Patents

Literature

128results about How to "Shorten drilling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

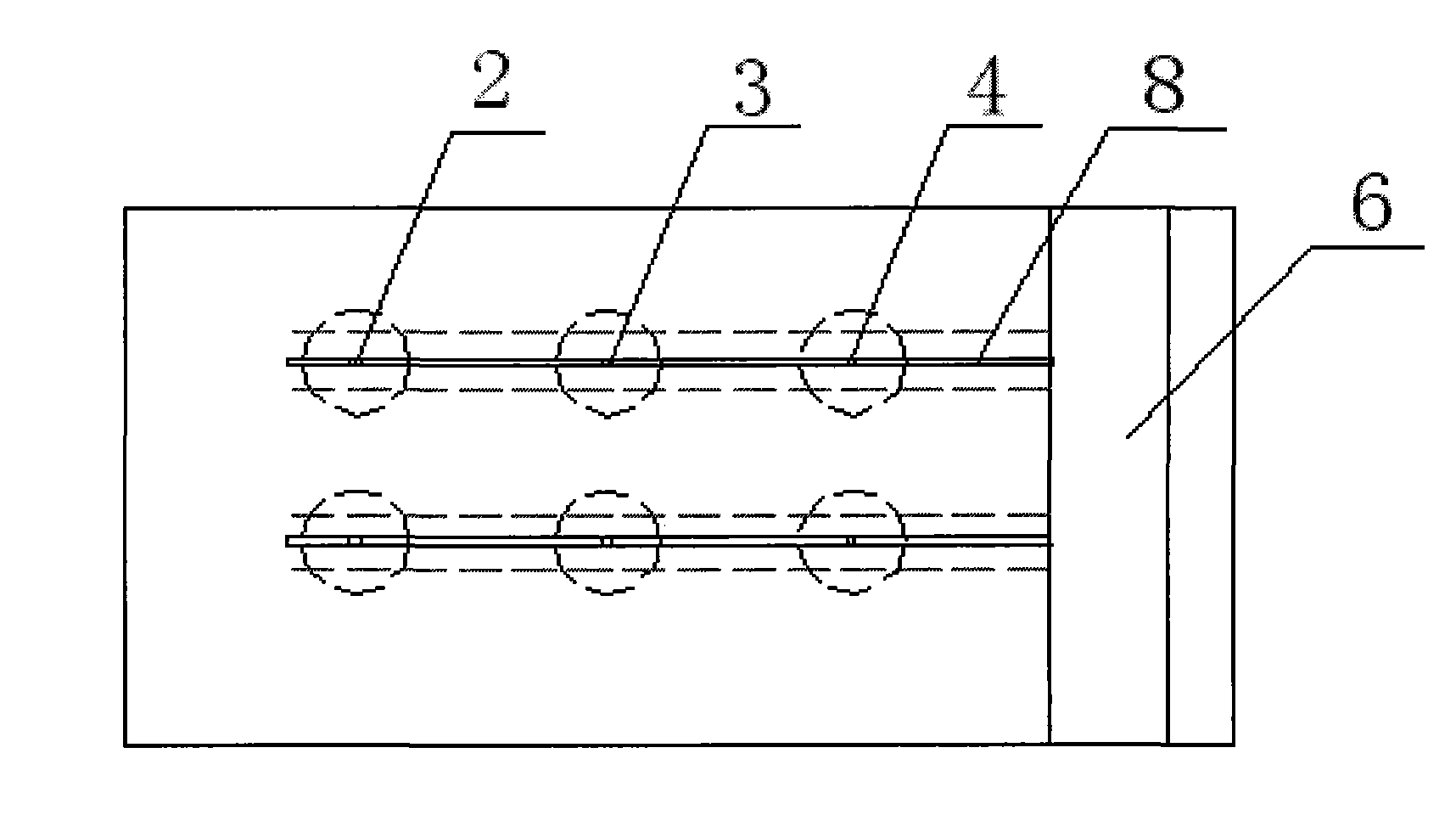

Method for extracting coalbed gases from coal mines by upper and lower combination

The invention relates to coalbed gas mining technology, in particular to a method for extracting coalbed gases from coal mines by upper and lower combination. The method solves the problem of poor gas drainage effects through surface well drilling and hole drilling in the coalbed. The method comprises the following steps: constructing extraction drilled wells on the surface, constructing underground directional long drilled holes in the coalbed, crosslinking the fracture areas of the extraction drilled wells with the drainage areas of the underground directional long drilled holes, then effectively sealing the underground directional long drilled holes in the coalbed, then utilizing fracturing equipment on the surface to fracture the drainage areas drilled on the surface and the drainage areas of the long drilled holes in the coalbed via the extraction drilled wells and finally carrying out extraction. The method has the advantages of improving the extraction rate and efficiency of the coalbed gases and shortening the construction period of the coalbed gas extraction engineering.

Owner:山西蓝焰煤层气集团有限责任公司

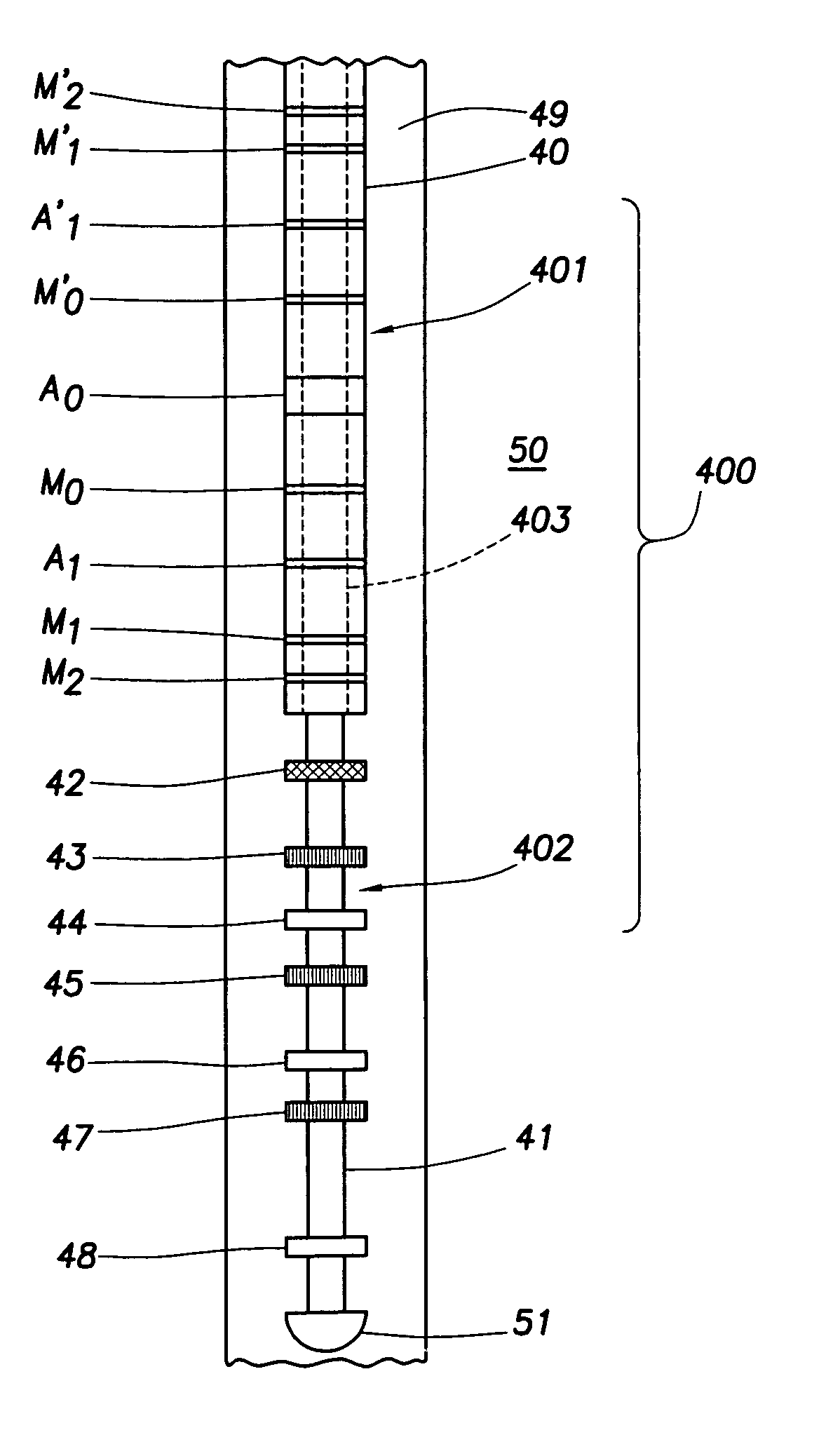

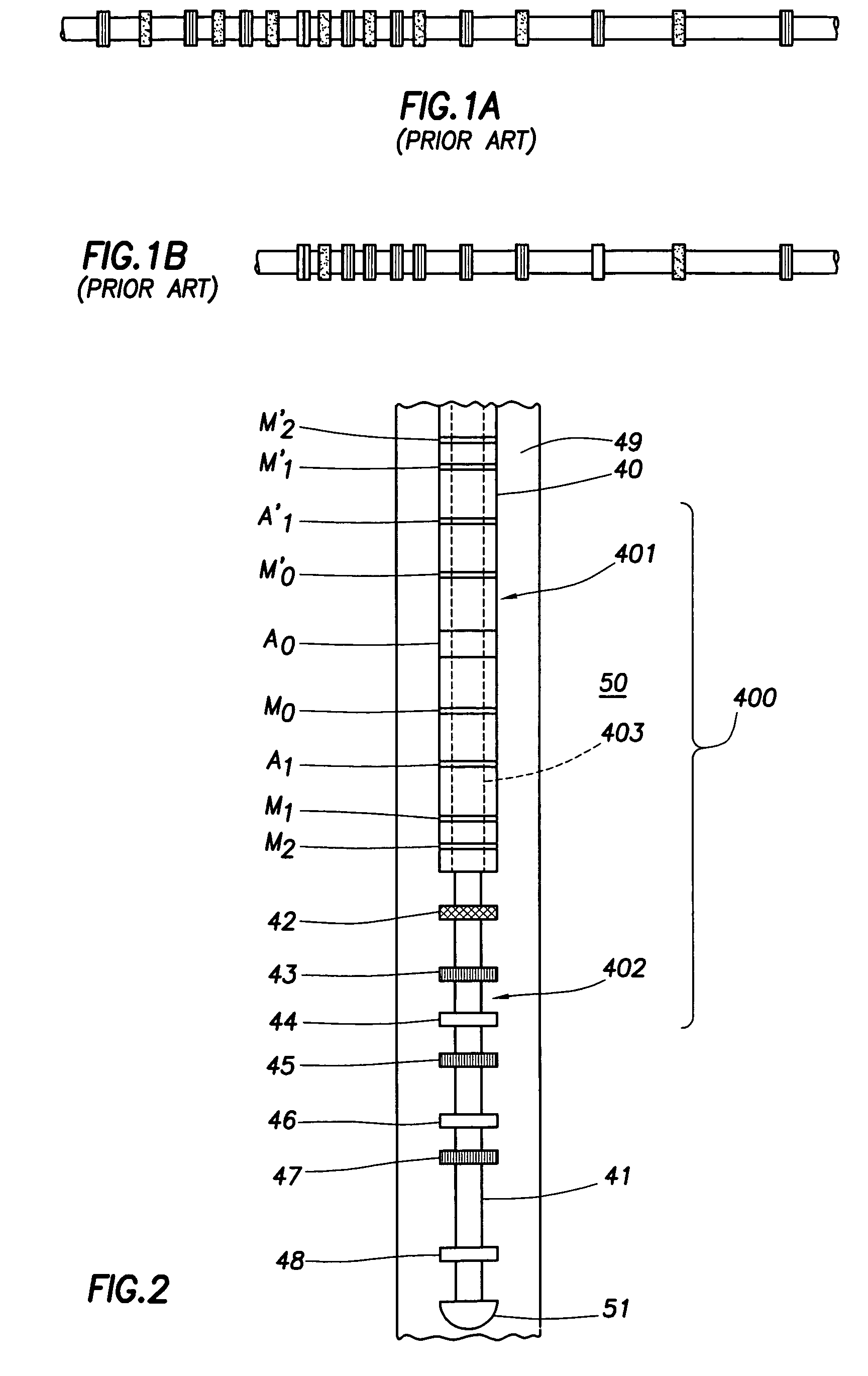

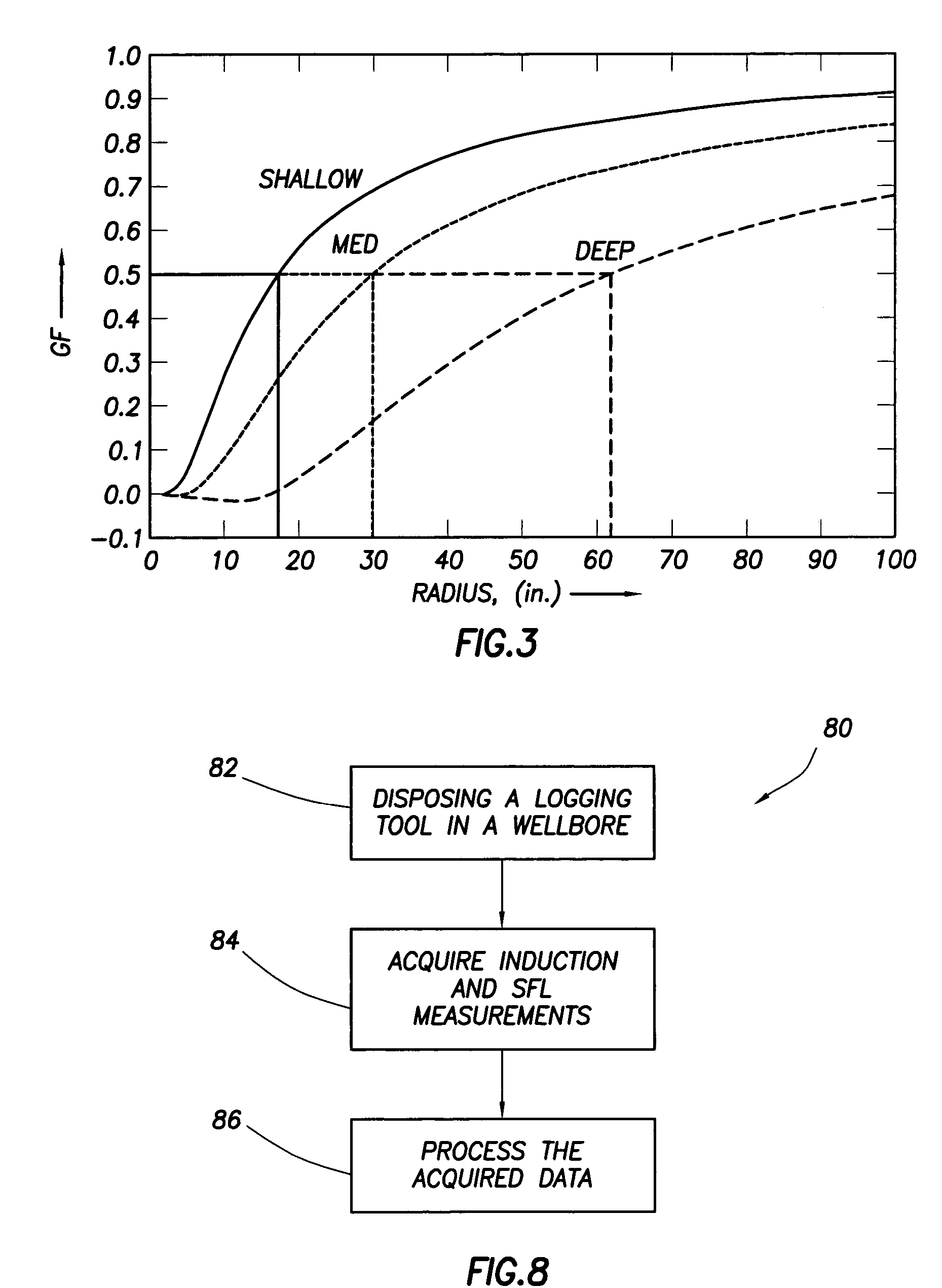

[apparatus and methods for induction-sfl logging]

InactiveUS20050127917A1Reduce riskIncrease opportunitiesElectric/magnetic detection for well-loggingAcoustic wave reradiationWell loggingTransmitter antenna

A well logging tool includes an induction array stack disposed on a mandrel; an electronic module stack disposed adjacent the induction array stack along a longitudinal axis of the well logging tool; and a shallow electrode array arranged on a housing disposed around the electronic module stack, wherein the induction array stack comprises a transmitter antenna, a first receiver antenna, and a second receiver antenna spaced apart from each other along the longitudinal axis of the well logging tool, the second receiver antenna being disposed between the transmitter antenna and the first receiver antenna.

Owner:SCHLUMBERGER TECH CORP

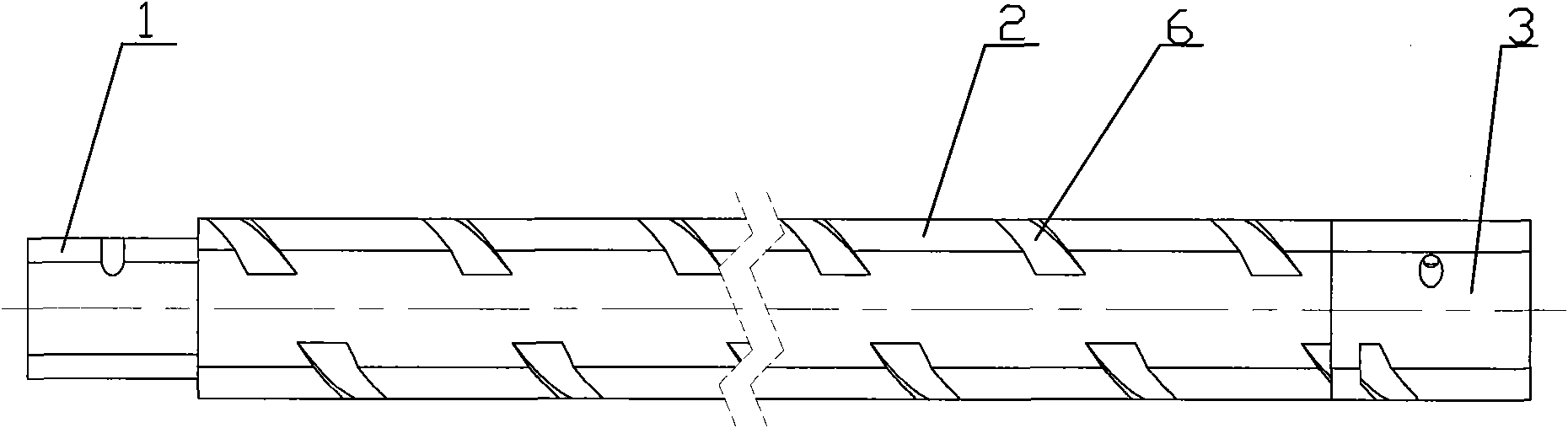

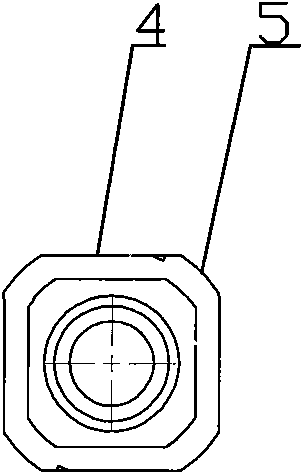

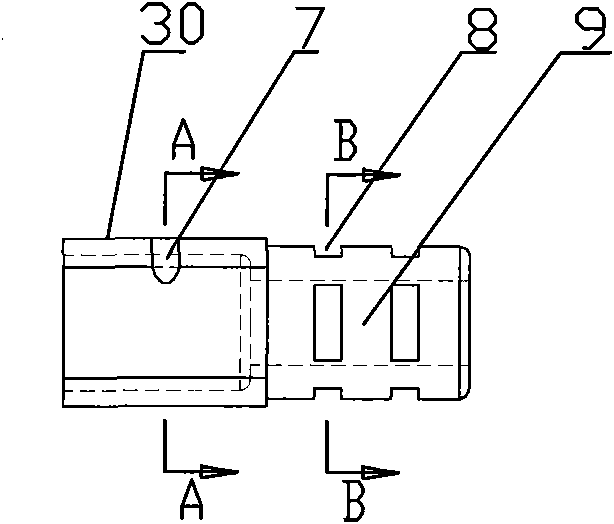

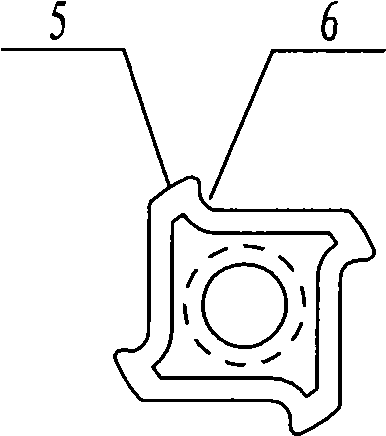

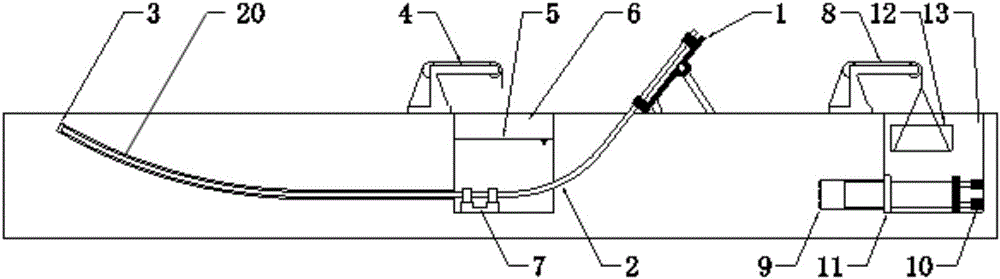

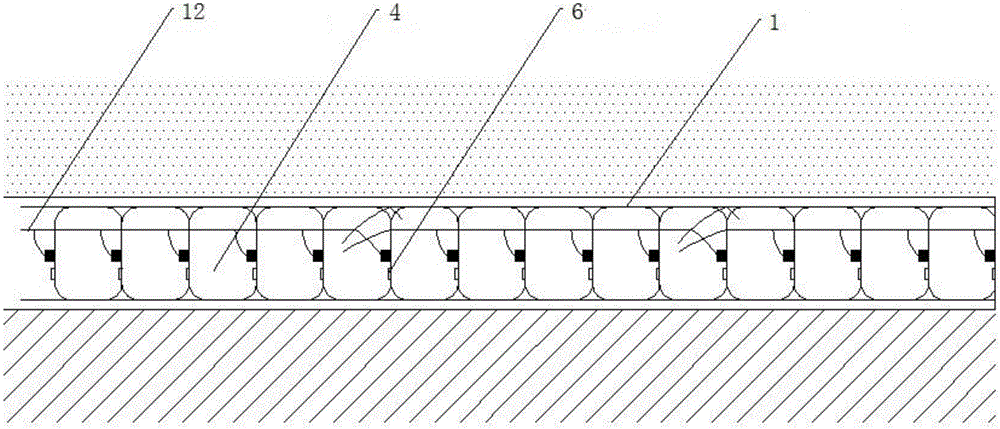

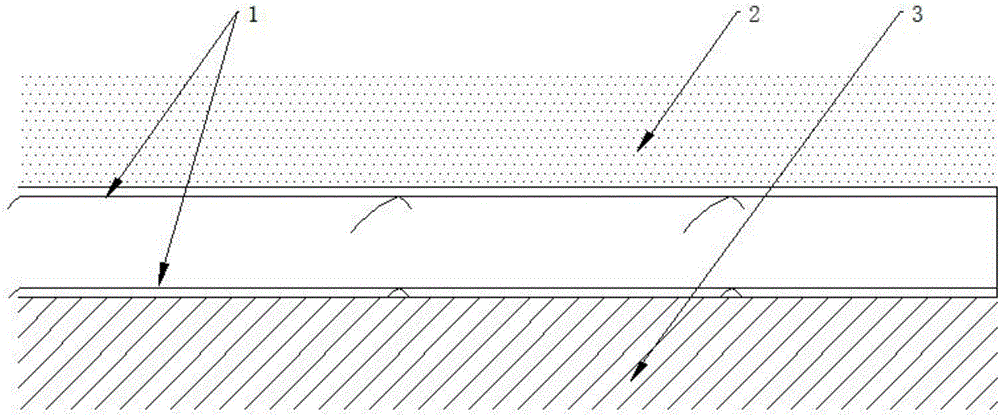

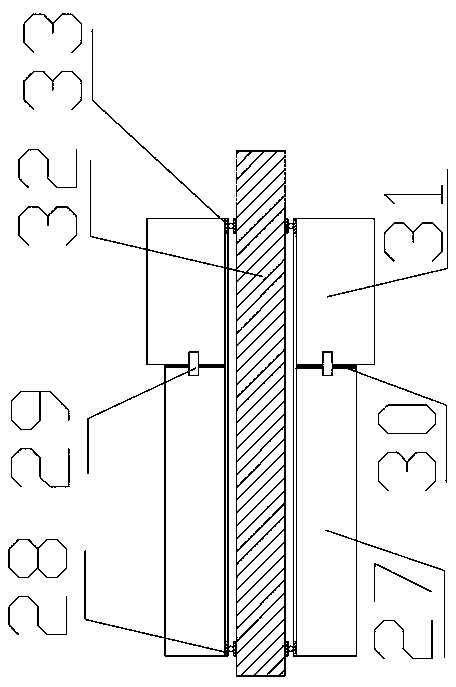

Irregularly shaped multi-land notch groove drill rod

ActiveCN101566049ALow rotational resistanceTake away in timeDrilling rodsDrilling casingsLine segmentHelix

The invention discloses an irregularly shaped multi-arris notch groove drill rod, which consists of a hollow multi-arris rod body and a connecting piece, the section outline of the multi-arris rod body consists of tangential paths and circular arc sections, and incontinuous spiral grooves are distributed on the surface of the rod body simultaneously. The drill rod can cause vortex flow when whirling in loose cinder and raise coal dust deposited on the bottom of a drilling hole in virtue of the arris of the drill rod, and the coal dust in the drilling hole is at a moving status all the time, thus preventing the coal dust from accumulating in the drilling hole and resulting in blockage; simultaneously, the incontinuous spiral grooves distributed on the surface can assist in the outward transmission of the cinder, and when hole collapsing in the drilling hole, the outside of the collapsed hole is unchoked by the hole digging function of the spiral grooves, thus being not easy to have drill absorption and drill blockage. The drill rod has the advantages of reasonable design, simple structure, safety and reliability, thus greatly improving deslagging effect, being beneficial to increasing the depth of the drilling holes, shortening hole drilling time, improving work efficiency and having high hole forming rate. Therefore, the drill rod is worth popularizing and applying in mining enterprises.

