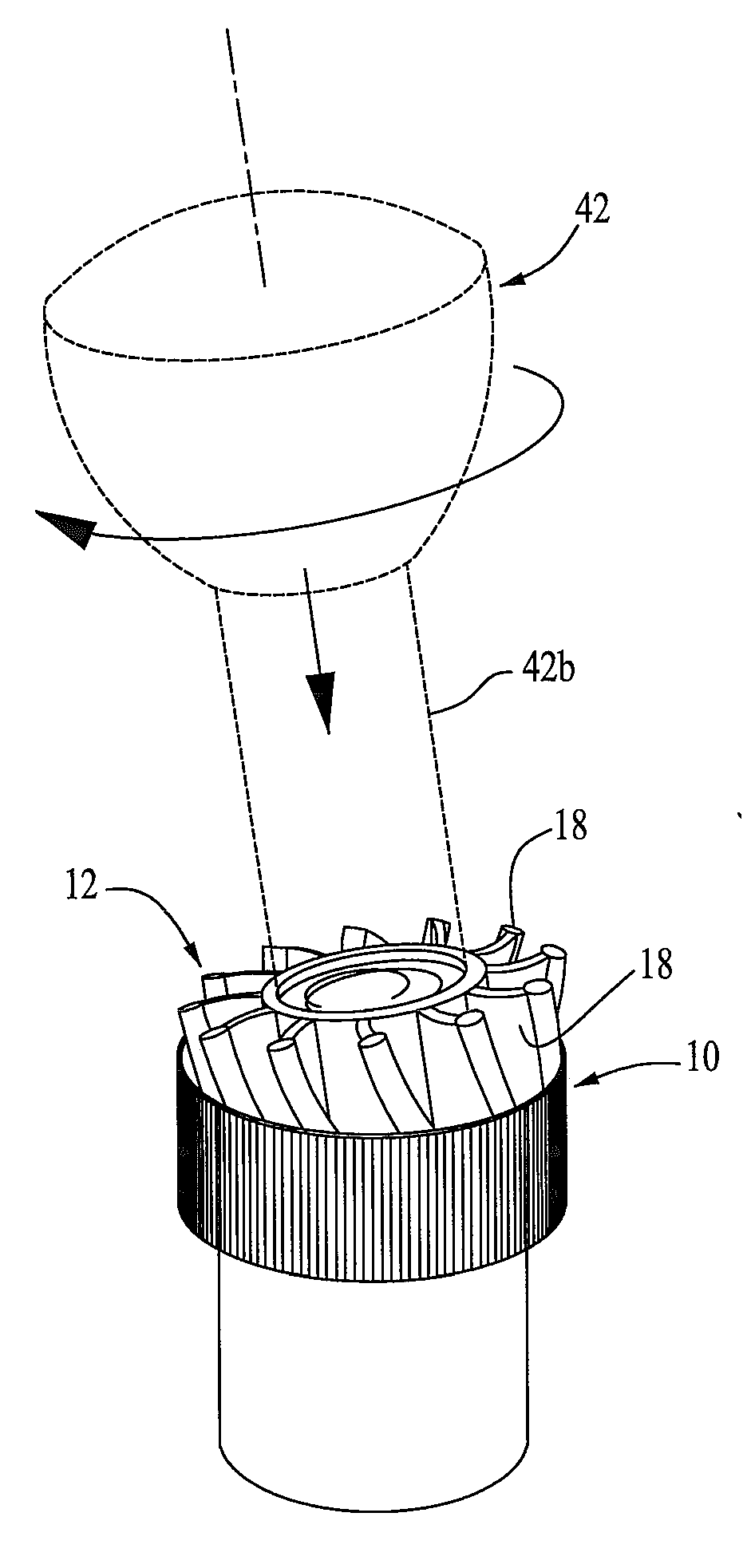

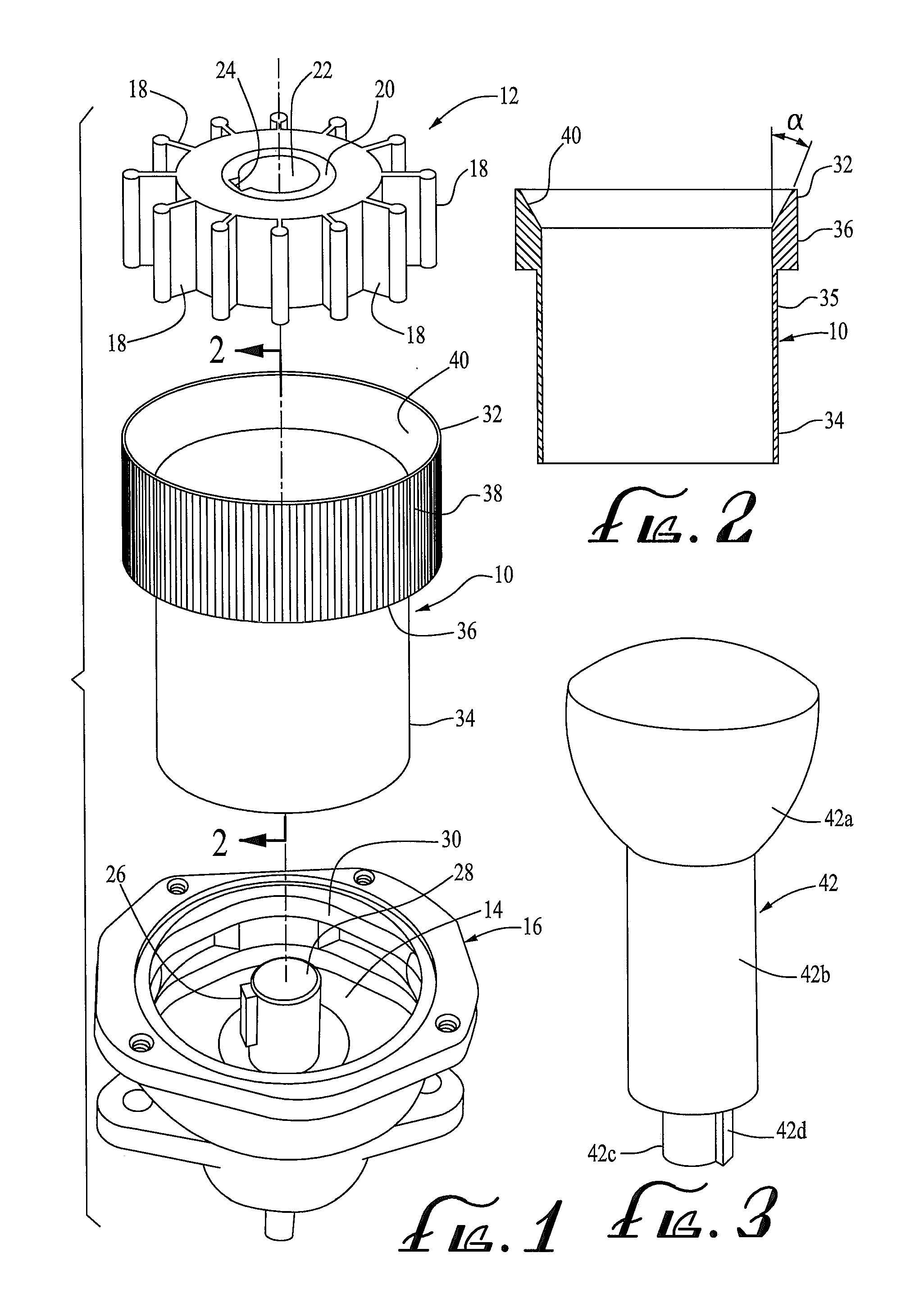

Impeller Installation Tool

ActiveUS20110146044A1Precise positioningEasy to installRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

A tool for installing a flexible impeller on a drive shaft in the impeller cavity in a water pump including a gripping surface extending about an upper portion of the tool and an open ended channel extending axially through the tool for receiving and releasably retaining a flexible impeller therein in a compressed state. The channel has an upper portion circumscribed by an annular outwardly inclined impeller abutment surface and a lower constant radius portion circumscribed by a depending cylindrical wall. The inclined impeller abutment surface terminates in the constant radius portion.

Owner:PECHERZEWSKI ANDRZEJ

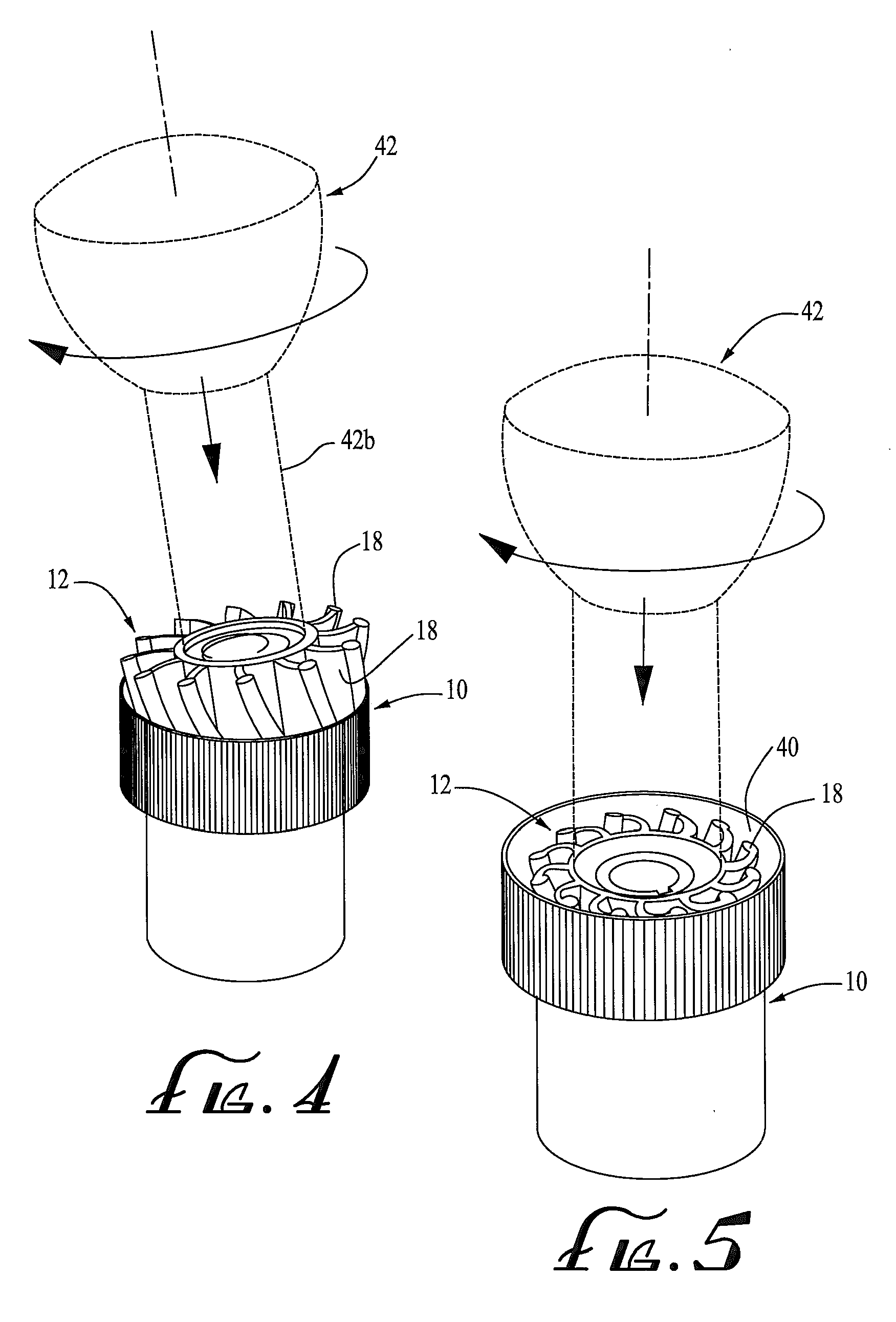

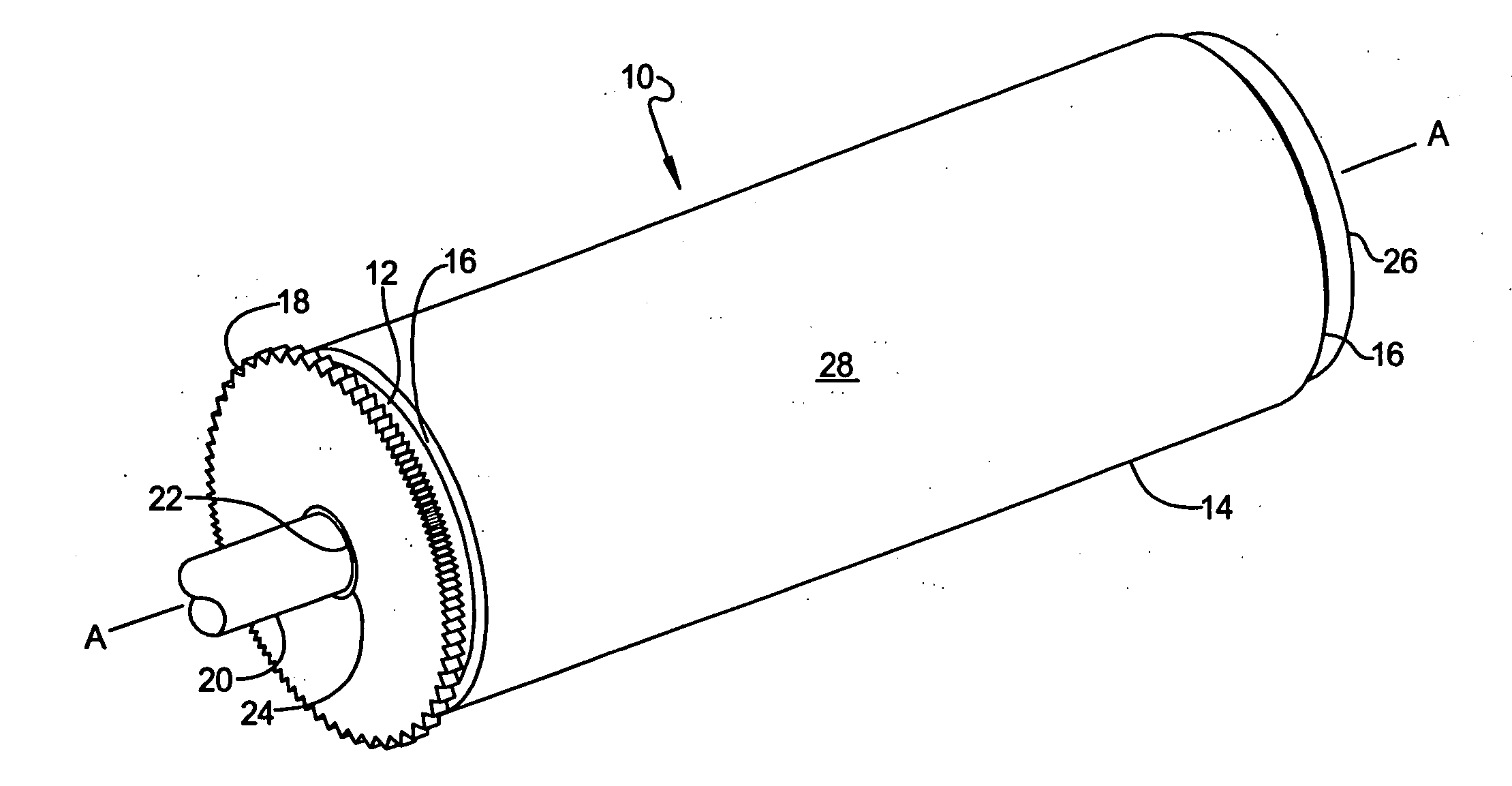

Apparatus and method of enhancing printing press cylinders

InactiveUS20060021530A1Consume energyAvoid print qualityRotary letterpress machinesRelief printingEngineeringPrinting press

A printing press cylinder and a method of manufacturing the same. The printing press cylinder includes a rigid base member having a reduced radius section and a polymer layer formed about the rigid base member generally within the reduced radius section. The polymer layer is operable to absorb forces and dissipate energy that degrades print quality. A gear portion is operably coupled to the rigid base member for rotation therewith. The printing press cylinder is manufactured by turning a rigid base member to produce a reduced radius section and subsequently molding a polymer layer generally within the reduced radius section of the rigid base member. The polymer layer is cured and then turned to reduce the circumference thereof and produce a smooth surface.

