Feed stirring device

A feed and mixer technology, which is applied to mixers with rotating stirring devices, feed, mixer accessories, etc., can solve the problems of insufficient feed mixing and cutting, and achieve the effects of avoiding machine jamming, high mixing efficiency, and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

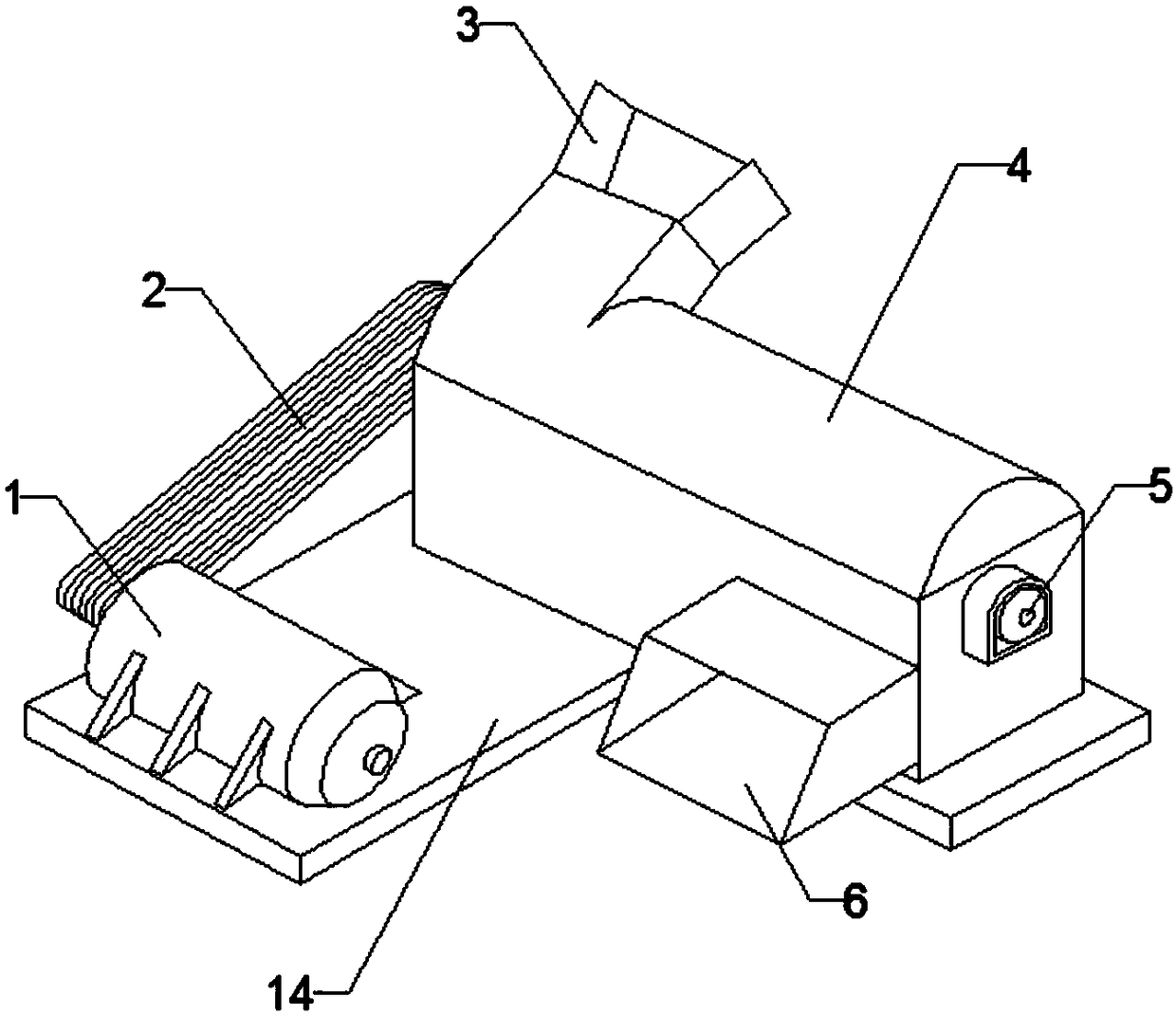

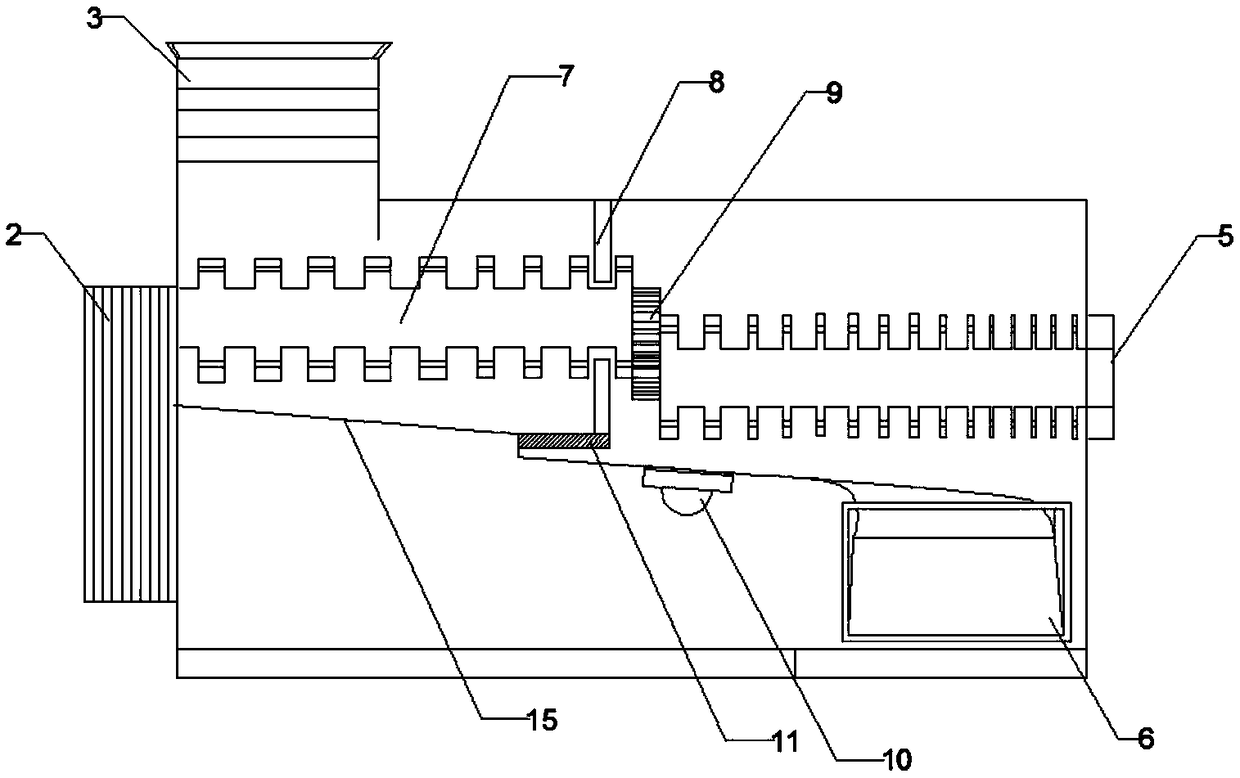

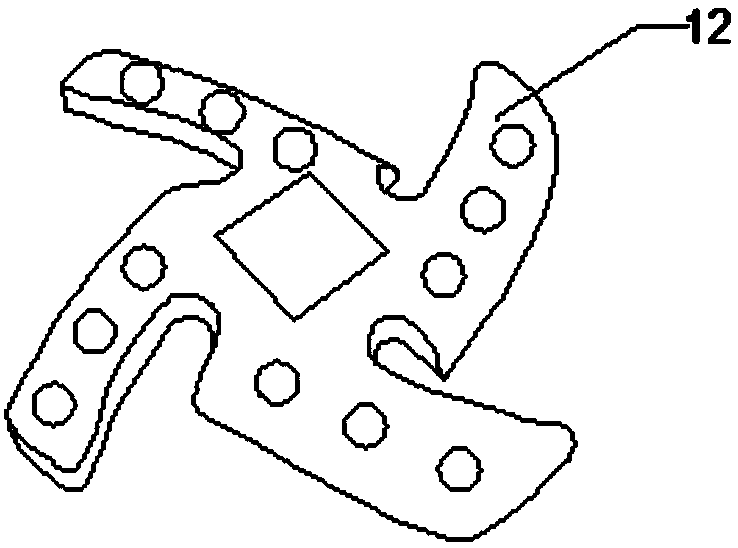

[0026] Example: such as figure 1 and figure 2 As shown, a device for stirring feed includes a mixer casing 4, the mixer casing 4 is provided with a feed inlet 3, a discharge port 6 and a rotating shaft 5, and the mixer casing 4 is provided with a guide plate 15 , fan 10, funnel 11, separating plate 8 and a plurality of knife groups 7 of different shapes and sizes driven by the rotating shaft 5, a guide plate 15 is provided below each knife group 7, and separating plates are arranged between the knife groups 7 8. The guide plate 15 and the isolation plate 8 form an independent space for accommodating the first knife group 7; the guide plate 15 is provided with a funnel 11 for inputting materials to the lower knife group 7, and the top of the guide plate 15 is provided with a fan 10 for blowing up materials. The last section guide plate 15 links to each other with the discharge opening 6 on the mixer casing 4, and the discharge outlet 6 is a truncated cone shape, and it is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com