Owner:山东益矿钻采科技有限公司

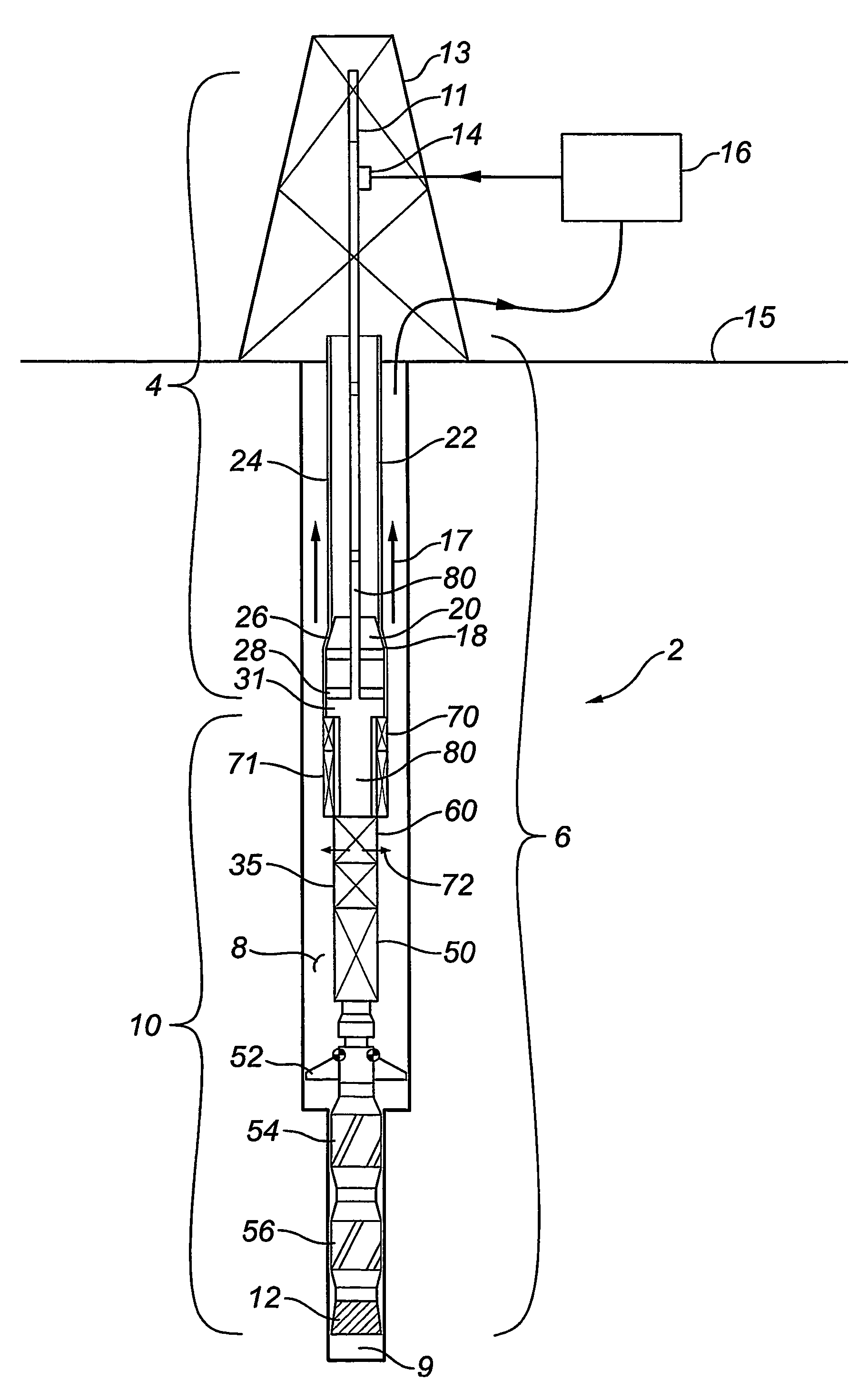

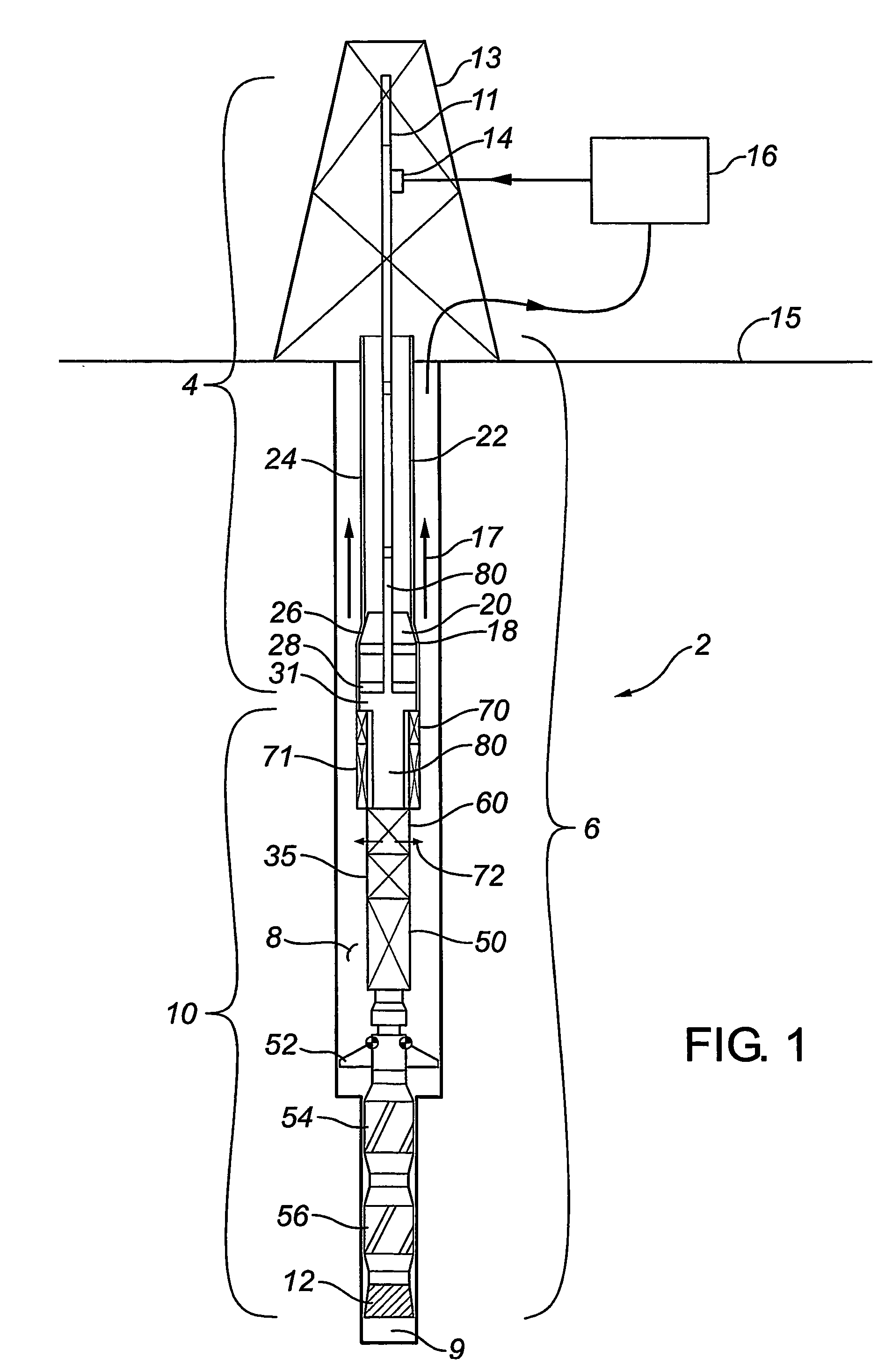

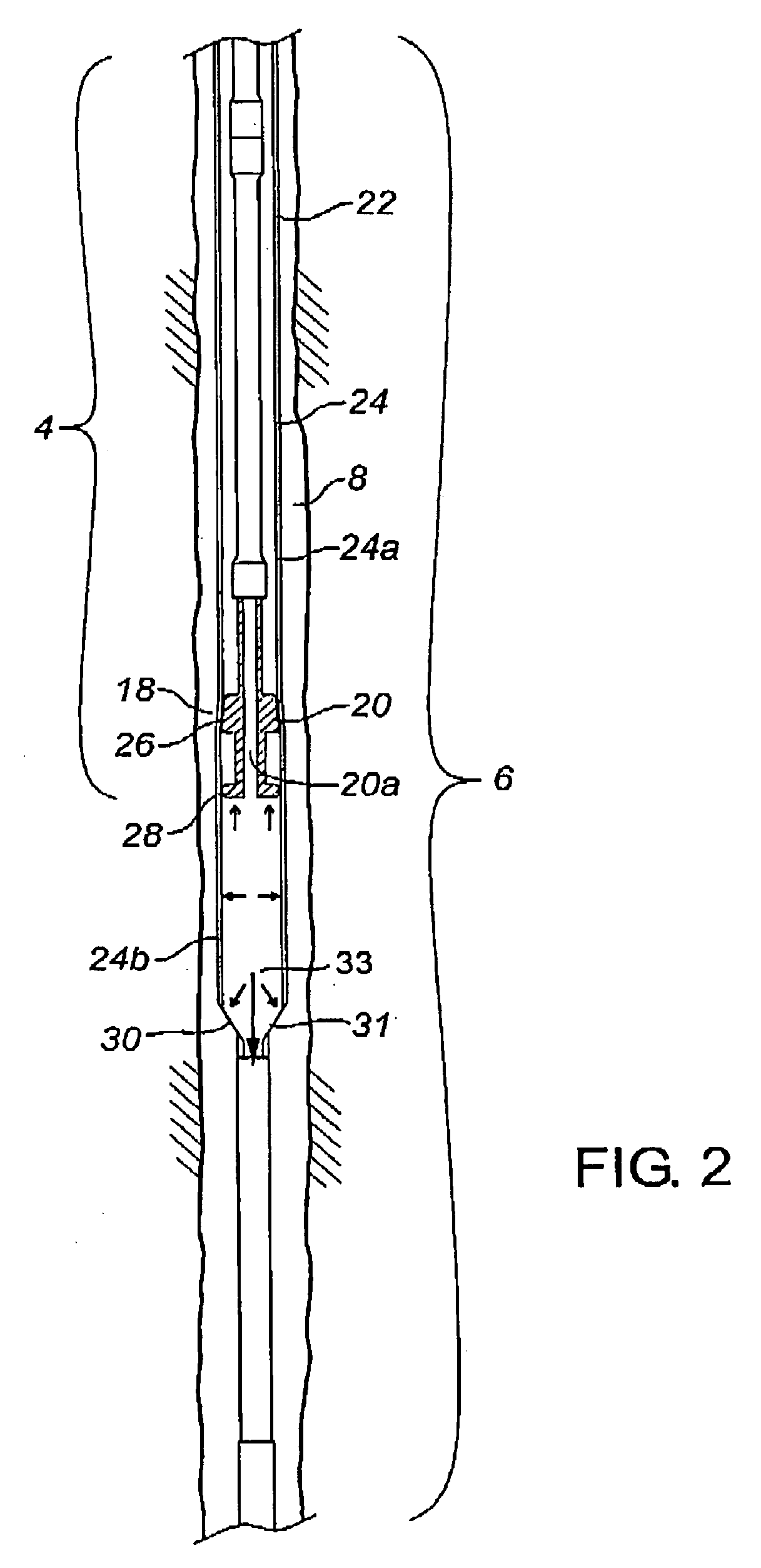

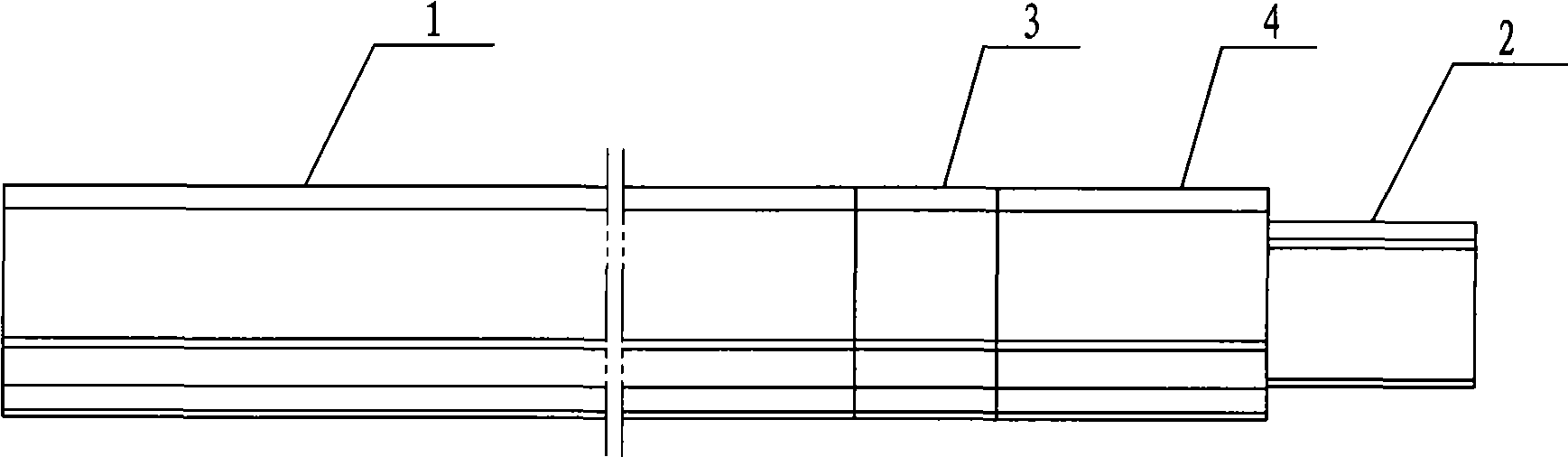

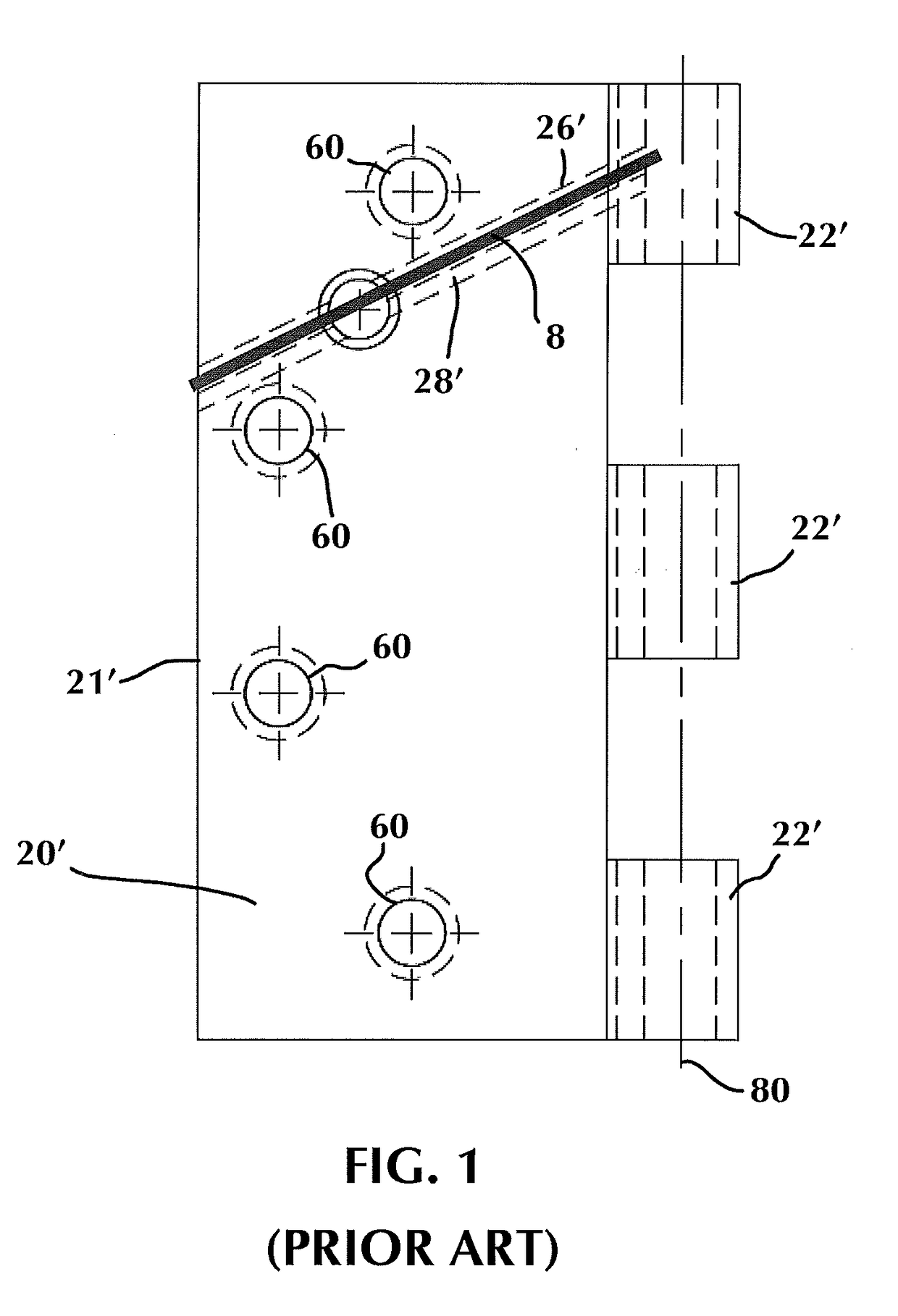

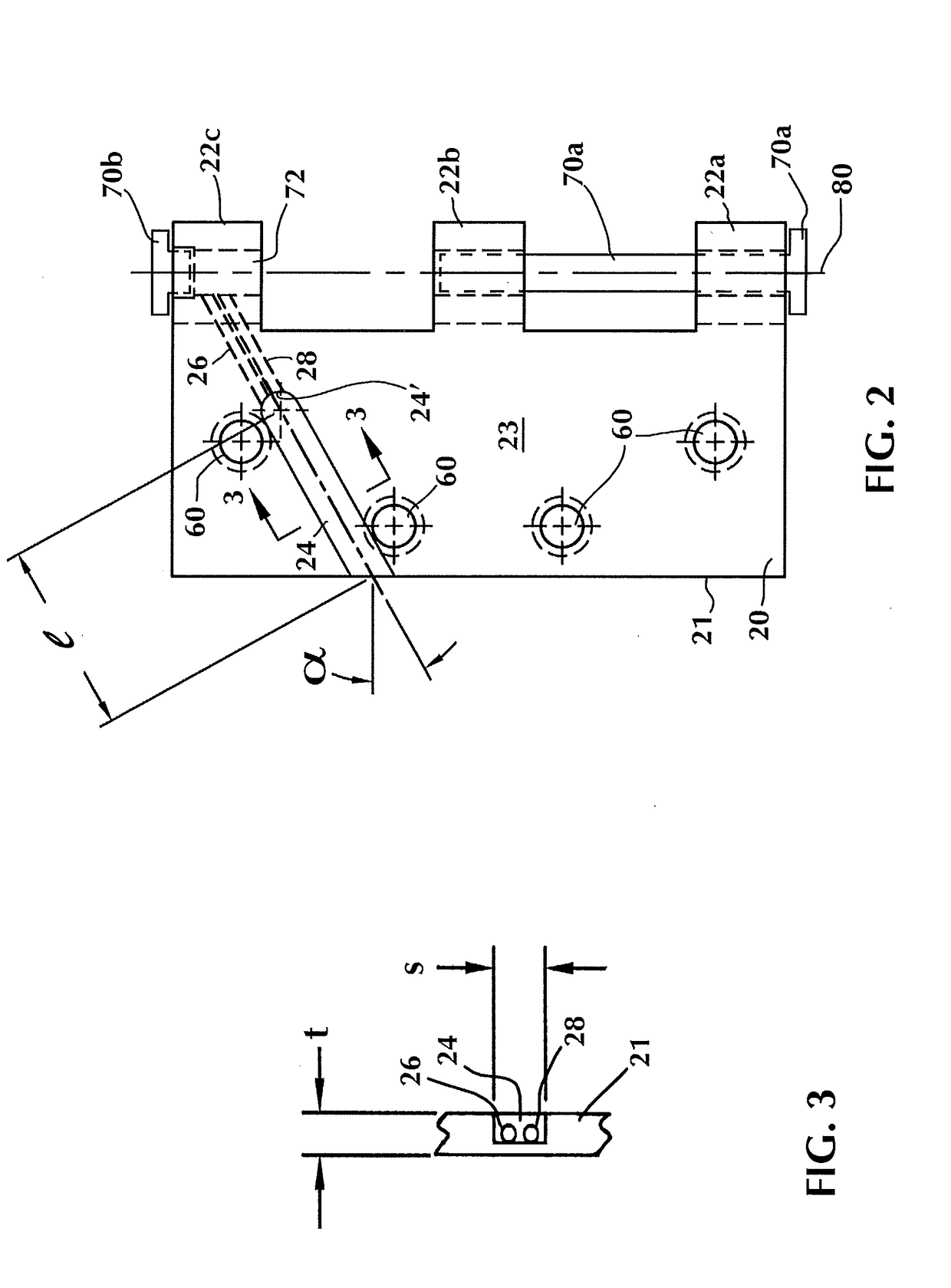

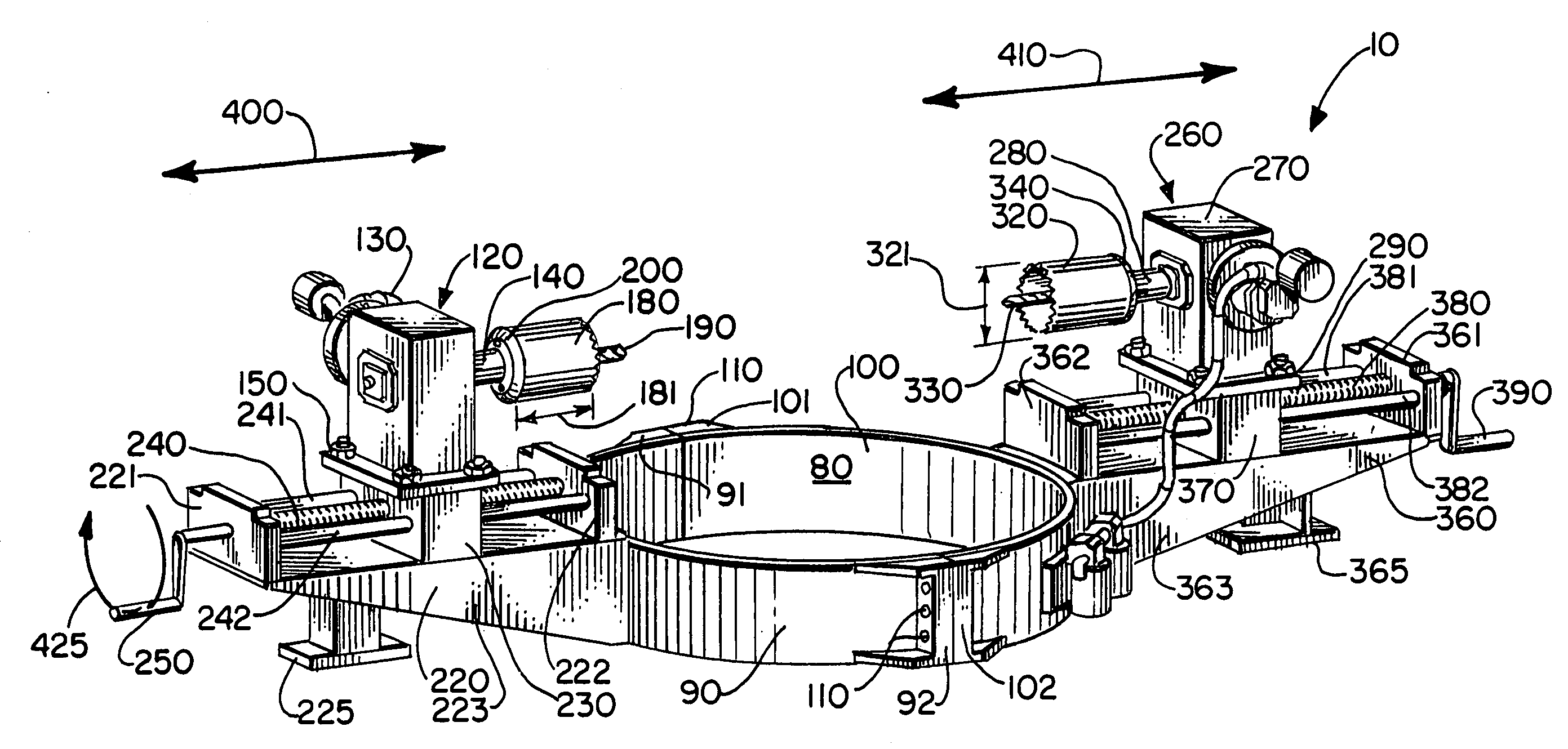

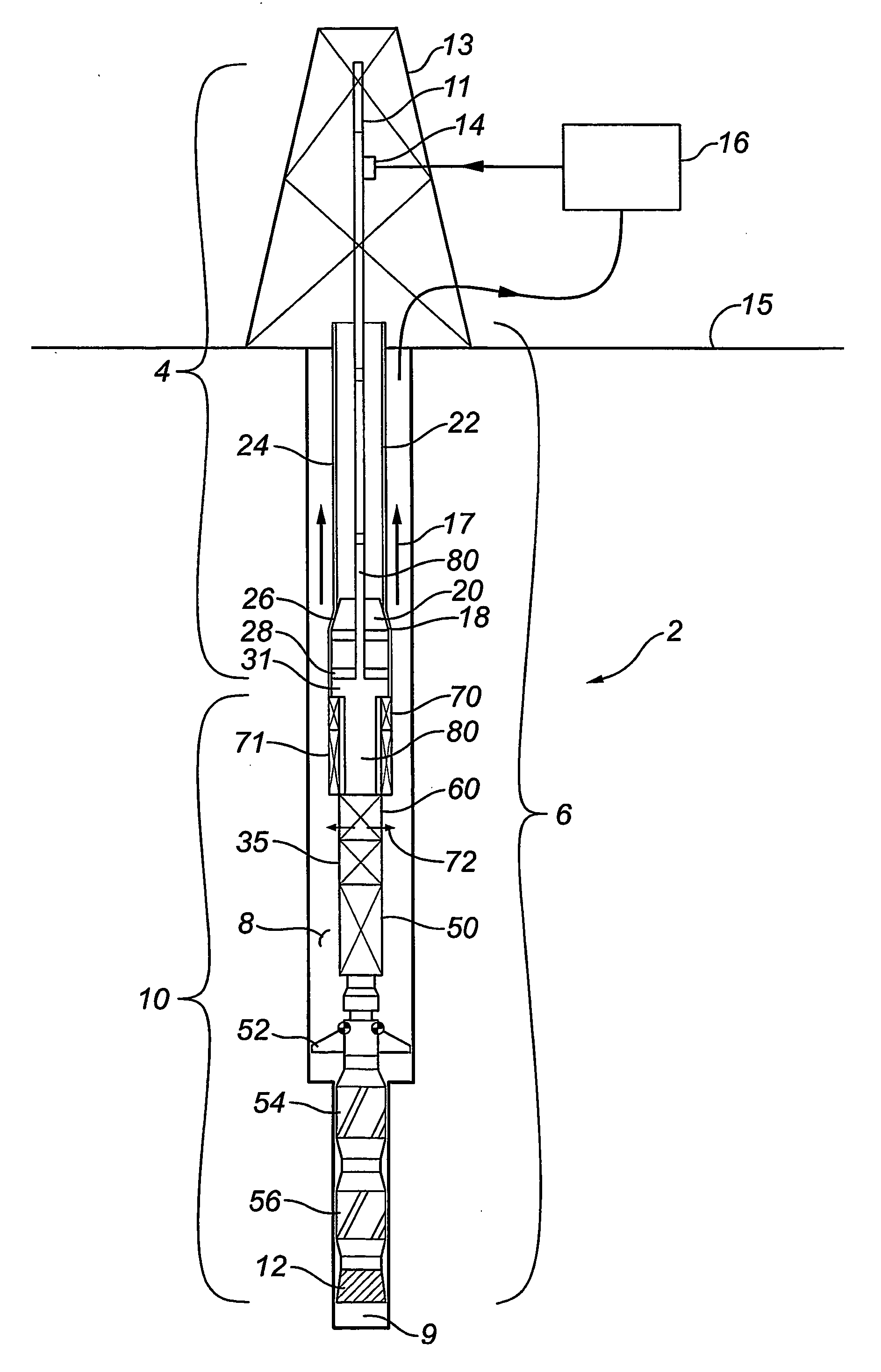

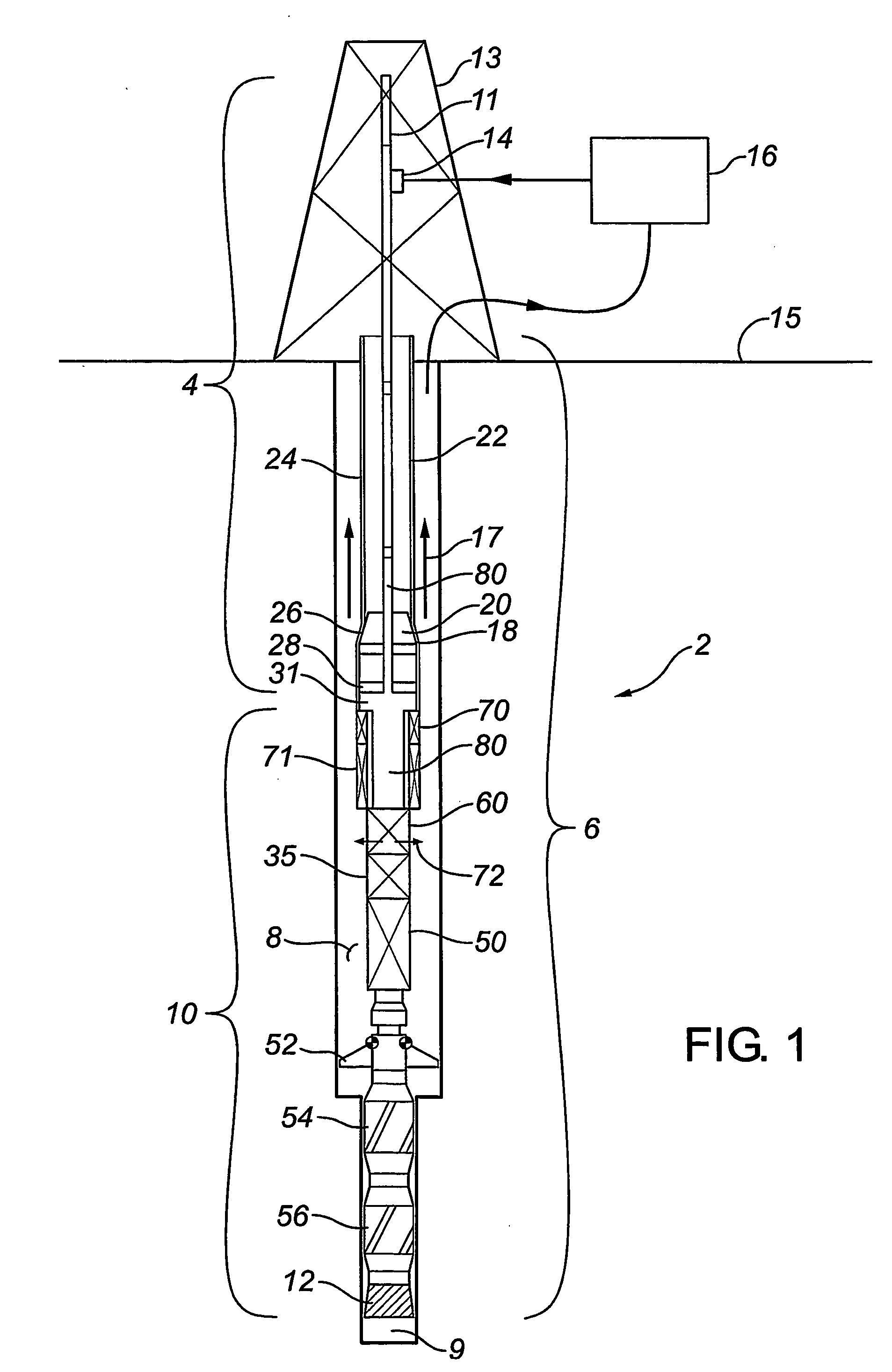

