Planetary gear device

A technology of planetary gears and internal gears, used in gear transmissions, hoisting devices, transmissions, etc., can solve problems such as difficulty in securing a large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, an example of embodiment of the present invention will be described in detail with reference to the drawings.

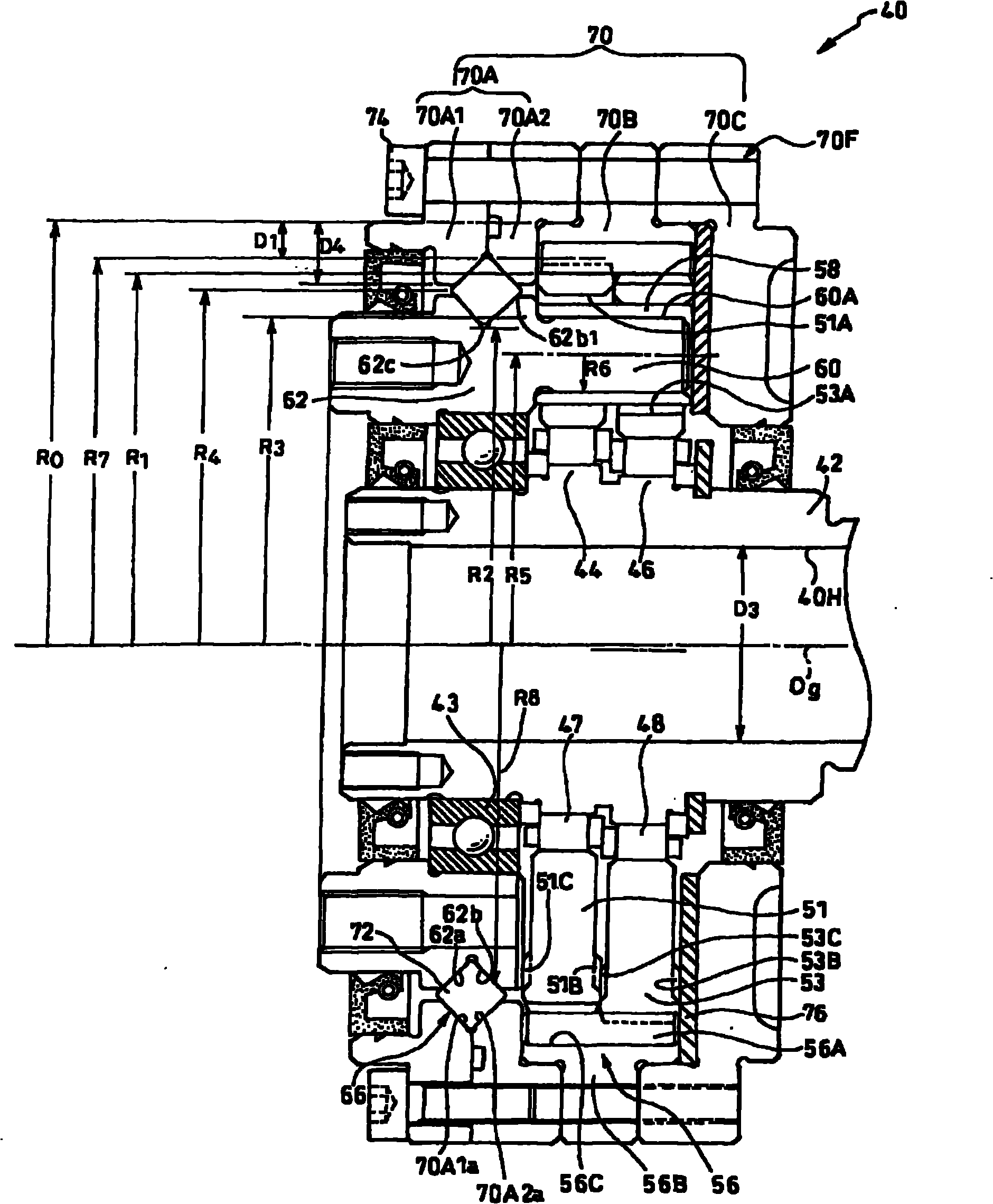

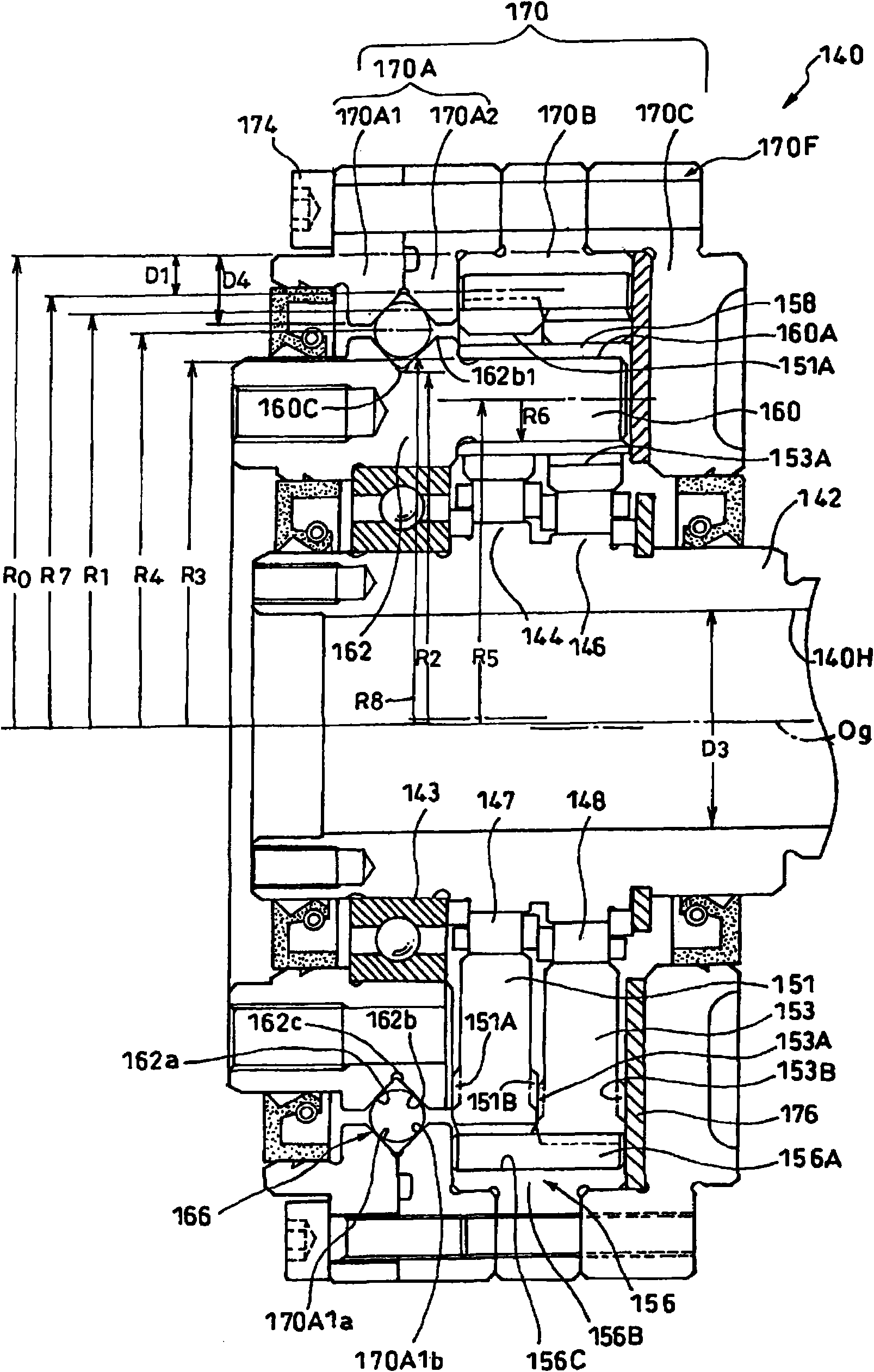

