Axial flow type stirrer and method for producing the same

A stirrer and axial flow technology, which is applied in the field of axial flow stirrer and its production, can solve the problems of inability to form a space torsion structure, decrease of steel plate utilization rate, and unfavorable cost saving, etc., so as to optimize hydrodynamic performance, optimize Flow field distribution, beneficial to diversification and large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

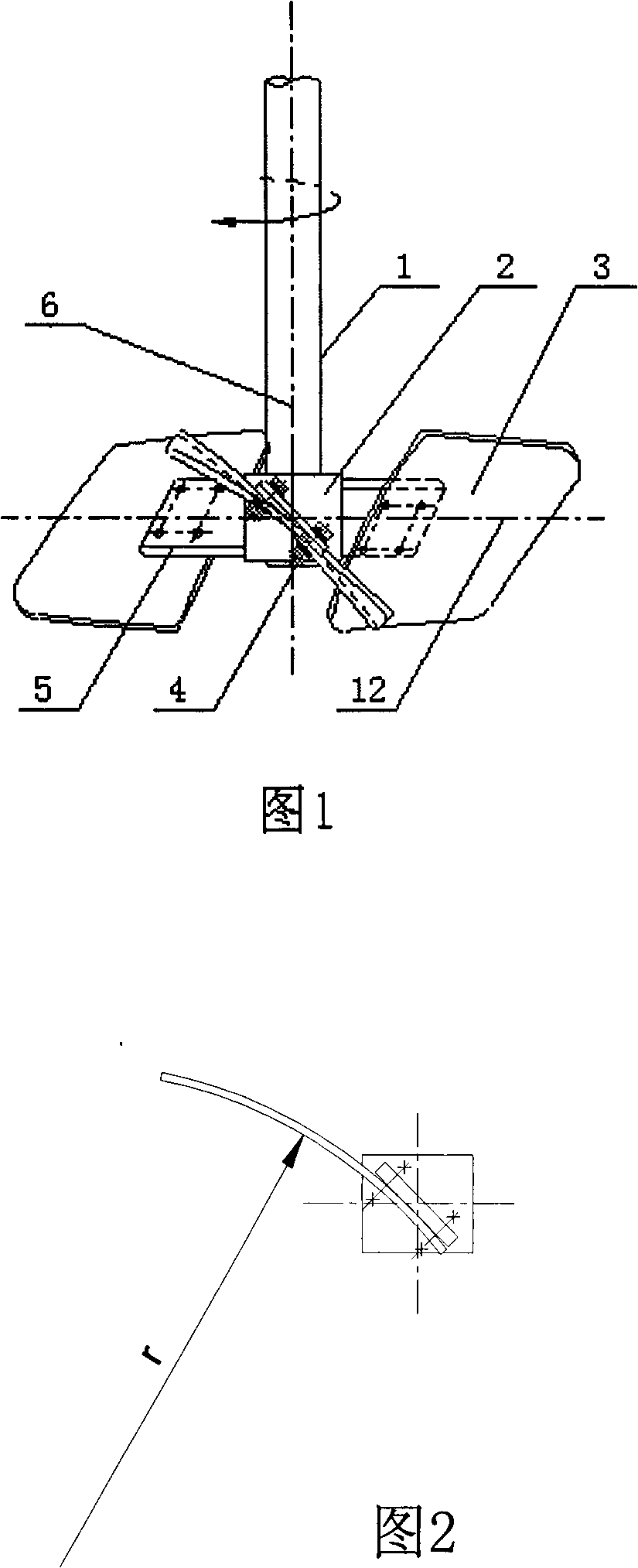

Embodiment 1

[0056] The effective volume is 2.5m 3 The high-pressure liquid-phase catalytic hydrogenation reaction device is used for the production of vitamin H intermediates. When the conventional design is adopted, the bottom layer is a propulsive agitator, which is used for the suspension of the catalyst and the macroscopic mixing of the material. The upper layer is a six-blade disc turbine. For the dispersion of hydrogen, when the rotation speed is 191rpm, after 16 hours of reaction, the residual raw materials still exceed the process requirements and cannot be used normally. Under the condition of adding catalyst many times during the reaction, after 30 hours of reaction, the residual raw materials In order to meet the process requirements. In this embodiment, when the process conditions such as stirring power, rotating speed, catalyst, reaction pressure, and reaction temperature remain unchanged, the original double-layer agitator is changed into a three-layer axial flow agitator ac...