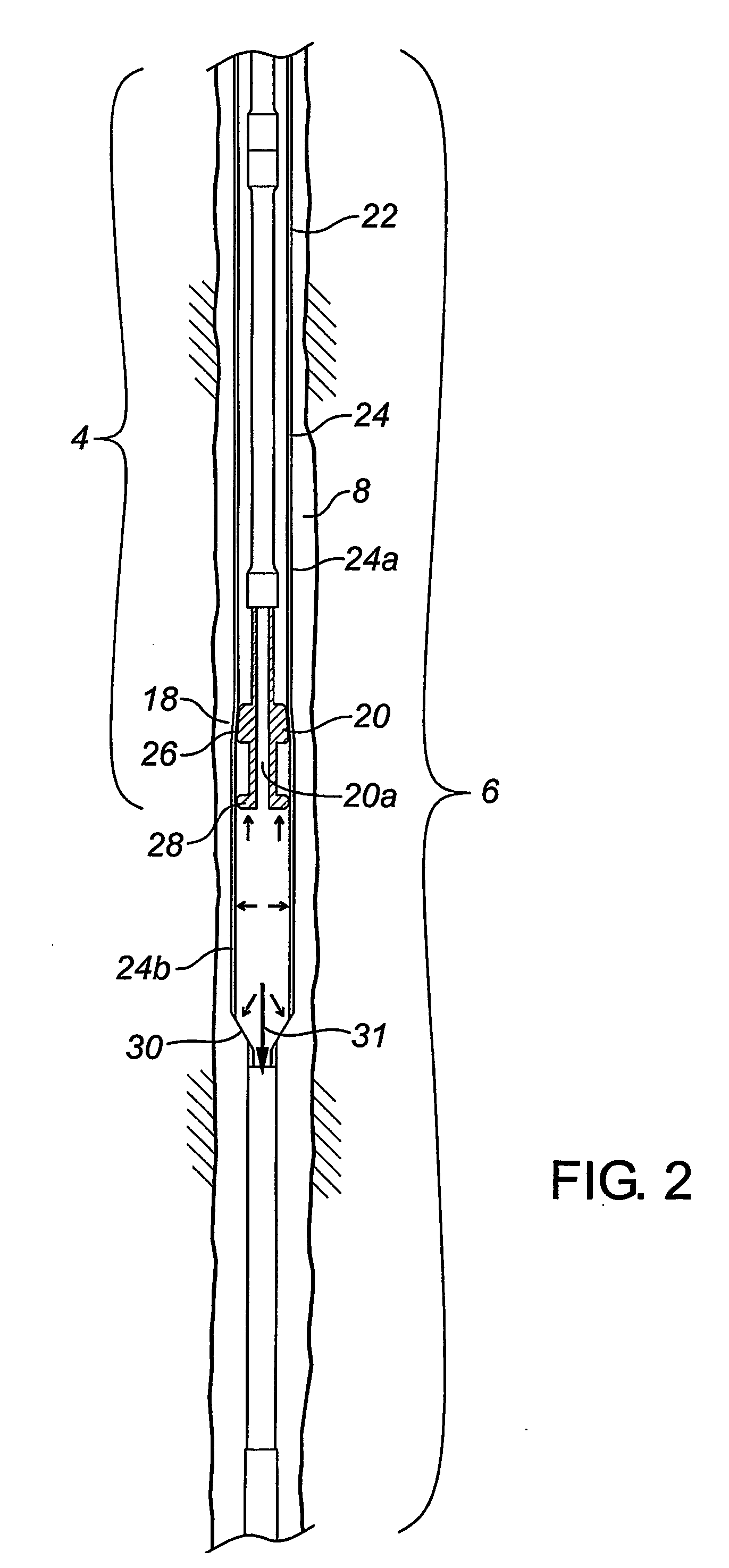

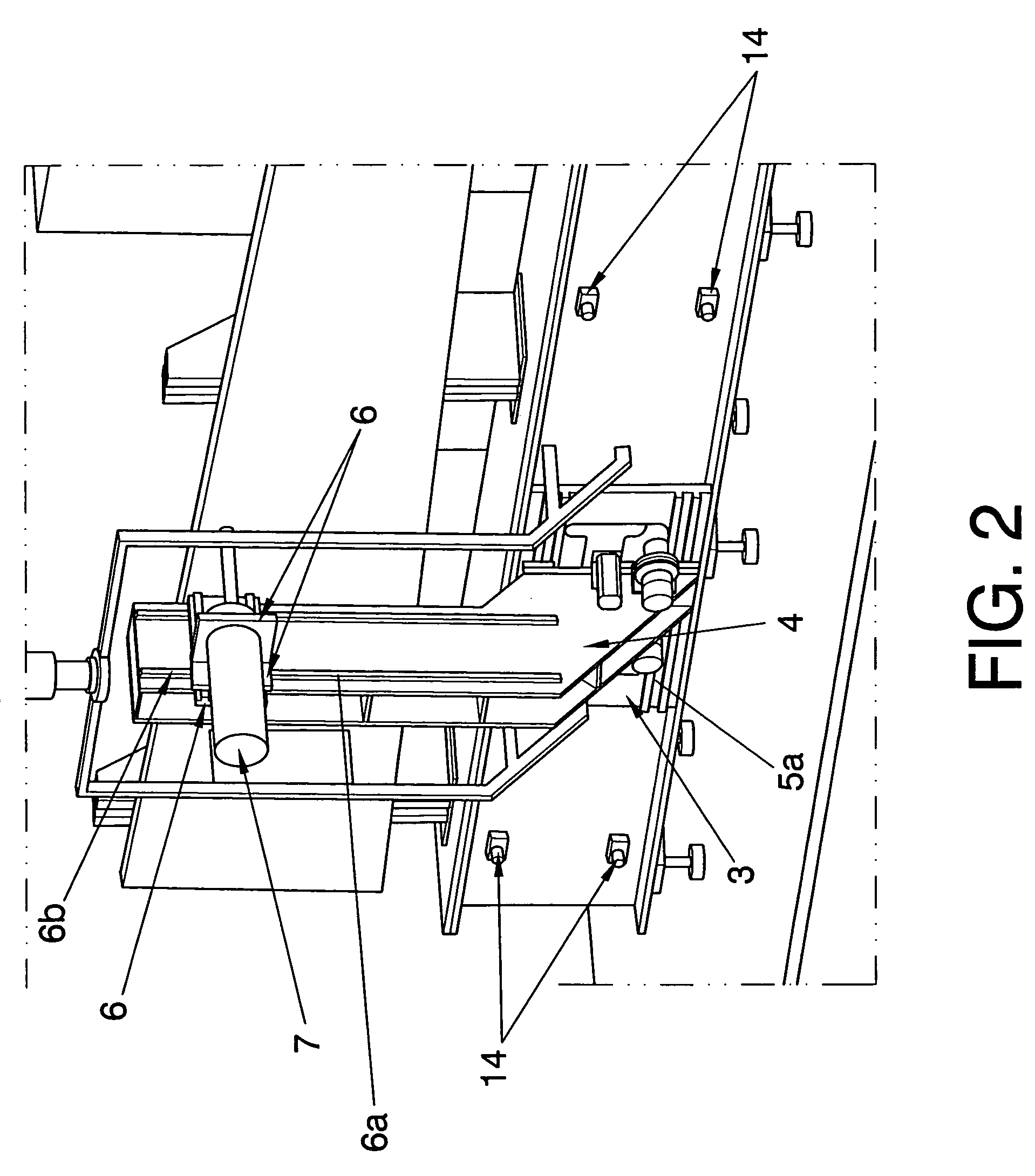

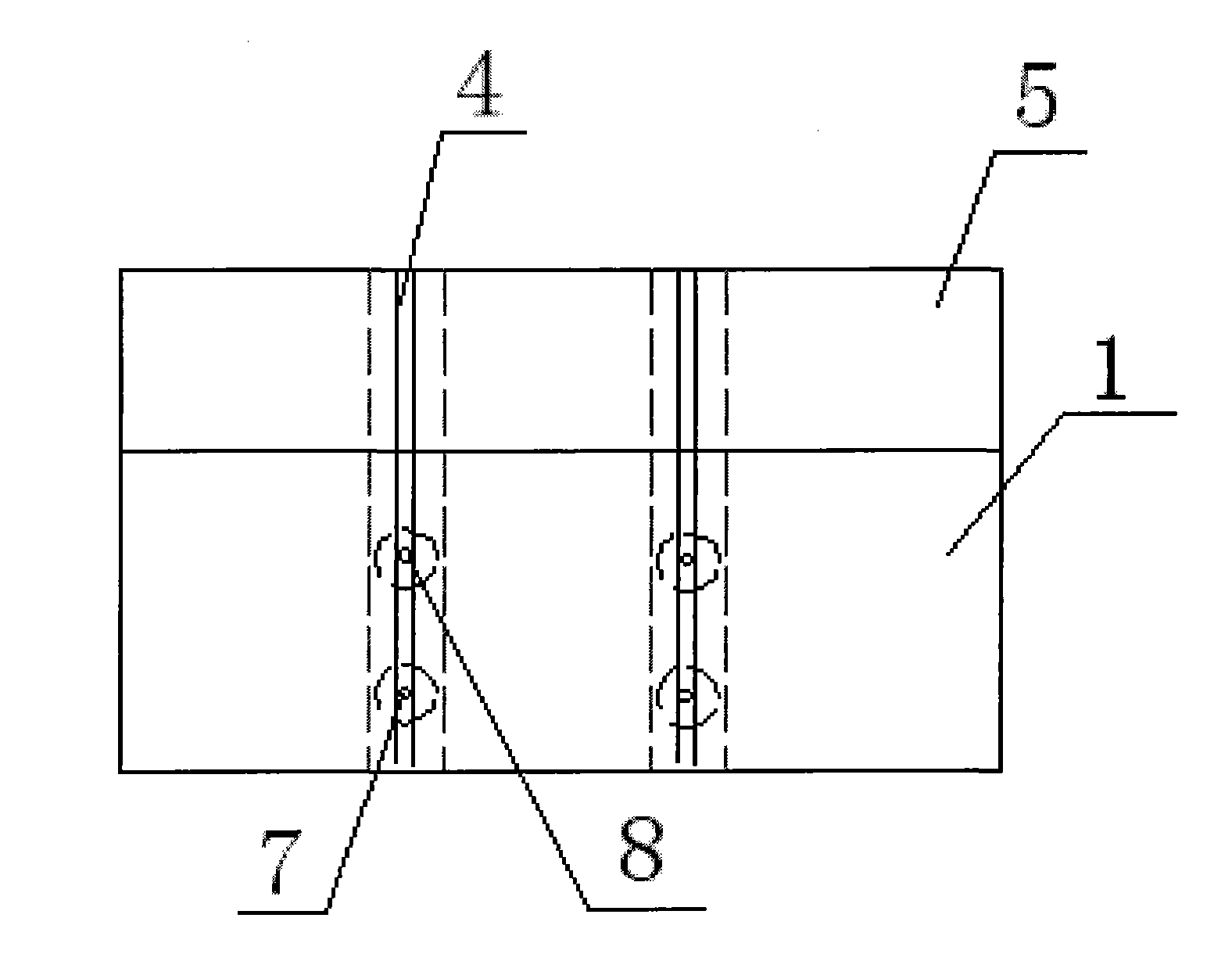

Combined casing expansion/casing while drilling method and apparatus

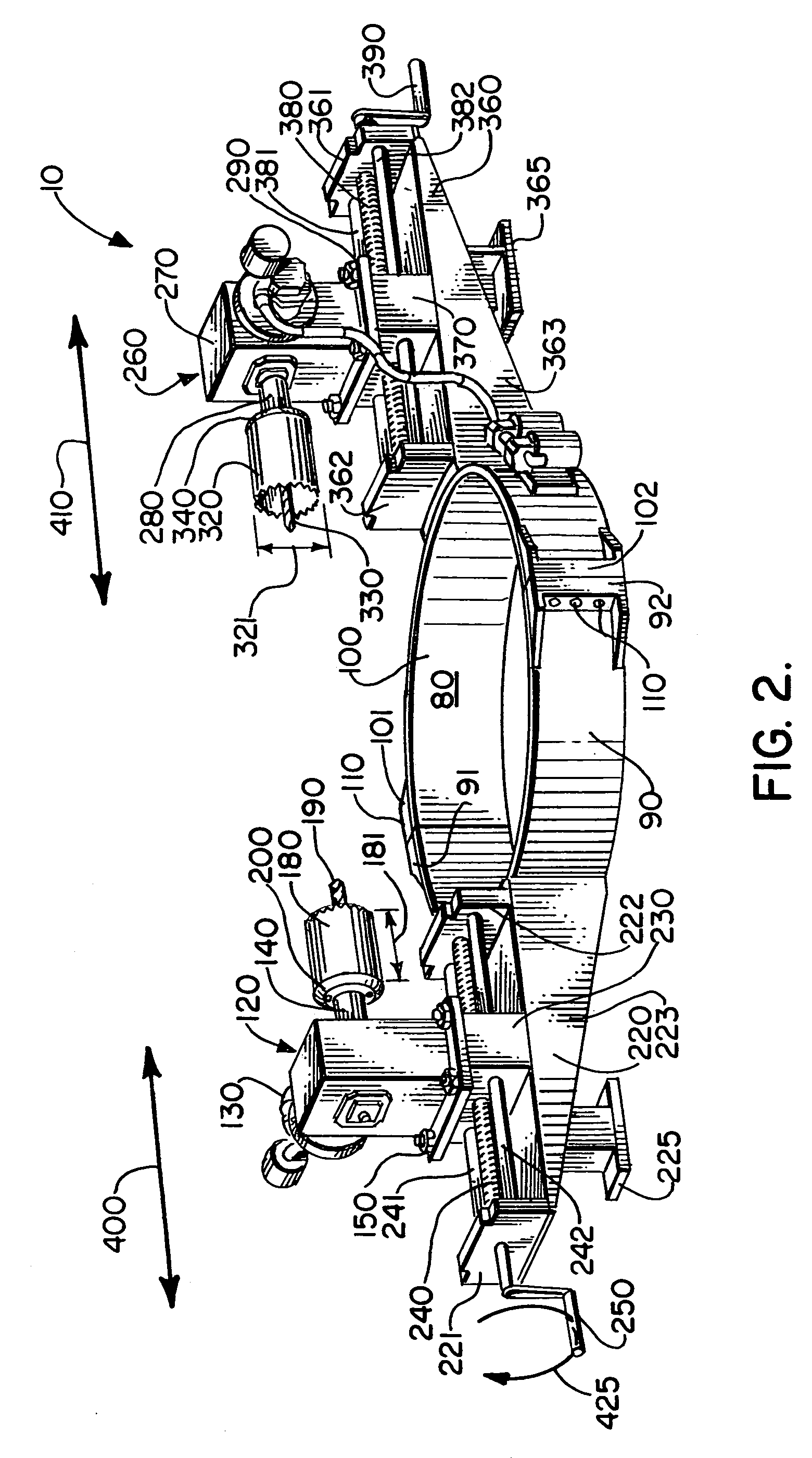

ActiveUS7287603B2Increase drilling speedShorten the timeDrilling rodsReciprocating drilling machinesCasing stringEngineering