Owner:NU TECH COATINGS

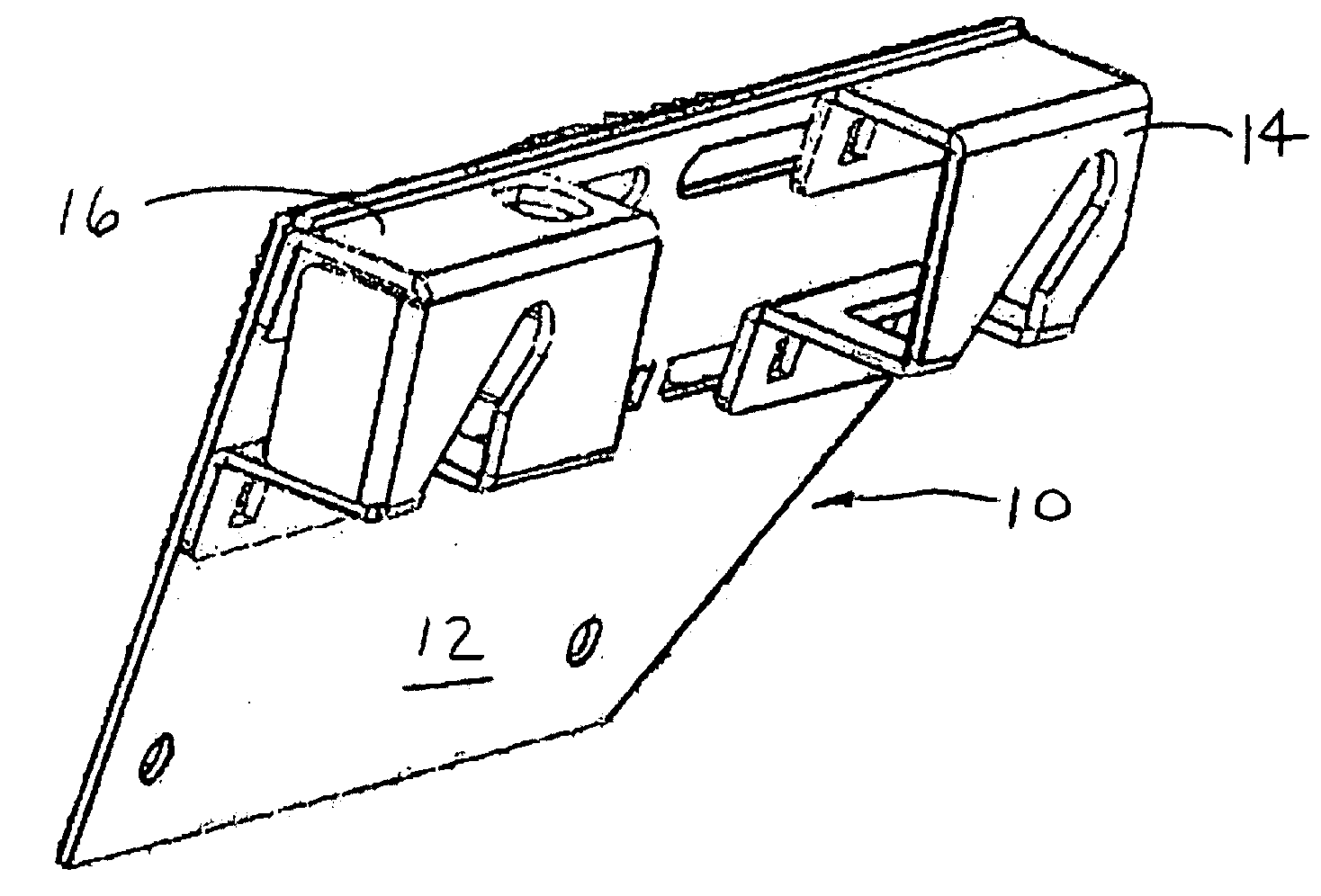

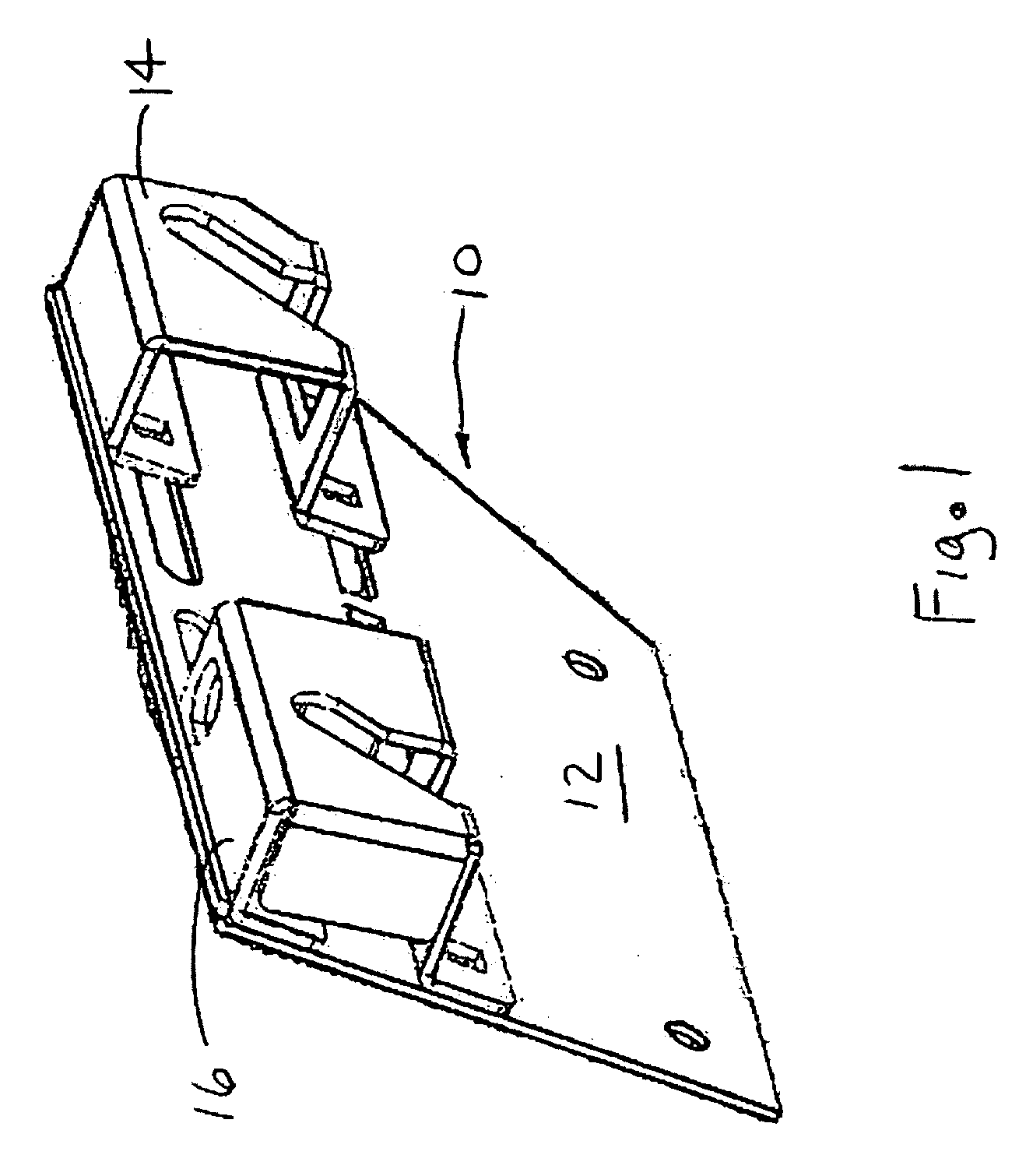

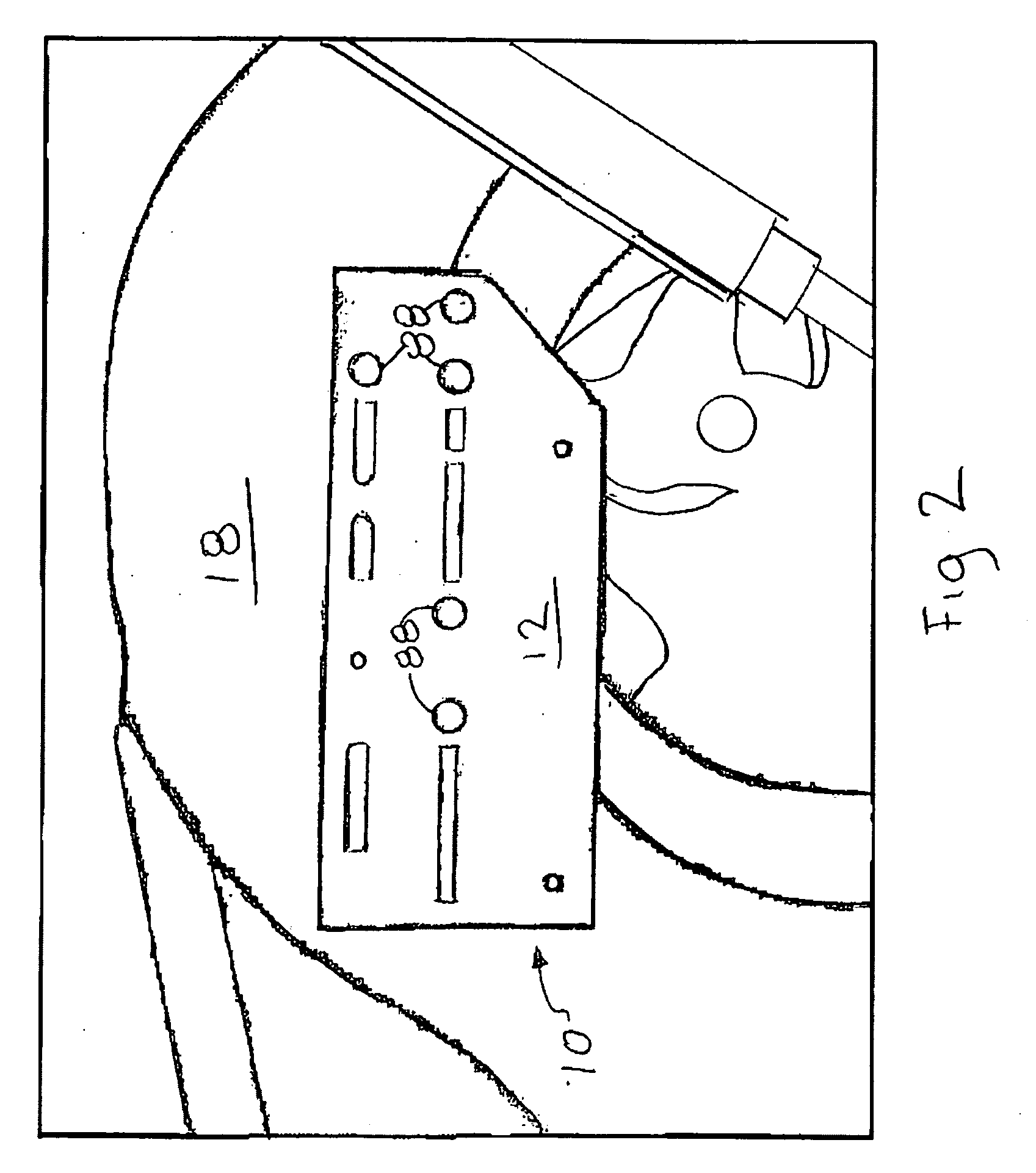

Fully adjustable bracket for removable & stationary saddlebag support system

One embodiment of the present invention relates to an adjustable bracket assembly for mounting to a vehicle. The bracket assembly comprises an integral planar attachment portion, at least one integral mounting portion separate from the planar attachment portion, at least one integral locking portion separate from the attachment portion and at least one integral keeper. The integral planar attachment portion includes a reception portion, wherein at least one of the planar attachment portion and reception portion include at least one slot. The at least one integral attachment mounting portion includes an engaging portion and a mating portion that engages the reception portion, wherein at least the engaging portion is substantially parallel to the planar attachment portion when engaged. The engaging portion includes a receiving portion having diameter “drc” and a radius portion in fluid communication with the receiving portion, the radius portion having diameter “drd”, wherein drc>drd. The at least one integral locking portion engages the attachment portion, and mates with at least the radius portion. The keeper has a diameter “dk”, wherein drd−dk=α. As a approaches a manufacture tolerance, drd approaches and is substantially equal to dk.

