Strengthening and application of power type vane pump

A power and power output technology, applied in the extended application field of this method, can solve the problems of small output pressure or flow rate, reduced application volume and range, low fluid and power exchange efficiency, etc., to expand the application range and improve energy exchange efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

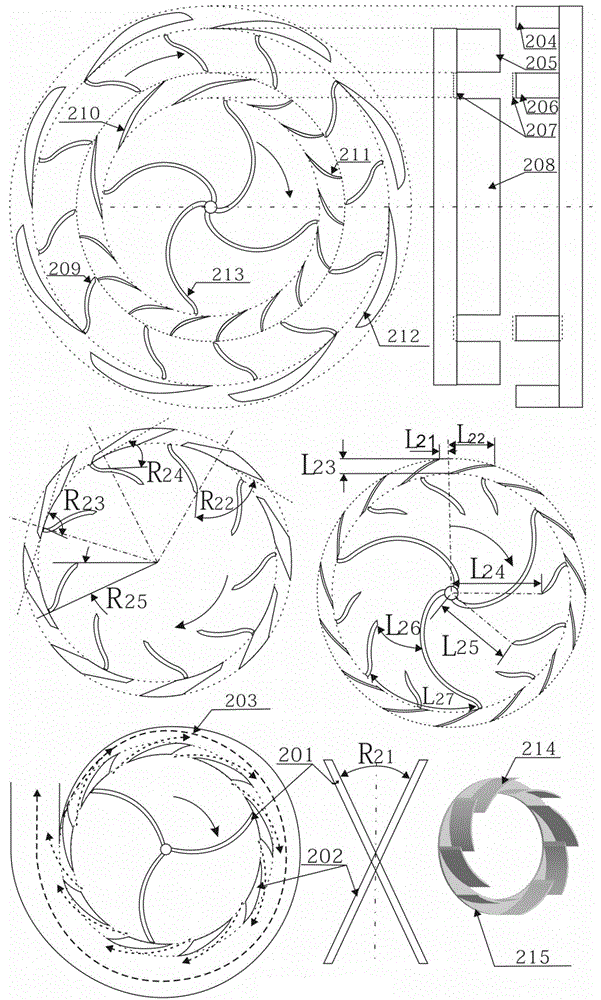

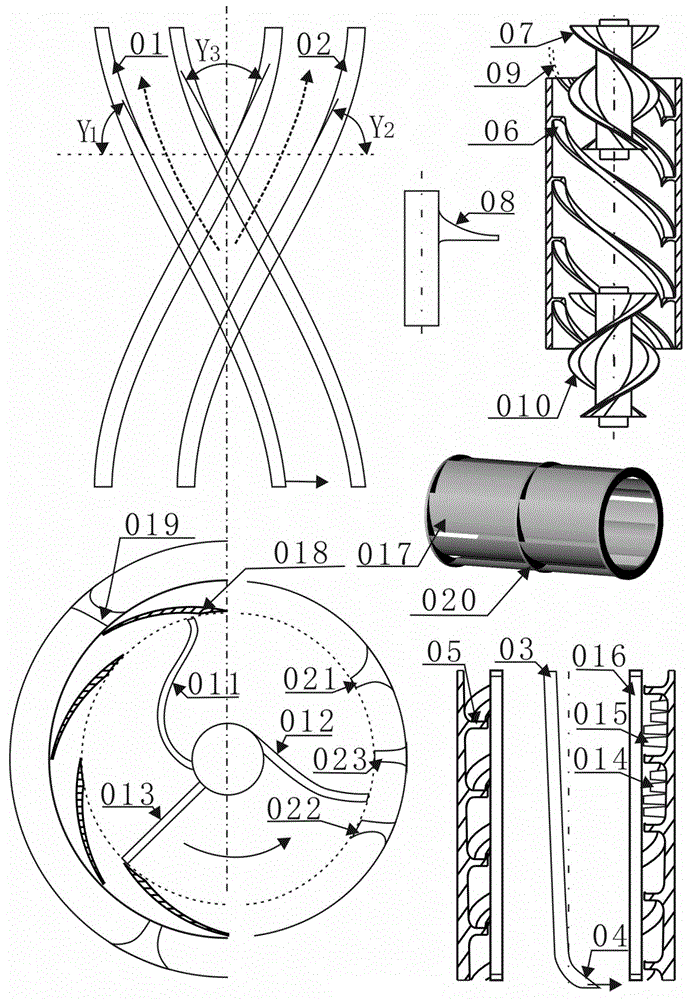

[0014] exist figure 1 Among them, the fins (7, 9, 11, 16, 17) of the pump supercharger are subjected to the rotational movement of the pump blades (10, 12, 14) so that the fluid is sheared and extruded to flow to the fins of the supercharger One side, (2) is the action fluid surface of the sharp angle between the supercharger fin and the pump blade, and the mating surface of the pump blade (in the application of axial flow pump) or the tangent line of the sharp angle (in the application of centrifugal pump) (18) The included angle is R 2 , the smaller the angle is, the better it is for the supercharger fin to shear the fluid, and the more the conversion efficiency between the power of the pump blade and the fluid flow is increased; (8) is the matching surface of the supercharger fin and the sharp angle of the pump blade at the shortest distance, ( The sharp angle formed by 2 and 8) is the closest part between the turbocharger fin and the pump blade, (8) and the pump blade m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com