A drilling assembly (2) comprises upper (4) and lower (6) drill strings with a fluid passage (80) therethrough for distributing fluid to a bottom hole assembly (10). The upper drill string (4) has an upper end (11) connectable to a drilling apparatus (13) and fluid source (16) and a lower end (18) with an attached casing expander unit (20) that communicates the fluid passage (80) of the upper (4) and lower (6) drill strings. An upper end (22) of the lower drill string (6) is formed from a casing string (24) telescoped over the casing expander unit. A constriction (31) connects the casing string (24) with the rest of the lower drill string (6). A flow restriction device (35) in the lower drill string acts to control fluid flow through the fluid passage. In use, the flow restriction device creates a pressure in the fluid passage that acts at the constriction to advance the lower drill string past the upper drill string while simultaneously expanding the portion of the casing string moving past the expander unit.

Owner:HALLIBURTON ENERGY SERVICES INC

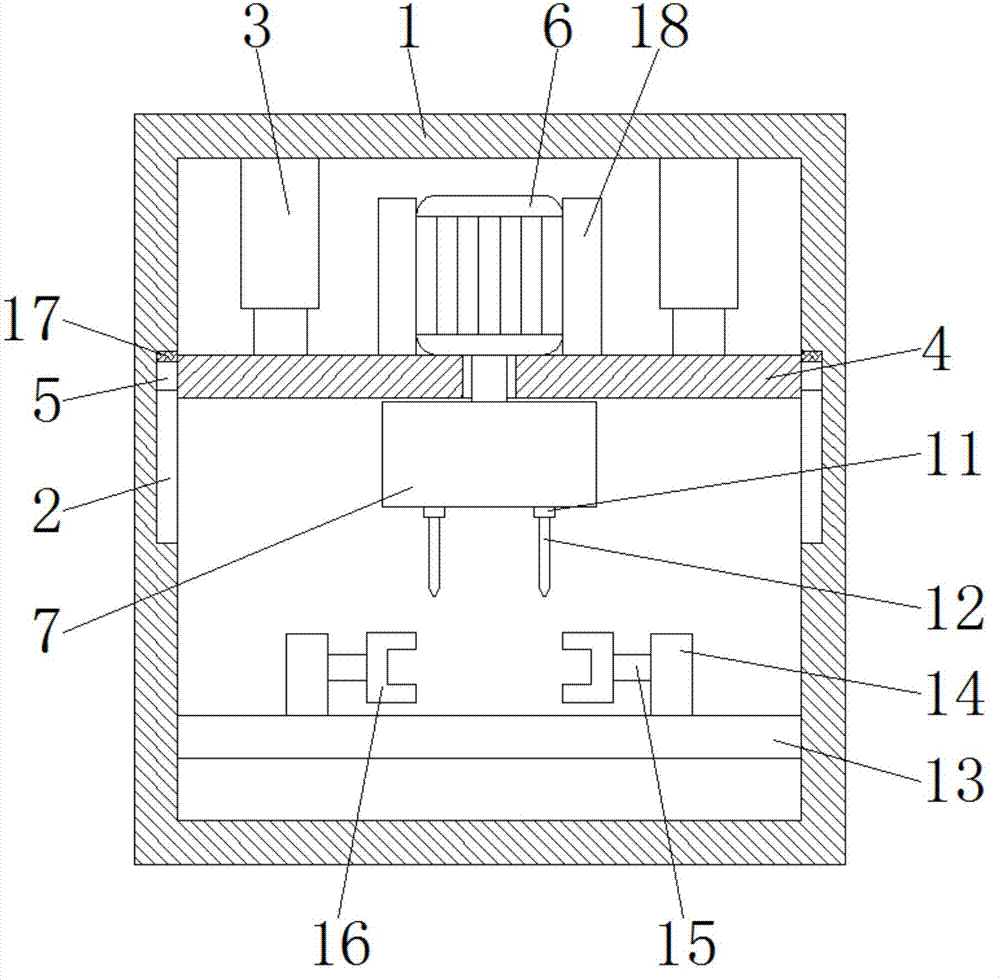

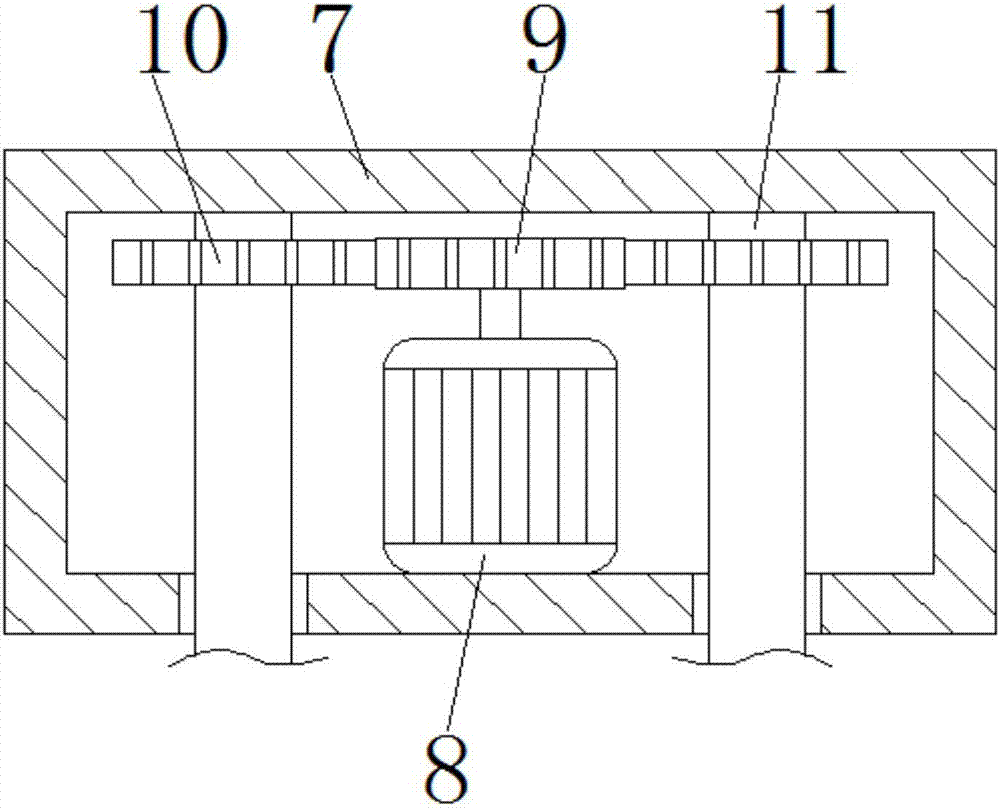

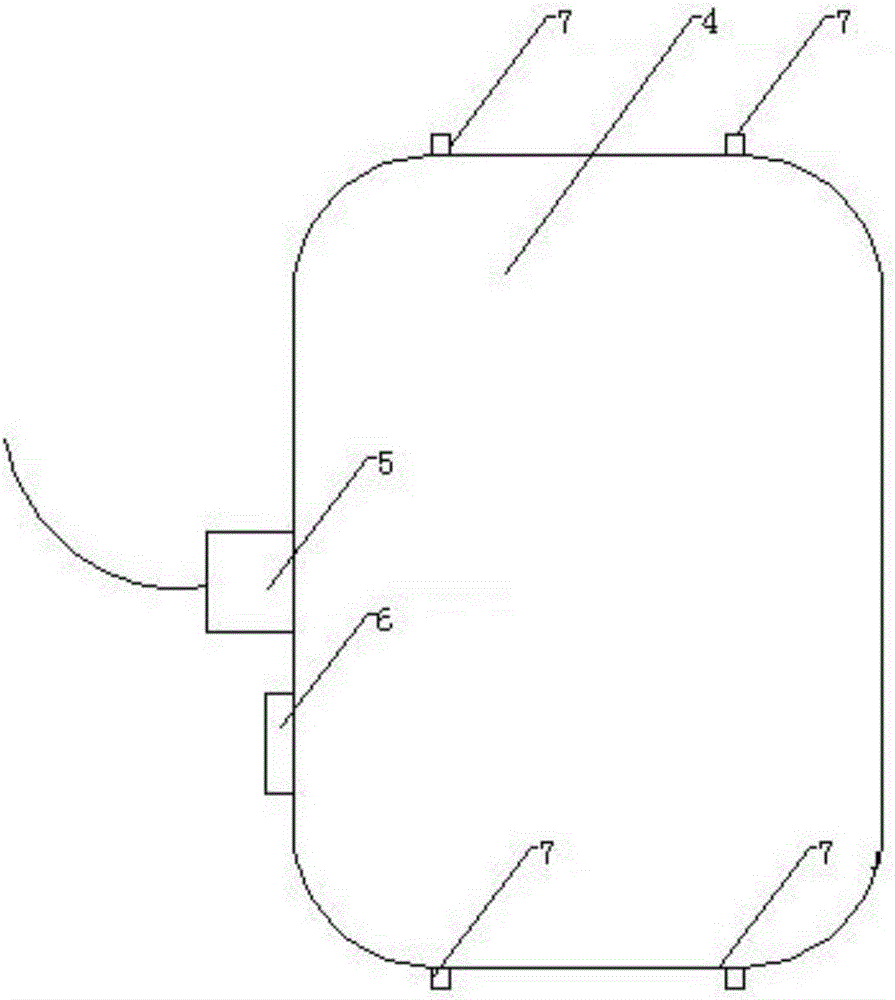

Drilling device for automobile part

InactiveCN107538038AImprove drilling efficiencyShorten drilling timeBoring/drilling componentsBoring/drilling machinesMotor vehicle partDrill bit

The invention discloses a drilling device for an automobile part. The drilling device comprises a machine frame; sliding grooves are formed in the two sides of an inner cavity of the machine frame; electric telescopic rods are fixedly connected to the two sides of the top of the inner cavity of the machine frame; and a movable plate is fixedly connected to the bottom ends of the electric telescopic rods. The drilling device for the automobile part has the advantages that the machine frame, the sliding grooves, the electric telescopic rods, the movable plate, sliding blocks, a first motor, a box body, a second motor, a first gear, second gears, rotating shafts, drill bits, a fixed plate, fixing blocks, connecting blocks and clamping plates are coordinated for use so that the problem that when a plurality of holes are drilled in the automobile part by an existing drilling device for the automobile part, a plurality of drill bits are needed for machining one part can be solved, the drilling efficiency is high, the multiple holes can be quickly drilled in the automobile part by the drilling device, and therefore the drilling time of the automobile part can be shortened, the machining efficiency of the automobile part can be improved, and a user can conveniently use the drilling device.

Owner:HEFEI HUAJUN AUTOMOBILE PARTS

Apparatus and methods for induction-SFL logging

InactiveUS7042225B2Reduce riskIncrease opportunitiesElectric/magnetic detection for well-loggingAcoustic wave reradiationWell loggingEngineering

A well logging tool includes an induction array stack disposed on a mandrel; an electronic module stack disposed adjacent the induction array stack along a longitudinal axis of the well logging tool; and a shallow electrode array arranged on a housing disposed around the electronic module stack, wherein the induction array stack comprises a transmitter antenna, a first receiver antenna, and a second receiver antenna spaced apart from each other along the longitudinal axis of the well logging tool, the second receiver antenna being disposed between the transmitter antenna and the first receiver antenna.

Owner:SCHLUMBERGER TECH CORP

Entry sheet for drilling and method for drilling hole

InactiveUS6866450B2High-quality drilling processingShorten drilling timeThread cutting machinesBearing componentsMetal foilWater insoluble

An entry sheet for drilling for a printed wiring board material, which comprises a water-soluble resin (A) and a water-insoluble lubricant (B) as essential components,an entry sheet for drilling for a printed wiring board material, which sheet comprises a metal foil having a thickness of 5 to 200 μm and a thermosetting resin (E) layer having an average thickness of 1 to 10 μm, the thermosetting resin (E) layer being formed on one surface of the metal foil, anda method for drilling a hole by using the above entry sheet.

Owner:MITSUBISHI GAS CHEM CO INC

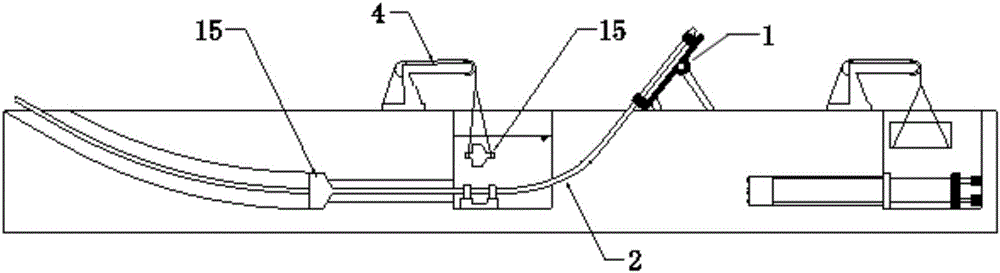

Drilling rod with asymmetric special-shaped cross section

ActiveCN101481999ALow rotational resistanceHigh porosityDrilling rodsDrilling casingsSlagDrilling riser

The invention discloses an asymmetric deformed-section drill pipe which is composed of a hollow pipe body and a connecting piece which are detachably connected; beads which are more than or equal to two and less than or equal to eight are arranged on pipe body along the pipe body, and the outer surface of the bead is an arc surface which takes an axle wire of the pipe body as a circle center, and one side of the bead and the pipe body form a long-strip groove. The drill pipe has reasonable design and simple structure; drill adsorption and drill blocking can not easily happen according to the principle of vortex flow caused by rotation of the deformed-section rigid body in loose coal slag, therefore, the drill pipe is safe and reliable, slag-off effect is greatly improved, thus being beneficial to improving drilling depth, shortening drilling time and improving working efficiency and pore-forming efficiency and being worth of being popularized and applied in coal mine enterprises.

Owner:山东益矿钻采科技有限公司

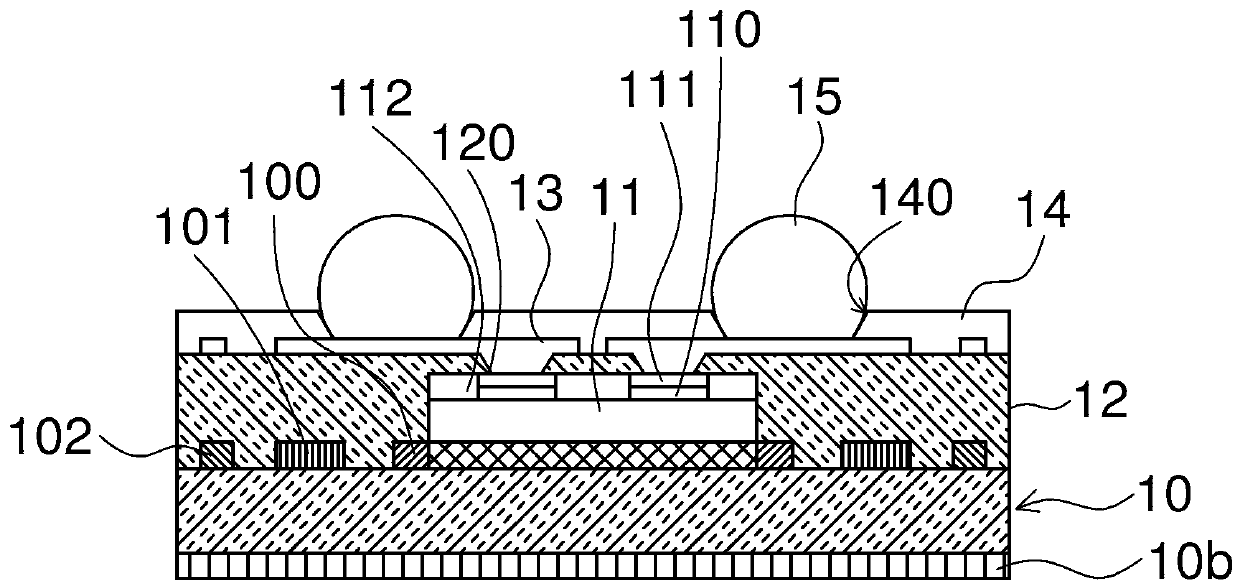

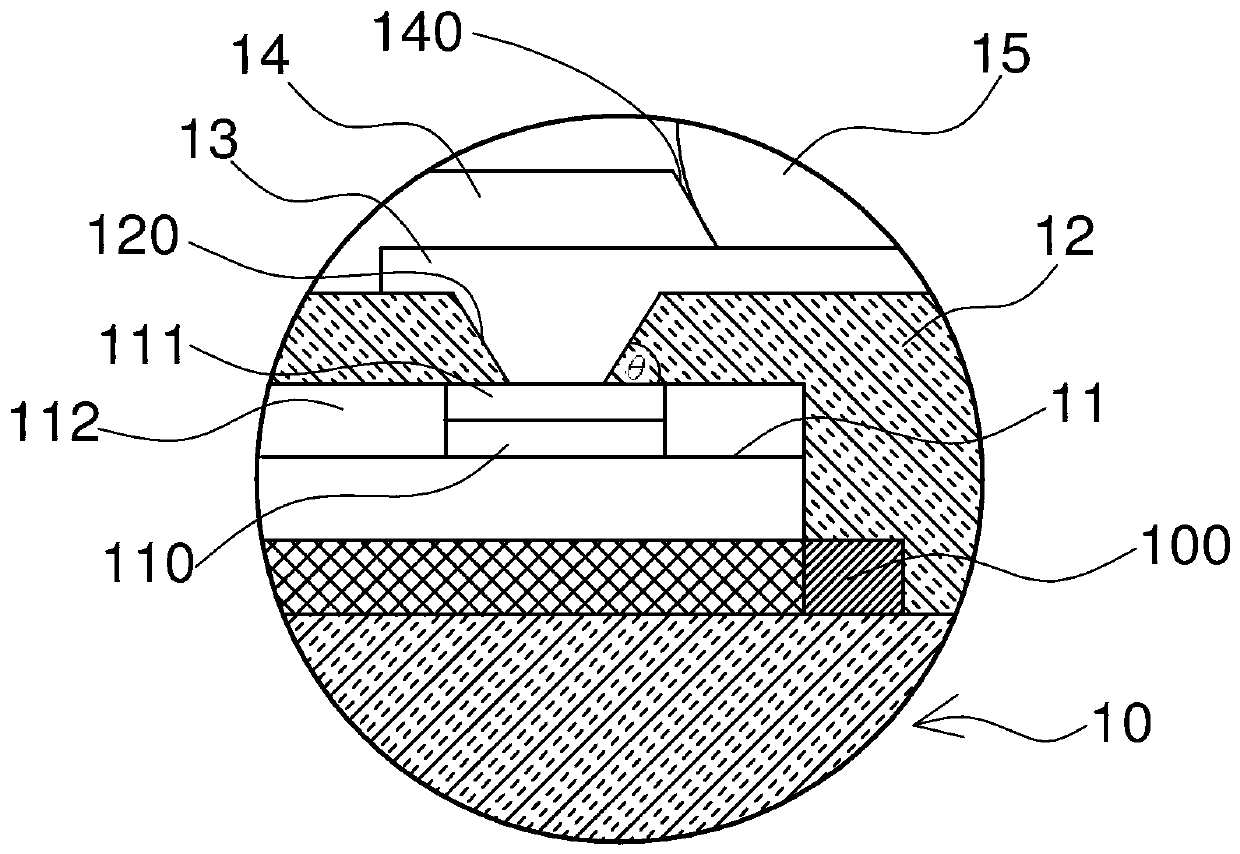

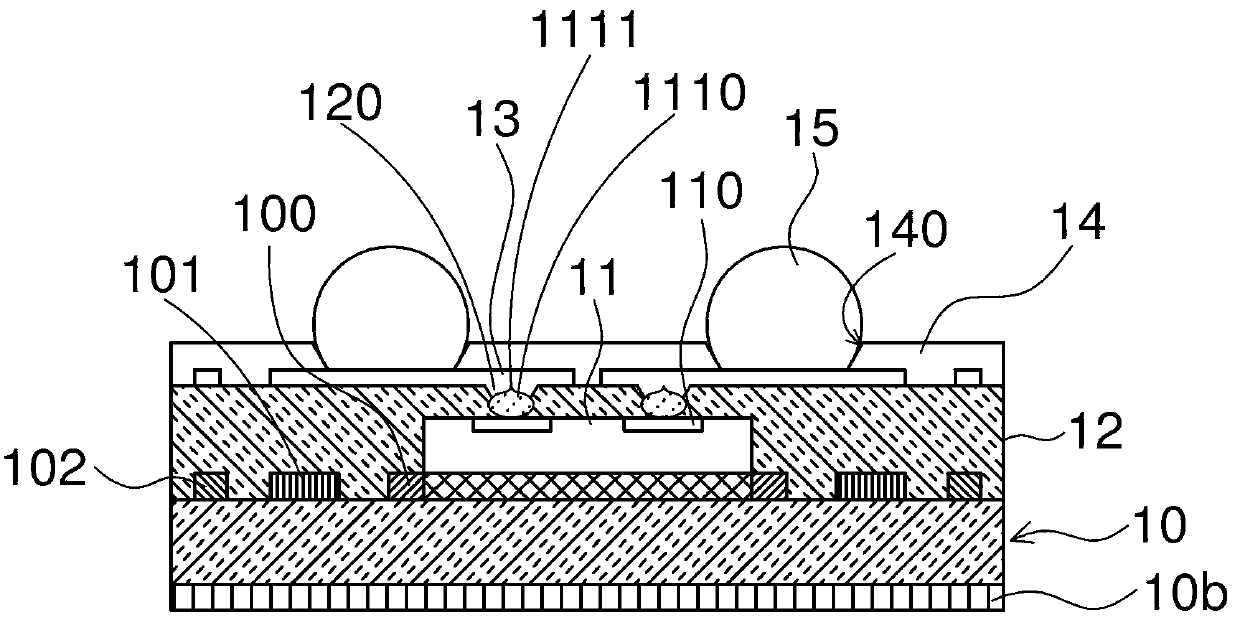

Wafer level packaging structure and manufacturing method thereof

InactiveCN103021984AReduce depthImprove plate yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

The invention discloses a wafer level packaging structure and a manufacturing method thereof. The wafer level packaging structure comprises a supporting layer, a chip, an insulating layer and a heavy wiring layer, the chip is arranged on the supporting layer and provided with an active surface which is opposite to the supporting layer and provided with multiple welding pads, each welding pad is provided with an incrassation metal object, the insulating layer is arranged on the chip and the supporting layer and provided with multiple blind holes which respectively correspond to and expose the incrassation metal objects on the welding pads, and the heavy wiring layer is arranged on the insulating layer and electrically connected with the welding pads through the blind holes and the chip. The incrassation metal objects can relatively reduce the depth of the blind holes and lower boring difficulty on the insulating layer.