Owner:DUBINSKIY YURIY +1

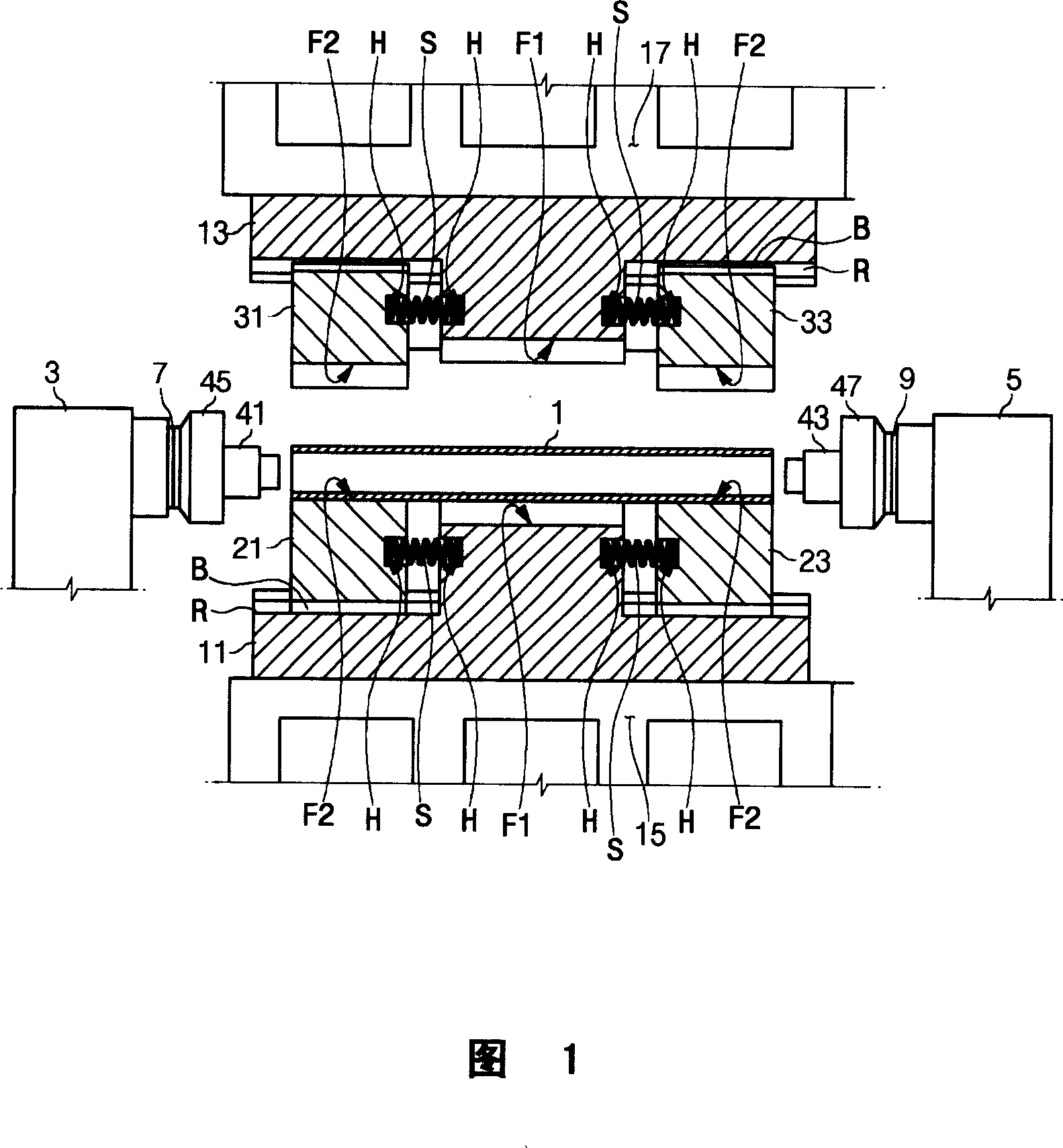

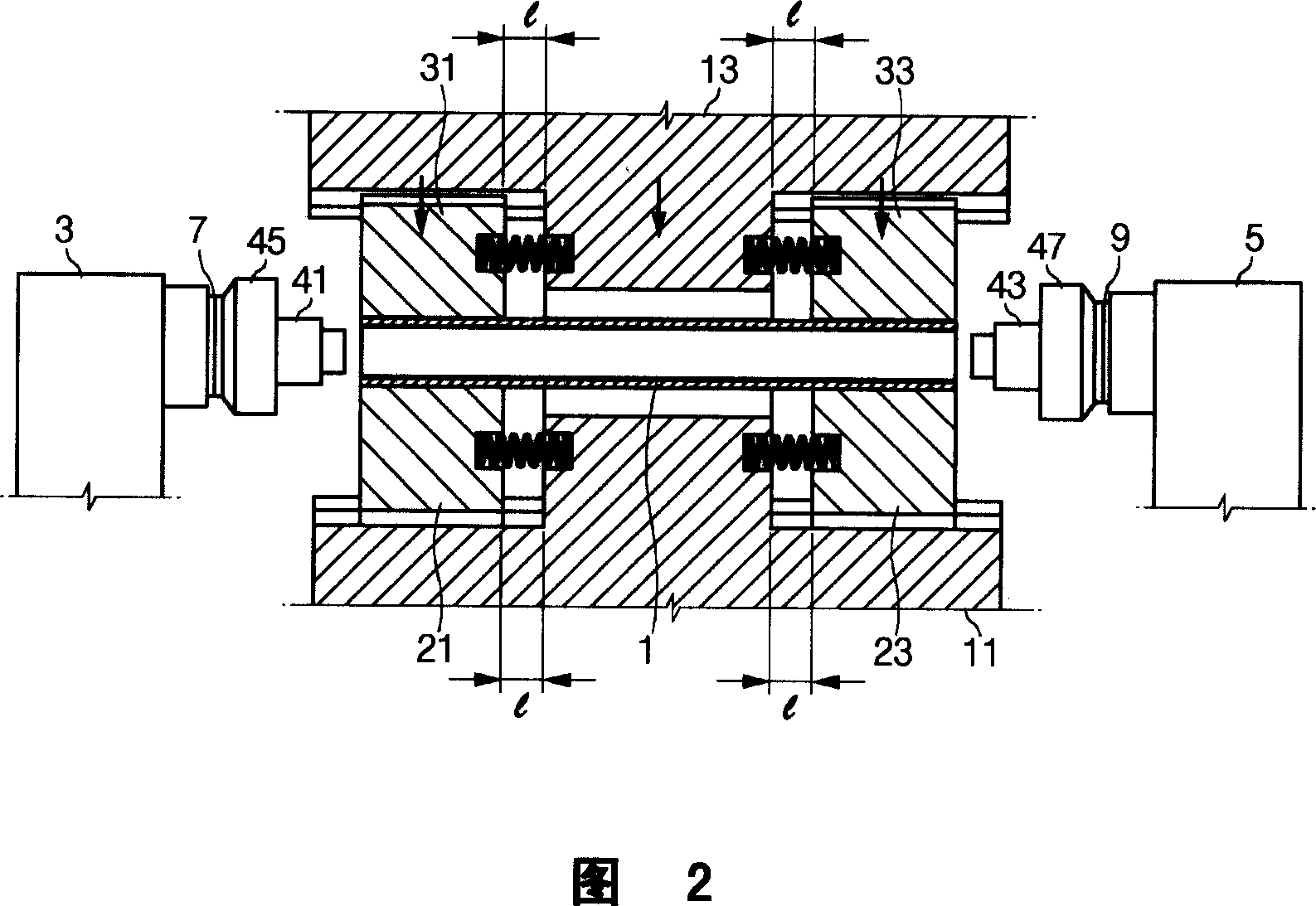

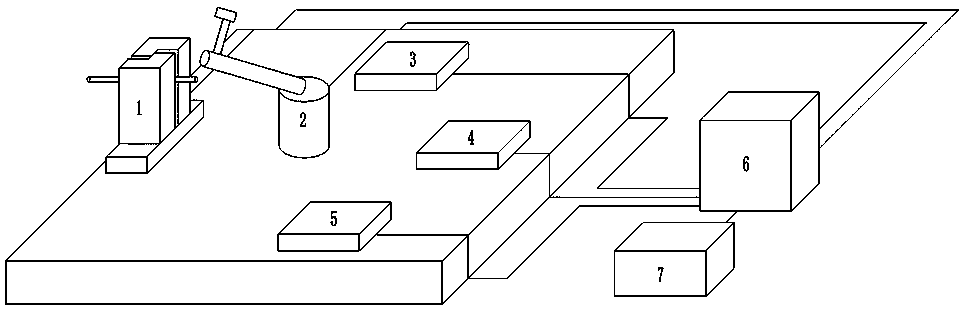

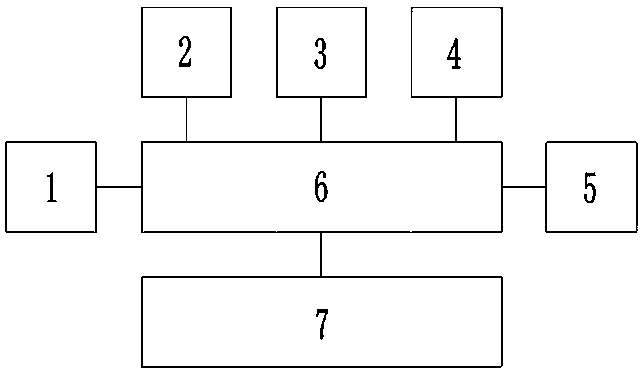

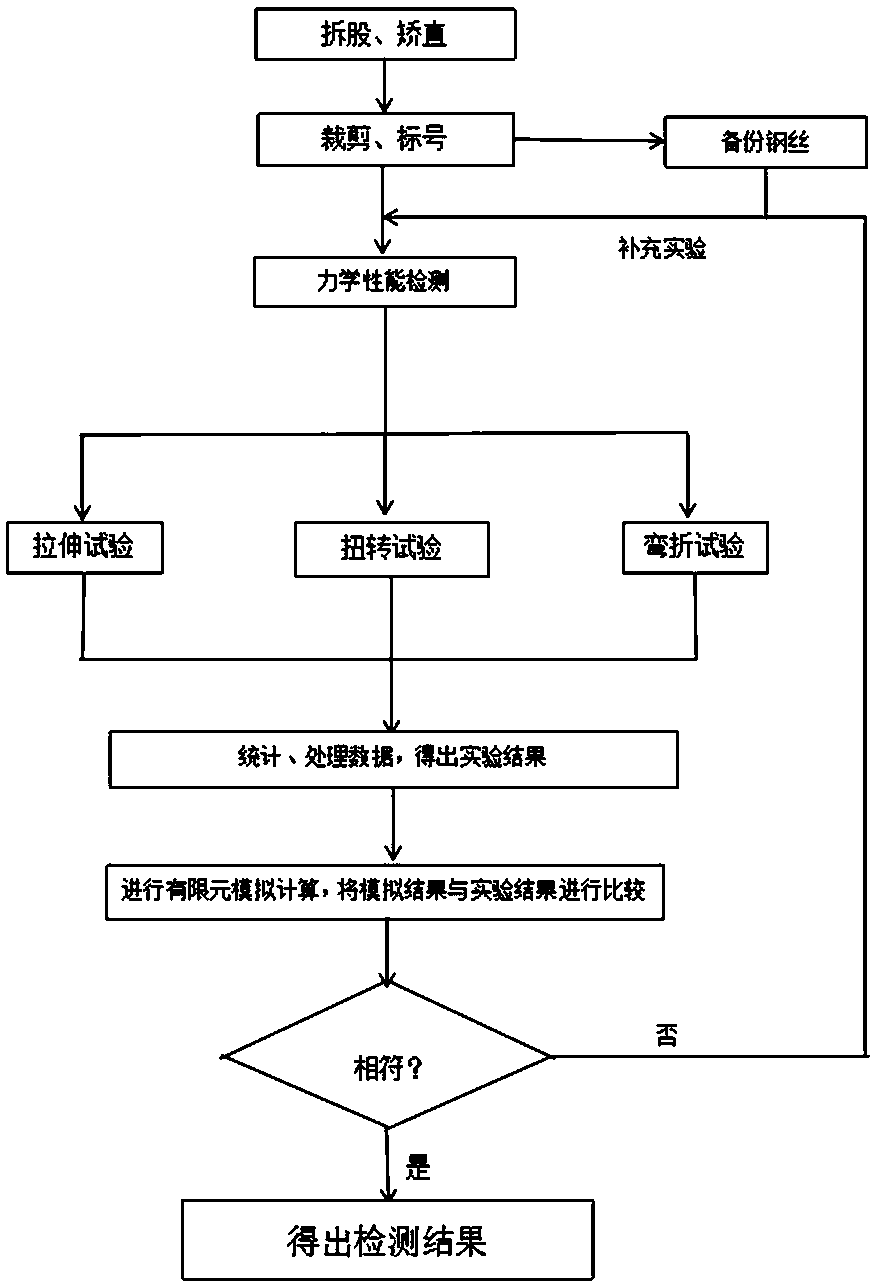

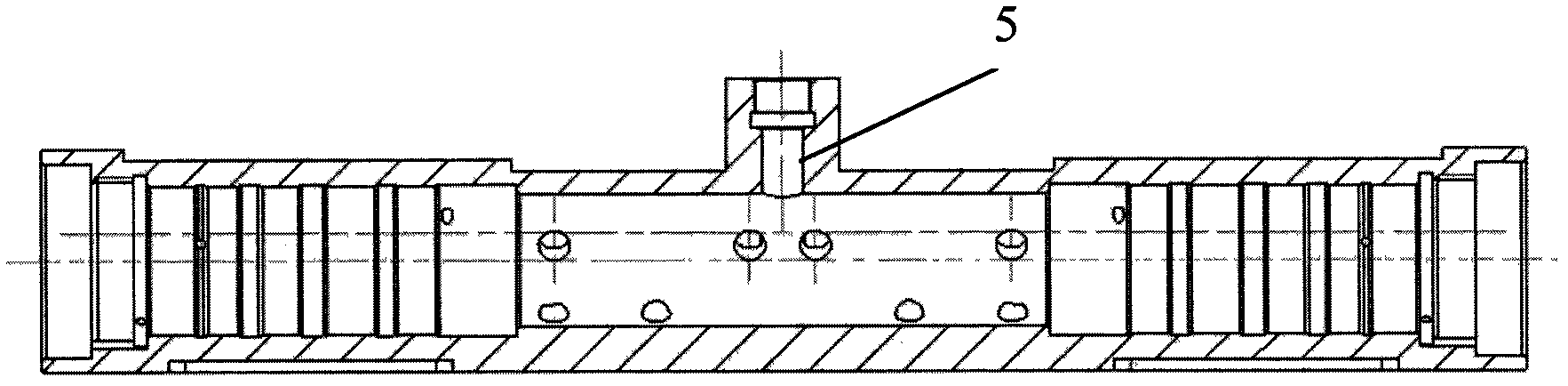

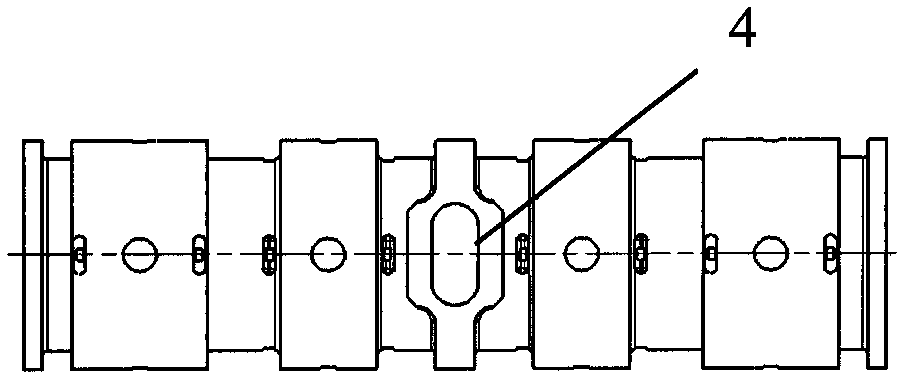

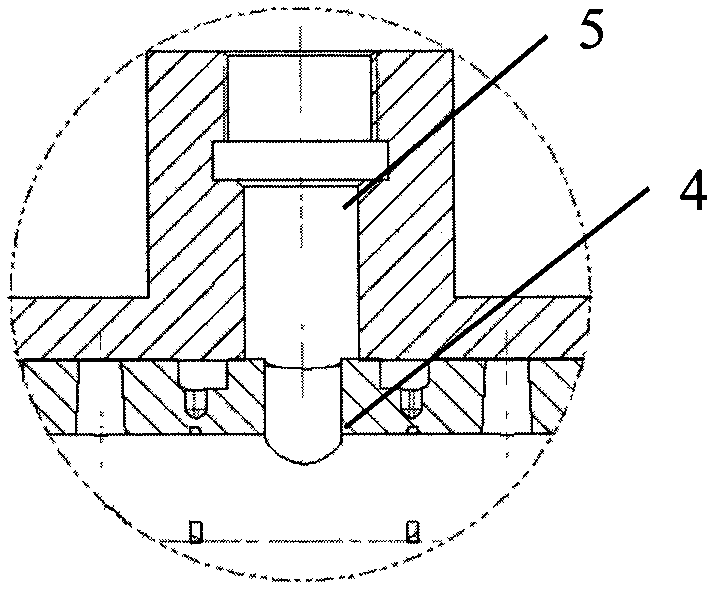

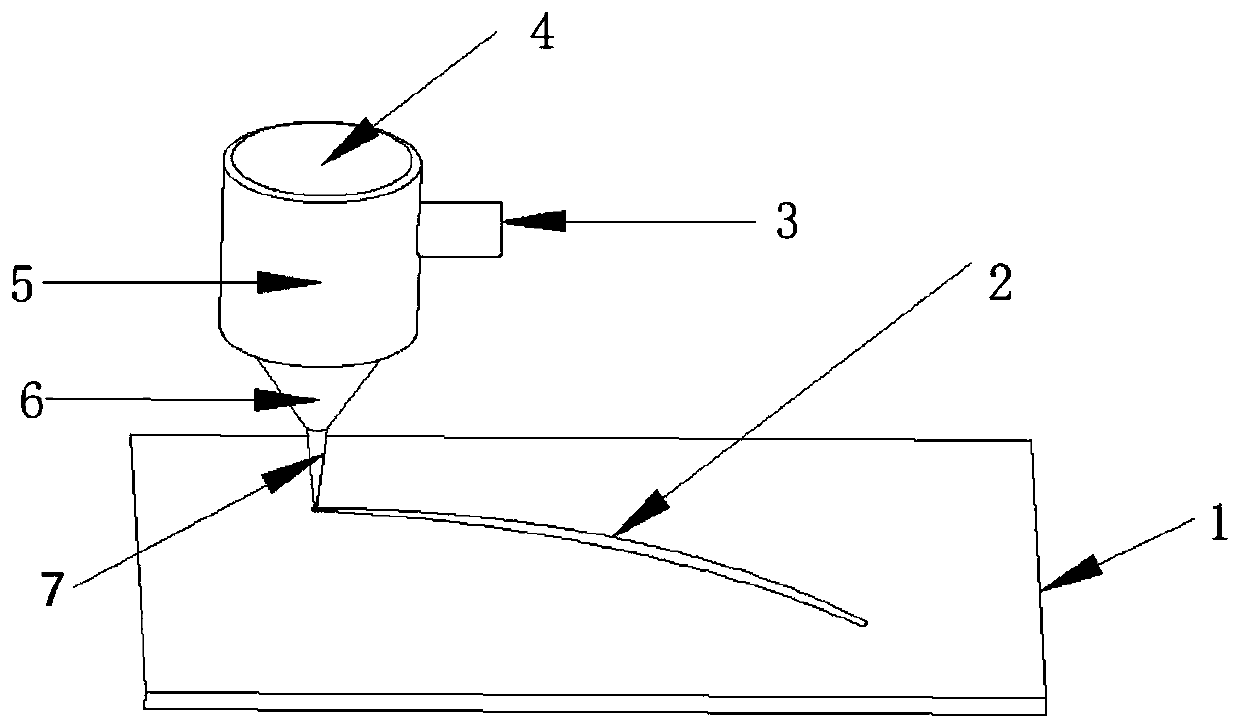

Full-automatic steel wire rope mechanical property detecting system and method

ActiveCN109668788AWith automatic data processing functionRealize automatic collectionMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesControl circuitControl theory

The invention relates to a full-automatic steel wire rope mechanical property detecting system and method, and belongs to the technical field of full-automatic steel wire rope mechanical property detecting. According to the adopted technical scheme, the full-automatic steel wire rope mechanical property detecting system comprises a detecting machine, a base is arranged at the bottom of the detecting machine, a straightening machine is arranged on the base, a mechanical arm is arranged at a discharging outlet of the straightening machine and specifically is a rotating mechanical arm fixed to abase plate, a stretcher, a bending machine and a twisting machine are arranged in the movable radius part of the mechanical arm, control ports of the straightening machine, the mechanical arm, the stretcher, the bending machine and the twisting machine are connected with a four-axis controller through wires correspondingly; and a control circuit is integrated inside the four-axis controller, and an AD conversion module arranged on the control circuit is provided with six signal input ports and six bidirectional communication ports. The full-automatic steel wire rope mechanical property detecting system can be applied and popularized in a laboratory for detecting the mechanical properties of steel wires.

Owner:TAIYUAN UNIV OF TECH

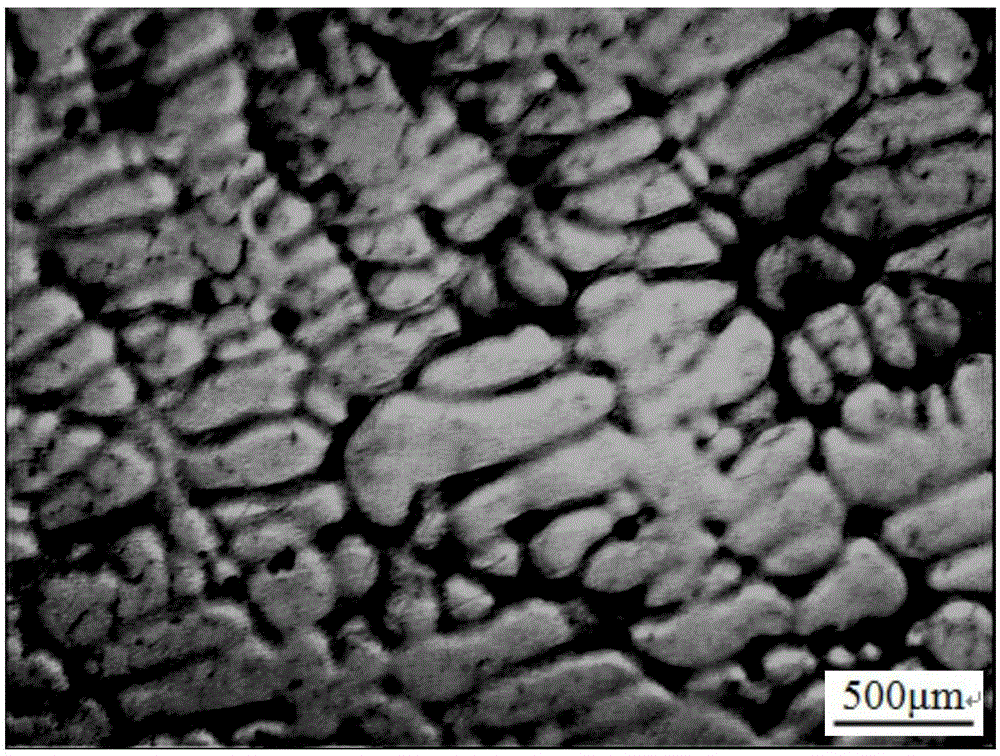

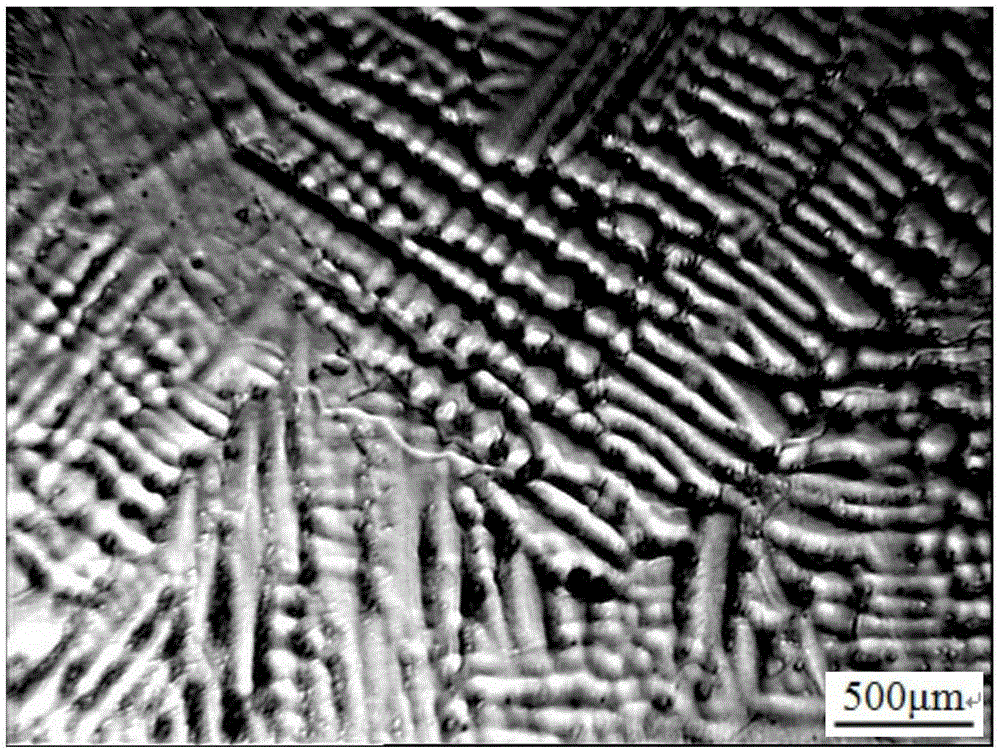

Etching agent for displaying solidification dendritic structures of middle-high grade non-oriented silicon steel as well as etching method