Embodiment 2

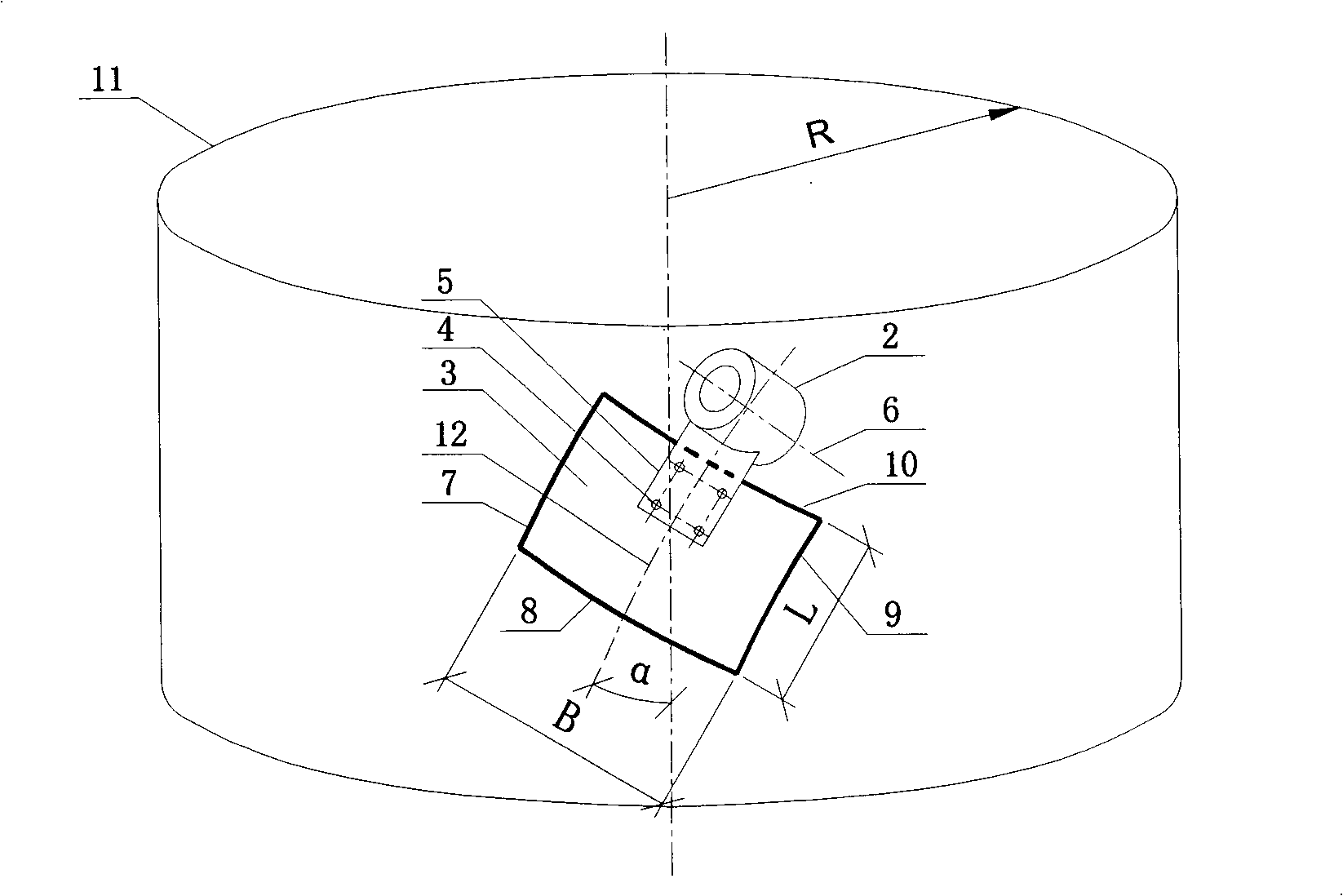

[0063] In the 100kt / a nitrochlorobenzene plant, the high-efficiency axial flow agitator of the present invention is used to replace the traditional propulsion agitator in the tank-type nitration reactor, which can be obtained by consuming 87% of the energy consumption of the traditional agitator. With the same single-pot conversion rate and reaction efficiency, the weight of the agitator is only 65% of that of the pusher agitator, and the corresponding cost of the agitator shaft, coupling, frame, etc. is reduced by more than 25%. The main technical parameters of the mixer are as follows:

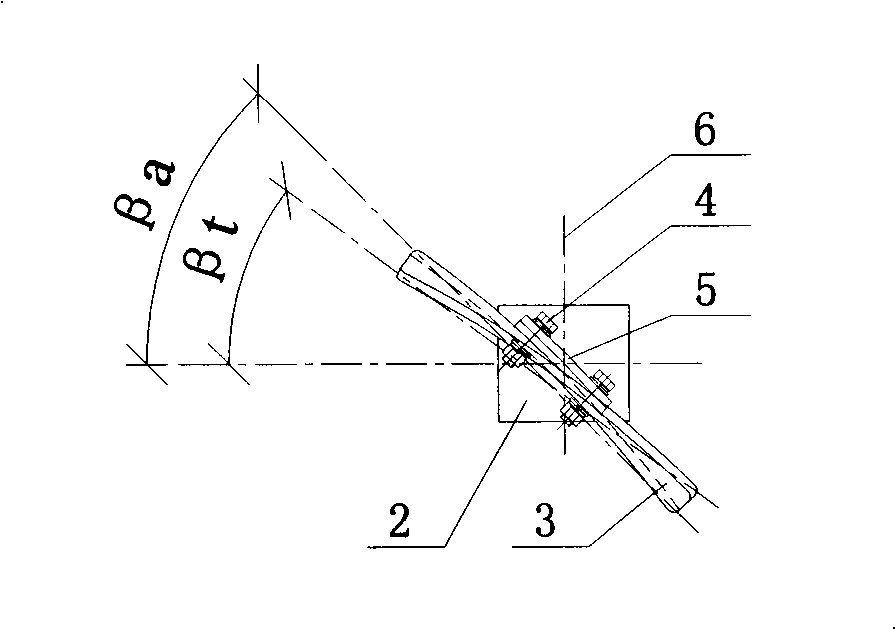

[0064] 1) Number of blades n b = 3;

[0065] 2) Blade area ratio = 19%;

[0066] 3) The inclination angle β of the blade end t = 18°;

[0067] 4) The inclination angle β of the blade root a = 43°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com