Owner:ADVANCED SEMICON ENG INC

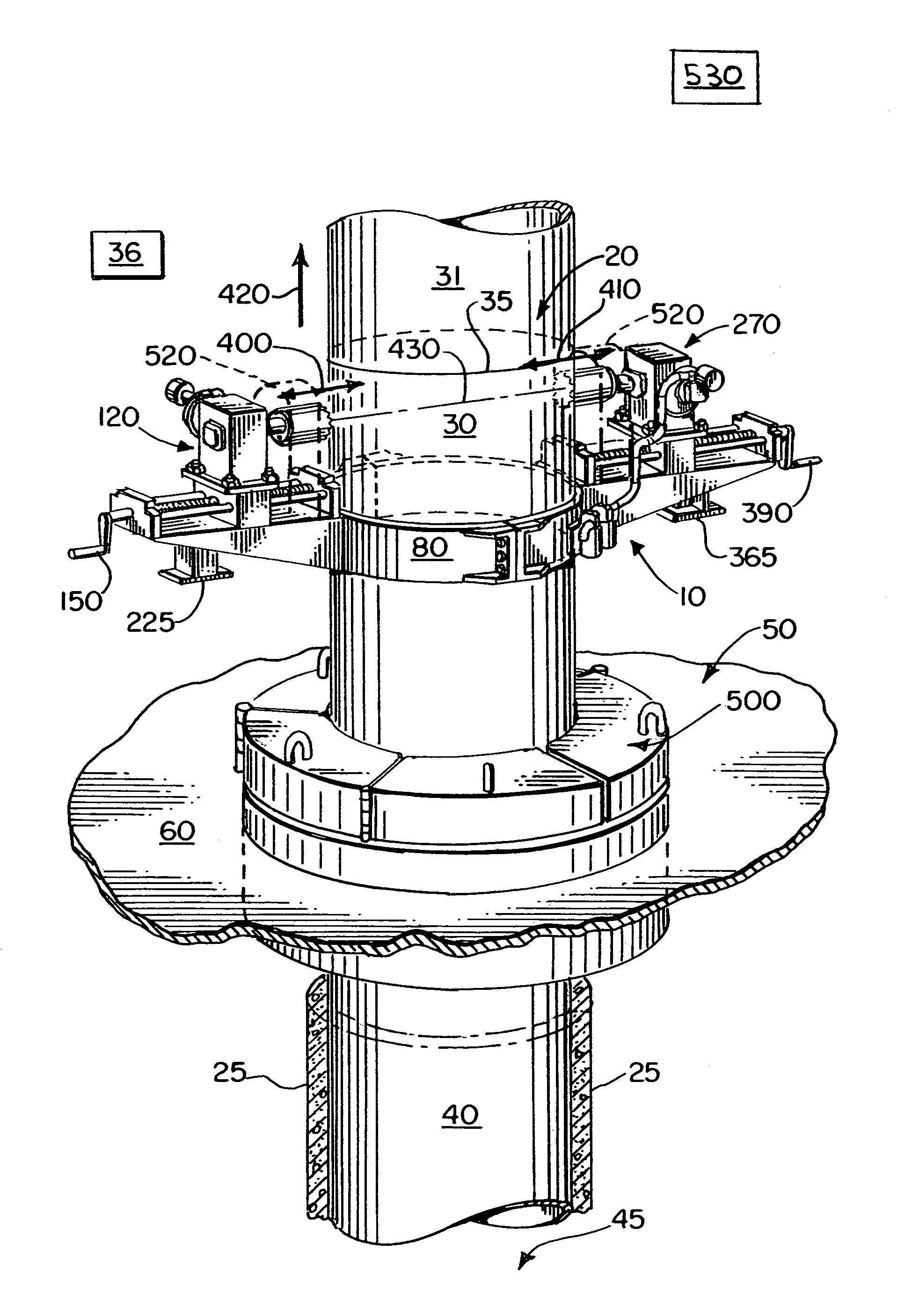

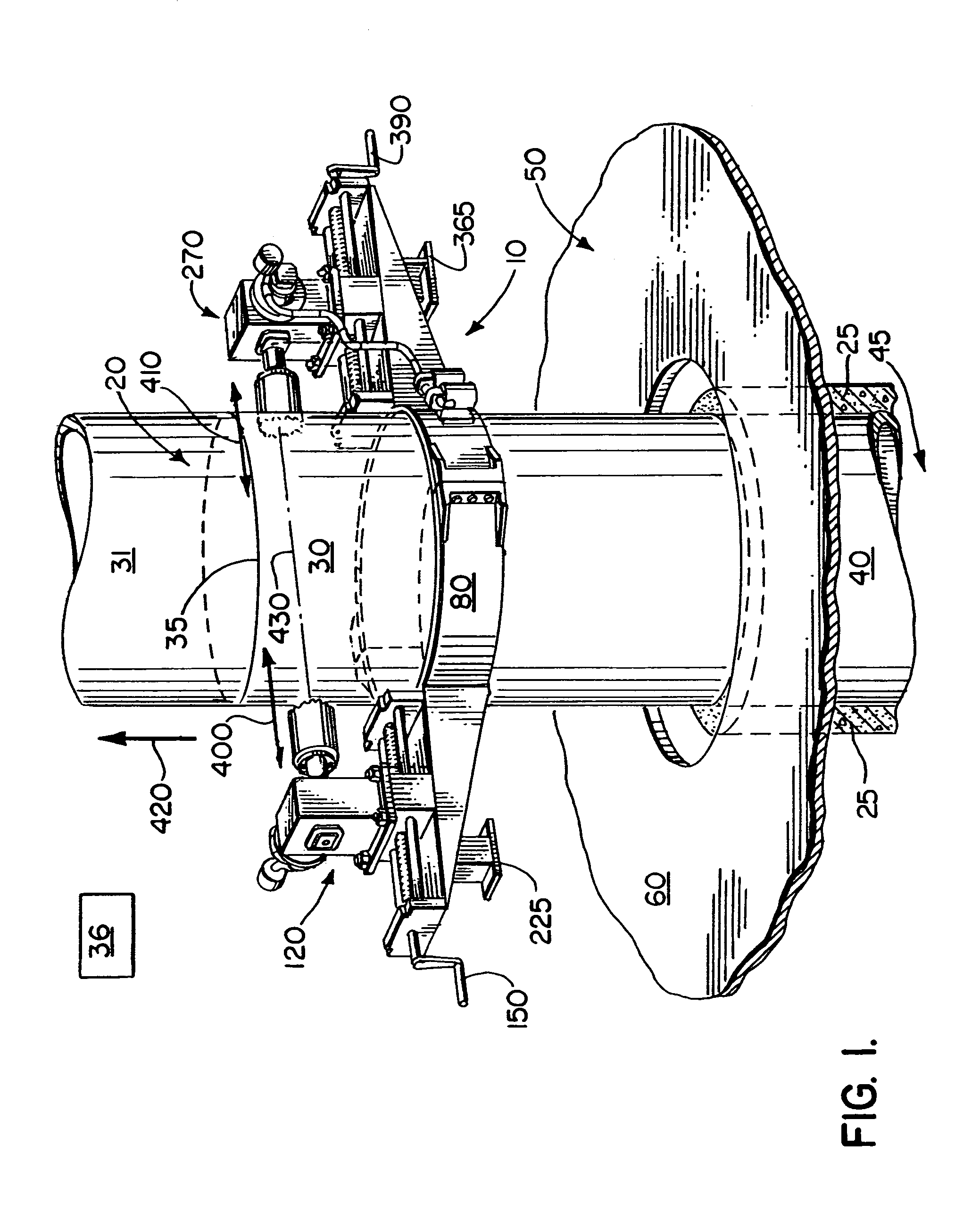

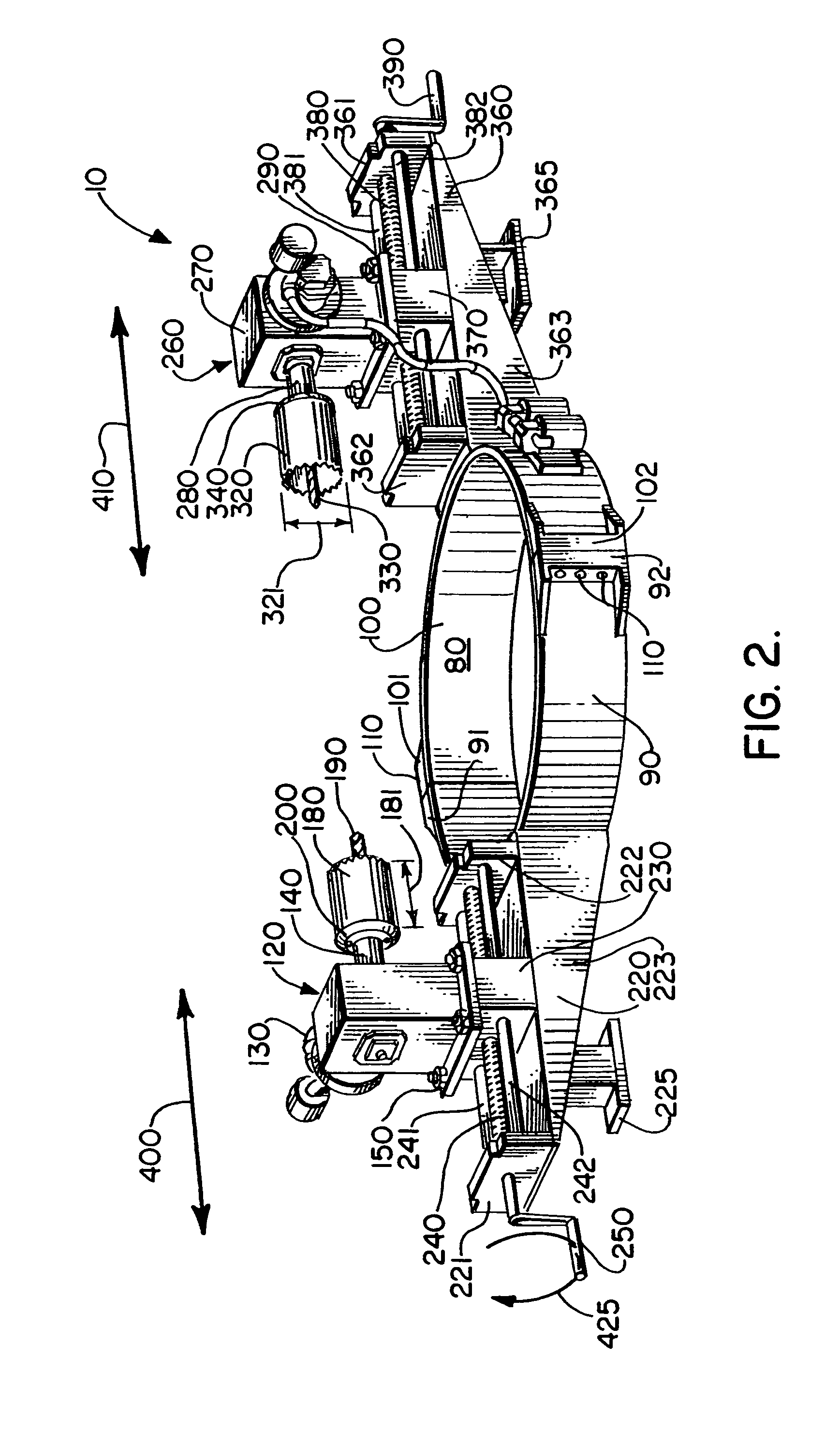

Method and apparatus for removing casing

InactiveUS7021381B1Shorten drilling timeSolve the real problemDrilling rodsFluid removalEngineeringCasing string

A method and apparatus for removing a string of casing from a well bore. The method and apparatus include a plurality of drill bits substantially aligned with each other for drilling a plurality of holes in the string of casing. The plurality of holes can be used to lift the string in casing from the well bore via a series of incremental casing sections.

Owner:HUDSON SERVICES

Non-excavation and top drilling combined crossing and spanning pipeline laying method

ActiveCN106594386ASave construction costSave construction timePipe laying and repairEngineeringDirectional drilling

The invention provides a non-excavation and top drilling combined crossing and spanning pipeline laying method. The method comprises the steps of carrying out pipe-jacking construction and horizontal directional drilling construction at the same time; getting through the position, where pipelines are to be laid, at the bottom of a receiving shaft; then, enabling the pipelines to communicate with each other; and finally, carrying out backfilling, so as to achieve pipeline laying. According to the method, the part, difficult to construct through a horizontal directional drilling machine, of a pipeline construction zone of a complex stratum is selected as a pipe-jacking construction section, other complex stratums are adopted as horizontal directional drilling machine construction parts according to reconnaissance information, the one-time crossing distance is long, the constructable pipe diameter is large, large-diameter long-distance pipelines can be laid in the complex stratums through one step, construction cost is greatly reduced, and construction time is greatly saved.

Owner:CHINA PETROCHEMICAL CORP +3

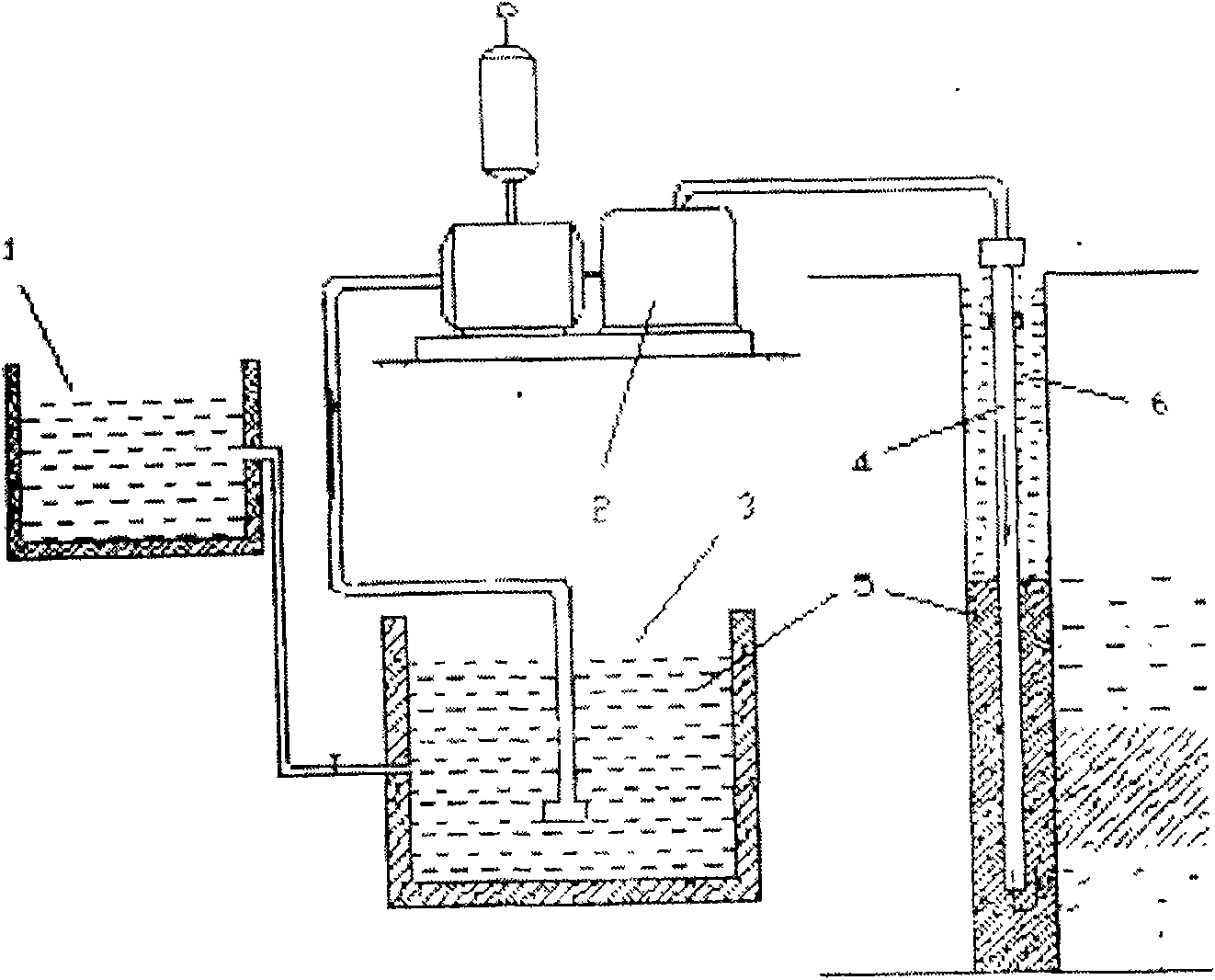

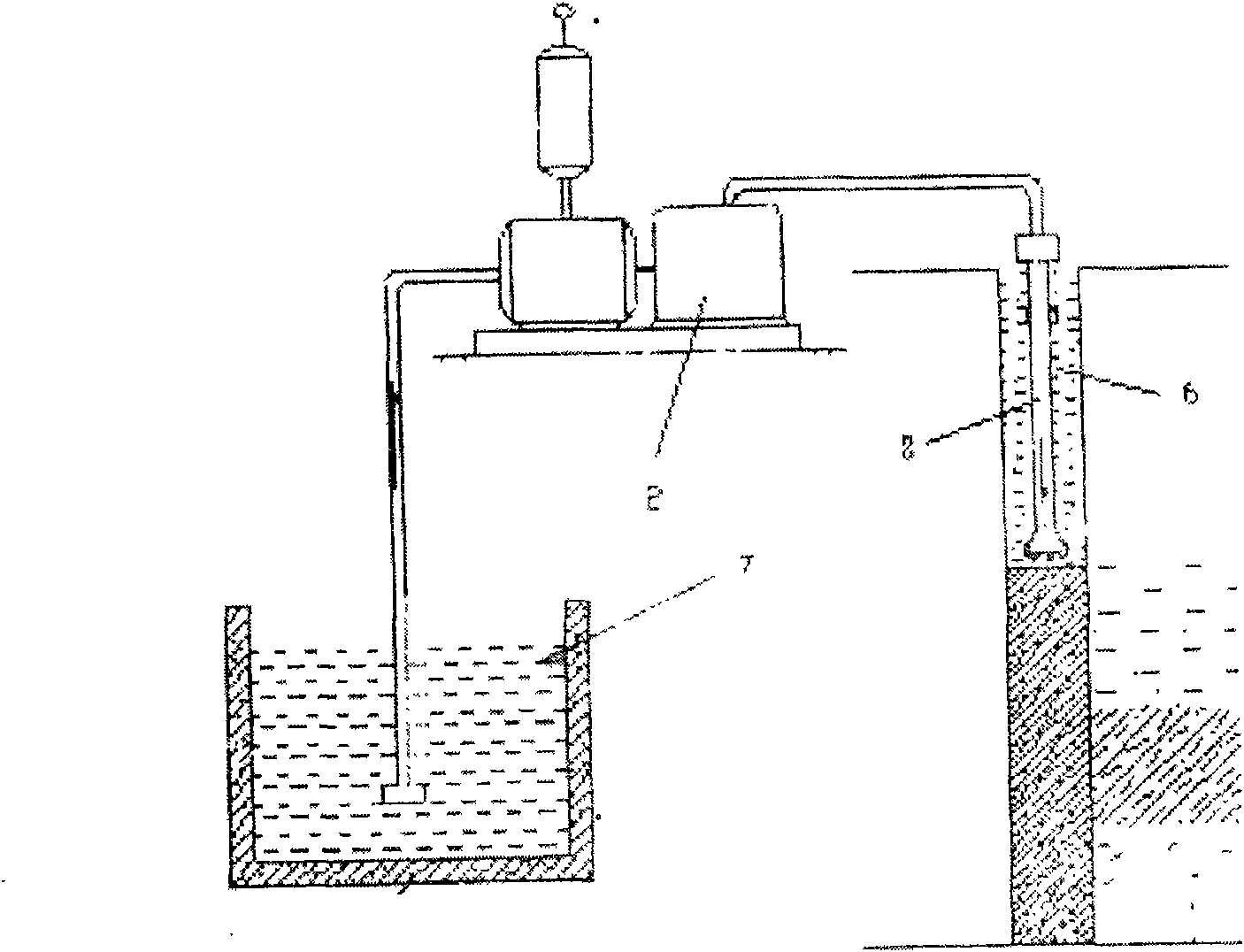

Technology for constructing and stopping leakage of freezing borehole

InactiveCN101660415AReduce drilling timeFast constructionShaft sinkingShaft liningWater storage tankSlurry

The invention discloses a technology for constructing and stopping leakage of a freezing borehole, comprising the following steps: (1) preparing a given amount of double-liquid chemical mud in a mud storage sump according to the condition of mud leakage; (2) picking up a drill and removing a drill bit, and running a hollow drill rod to the position of leakage layer, and running the hollow drill rod to the position of 2-5 m from the bottom of a borehole if mud is leaked from the bottom of the borehole; (3) hermetically communicating a mud outlet of a mud pump with the upper end of the hollow drill rod running to the position of the leakage layer by using a high pressure pipeline, and hermetically communicating a mud pumping port of the mud pump with the mud storage sump by using the high pressure pipeline; (4) uniformly stirring the double-liquid chemical mud in the mud storage sump; (5) starting up the mud pump to press the stirred-uniformly double-liquid chemical mud in the mud storage sump (3) into the mud leakage position of the freezing borehole through the hollow drill rod; (6) injecting clear water in a water storage tank into the mud storage sump and pressing the clear waterin the mud storage sump into the hollow drill rod by using the mud pump to replace the double-liquid chemical mud in the hollow drill rod; (7) stopping the mud pump; (8) pulling out the hollow drillrod; (9) enabling the double-liquid chemical grout to stand in the borehole for 4-6 hours; and (10) preparing fresh mud, running the drill and starting up the mud pump for circulation and replacing the original mud and then normally drilling subsequently after cleaning the bottom of the hole.