ActiveCN105200429AShort erosion timeSimplify operating proceduresPreparing sample for investigationEtchingSODIUM DODECYL BENZENE SULFONATE

The invention discloses an etching agent for displaying solidification dendritic structures of middle-high grade non-oriented silicon steel as well as an etching method, and belongs to the technical field of metallographic examination analysis. The etching agent comprises the following components according to ratio: 1.5-2.0 g of picric acid, 35-50 ml of distilled water, 0.4-0.6 ml of hydrochloric acid, 0.3-0.5 g of anhydrous cupric chloride and 0.5-1 g of sodium dodecyl benzene sulfonate. The etching method of the etching agent comprises the following steps: heating the prepared etching agent to be in the boiling state, and then suspending a processed sample in the etching agent for 8-15 s, wherein the polished surface of the processed sample faces downwards; after the etching is finished, conducting clean water washing and cotton ball wiping treatment on the etched surface; then polishing the sample at the 1 / 2 radius part of a polishing machine for 5-10 s. The etching time is short, and the operation procedures are simple; the clear primary and secondary solidification dendritic structures of the middle-high grade non-oriented silicon steel can be quickly observed, so that technical bases can be provided for optimization of the continuous casting process and increase of the axis crystal proportions of a casting blank and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

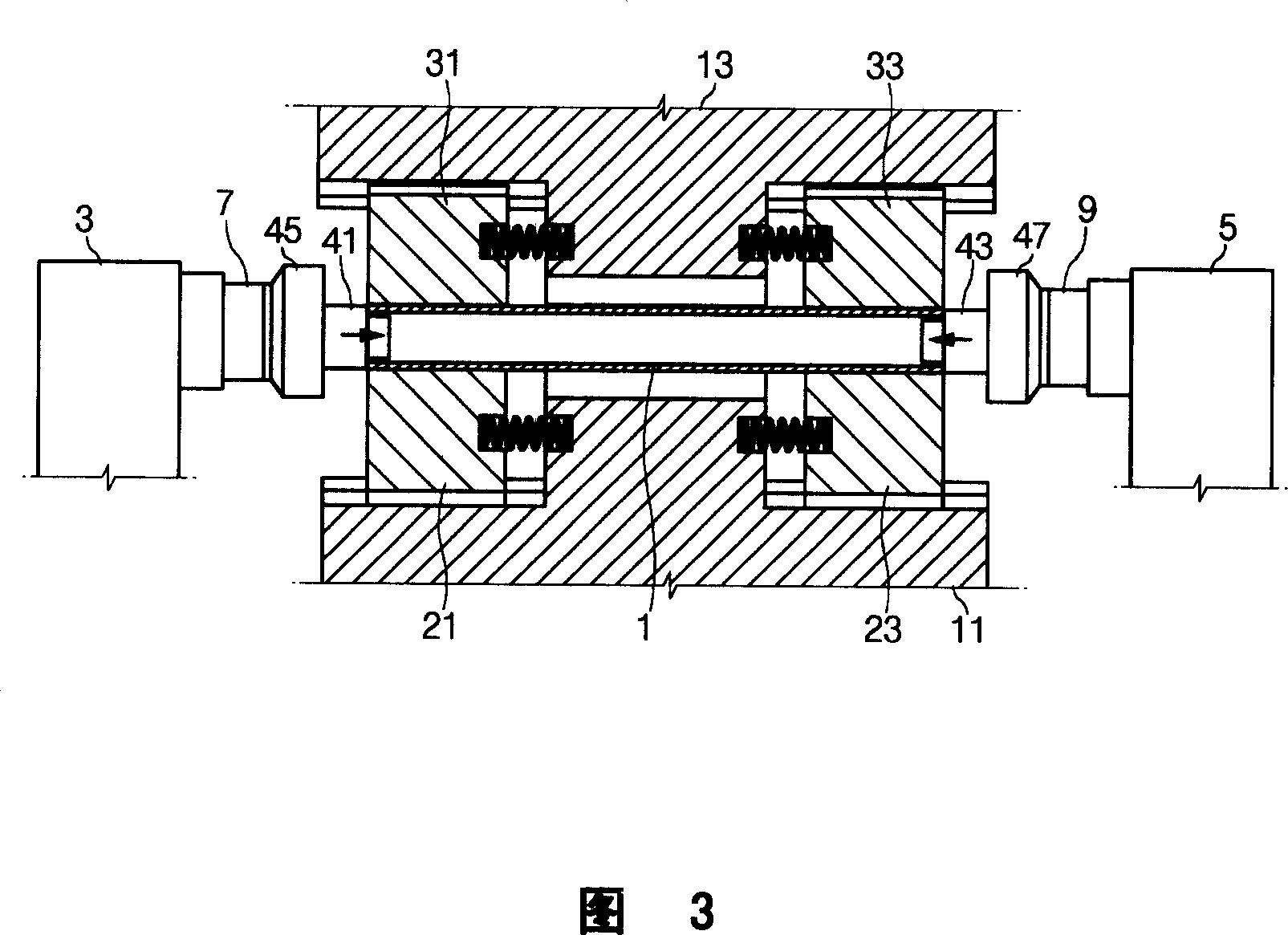

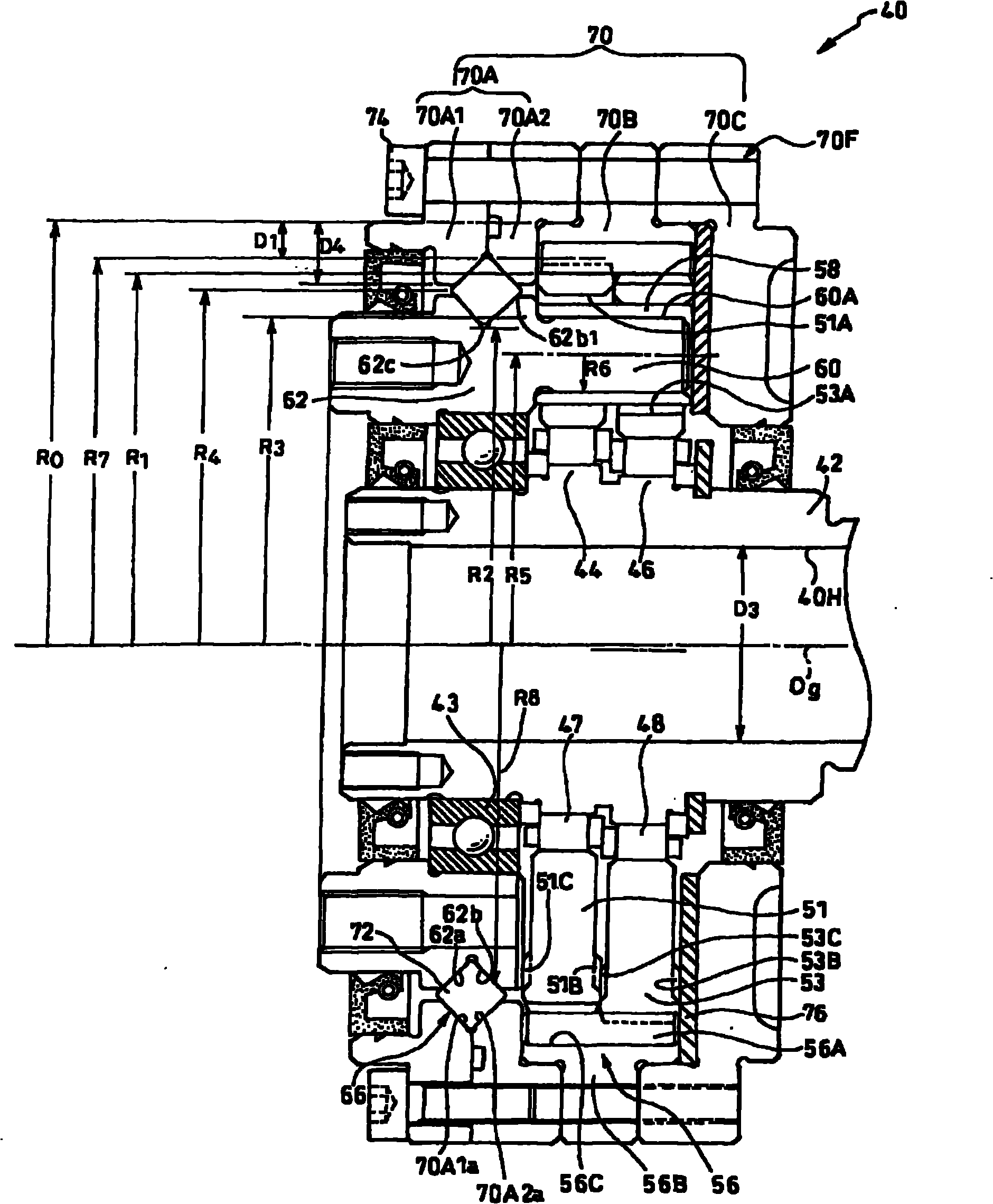

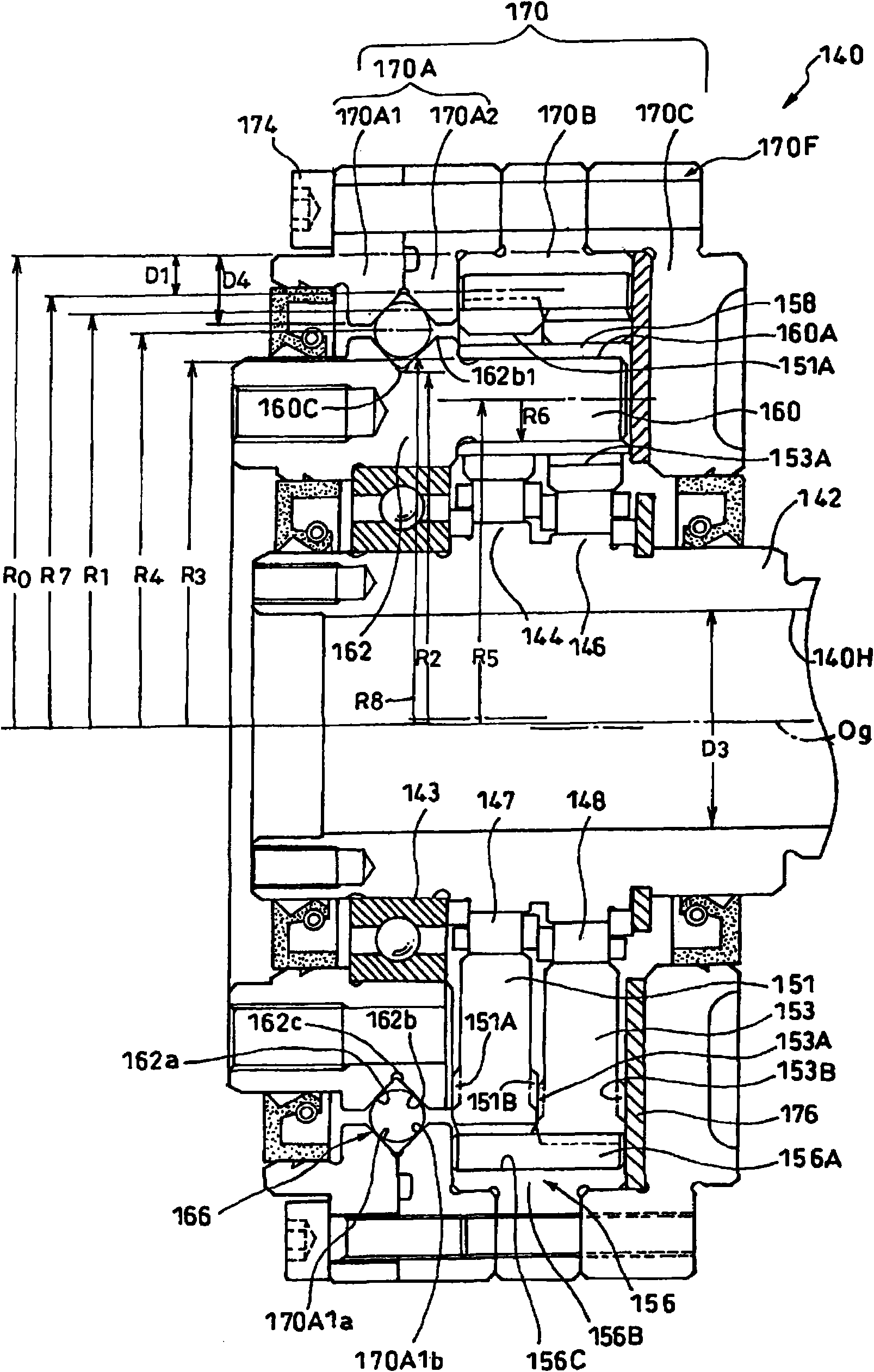

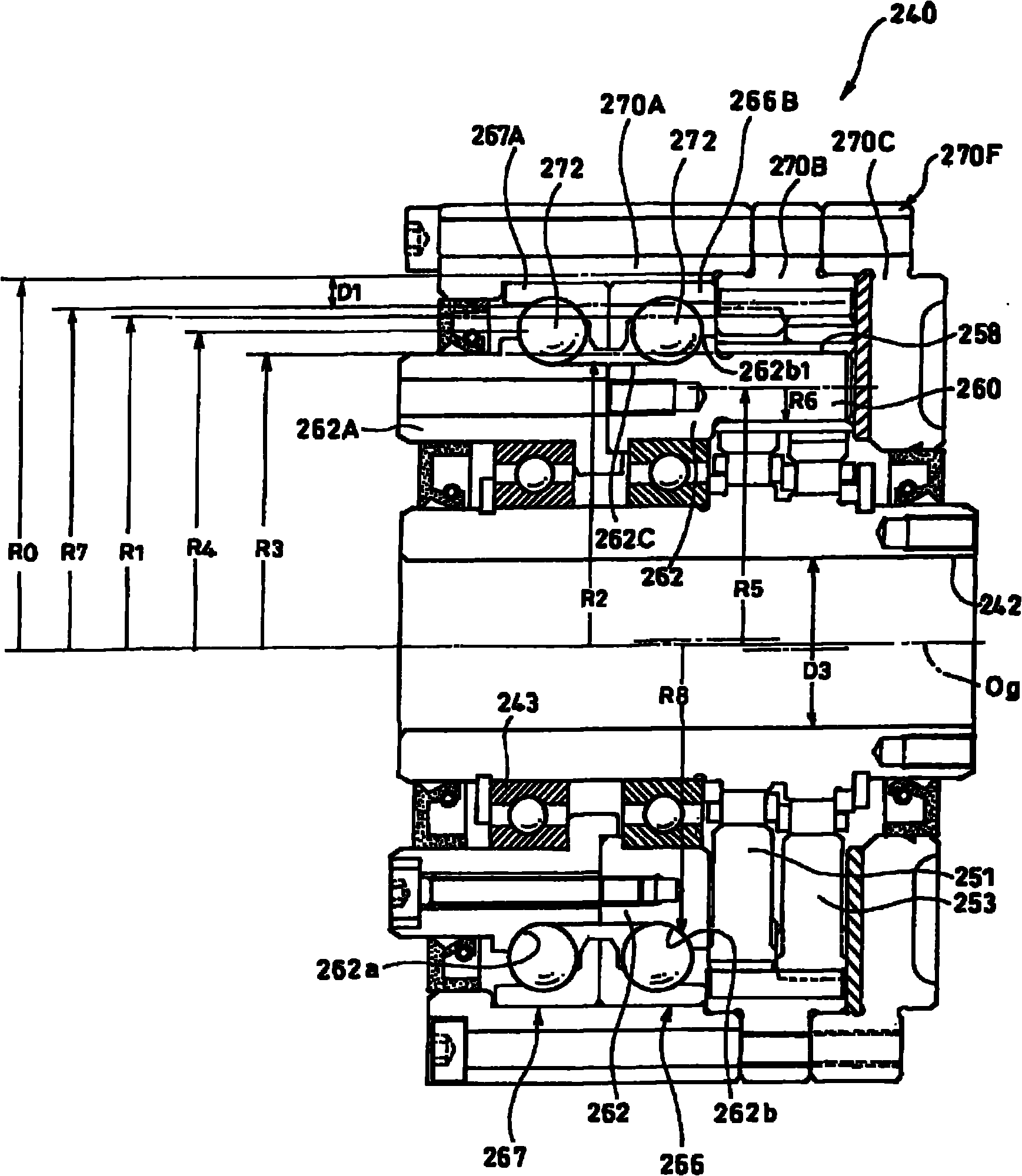

Planetary gear device

The present invention provides a planetary gear device which ensures a large space at a central part in a radius direction of the device without enlarging the dimension in a radius direction of the whole body of the planetary gear device. An inner pin (pin component) which projects from a gear frame flange (62) and penetrates through outer gears (51,53) is formed integrally with the gear frame flange (62). The most outer peripheral outer (60A) of the inner pin (60) is provided more adjacently to the outside in a radius direction compared with the inner ring side rolling surfaces (62a,62b) of a cross roller bearing (main bearing) (66) which is used for supporting the gear frame flange (62) on a housing (70) or a least radius part (62c) of an elongated surface.

