Tube-type spiral conveyer

A screw conveyor and tube-type technology, applied in the field of conveyors, can solve the problems of suspension bearings increasing the material blocking area, affecting normal work, and having no support devices, so as to reduce maintenance workload, maintenance costs, and weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

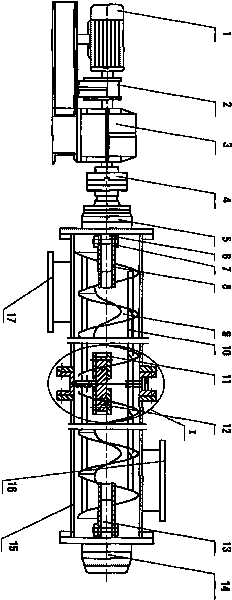

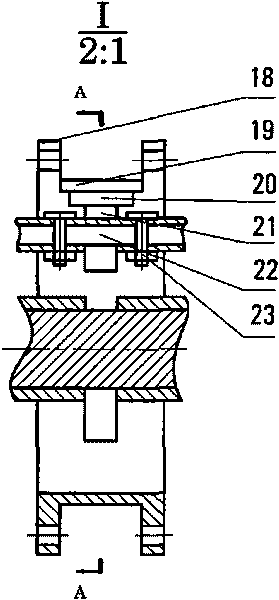

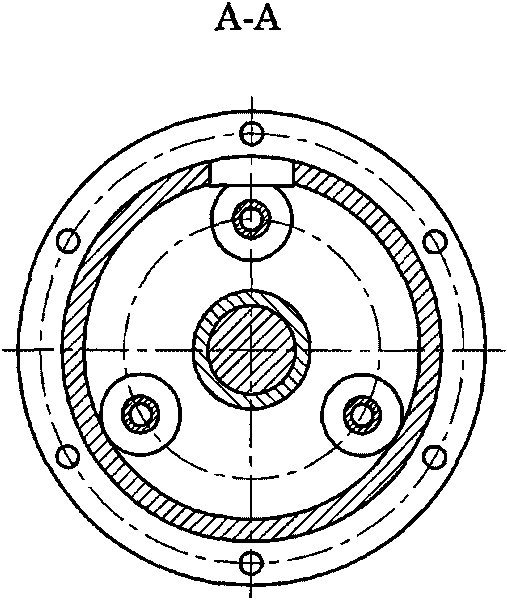

[0014] Such as figure 1 Shown is a schematic structural view of the tubular screw conveyor of the present invention, in which the motor 1 is connected to the reducer 3 through a coupling 2, the reducer 3 is connected to one end of the head shaft 6 through a coupling 4, and the head shaft 6 passes through the head The other end of the bearing device 5 is inserted into the short pipe 8 on the spiral body 11, and is fastened by the pin shaft 7; the two ends of the spiral body 11 are welded by a short pipe 8 slightly larger than one pitch, several spiral blades 9, and three seamless steel pipes 10 Formed, the helical blades 9 are connected continuously at the same angle, and three seamless steel pipes 10 penetrate into the holes uniformly distributed along the circumference of the helical surface at an appropriate radius, and are parallel to the axis, and are equal in length to the helical body 11 for connection and support. The function of the spiral body 11; the short tube 8 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com