Owner:HANDAN SPECIAL SHAFT SINKING CHINA COAL ENERGY GROUP

Deep-hole smooth tunnel blasting system and construction method for tunnel

ActiveCN107355229AImprove stabilityReduce harmUnderground chambersBlastingEngineeringExplosive material

The invention relates to a deep-hole smooth tunnel blasting system. The deep-hole smooth tunnel blasting system comprises a multi-shaft drilling mechanism and a deep-hole smooth blasting mechanism; the drilling mechanism comprises a drill rod arranged on an adjusting bracket, the drill rod is driven by a horizontal driving mechanism to move horizontally and implement hole digging operation, and a spatial position, located on the adjusting bracket, of the drill rod can be adjusted; the deep-hole smooth blasting mechanism comprises a plurality of explosive material charging tube standard joints arranged in a blasting hole; tube openings of the explosive material charging tube standard joints are sequentially connected to form a blasting tube, and trays are arranged on the connecting parts of adjacent explosive material charging tube standard joints for supporting explosive materials; a base is arranged at one end of the blasting tube, and a top cover is arranged at the other end of the blasting tube; and a through hole is formed in the tray surface of the tray for penetrating of a detonating cord, the detonating cord sequentially and upwardly penetrates through the through hole in the tray from the base and leads out from a through hole formed in the top cove of the blasting tube, and cracks are further arranged on the tray. The deep-hole smooth tunnel blasting system can improve the drilling efficiency, and weaken the influence of complex geological environment of a coal mine on explosive material charging at the same time, and premature overflowing of explosion gas is prevented.

Owner:ANHUI UNIV OF SCI & TECH

Air cushion type space-reserved drift and fill type mining device and method

InactiveCN106014415AExtension of timeIncreased overall time, increased throughputUnderground miningSurface miningEngineeringCut and fill

The invention provides an air cushion type space-reserved drift and fill type mining device and method and belongs to the technical field of mine cut and fill mining. The device comprises an air cushion, a fixing mechanism and auxiliary equipment. The air cushion comprises air bags, inflating and deflating valves, safety valves and the like. The air cushion is fixed to ore body drift and fill road sides by the fixing mechanism through fixing ropes, and the air cushion is inflated through the auxiliary equipment. In the using process of the device, the air cushion is erected on the side close to an ore about every 10 m before filling of a drift and fill path is carried out, multiple air cushions are consecutively erected along the total length part in the axial direction of the drift and fill path, and then the drift and fill path is filled. When the device and the method are used for mining adjacent mining drift and fill paths, the air cushions can be recycled first, the space reserved for the air cushions serves as a blasting free surface, and mining blasting is carried out in a row-by-row lateral blasting mode; the blasting efficiency and mining efficiency can be greatly improved, consumption of explosives can be greatly reduced, holes can be reduced, the total time of total mining circulation can be prolonged, the capacity of total mining circulation can be improved, and the safety of recovery work is promoted.

Owner:UNIV OF SCI & TECH BEIJING +1

Electric hinge

ActiveUS20170306674A1Shorten drilling timeImprove manufacturingWing accessoriesPin hingesEngineeringKnuckle

A method for making an electric hinge comprising providing first and second hinge plates, each hinge plate having at least one knuckle and forming in each hinge plate an open slot extending from an edge distal from the knuckle and terminating at a mid-portion of the hinge plate to the knuckle. The open slot depth is less than the thickness of the hinge plate. The method includes drilling a hole from the terminus of each open slot to the knuckle of the hinge plate and passing a wire through the hole from the terminus of the open slot to the knuckle in the first hinge plate and from the knuckle of the second hinge plate to the corresponding terminus of the second hinge plate. The method includes mating the first and second hinge plates by inserting a hinge pin through the knuckle of each hinge plates to form the electric hinge.

Owner:CORBIN RUSSWIN

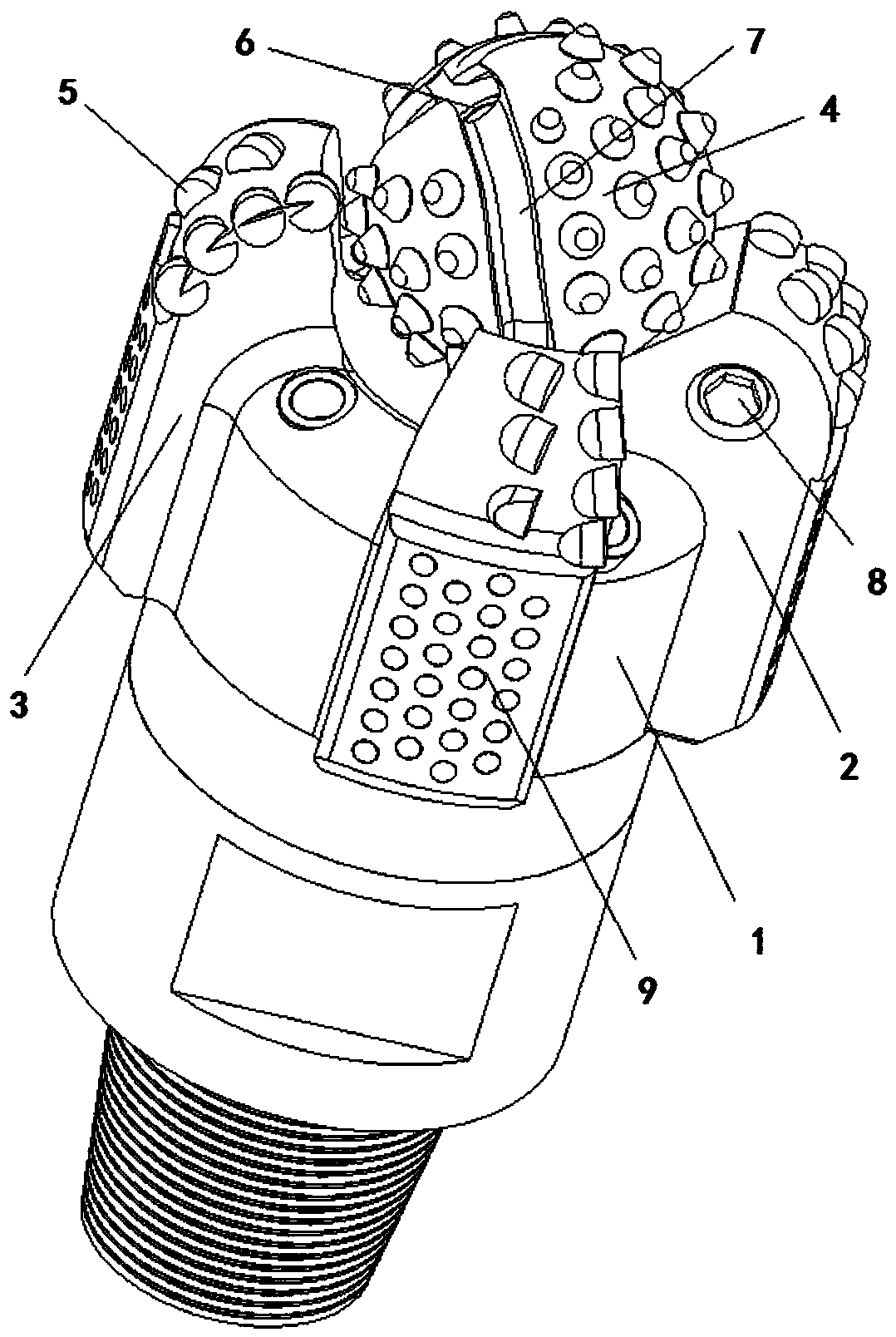

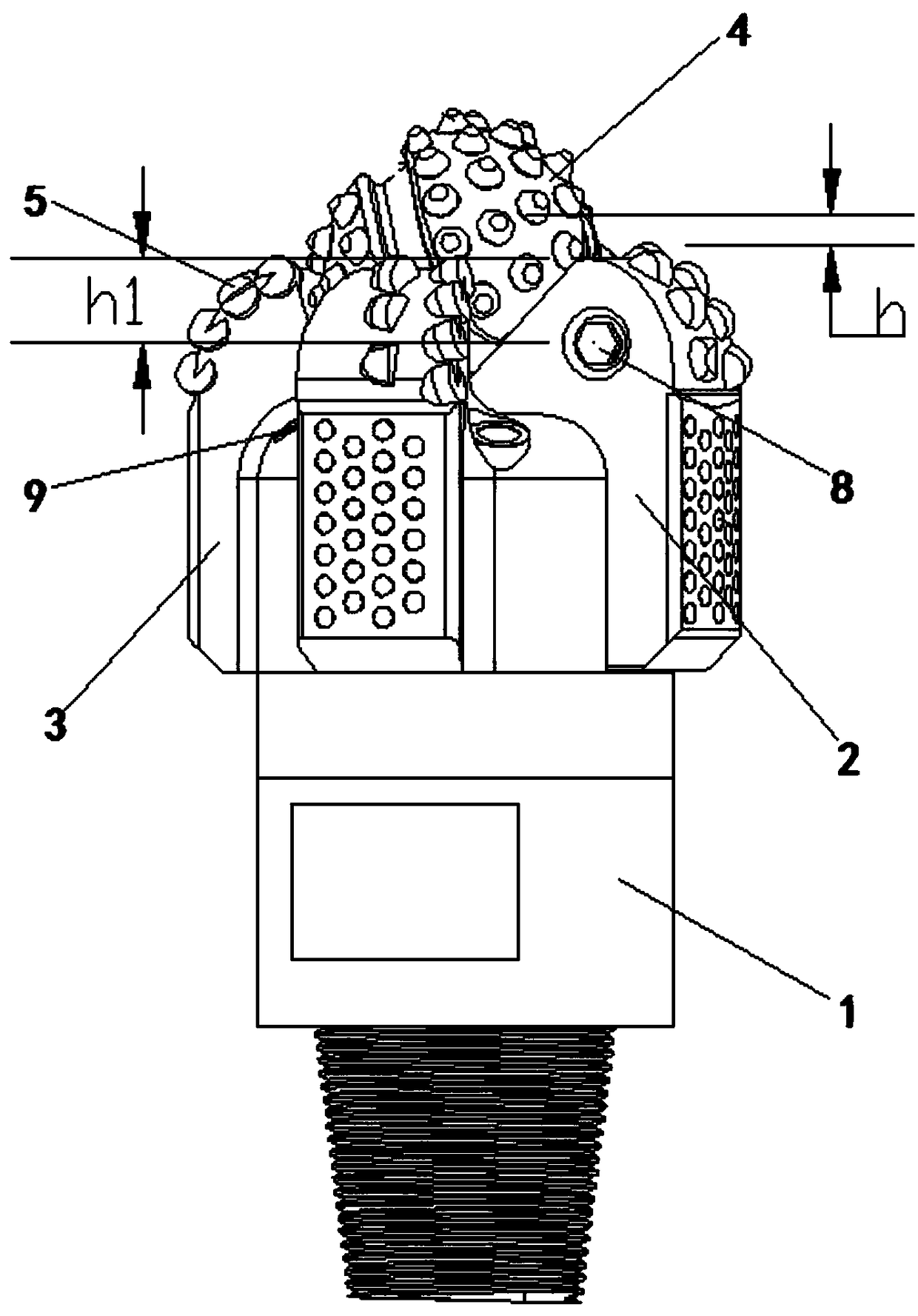

Novel pdc and roller cone composite drill bit

The invention discloses a novel pdc and roller cone composite drill bit. The novel pdc and roller cone composite drill bit comprises a drill bit body, a roller cone palm, a cutting blade, and a spherical roller cone. The spherical roller cone is installed the roller cone palm. The outer sides of the roller cone palm and the cutting blade are provided with pdc cutting teeth and fixed on the drill bit body. The spherical roller cone is positioned above the drill bit body, and a center line of the spherical roller cone is coincided with an axis of the drill bit body. A vertical distance between asphere center position of the spherical roller cone and a highest point of the cutting blade is within a range of 18-29 mm. The side face of the roller cone palm is provided with an oil storage seal.According to the related novel composite drill bit, in a drilling process, a bit pressure is shared by the pdc cutting teeth and the roller cone together, a pressure applied to each tooth is reduced,the wear-resistant capacity of the drill bit is improved, thereby the service life of the whole drill bit is prolonged. In addition, because a position of the oil storage seal is closer to the top ofthe drill bit, a sensitivity of a drill bit lubricating system for sensing a bottom hole pressure is improved, and the drill bit is positioned in the better lubricating environment, so the service life of the drill bit is improved.

Owner:SOUTHWEST PETROLEUM UNIV

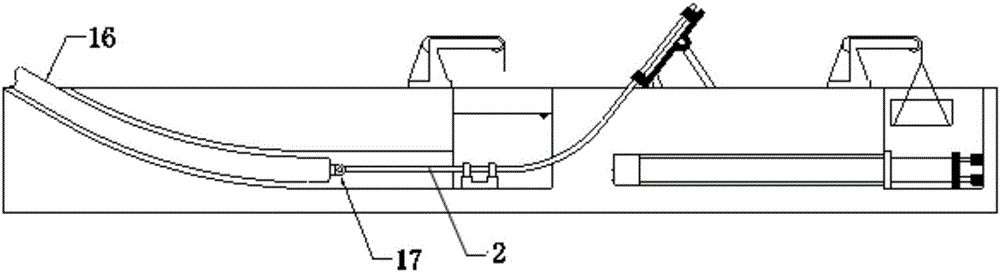

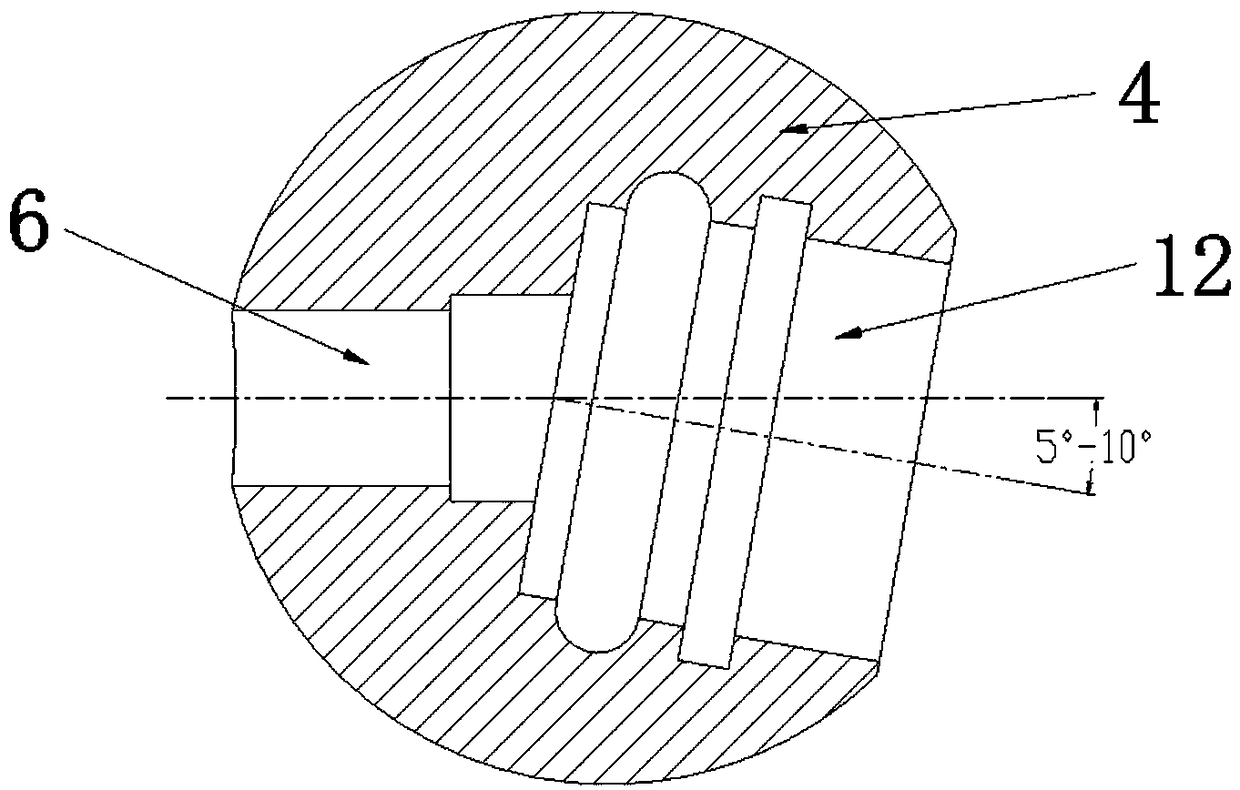

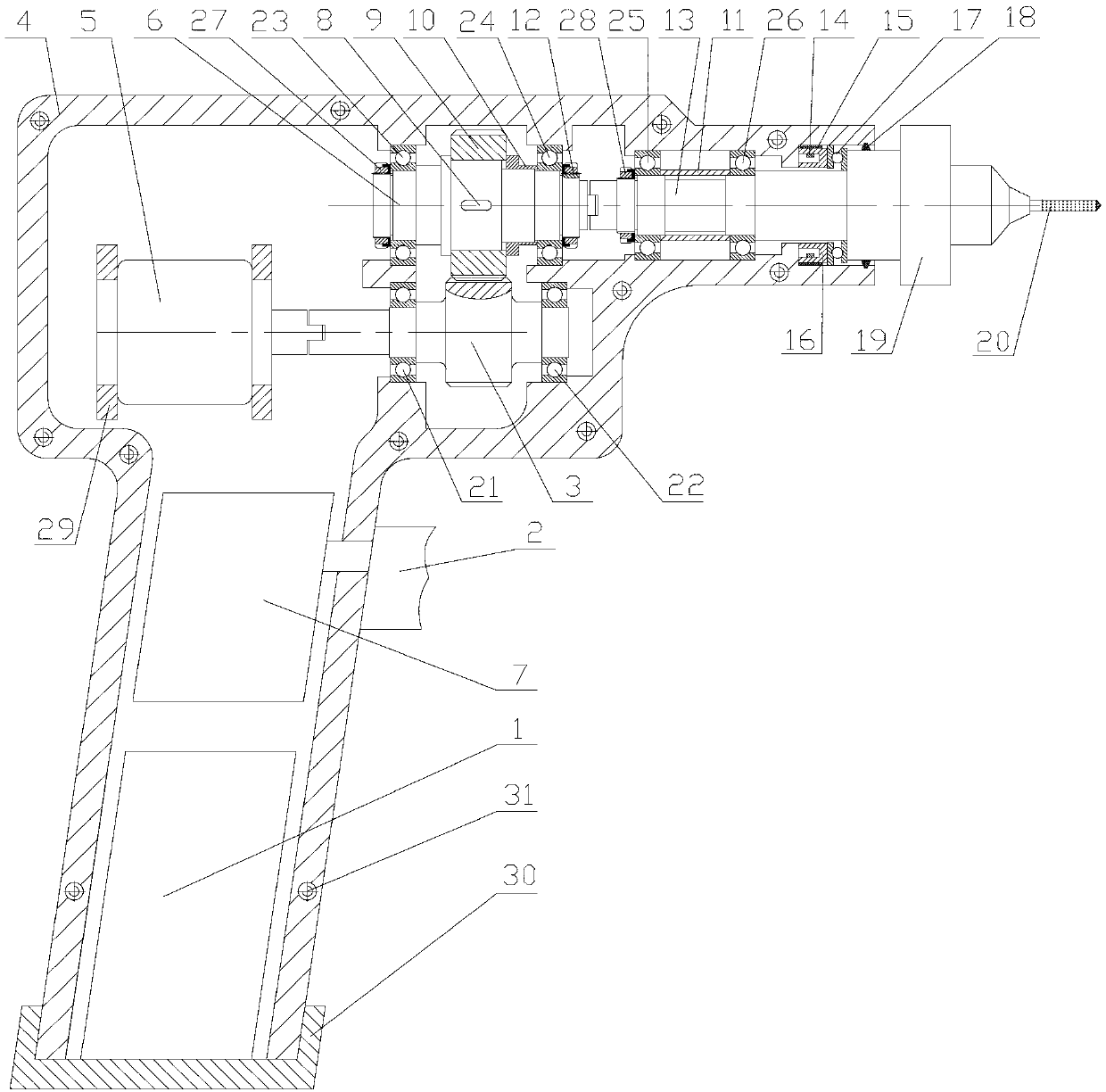

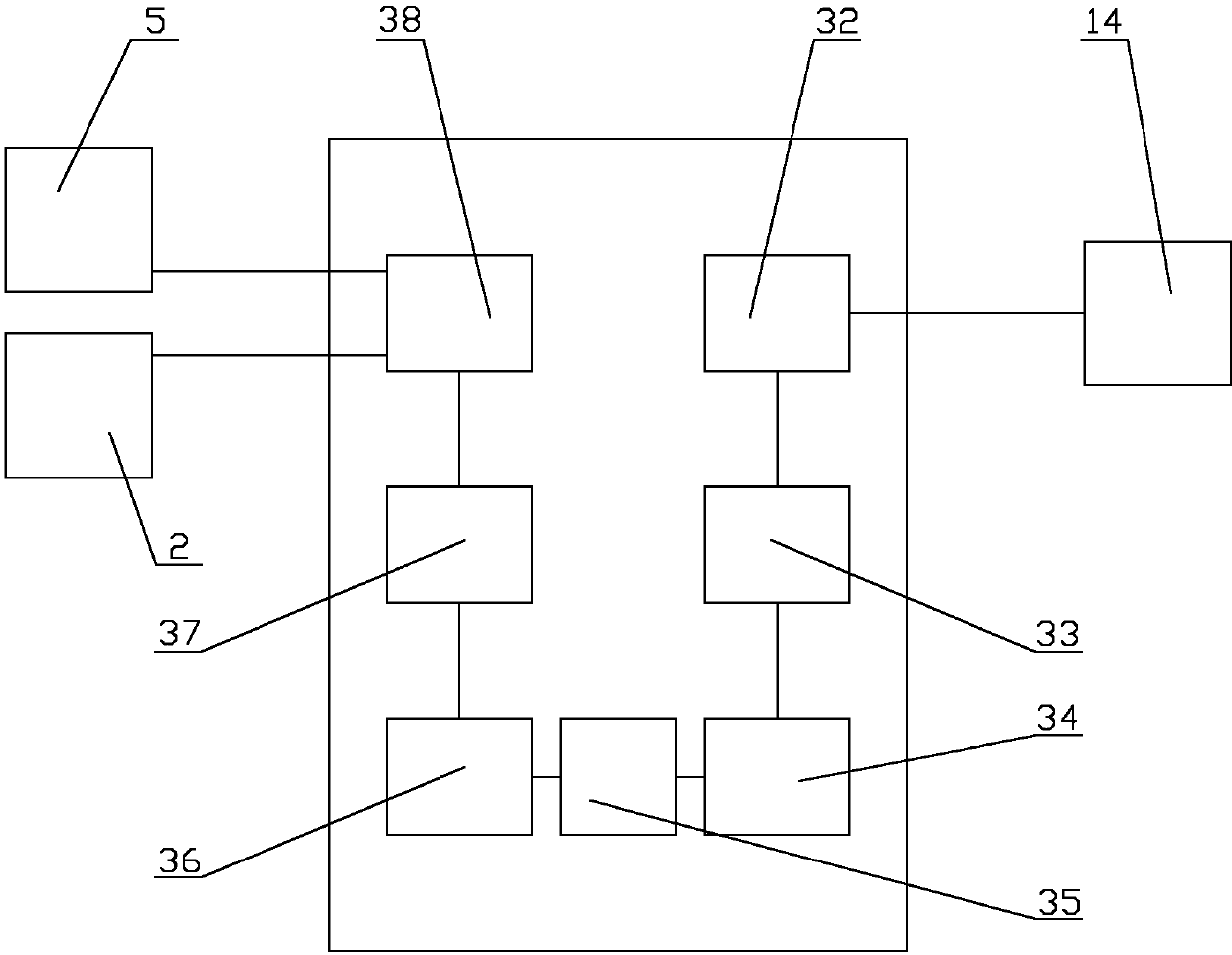

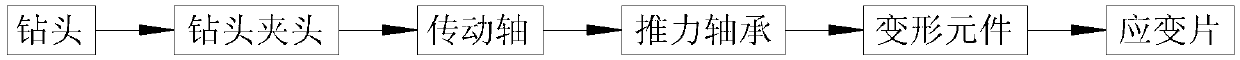

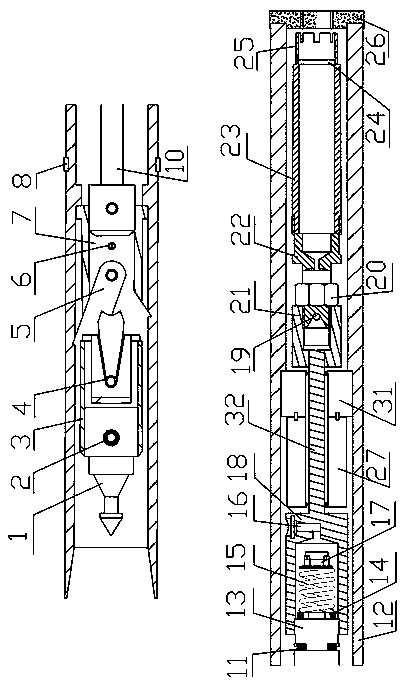

Axial force controllable surgical bone drill with abrasive grain bit

The invention relates to an axial force controllable surgical bone drill with an abrasive grain bit. The axial force controllable surgical bone drill with the abrasive grain bit is high in control precision and capable of effectively preventing injury to brain tissues and comprises a drill body and the bit, the drill body comprises a casing, a direct-current motor is arranged in the casing and is connected with an intelligent integrated control system and a direct-current power supply, an output shaft of the direct-current motor is connected with a gear transmission device which is connected with a drill chuck through a transmission shaft, and the bit is mounted on the drill chuck. A thrust bearing is arranged at the joint of the drill chuck and the transmission shaft and clings to a deformation element, the deformation element is closely attached onto the casing and is positioned by an elastic element, a resistance strain gauge is adhered to the inner surface of the deformation element and is further connected with the intelligent integrated control system, and a sealing device is arranged between the drill chuck and the casing. Besides, the bit is a cylindrical rod with a cone, and abrasive grains are arranged and mounted on surfaces of working portions of the cone and the cylindrical rod.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