Owner:SUMITOMO HEAVY IND LTD

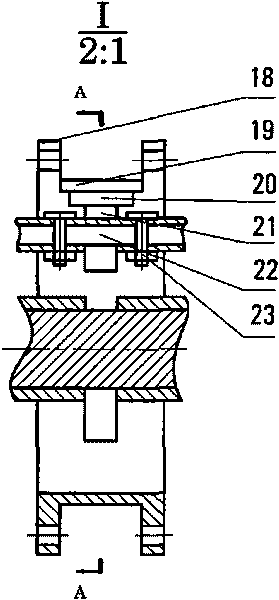

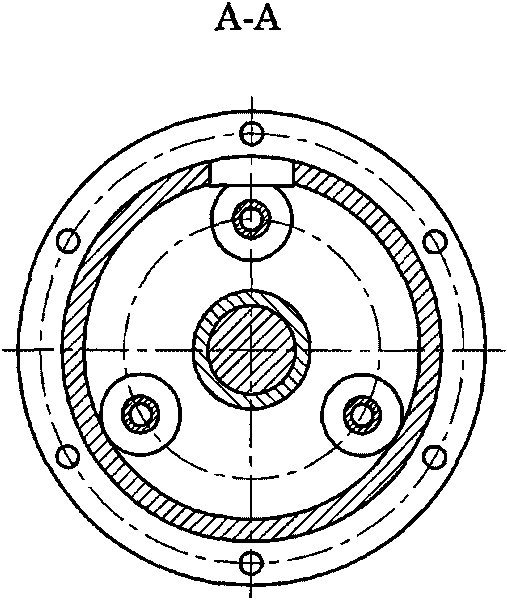

Inner cavity centering adjustment method and adjustment tool thereof

The invention relates to an inner cavity centering adjustment tool which comprises a knob (1), a positioning shaft (2) and an eccentric block (3), wherein the eccentric block (3) is rotatably mounted in an inner hole of the positioning shaft (2); one end of the eccentric block (3) is fixedly connected with the knob (1), and the other end of the eccentric block (3) extends out of the positioning shaft (2); and the eccentric block (3) extending out of the positioning shaft (2) is an asymmetric revolution body which only has one maximum-radius part, wherein the clearance between the maximum radius b and the narrow side of a valve bush waist-shaped hole (4) is 1 / 3-1 / 5 of the required symmetry tolerance. In the invention, the centering requirement of two inner cavity structures is converted into the requirement of clearance between two centering structures of a special tool. By rotating the special tool and adjusting the axial position of the pressed part, the clearance of the special tool in the inner cavity structure is uniform, and the rotation is flexible so as to ensure the symmetry index. Through the invention, the problems of hole wall scratching, part deformation, friction increase and the like caused by repeated trial assembly are avoided, the centering accuracy is ensured, and the operation is simple and easy.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

Special fertilizer for preventing and controlling forest iron-deficiency yellows and application method thereof

InactiveCN102010263AFully configuredNutrient balanceFertilising methodsFertilizer mixturesDiameter at breast heightGram

The invention discloses a special fertilizer for preventing and controlling forest iron-deficiency yellows and an application method thereof. The special fertilizer comprises the following components: 25 to 66.9 percent of composite inorganic nitrogen-phosphorus-potassium fertilizer, 26.6 to 55 percent of acidic material and 6.5 to 20 percent of trace element fertilizer. The application method comprises the following steps of: (1) annularly ditching or digging holes with the depth of 10 to 15 centimeters on the 50 to 70 percent of radius part in crown orthographic projection according to forest diameter at breast height (DBH), uniformly spreading 400 to 500 grams of special fertilizer every 10-centimeter DBH, and covering soil after applying the fertilizer; and (2) applying the fertilizer once by repeating the step (1) in early spring, late summer and early autumn every year for 1 to 2 years continuously. A preventing and treating method has the advantages that: the fertilizer is convenient to apply and easy to popularize. The special fertilizer provided by the invention has the advantages of improving rhizosphere soil, reducing the pH value of the rhizosphere soil and improving the activity of trace elements, such as iron and the like, in soil so as to control the yellows completely.

Owner:于永忠

Optical fiber laser cutting blade type hole energy regulation method for sheet metal

The invention belongs to the technical field of efficient, high-precision and high-quality laser cutting forming of metal plates, and relates to an optical fiber laser cutting blade type hole energy regulation method for sheet metal. The method comprises the following steps that firstly, a machining graph is reasonably segmented, so that the whole machining graph is divided into four sections, theregion with the larger arc radius difference is divided into an individual line segment, then a method for combining four-section variable-speed and variable-power energy compensation is adopted to reduce erosion and slag adhering of a small arc section in the machining process in a mode of energy regulation and control on separate lines of the sheet metal in the laser cutting process, the energycaused by heat dissipation and heat accumulation is balanced by reducing the laser energy density at a small arc radius part of the sheet metal, the cutting precision is improved, erosion and slag adhering are reduced, and the large arc profile error meets the technical requirements.

Owner:DALIAN UNIV OF TECH

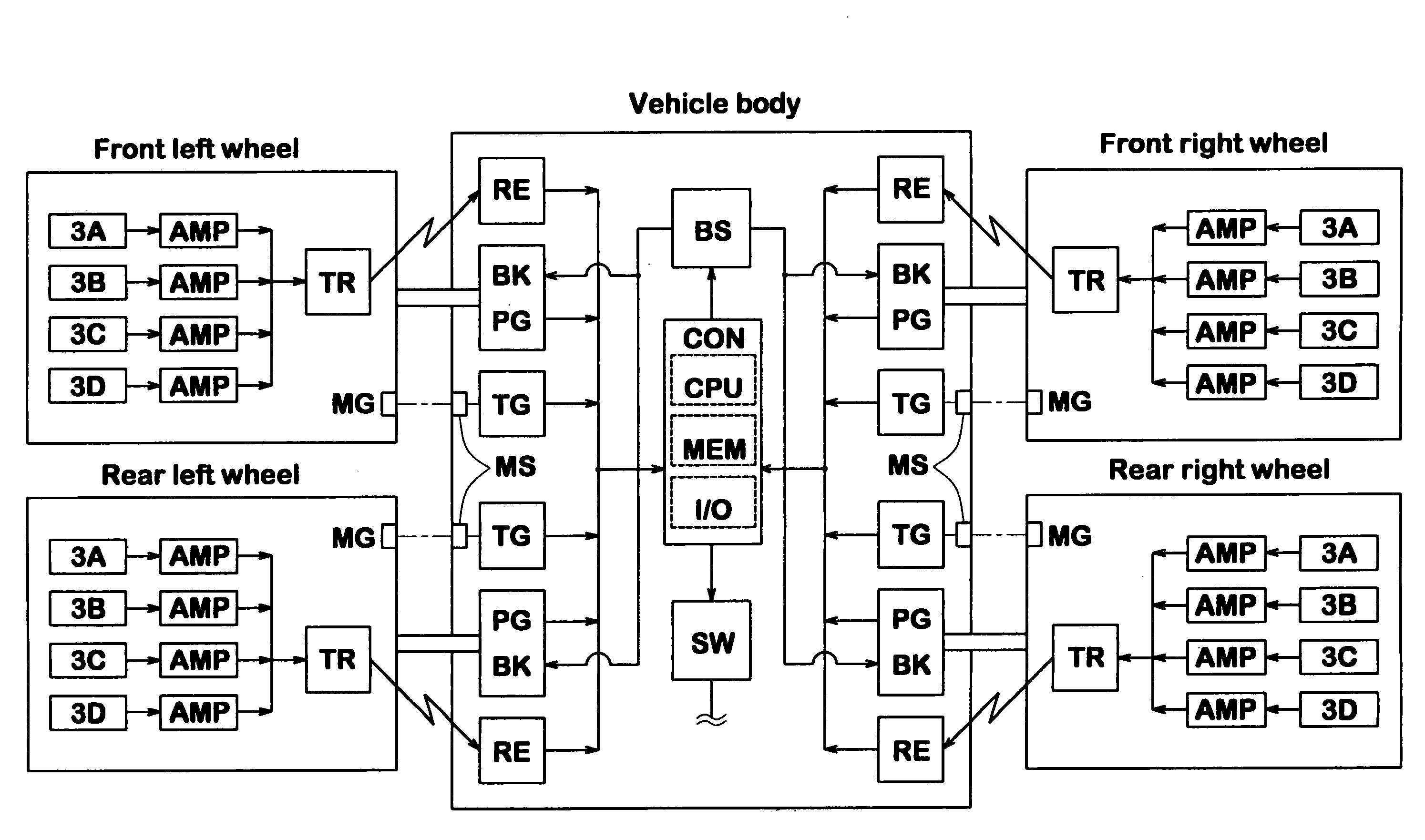

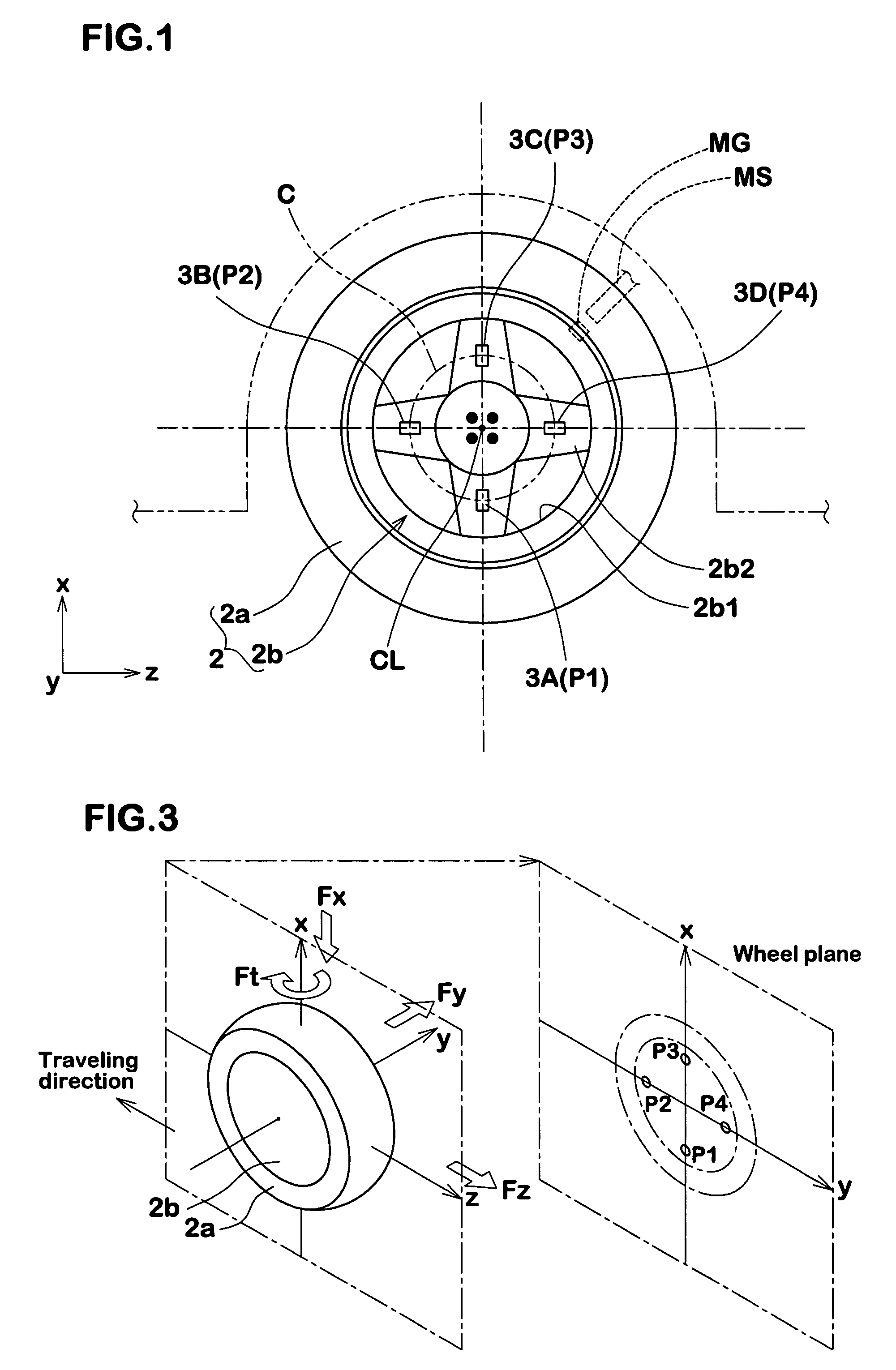

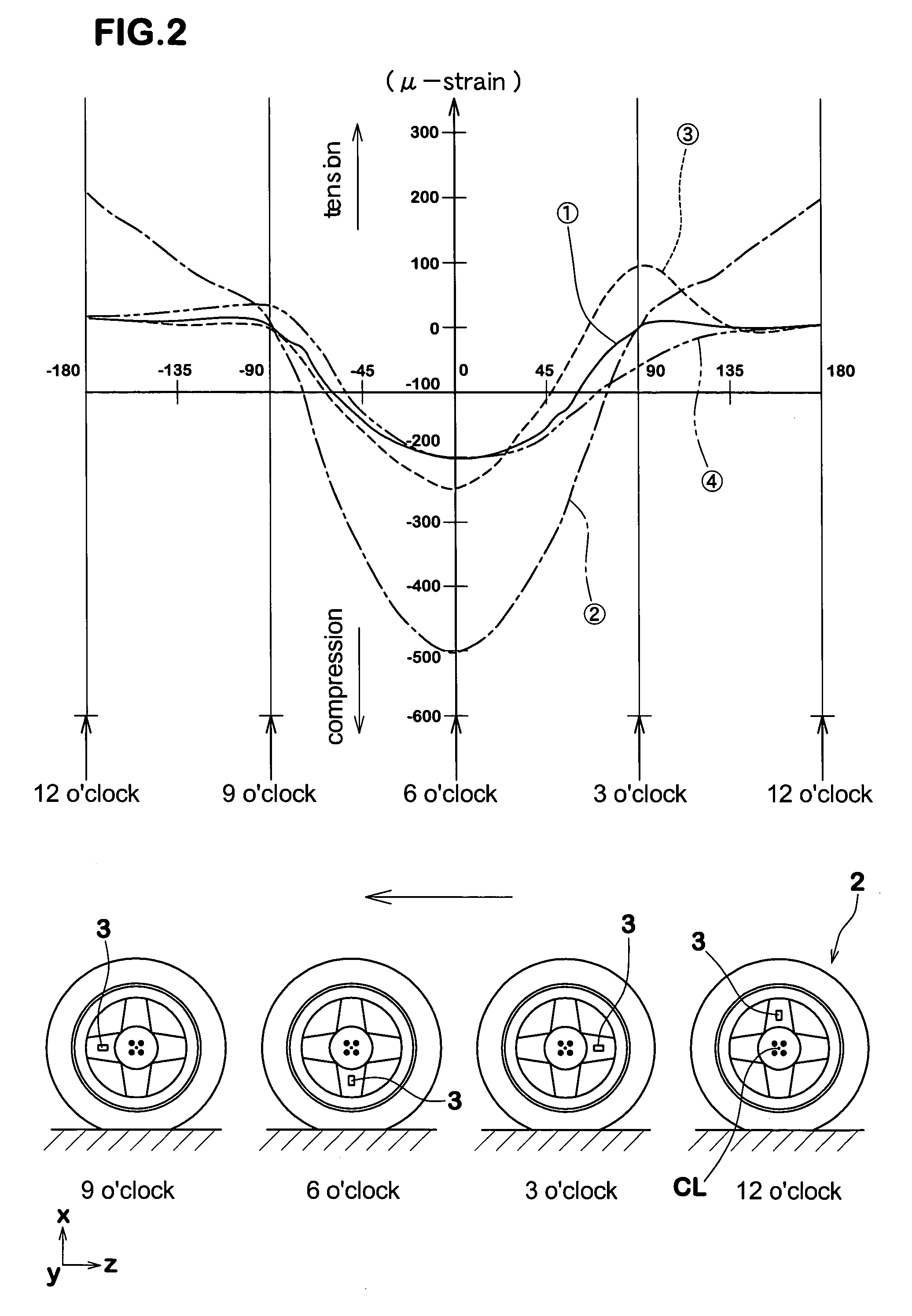

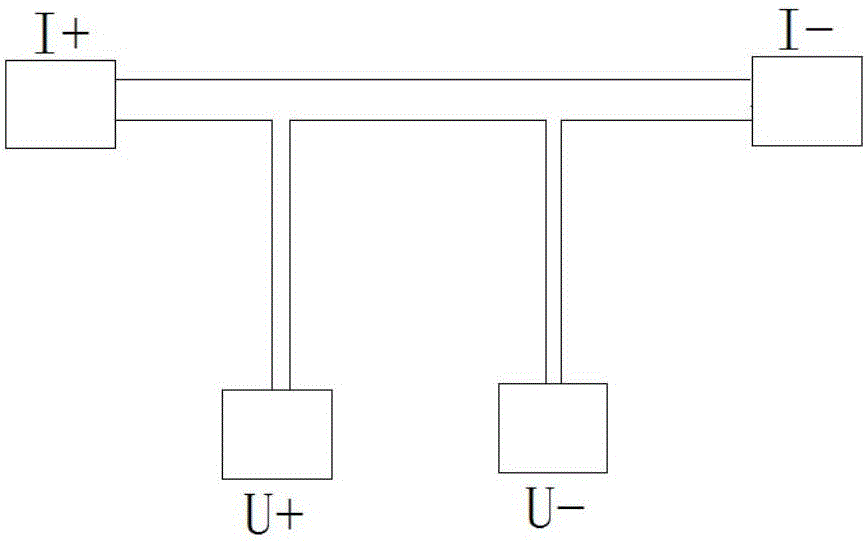

Method and device for determining wheel force

InactiveUS7418362B2Sure easyForce measurementLinear/angular speed measurementEngineeringVertical force

A method and device for determining force exerted on a rolling vehicle wheel. Firstly, data on a relationship between a force exerted on a vehicle wheel and a physical parameter such as strain of the radius part of the wheel at predetermined measuring positions are obtained. Using the obtained data on the relationship, a formula for the force is made. Then, the vehicle wheel is measured for the physical parameter during rolling, and using the measured physical parameter and formula, the force is calculated. The force may be a vertical force, lateral force, longitudinal force or self aligning torque. The physical parameter may be the magnitude of a radial strain.

