Optical fiber laser cutting blade type hole energy regulation method for sheet metal

A thin metal plate and fiber laser technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of slag hanging on the lower surface, corner ablation on the upper surface, and uneven energy distribution, so as to improve cutting accuracy and repeatability. High performance, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be further described by comparing the before and after improvement of the laser cutting of the airfoil hole sample with reference to the accompanying drawings and the technical scheme.

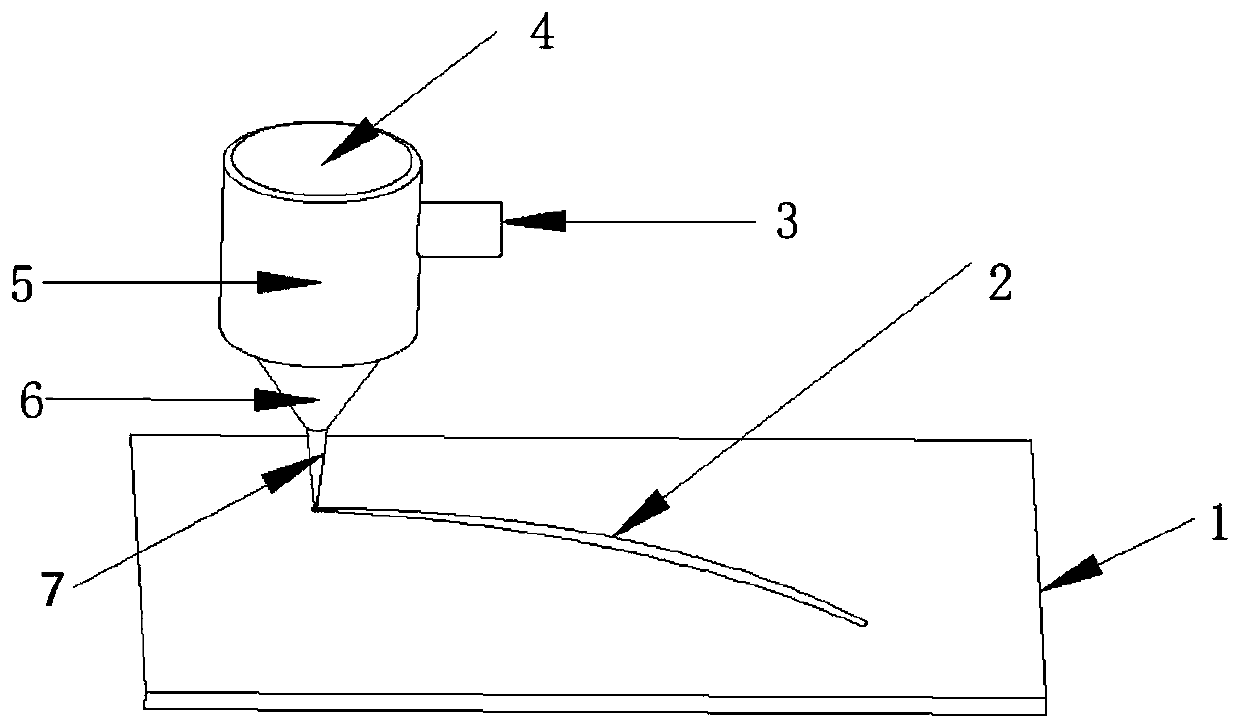

[0027] Metal sheet laser cutting leaf hole processing process such as figure 1 shown.

[0028] (1) The production of leaf-shaped hole samples has not been improved (constant laser parameters are used for all lines of the holes)

[0029] ①The metal sheet 1 is made of stainless steel-carbon steel laminate, and the laminate with a thickness of 1 mm is cut into a rectangular sample with a length of 47.5 mm and a width of 27.5 mm by using a laser cutting machine. % alcohol solution to clean the surface of the plate.

[0030] ② Place the metal sheet 1 on the laser processing workbench. In order to prevent the auxiliary blowing in the auxiliary blowing air inlet 3 from changing its position, use adhesive tape to fix the two ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com