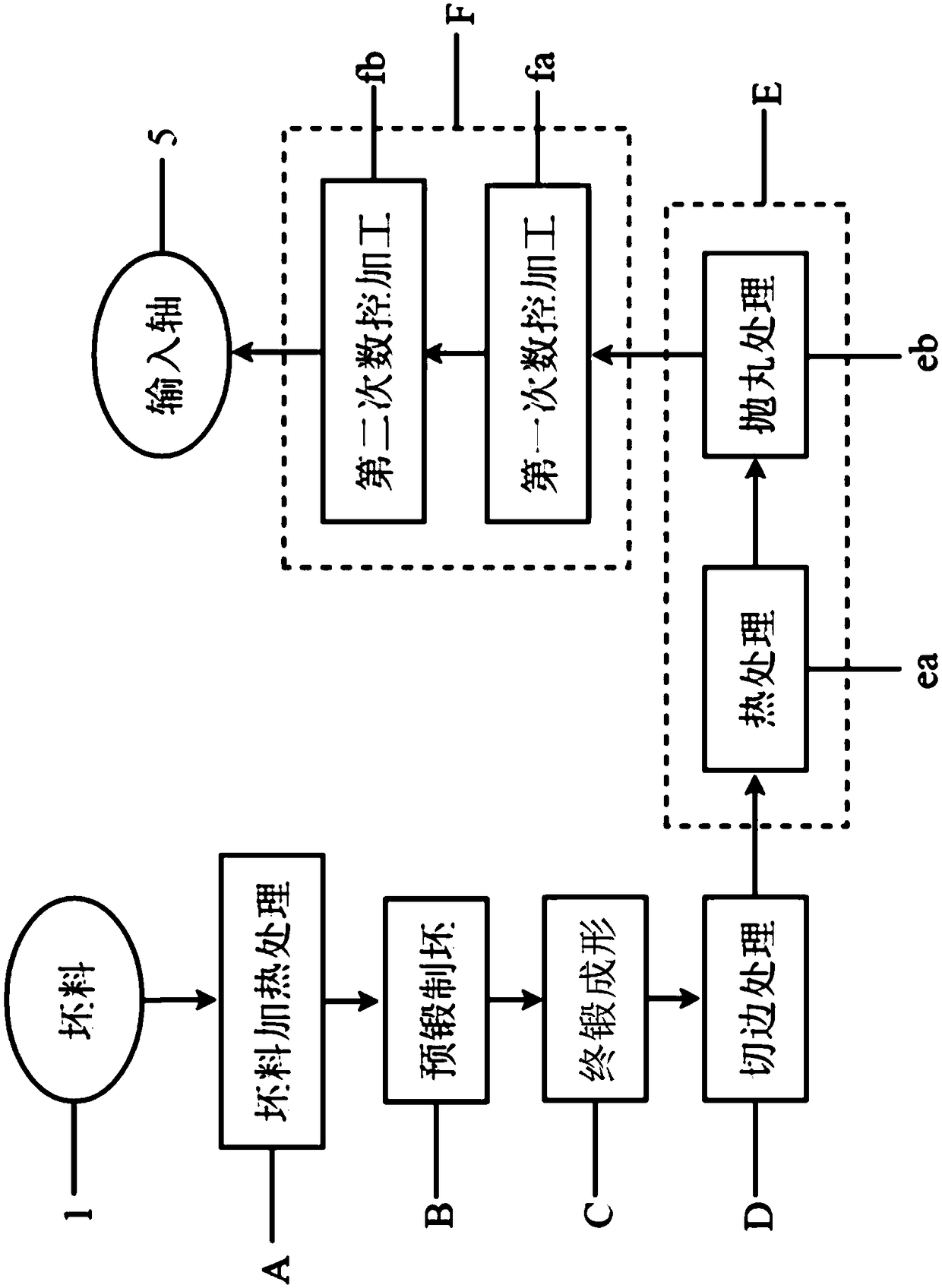

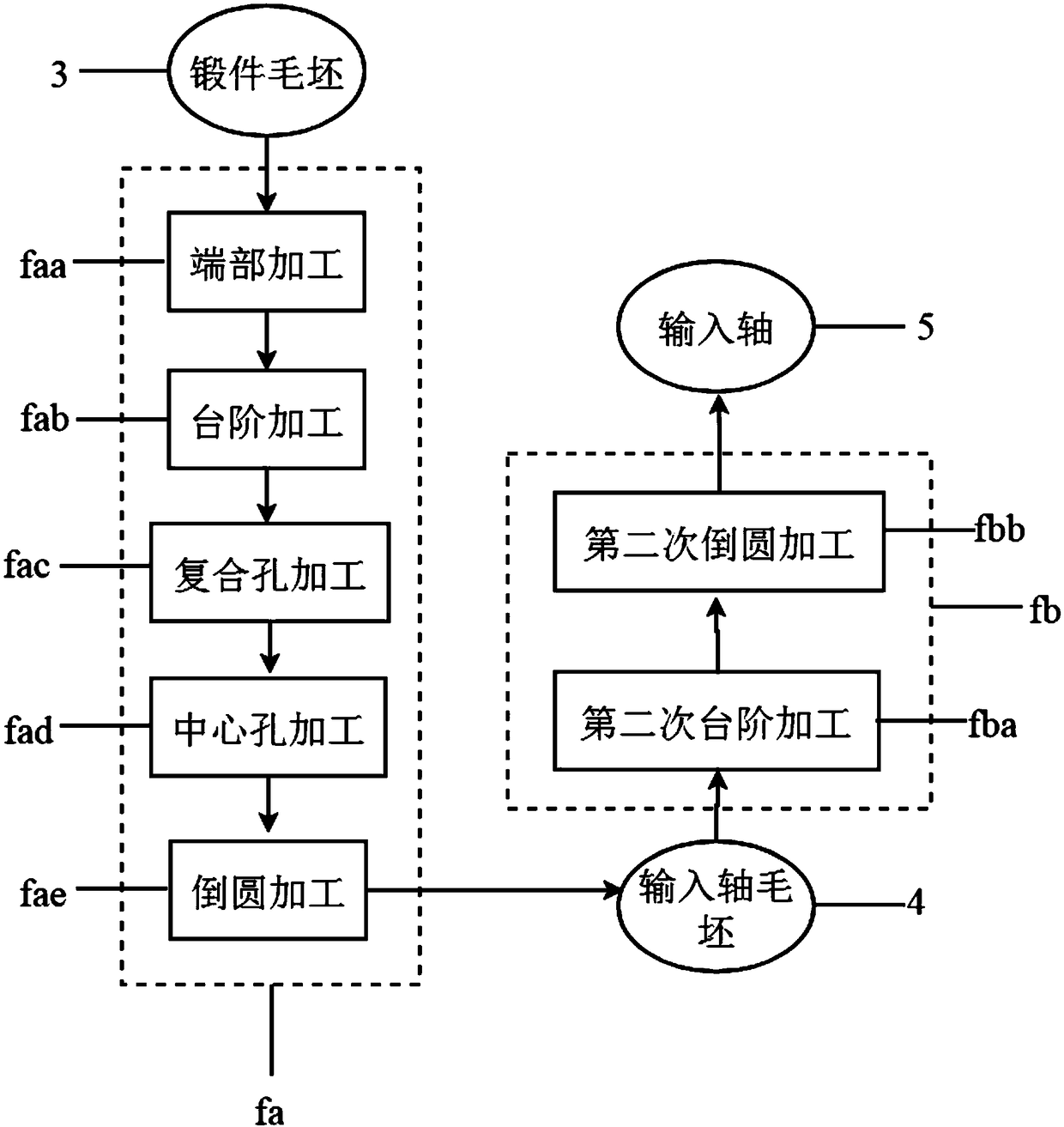

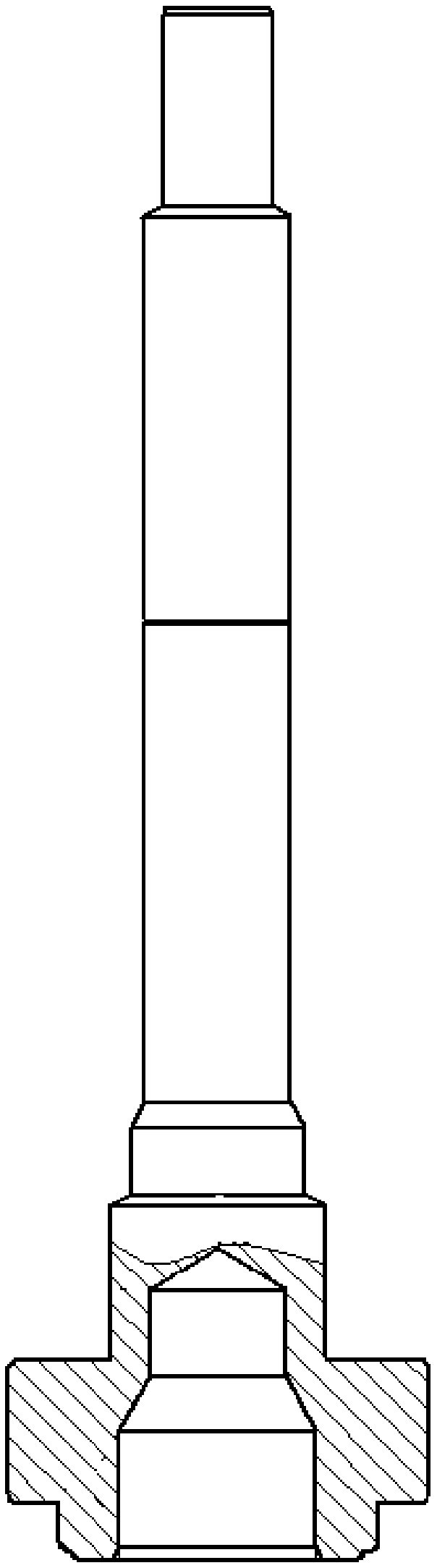

Method for automobile gearbox input shaft forging and blank rough machining forming

The invention discloses a method for automobile gearbox input shaft forging and blank rough machining forming, and belongs to the field of metal mechanical part manufacturing. The method for automobile gearbox input shaft forging and blank rough machining forming comprises the following steps: 1, a blank is subjected to blank heating treatment and then is subjected to pre-forging and blank makingto form a pre-forged blank; 2, final forging forming is carried out on the pre-forged blank to form a forge piece blank; 3, after edge cutting treatment is performed on the forge piece blank, isothermal normalizing and shot blasting are carried out on the forge piece blank; and 4, numerical control machining is carried out on the forged piece blank for shot blasting to form an input shaft. According to the method for automobile gearbox input shaft forging and blank rough machining forming, vertical forging is adopted, and compared with a horizontal forging and wedge rolling technology, a blindhole can be forged, the material utilization rate is improved, a composite hole is conveniently machined in the later stage, and the drilling time of rough machining is saved.

Owner:NANCHANG GEAR FORGE PLANT

Method and apparatus for removing casing

InactiveUS7621321B1Shorten drilling timeSolve the real problemDrilling rodsFluid removalEngineeringCasing string

A method and apparatus for removing a string of casing from a well bore. The method and apparatus include a plurality of drill bits substantially aligned with each other for drilling a plurality of holes in the string of casing. The plurality of holes can be used to lift the string in casing from the well bore via a series of incremental casing sections.

Owner:HUDSON SERVICES

Ultrasonic vibration cord coring drill tool

InactiveCN105507804AIncrease drilling speedImprove drilling efficiencyConstructionsReciprocating drilling machinesRock coreResonance

The invention discloses an ultrasonic vibration cord coring drill tool. The ultrasonic vibration cord coring drill tool is characterized in that power can be supplied to a piezoelectric ceramic vibrator by a battery of the ultrasonic vibration cord coring drill tool, high-frequency voltages with different frequencies can be provided, and accordingly the piezoelectric ceramic vibrator can be excited to ultrasonically vibrate; generated ultrasonic vibration is transmitted to rock via an outer tube and a drill bit, and resonance breaking can be carried out on the rock; single-action characteristics of rock core tubes are kept among the battery, the piezoelectric ceramic vibrator and a solid shaft by the aid of bearings. The ultrasonic vibration cord coring drill tool has the advantages that the ultrasonic vibration cord coring drill tool is convenient to replace, the application range of ultrasonic drilling can be greatly expanded, the drilling periods can be shortened, and the cord coring drilling speeds can be increased.

Owner:JILIN UNIV

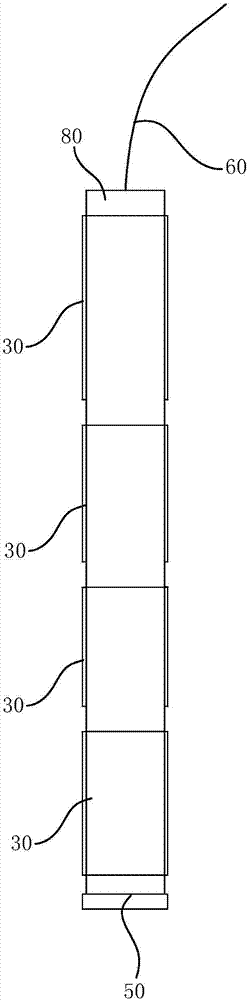

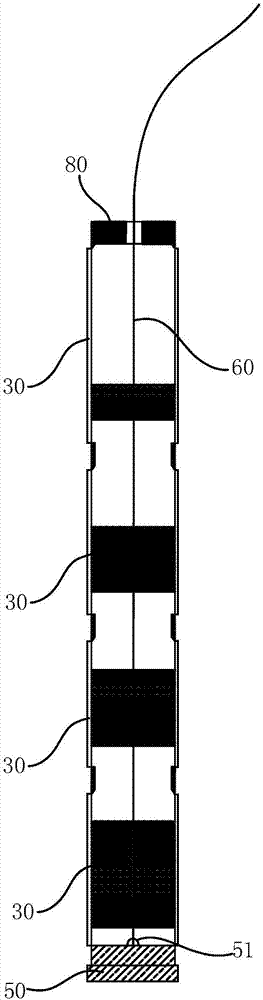

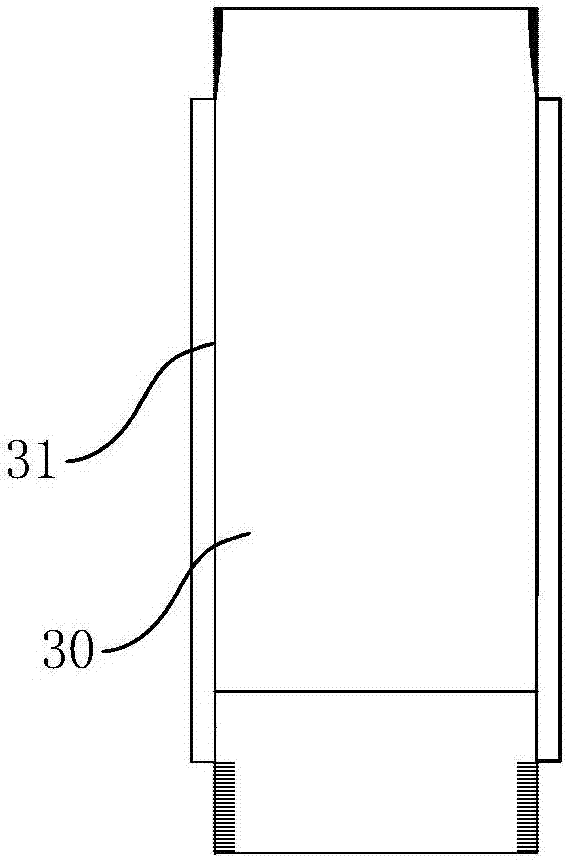

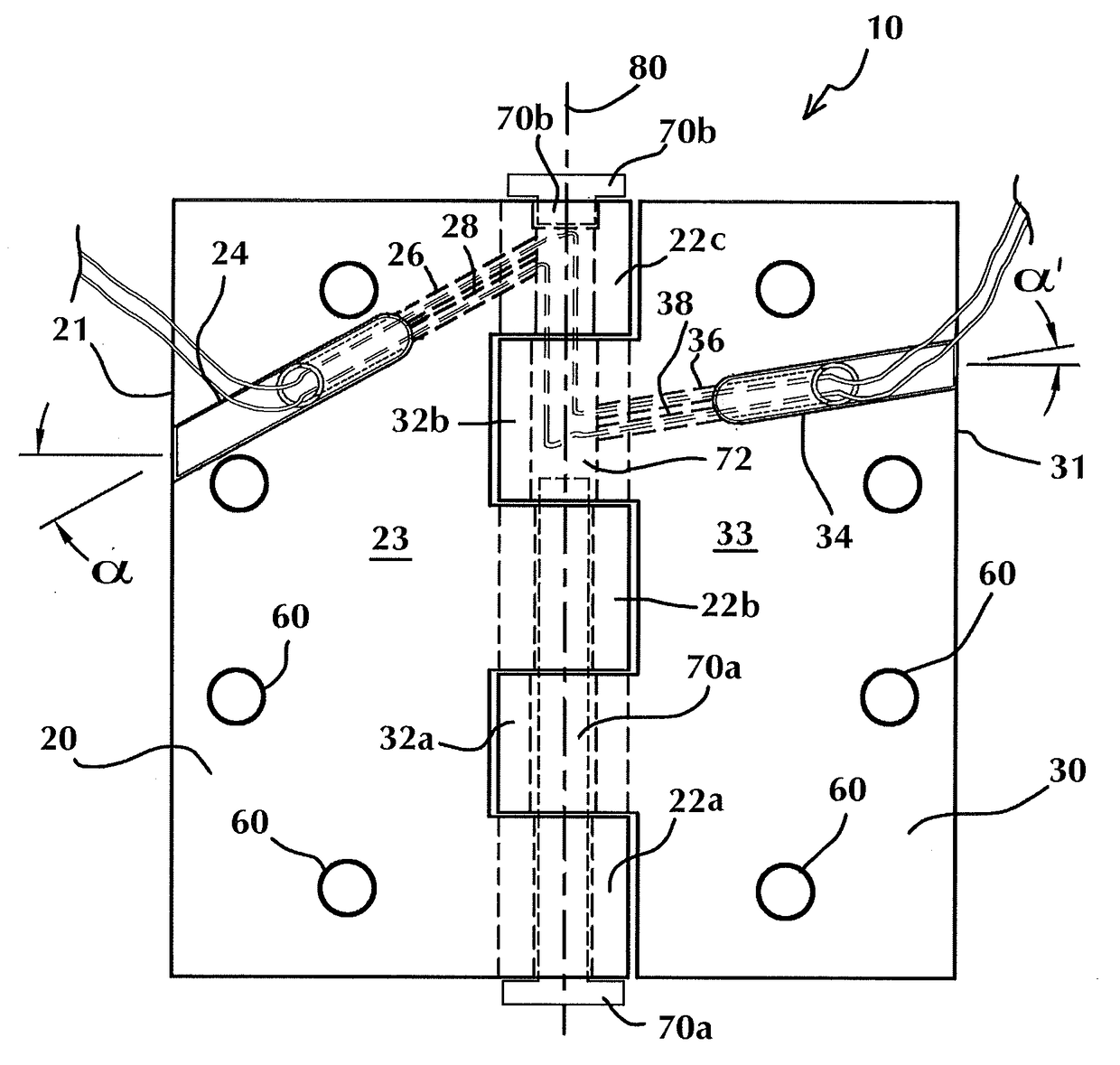

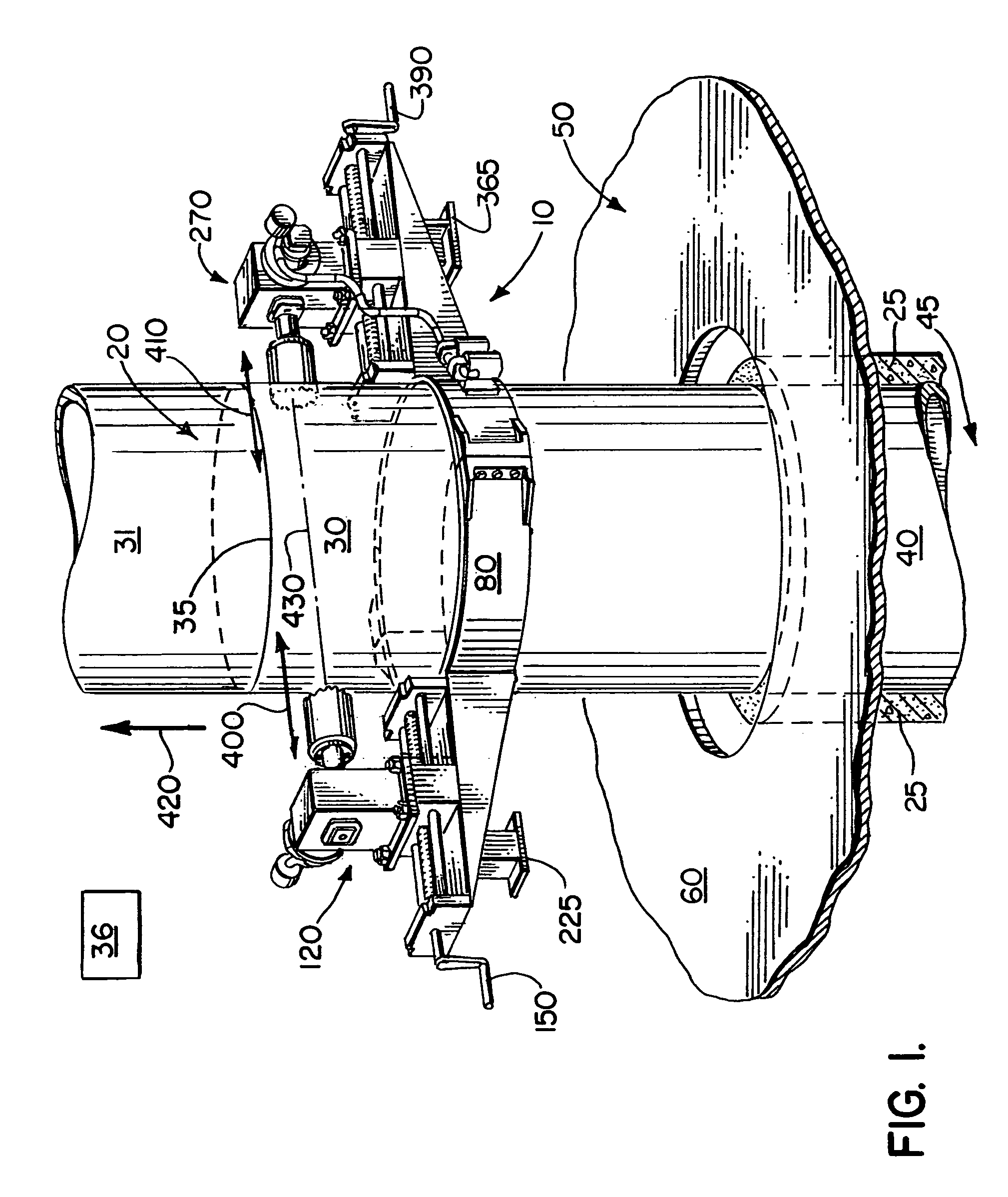

Combined casing expansion/casing while drilling method and apparatus

ActiveUS20050247485A1Increase drilling speedShorten the timeDrilling rodsConstructionsEngineeringCasing string

A drilling assembly (2) comprises upper (4) and lower (6) drill strings with a fluid passage (80) therethrough for distributing fluid to a bottom hole assembly (10). The upper drill string (4) has an upper end (11) connectable to a drilling apparatus (13) and fluid source (16) and a lower end (18) with an attached casing expander unit (20) that communicates the fluid passage (80) of the upper (4) and lower (6) drill strings. An upper end (22) of the lower drill string (6) is formed from a casing string (24) telescoped over the casing expander unit. A constriction (31) connects the casing string (24) with the rest of the lower drill string (6). A flow restriction device (35) in the lower drill string acts to control fluid flow through the fluid passage. In use, the flow restriction device creates a pressure in the fluid passage that acts at the constriction to advance the lower drill string past the upper drill string while simultaneously expanding the portion of the casing string moving past the expander unit.