Owner:SUMITOMO RUBBER IND LTD

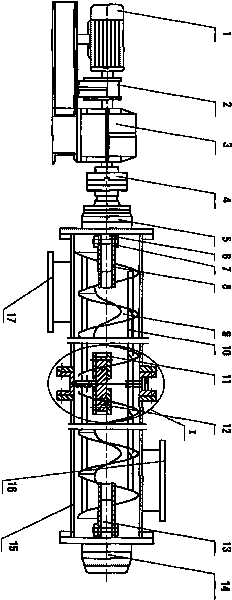

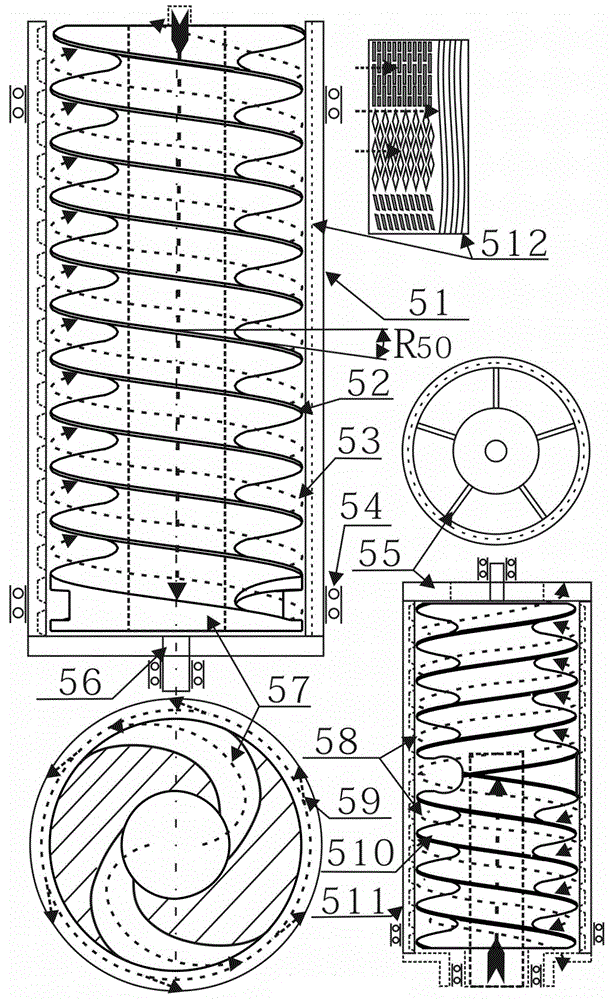

Tube-type spiral conveyer

The invention discloses a tube-type spiral conveyer which comprises a motor, a coupling, a speed reducer, a head bearing device, a tail bearing device, a delivery pipe, a support tube, a spirochaeta, and a material inlet and a material outlet on the delivery pipe, wherein the spirochaeta is formed by the welding of a stub pipe, a spiral blade and three seamless steel tubes; the three seamless steel tubes are all distributed at a proper radius part of the circumference of a helicoid, and are parallel to an axes, and have the same length with the spirochaeta; the middle circumference of the support tube is uniformly distributed with three rollers which are coaxial with the seamless steel tubes, inner holes of the three rollers are in clearance fit with a connecting shaft, and outer circles thereof are connected with inner wall of the support tube in a rolling manner. In the invention, as a suspension bearing is eliminated, and the three rollers that are uniformly distributed on the circumference of the spirochaeta are adopted to be contacted with the inner wall of the tube in the rolling manner, and the rollers are not easy to be damaged and do not need lubrication, therefore maintenance load is alleviated, maintenance cost is reduced, and use time is prolonged; and the delivery pipe and the support tube are connected by a flange, thus having good tightness and being especially suitable for delivering powdery materials.

Owner:南通全通建筑机械有限公司

Device and method of measuring film strain and thermal conductivity

ActiveCN106813718AMeet the requirements of thermal conductivitySimple structureMeasurement devicesPrecessionThin sheet

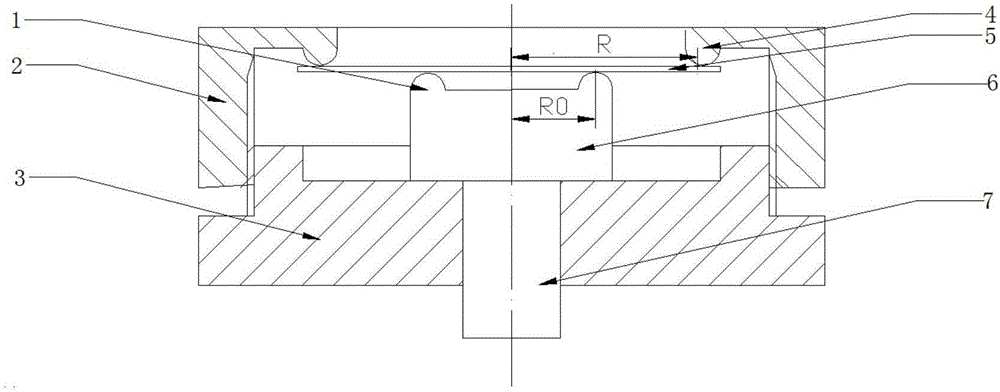

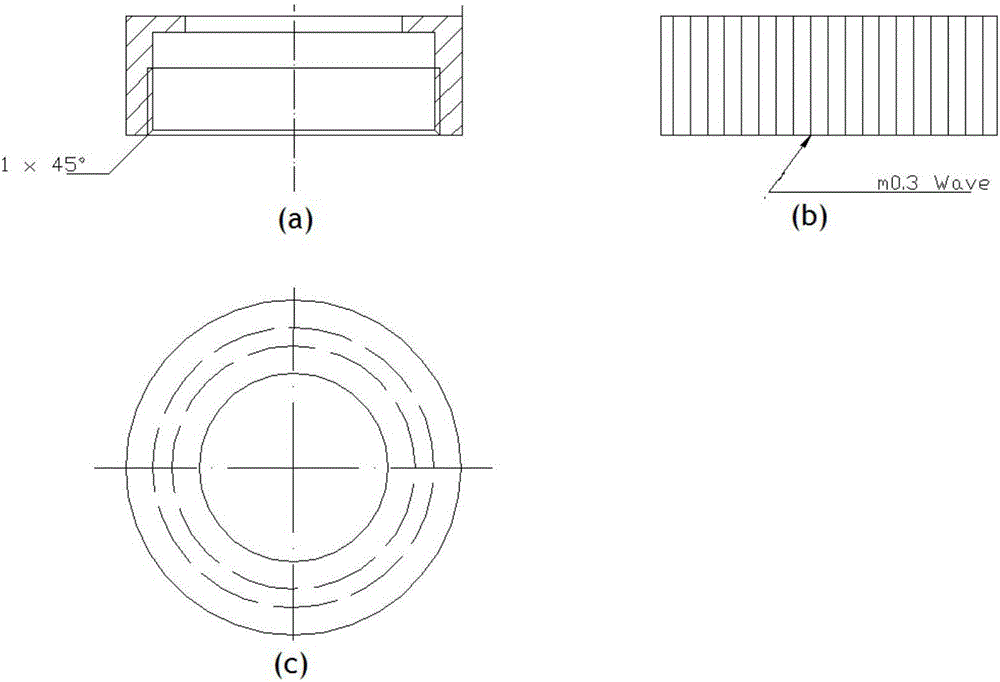

The invention discloses a device and a method of measuring film strain and thermal conductivity. The device comprises a base, a housing disposed on the base, and a loading end disposed on the base. A film sample is disposed on the loading end, and is connected with a simply supported fixed end disposed on the upper part of the housing. The lower part of the loading end is provided with a precession guide rod, and the film sample is connected with a power supply by a sputtering testing electrode. A precision guide rod is used to control feeding displacement S at a radius part of a circular film, and by adopting statics equilibrium and a deflection theory of an elastic thin plate, a deflection equation of an intermediate circular plate is acquired. When the radius is equal to R0, the deflection values of the above mentioned parts are equal to each other, and by adopting precision screw stroke, the feeding displacement S of the circular plate having the radius in a range from R to R0 is acquired, and then the peripheral strain value and the radial strain value of the intermediate circular film are acquired, and by adopting 3omega measuring method, the thermal conductivity of the film is measured, and the measurement of the thermal conductivities of the film under different strain conditions is realized.

Owner:XI AN JIAOTONG UNIV +1

Developing device and image forming apparatus

A trickle-type developing device comprising: a stirring and conveying tank provided with stirring and conveying screws that circulate the developer; a discharge member via which a part of the developer is conveyed from the tank to a discharge opening through which the developer is discharged, the discharge opening being provided in the discharge member; and a reverse flow generating screw provided inside a portion of the discharge member, sharing one of rotation shafts of the stirring and conveying screws, and pushing back a part of the developer, wherein the portion has a reduced-radius part and in a cross section thereof perpendicular to an axial direction of the one of rotation shafts, an inner radius of the portion is smaller in the reduced-radius part than in the remaining part, the reduced-radius part being located in a lower part of the portion with respect to a vertical direction of the portion.

Owner:KONICA MINOLTA BUSINESS TECH INC

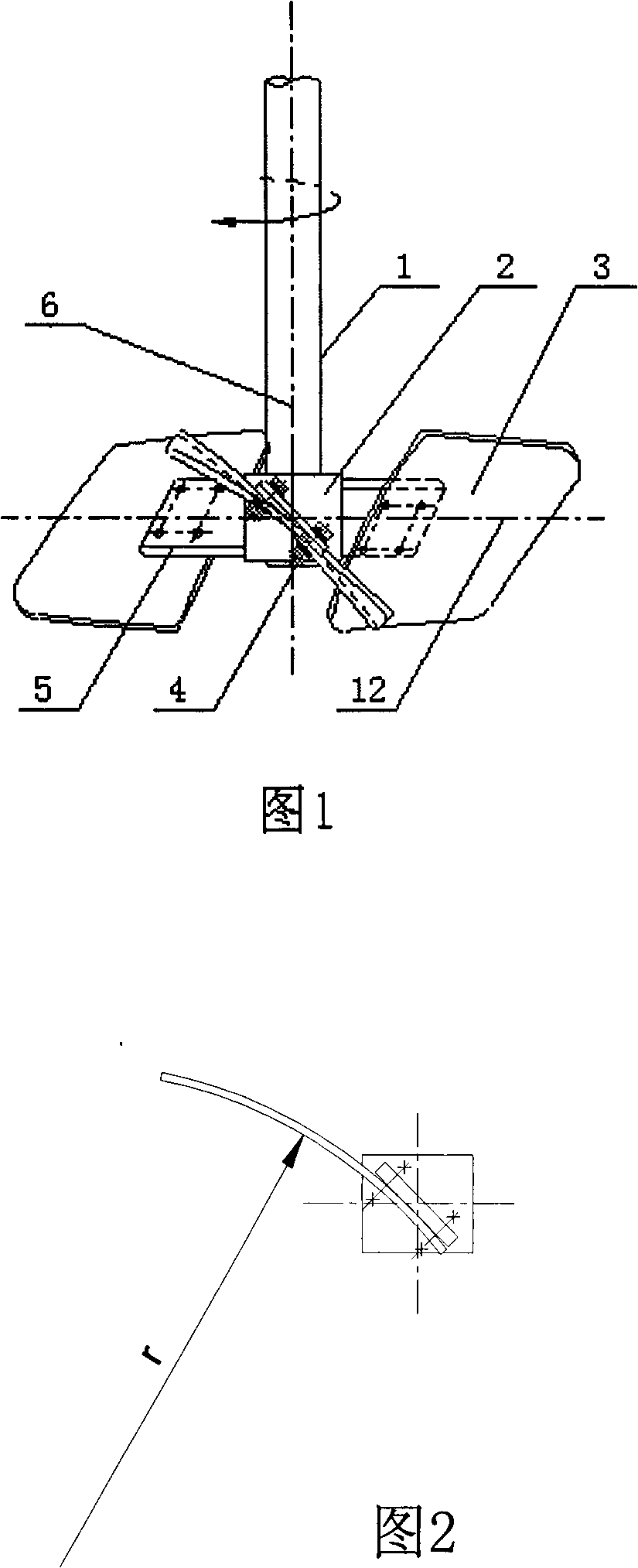

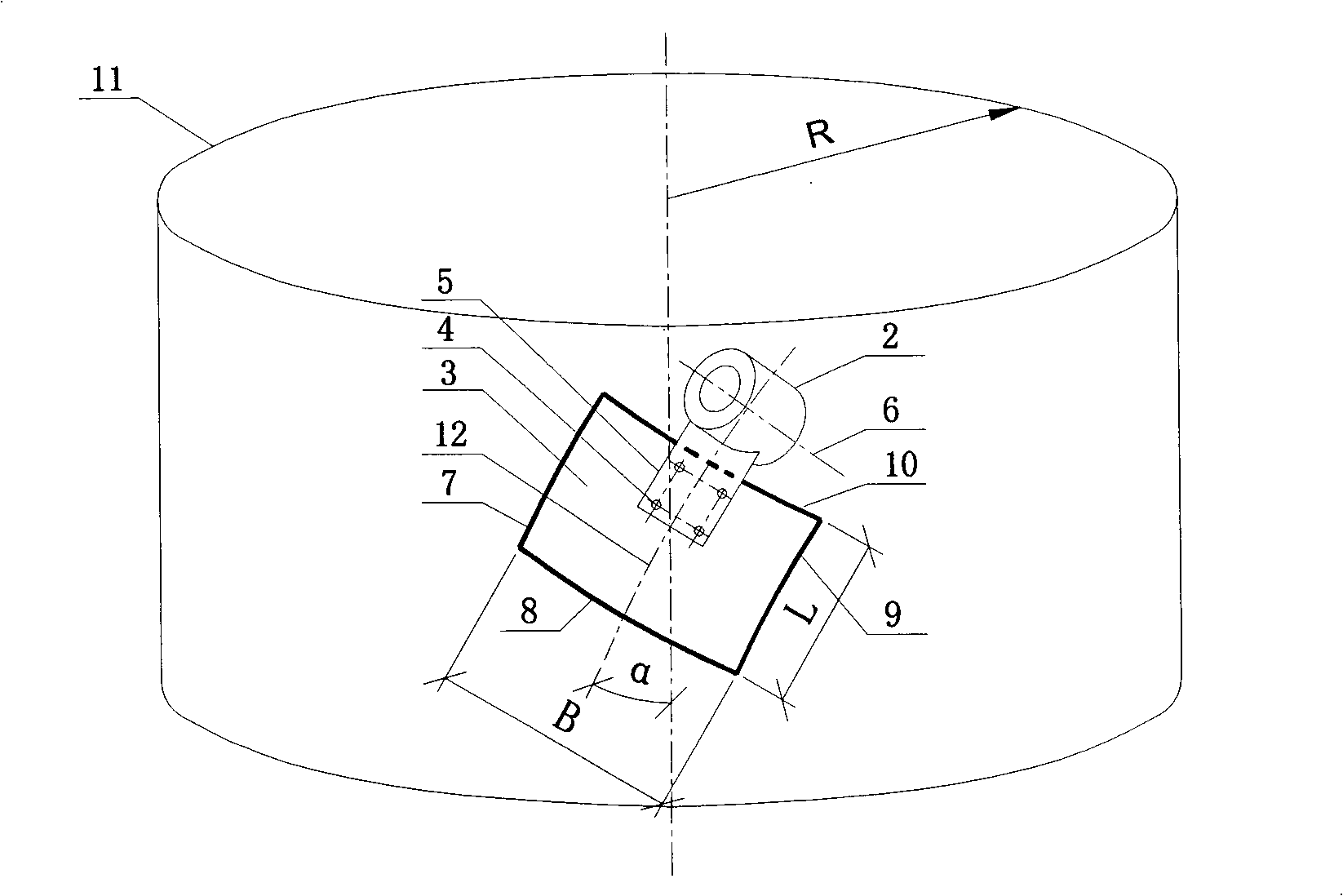

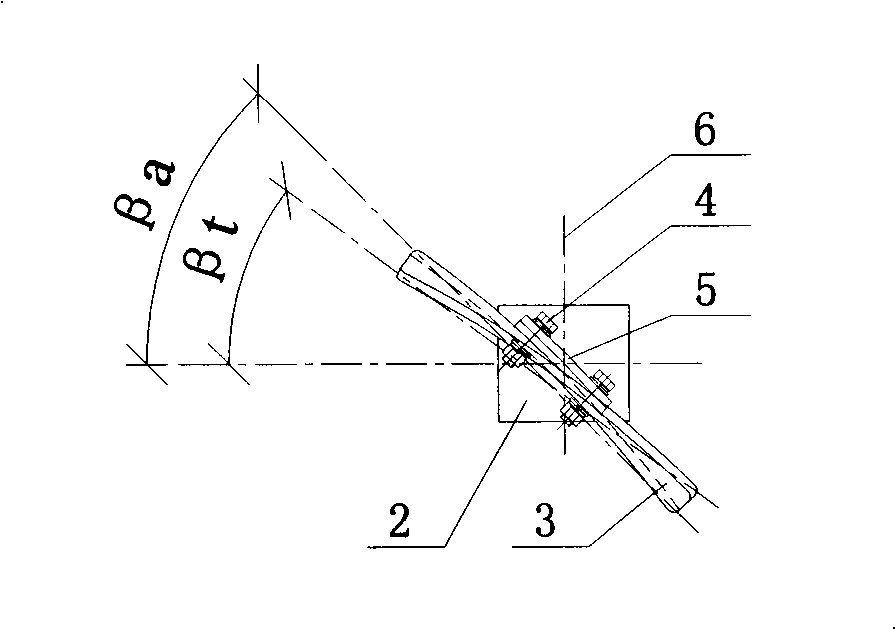

Axial flow type stirrer and method for producing the same

InactiveCN101352663AImprove flow field distributionEvenly distributedRotary stirring mixersTransportation and packagingPulp and paper industryBlade handle

The invention discloses an axial-flow blender and a manufacturing method thereof. The axial-flow blender comprises a mixer shaft, a hub, a blade, a fastening piece and a blade handle. The hub is arranged on the axial-flow blender; the blade is connected with the hub by the fastening piece through the blade handle. The blade of the mixer takes spatially twisted shape, the tilt angle of the front end of the blade, beta t is smaller than the tilt angle of the root part of the blade, beta a. The section of the blade at any radius part is of an arch structure. The surface of the blade is a part of a cylndrical surface and can be obtained from slantwise cutting a cylinder which is formed by rolling a sheet of metal beforehand or a part of the cylinder. The blender has the advantages of large discharging capability, simple manufacture requiring no mould, material saving and flexibly regulated parameters, etc. Taking catalytic hydrogenation of an intermediate of vitamin H for example, the reaction time is shortened to be within 3 hours from more than 16 hours of original time by adopting the axial-flow blender, and the energy consumption is small, the product quality is good and the catalyst is saved.