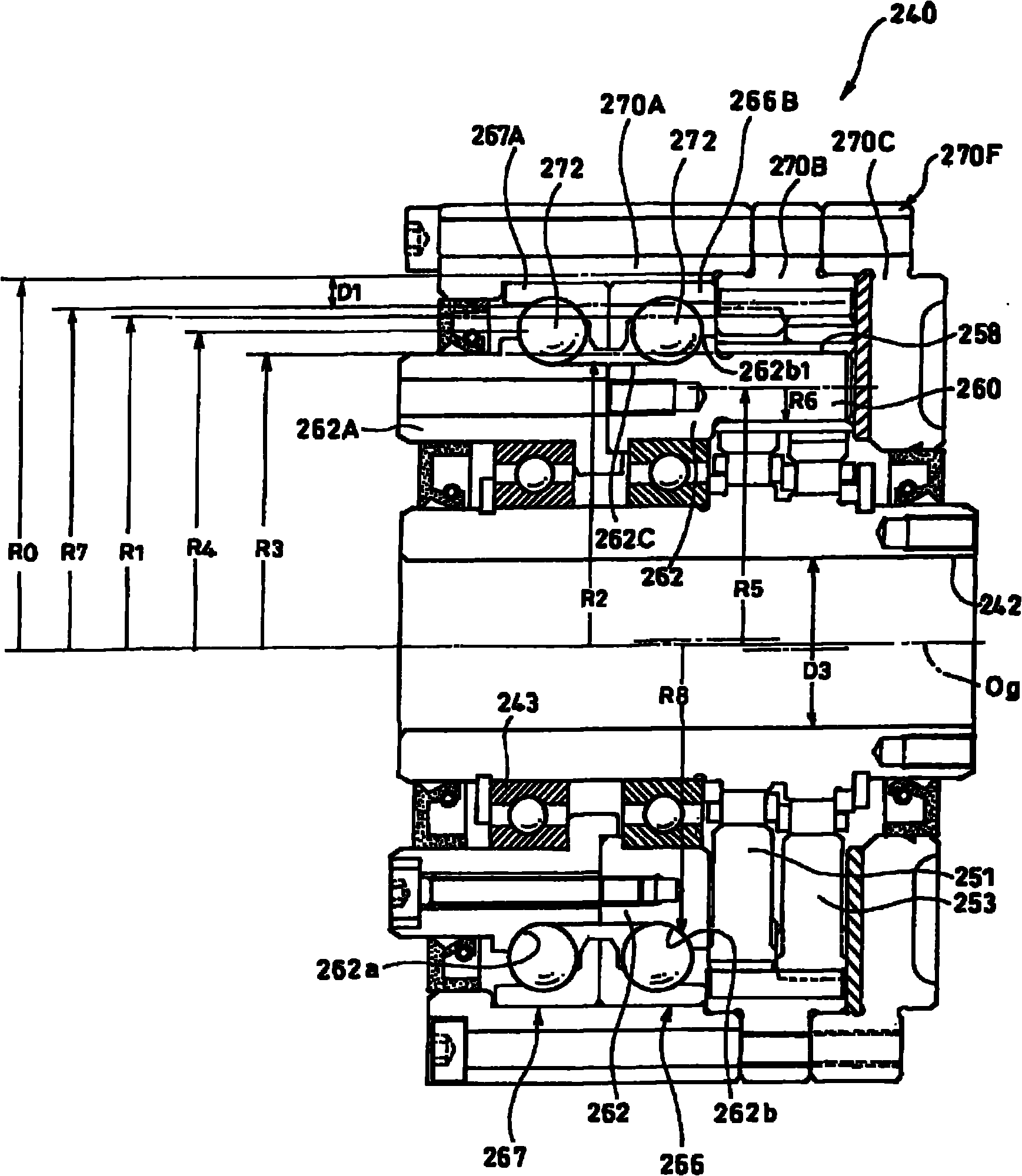

[0031] figure 1 It is a cross-sectional view showing a planetary gear speed reducer according to an example of an embodiment of the present invention.

[0032] The planetary gear reduction device 40 has a hollow portion 40H that axially penetrates the device 40 (penetrates along the axis Og of the device 40 ) in the space at the central portion in the radial direction. This planetary gear reduction unit 40 includes an input shaft (high-speed shaft) 42, two eccentric bodies 44, 46, two rollers 47, 48, two external gears (planetary gears) 51, 53, and external gears 51, 53. meshing internal gear 56 . This device has a structure in which the relative rotation component of the external gears 51 and 53 and the internal gear 56 is taken out as an output through the internal pin (pin member) 60 and the carrier flange 62 by swinging the external gears 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com