Rotary impact shock jet PDC (polycrystalline diamond compact) bit

A jet-type and drill bit technology, which is applied in the direction of drill bit, liquid/gas jet drilling, and rotary combined drilling driving device, etc., can solve the problems of cuttings starting and suspension under the drill bit, etc., so as to improve drilling efficiency and improve drilling efficiency. Flow field distribution, the effect of avoiding mud bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

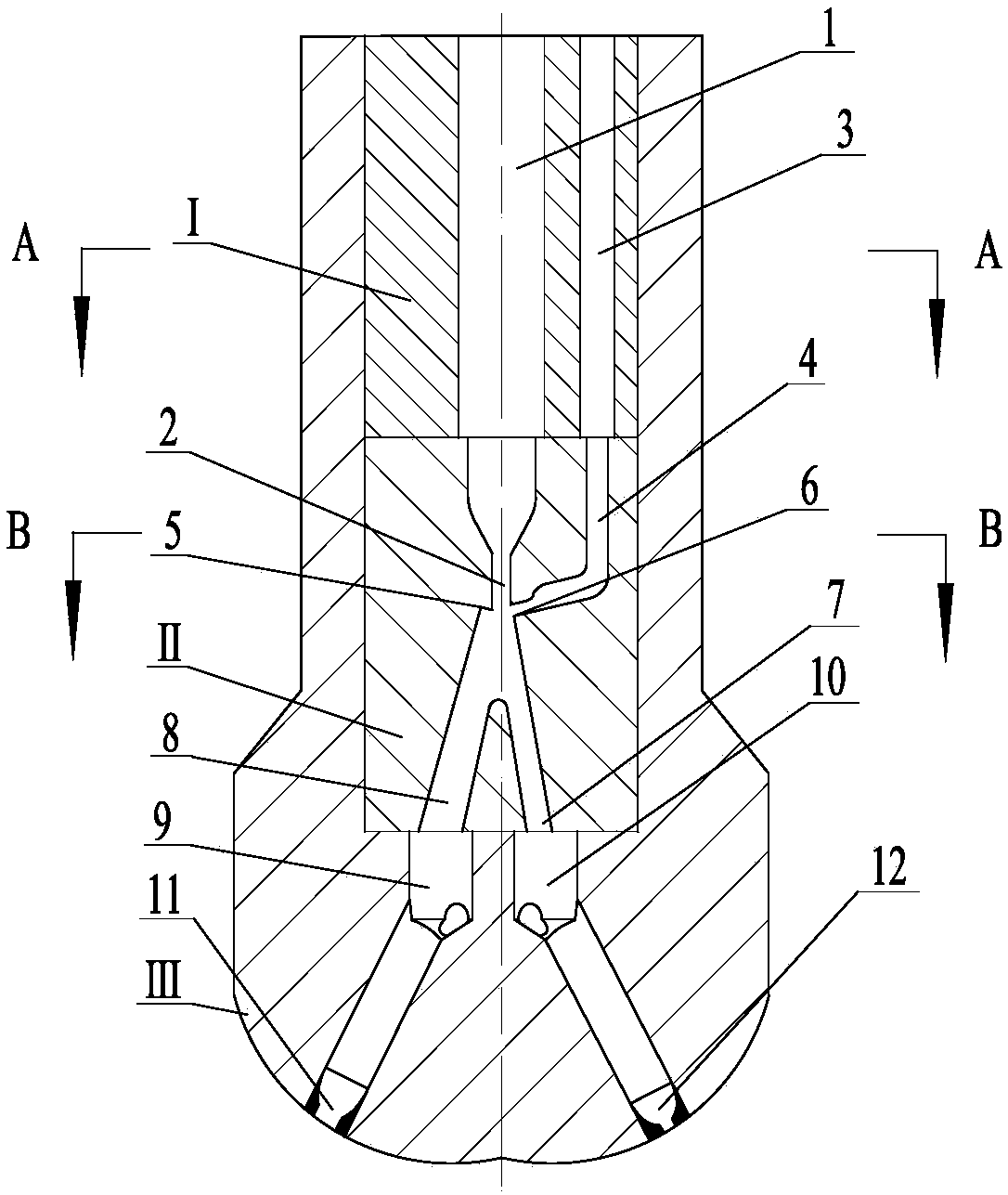

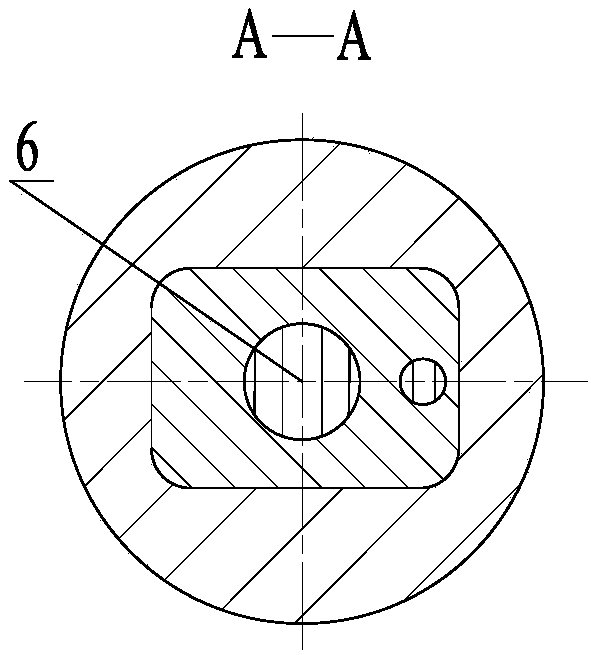

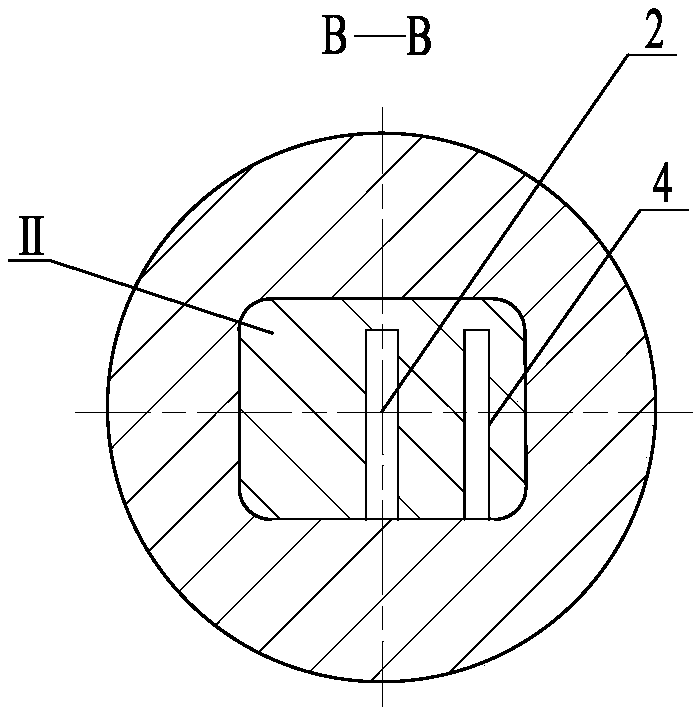

[0016] Such as figure 1 , figure 2 As shown, the rotary percussion oscillating jet type PDC drill bit described in this embodiment has a main body including three parts: the indenter I, the single control channel monostable jet element II and the bit body III. Two blind holes are respectively opened in the drill body III, wherein the left blind hole 9 is located under the large outlet 8 of the jet element, and communicates with two large nozzles 11, while the right blind hole 10 is located under the small outlet 7 of the jet element, It is connected with two small nozzles 12; there is a central channel 1 connected to the nozzle 2 of the single-control channel monostable jet element inside the pressure head I; the single-control channel monostable jet element II is a complete rectangular block, passing through the block The required flow channel is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com