Owner:杭州原正工程技术装备有限公司

Apparatus and method of enhancing printing press cylinders

InactiveUS7207268B2Consume energyQuality improvementRotary letterpress machinesRelief printingEngineeringPrinting press

A printing press cylinder and a method of manufacturing the same. The printing press cylinder includes a rigid base member having a reduced radius section and a polymer layer formed about the rigid base member generally within the reduced radius section. The polymer layer is operable to absorb forces and dissipate energy that degrades print quality. A gear portion is operably coupled to the rigid base member for rotation therewith. The printing press cylinder is manufactured by turning a rigid base member to produce a reduced radius section and subsequently molding a polymer layer generally within the reduced radius section of the rigid base member. The polymer layer is cured and then turned to reduce the circumference thereof and produce a smooth surface.

Owner:NU TECH COATINGS

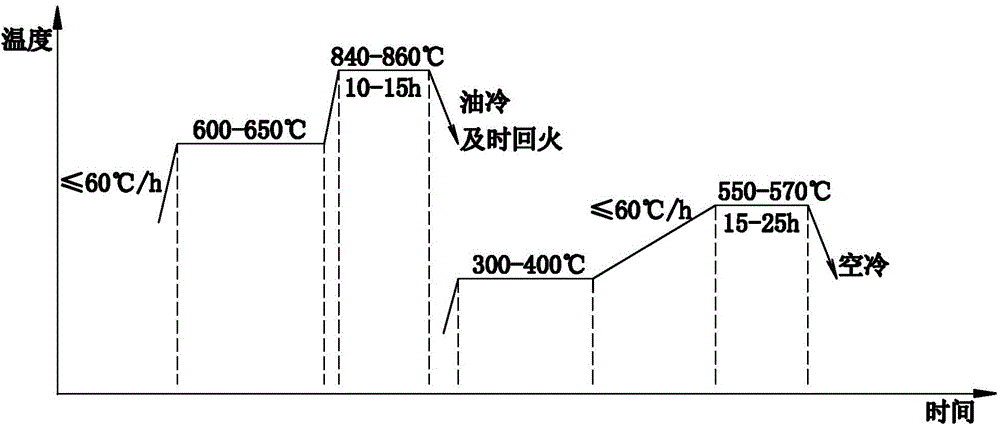

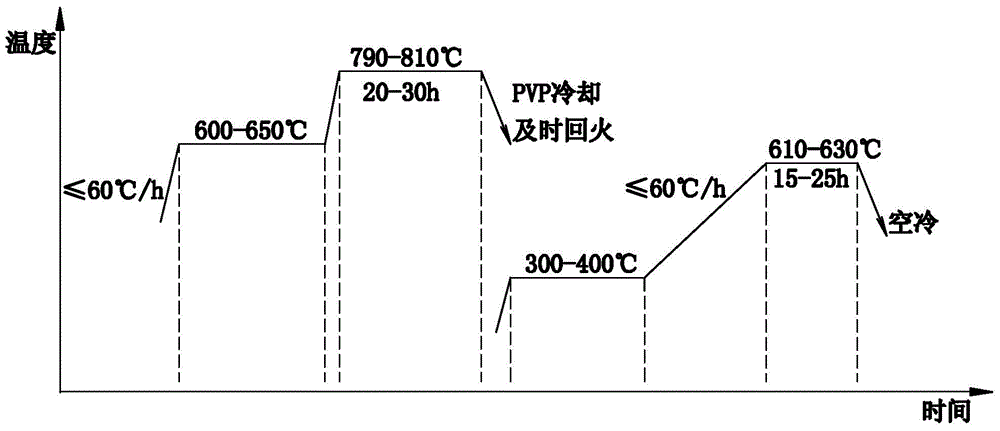

Manufacturing method of alloy steel for high and cold zone motor shaft

InactiveCN104451046ALower the tempering and quenching temperatureReduce manufacturing costQuenching agentsAqueous solutionQuenching

The invention discloses a manufacturing method of alloy steel for a high and cold zone motor shaft. The alloy steel is made of 42CrMo; the method comprises smelting and forging of a roller blank, tempering and quenching treatment and annealing treatment; the temperature of the tempering and quenching treatment is 790-810 DEG C and the time is 20-30 hours; a cooling medium adopted after the tempering and quenching treatment is polyvinylpyrrolidone aqueous solution; the temperature of the annealing treatment is 610-630 DEG C, and the time is 15-25 hours. Special heat treatment is performed on the conventional 42CrMo material, the tempering and quenching temperature is reduced, and the polyvinylpyrrolidone aqueous solution is used as the cooling medium, so that the motor shaft with larger specification which can meet the requirements that the temperature is 20 DEG C below zero and the impact force is greater than or equal to 27 J close to the surface and at the 1 / 2 radius part can be prepared; compared with the prior art, the method has the advantages that the production cost is reduced and the process is simple and is suitable for industrial large-scale production by adding a micro-alloyed element of higher price.

Owner:BAOSTEEL ROLL SCI & TECH

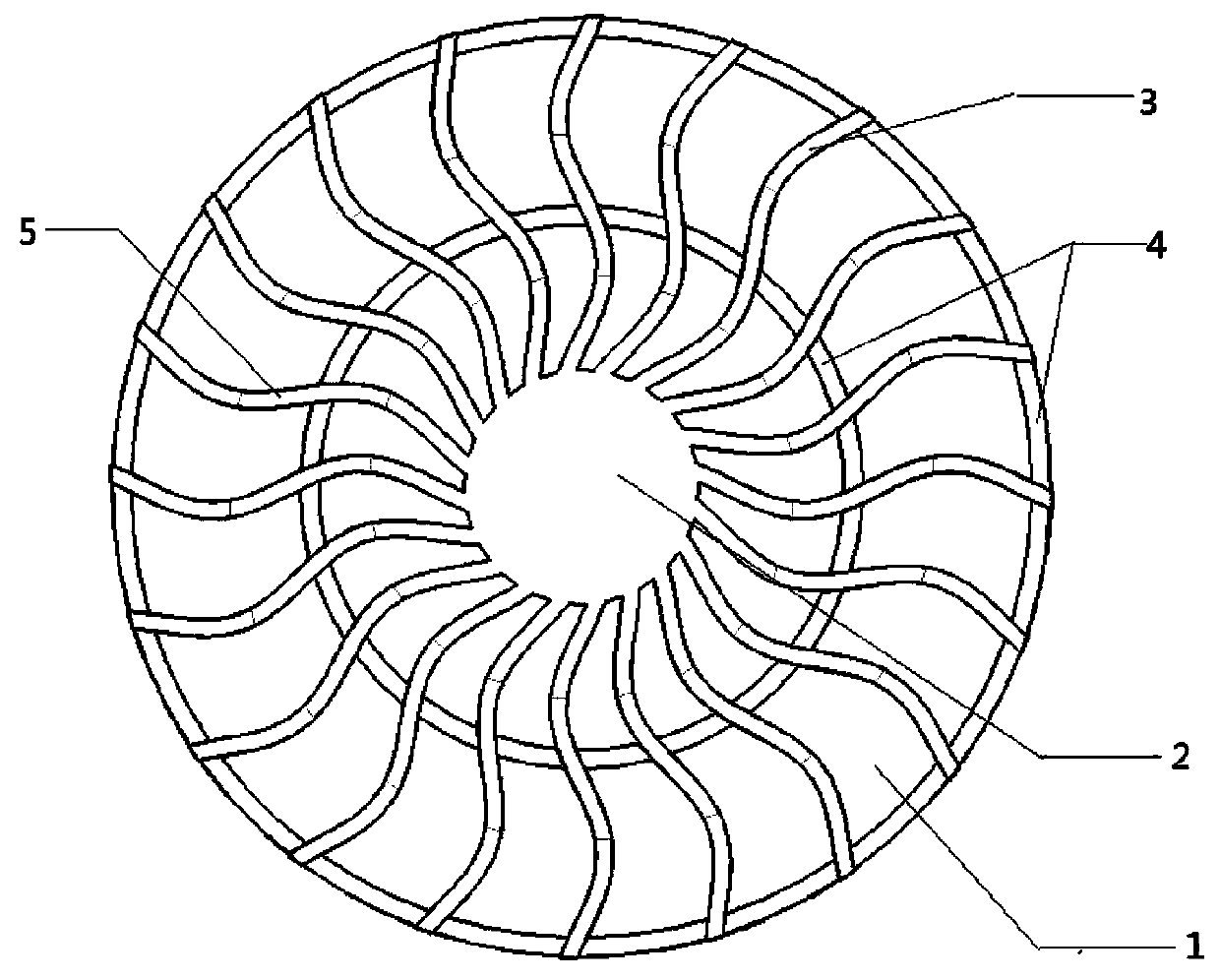

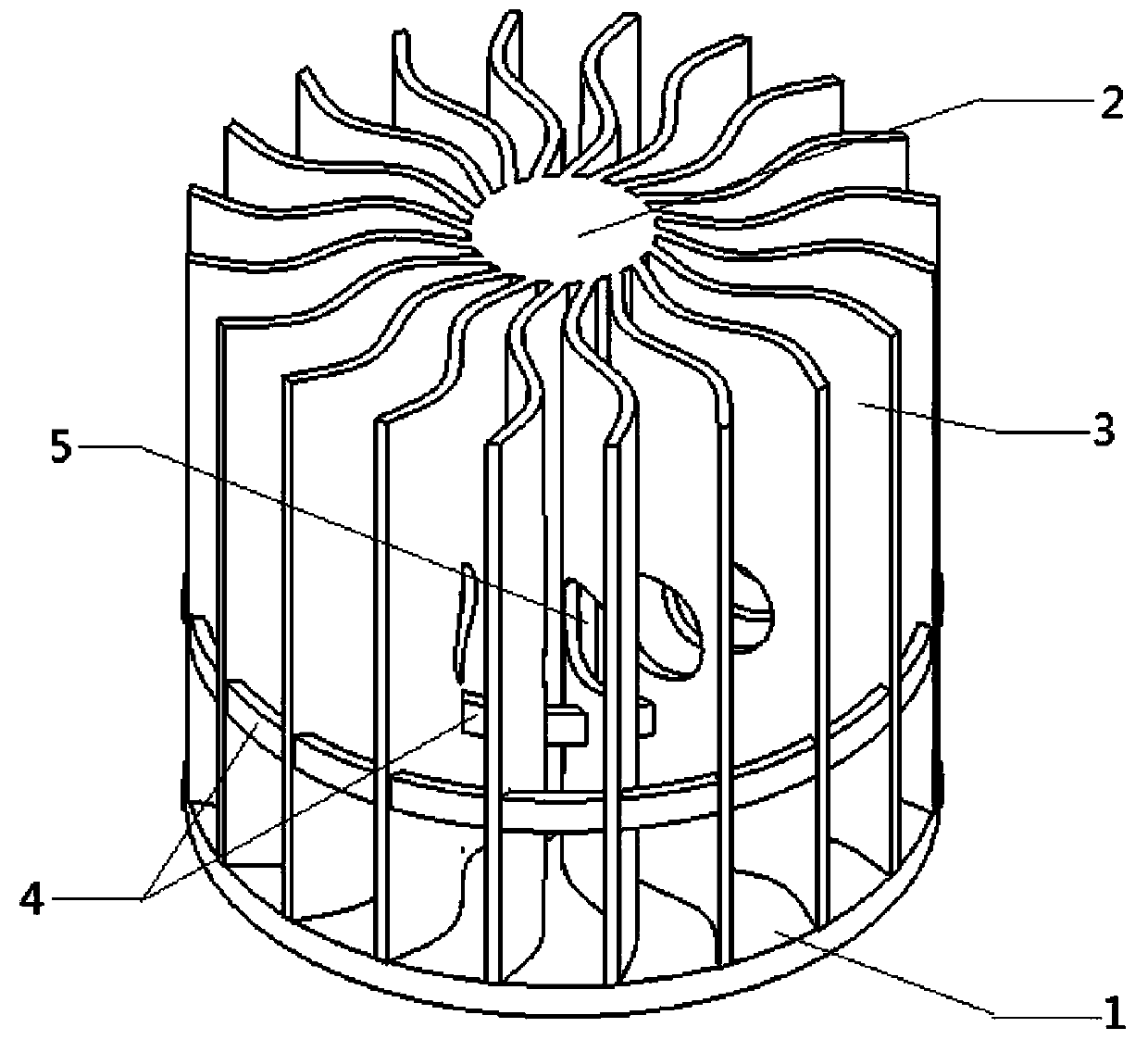

Graphite radiator and integral forming method thereof

ActiveCN107606982AIncrease surface areaImprove convective heat transfer coefficientAdditive manufacturing apparatusIndirect heat exchangersCarbonizationEngineering

The invention relates to a graphite radiator and an integral forming method thereof. The graphite radiator is composed of a radiating base plate, a thermal column, radiating fins and connecting rib pieces, wherein the thermal column is placed in the center of the radiating base plate; the radiating fins are radially distributed by taking the thermal column as the center; small holes are formed inthe radiating fins to increase the convective heat transfer coefficient; the radiating fins are designed to be hook face to increase the radiating area; and the connecting rib pieces are designed at different radius parts in the peripheral direction of the graphite radiator. The graphite radiator is integrally formed and comprises the technological links of mixed powder preparation, integral 3D printing forming, prefab preparation, carbonization and buried carbon high-temperature sintering. The integral forming method is simple in technology, practical and low in production cost and can manufacture a complicated graphite radiator; and the graphite radiator has the characteristics of being large in superficial area and high in convective heat transfer coefficient, strength, rigidity and radiating effect and has broad application prospect in the radiating field.

Owner:CHINA THREE GORGES UNIV

Decorative bench barrier

A decorative bench barrier serves the function of providing security for buildings, memorials, and people, while at the same time providing aesthetically pleasing seating suitable for long term use on city streets, in parks, and in other areas. The decorative bench barrier is constructed from one or more reinforced precast concrete elements which include a wide base, a central seating region, and a top back rest. The reinforced precast concrete elements are made in straight sections and radius sections. The radius sections are preferably either 45° or 90°. The sections are interconnectable so that a circular, square, serpentine or other suitable configuration for the bench barrier can be assembled on site.

Owner:MAYER RODIS NANCY J

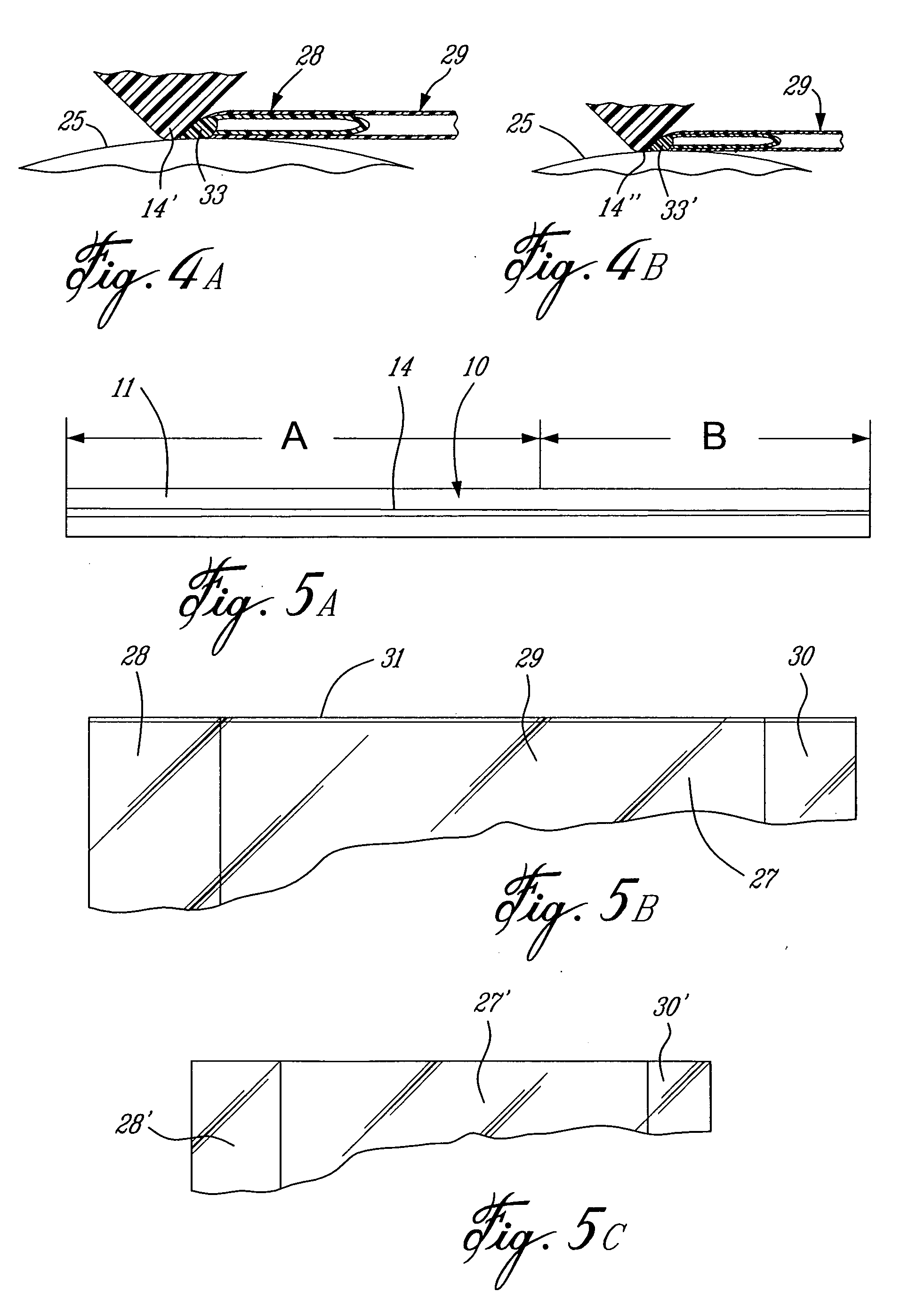

Heat sealing and slitting blade with variable radius cutting tip

InactiveUS20060185797A1Improves seal integrityLamination ancillary operationsLaminationEngineeringKnife blades

A heat sealing and slitting blade for slit sealing overlaid sheet of thermoplastic film material. The film material to be slit and sealed has at least two portions of different thickness. The blade has an elongated cutting tip having at least two different transverse radius sections therealong with a larger one of the radius sections being adapted to seal a thicker one of the two portions of different thickness to improve seal integrity along the predetermined length.

Owner:GLOPAK INC

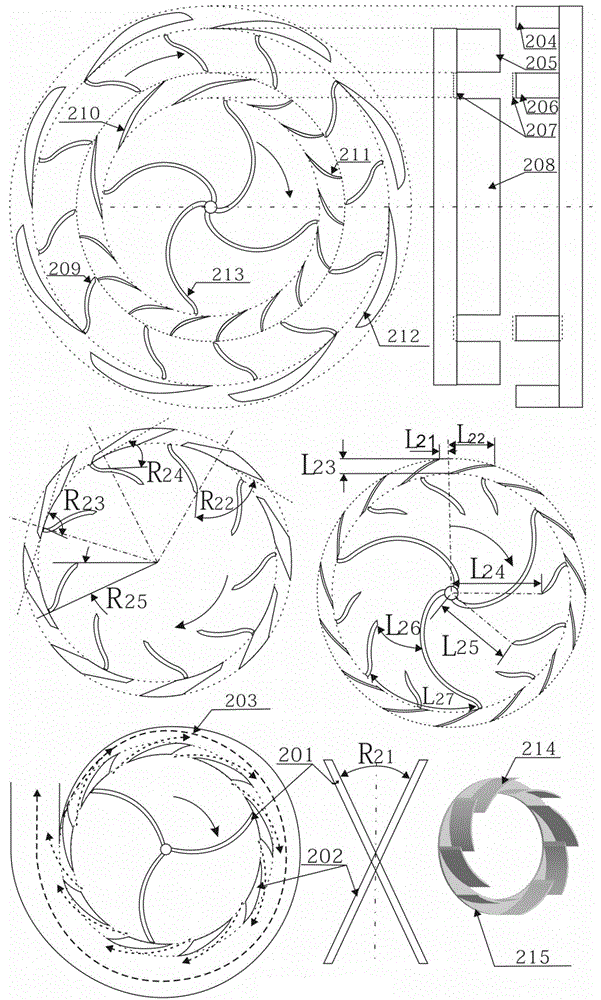

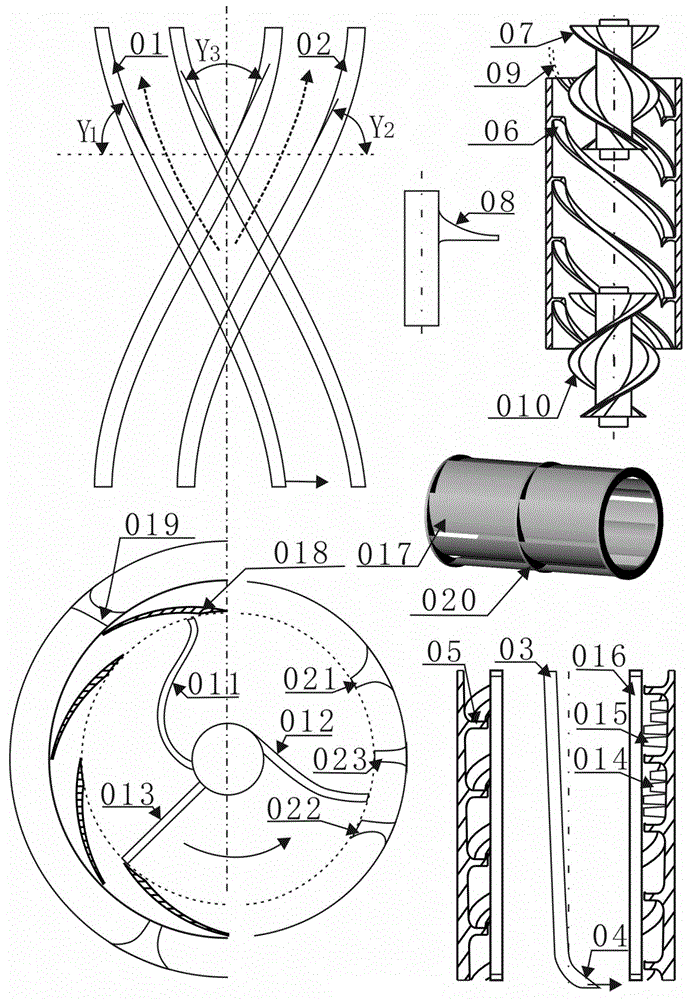

Strengthening and application of power type vane pump

ActiveCN105275884AImprove energy exchange efficiencyPump componentsBlade accessoriesHigh pressureSpiral flow

The invention discloses strengthening and application of a power type vane pump. A reasonable relation between fluid and power is obtained by means of the shape structure of parts of the pump and fluid features, and superchargers (017 and 423) with the small-angle R2 and small R1 and R2 fluid inlet included angle fins are added to the output end of pump vanes. Fins (06 and 410) are combined with the inner side of a pump shell to become flow channels to increase the output pressure or flow of fluid. Inner stators (52 and 510) of the spiral flow channels enable the fluid to impact rotors (51 and 511) with particle bars (512) on the inner surface of the pump shell in a centrifugal rotation manner for power output. The high-pressure fluid of pipelines (906 and 918) are used for impacting the small-radius part of a high-pressure fluid impacting pump blade (908) or large-radius parts of parts (911 and 916), backward flowing is conducted, and the rotation power output of rotors where the blades are located is obtained. A transmission device conducting transmission through the fluid force is formed by rotors with fins (52, 510, 416 and 419) and rotors with particle bars (51, 511, 415 and 418) on the inner side of the pump shell.

Owner:何家密

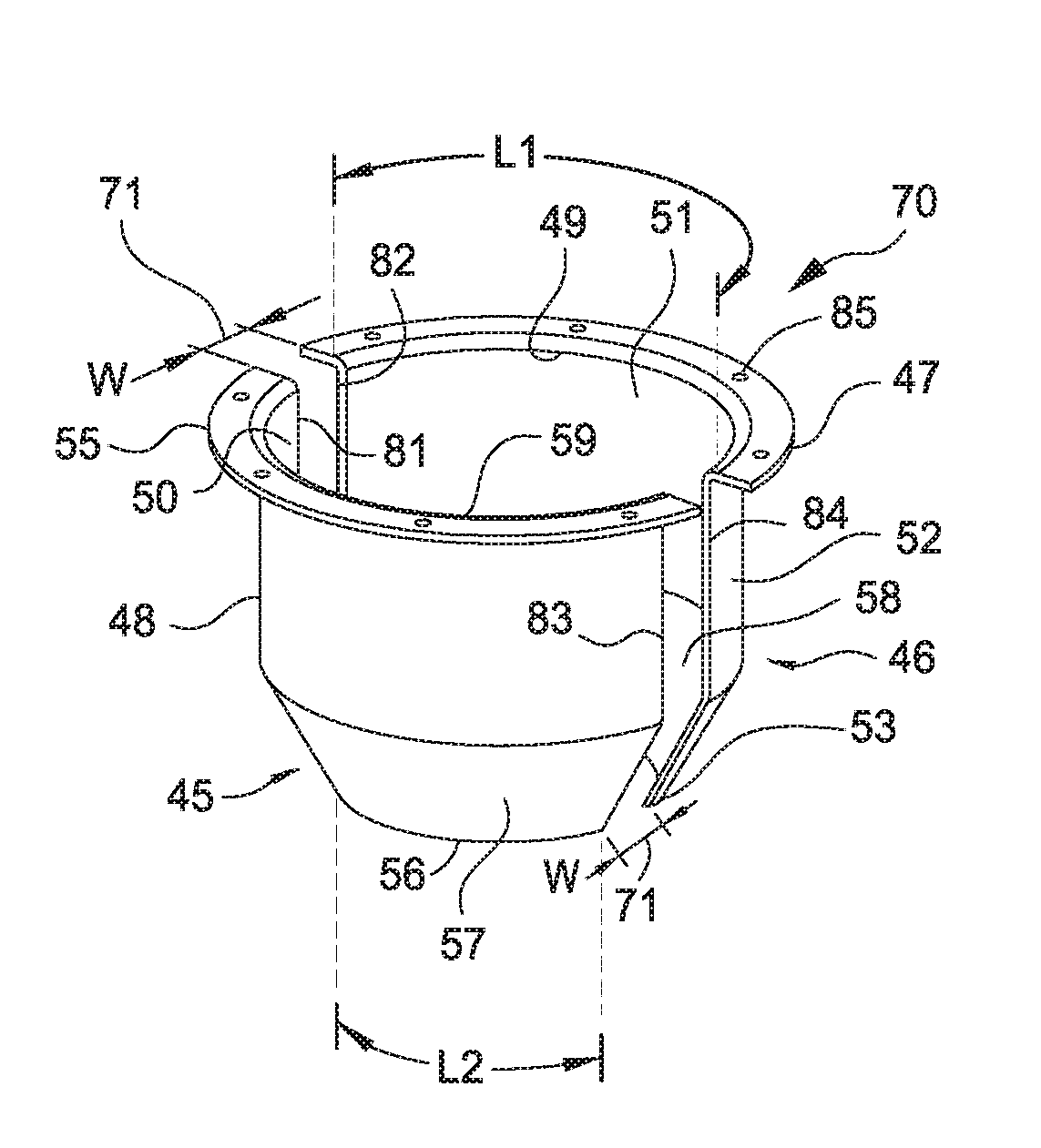

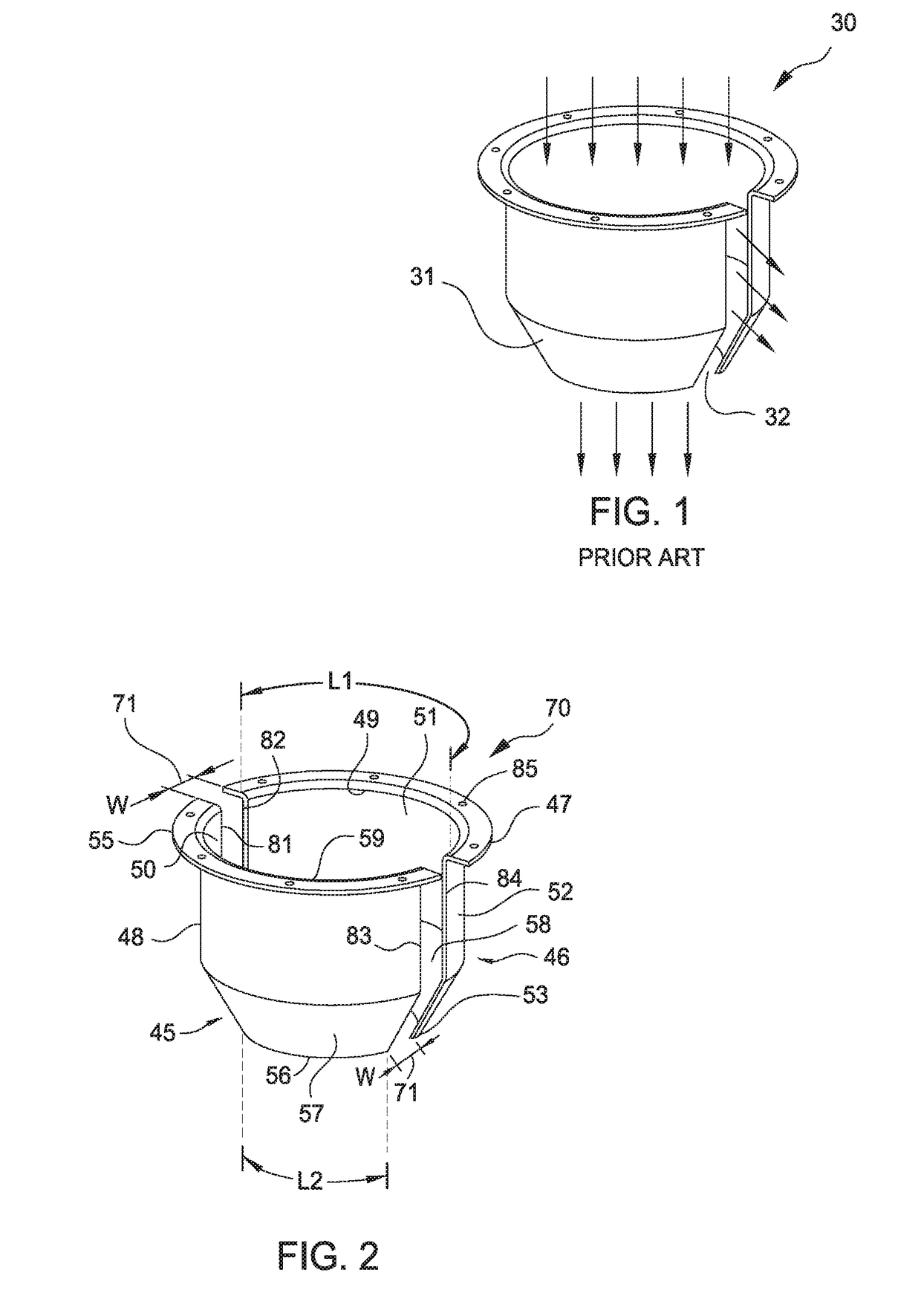

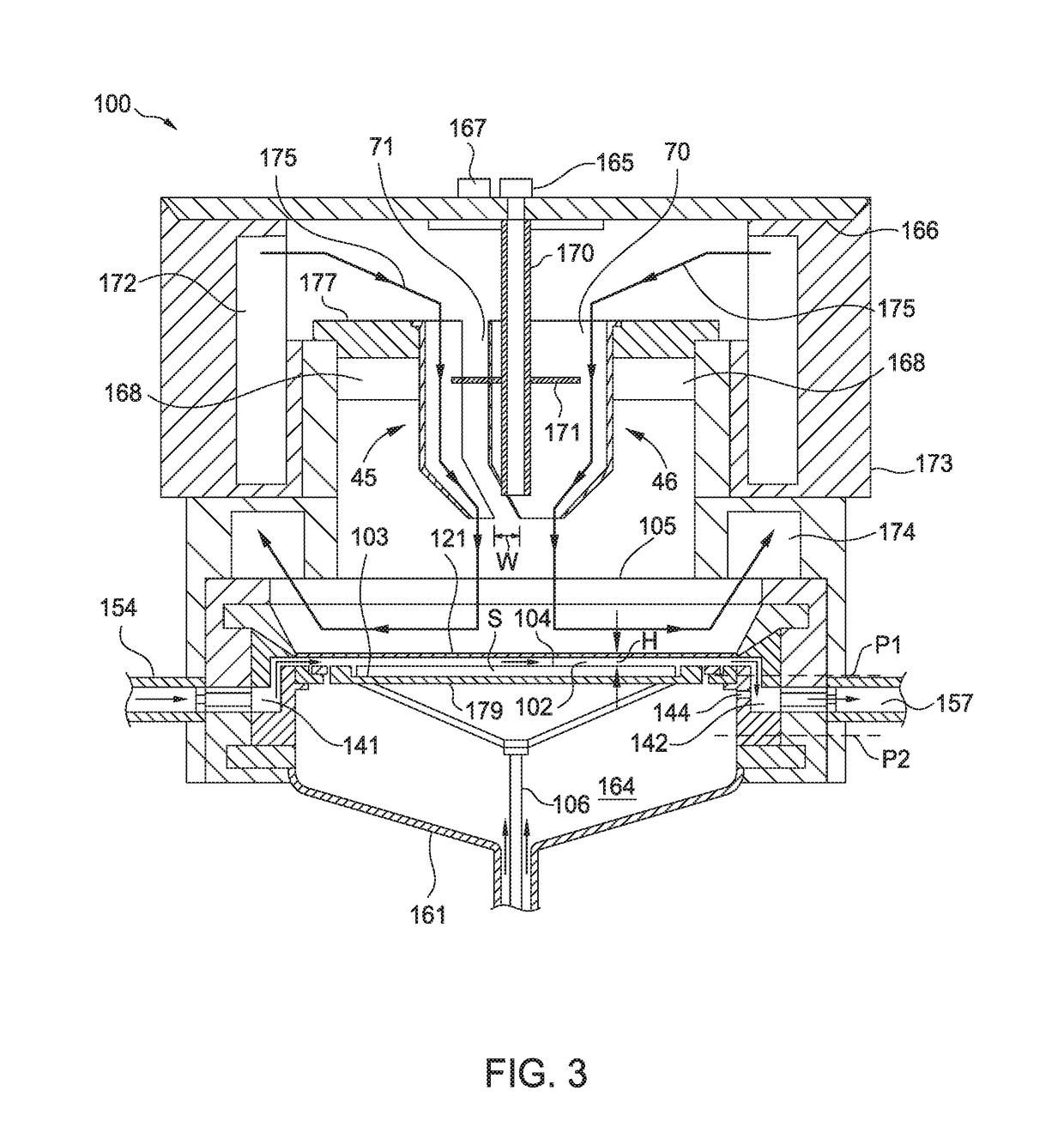

Upper cone for epitaxy chamber

ActiveUS20180053670A1Semiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringConoid

An epitaxial deposition chamber having an upper cone for controlling air flow above a dome in the chamber, such as a high growth rate epitaxy chamber, is described herein. The upper cone has first and second components separated by two or more gaps in the chamber, each component having a partial cylindrical region having a first concave inner surface, a first convex outer surface, and a fixed radius of curvature of the first concave inner surface, and a partial conical region extending from the partial cylindrical region, the partial conical region having a second concave inner surface, a second convex outer surface, and a varying radius of curvature of the second concave inner surface, wherein the second concave inner surface extends from the partial cylindrical region to a second radius of curvature less than the fixed radius of curvature.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com