Owner:HALLIBURTON ENERGY SERVICES INC

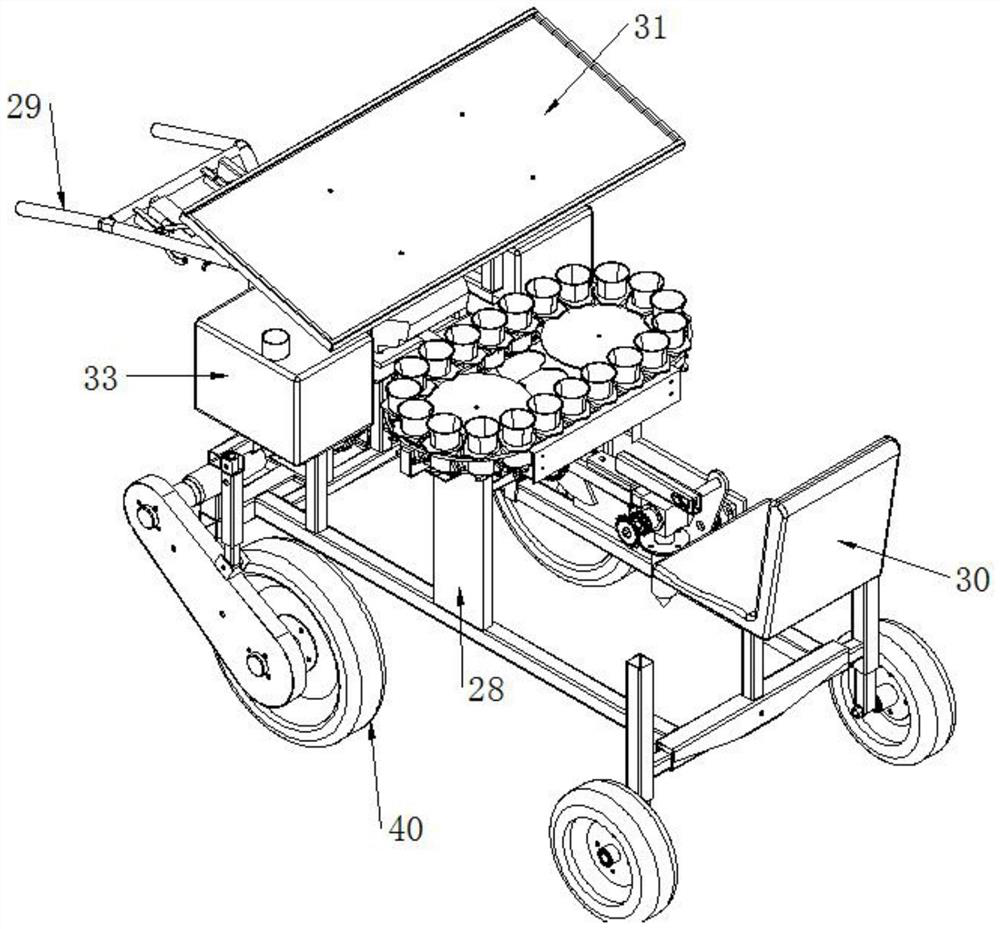

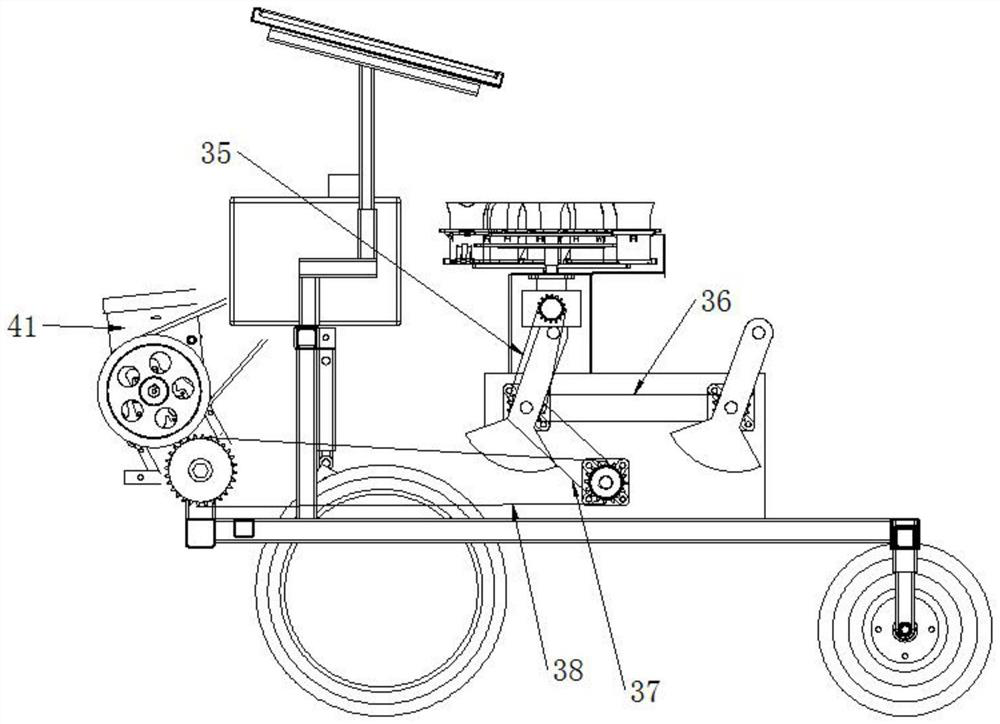

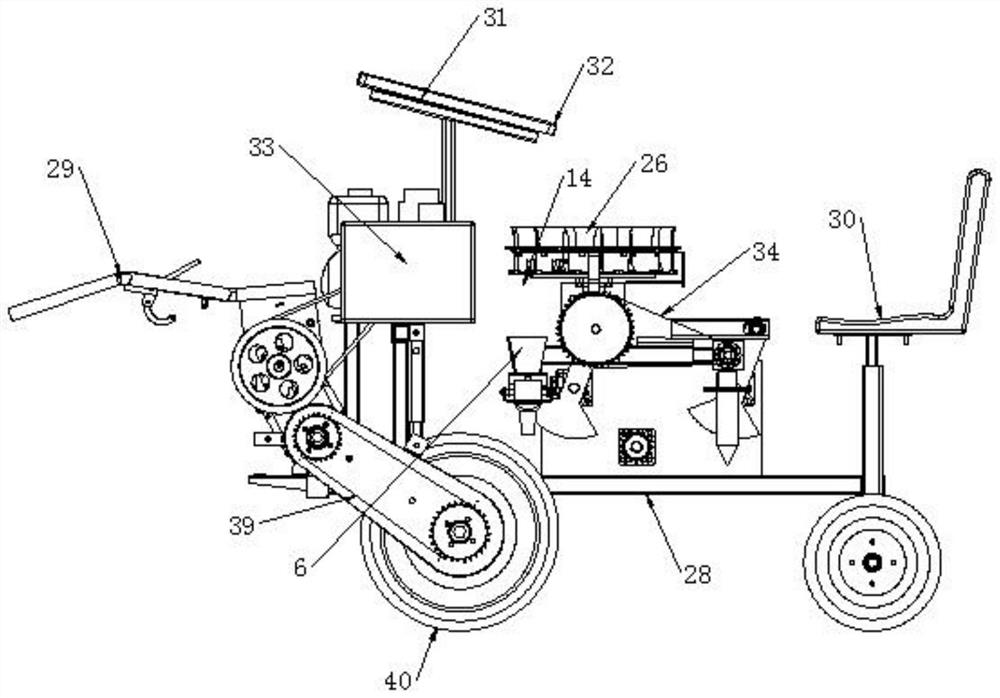

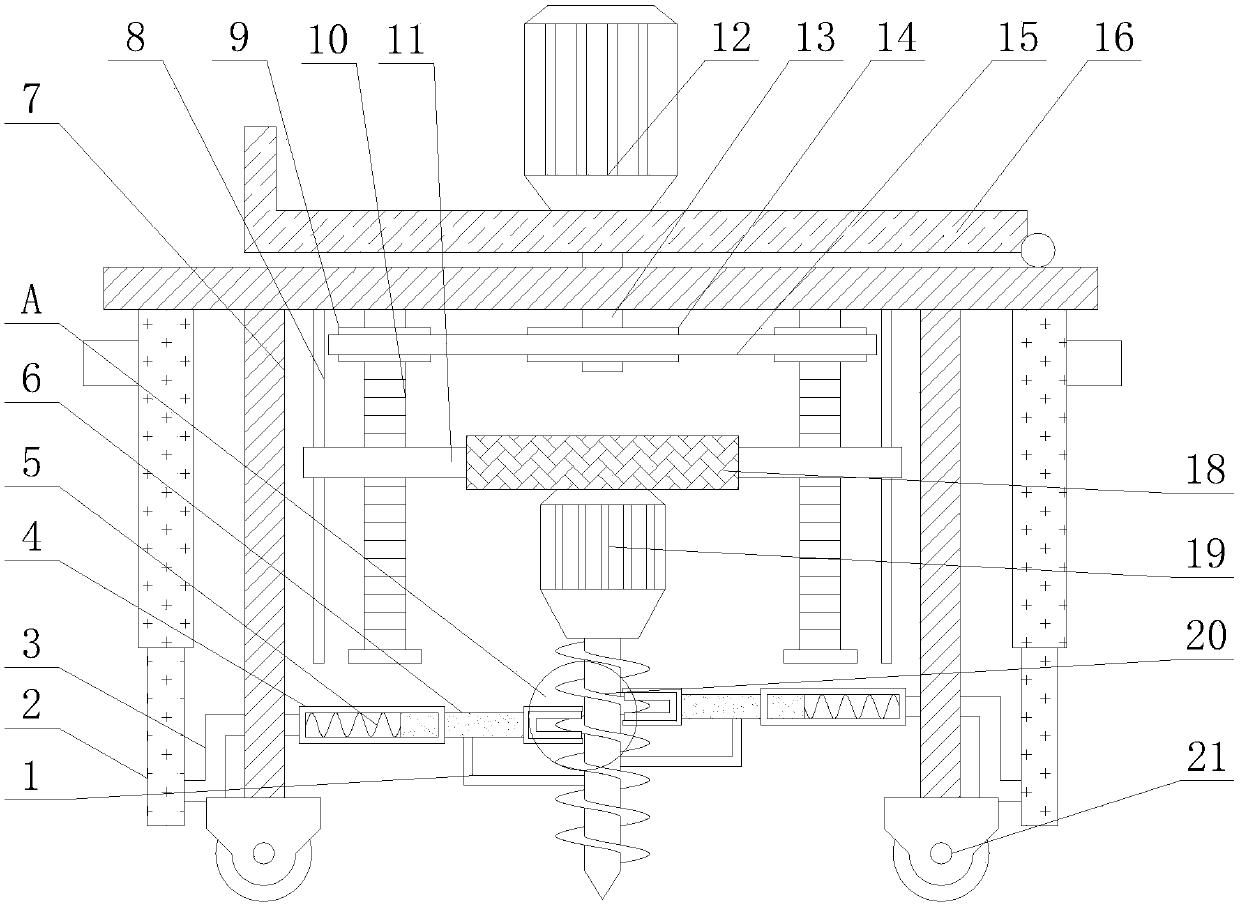

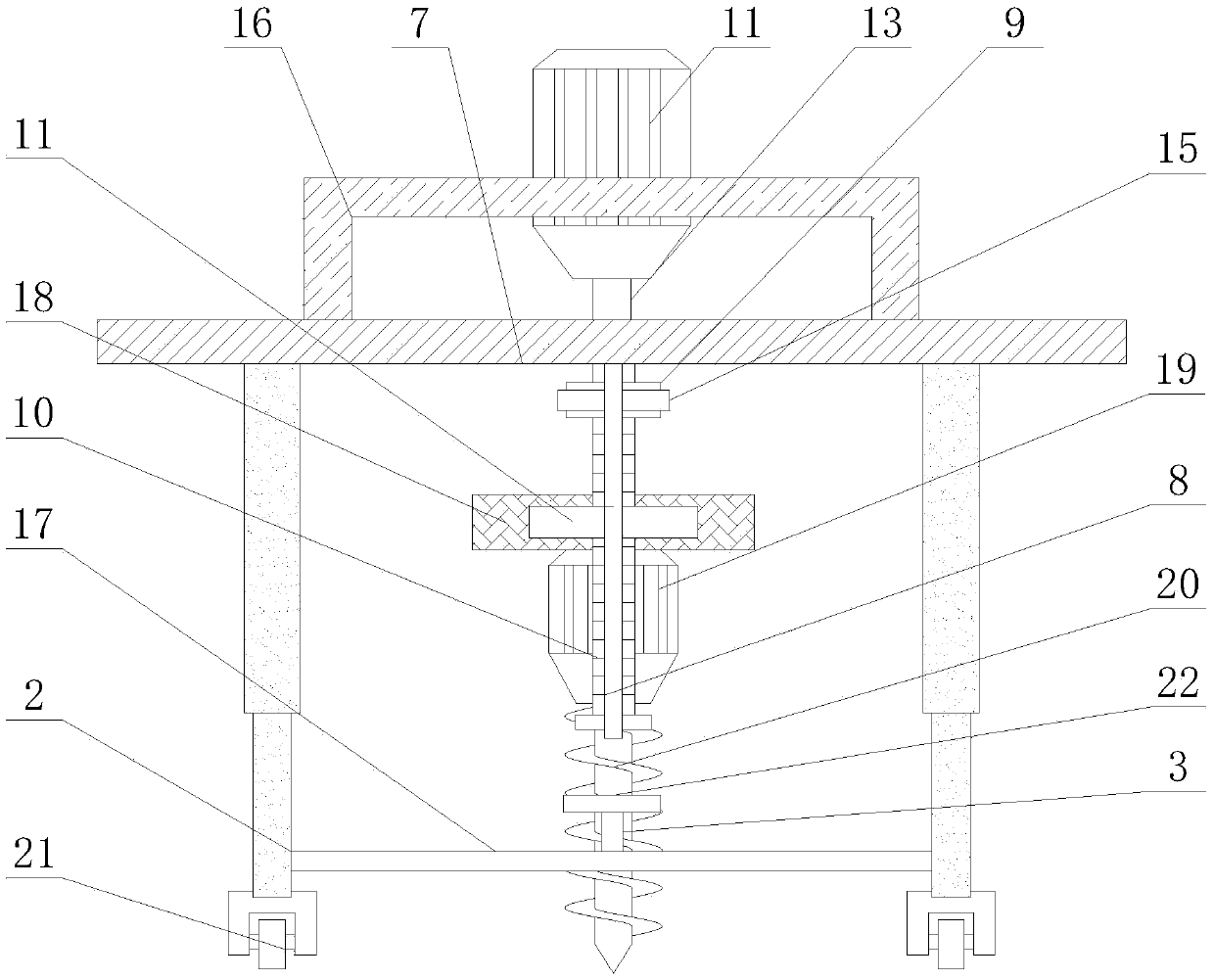

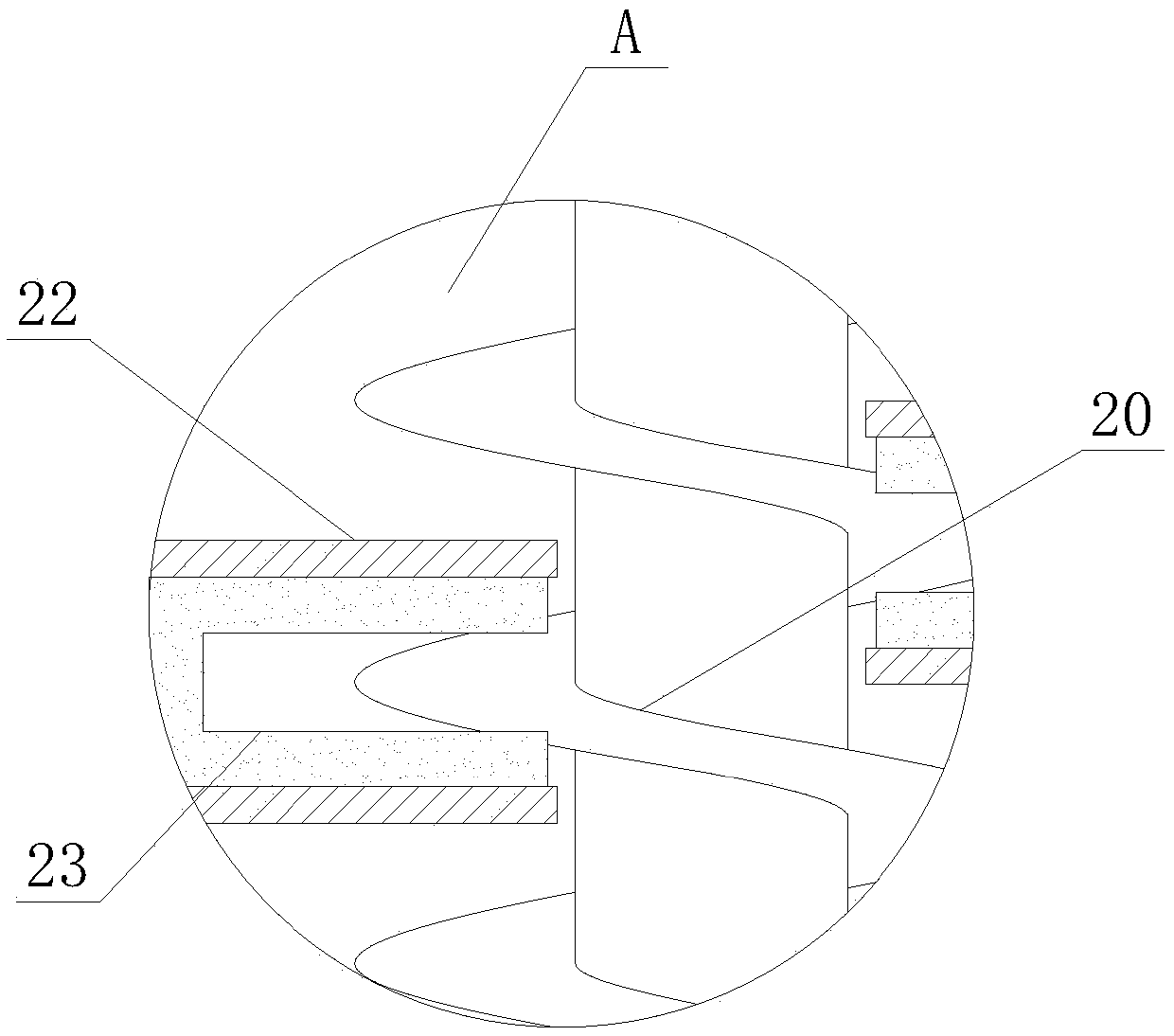

Well cellar type tobacco transplanter

InactiveCN112753331ARealize linkage workGuaranteed synchronicityTransplantingAgricultural engineeringBiology

The invention provides a well cellar type tobacco transplanter, and relates to the technical field of tobacco transplanting appliances. The well cellar type tobacco transplanter comprises a vehicle body, a seedling throwing device is arranged on the vehicle body, a hole forming transplanting device is further arranged below the seedling throwing device, a seedling placing frame is further arranged above the seedling throwing device, and a linkage mechanism for driving the hole forming transplanting device and the seedling throwing device to act synchronously is further mounted on the vehicle body. The well cellar type tobacco transplanter solves the following problems that in the prior art, a device is provided with too many working assemblies, each mechanism is independently provided with a power assembly, the complexity of the device is increased, and the action synchronism of all the mechanisms cannot be guaranteed; a single person holds a well cellar maker to walk and make holes, and other personnel follow the well cellar maker to carry out operations such as seedling throwing and water replenishing, so that time and labor are consumed; and an existing tobacco seedling putting structure is tedious, a large number of tobacco seedlings cannot be put in sequence, and working efficiency is low.

Owner:SHANDONG WEIFANG TOBACCO CO LTD

Rapid grouting method of deep overburden layer

ActiveCN106638606ATo achieve an organic combinationEliminate the disadvantages of the existing construction technology of drilling and groutingFoundation engineeringMaximum depthDrilling machines

The invention discloses a rapid grouting method of a deep overburden layer. The method comprises the following steps: step one, drilling to a maximum depth that a drilling machine can reach; step two, continuously drilling to a final hole depth; step three, filling till a hole orifice; step four, alternately pulling a casing pipe and supplementing filler into the hole; step five, supplementarily injecting the filler; step six, cleaning the hole, embedding a hole orifice pipe and waiting setting; step seven, cleaning the hole till the section bottom of a next grouting section, not picking up the drill after punching the hole, and taking a drill rod as a grouting pipe and grouting via a hole orifice sealing method; step eight, repeating the step seven, sectionally cleaning the hole and grouting till a final hole and completing rapid grouting of the deep overburden layer. Through the rapid grouting method of the deep overburden layer, the technical problems of high drilling accident rate and low working efficiency caused by curtain grouting construction in the deep overburden layer can be solved; the grouting effect and the construction efficiency are effectively improved; the rapid-construction, economical and efficient purpose is achieved.

Owner:GEZHOUBA GROUP FOUND ENG

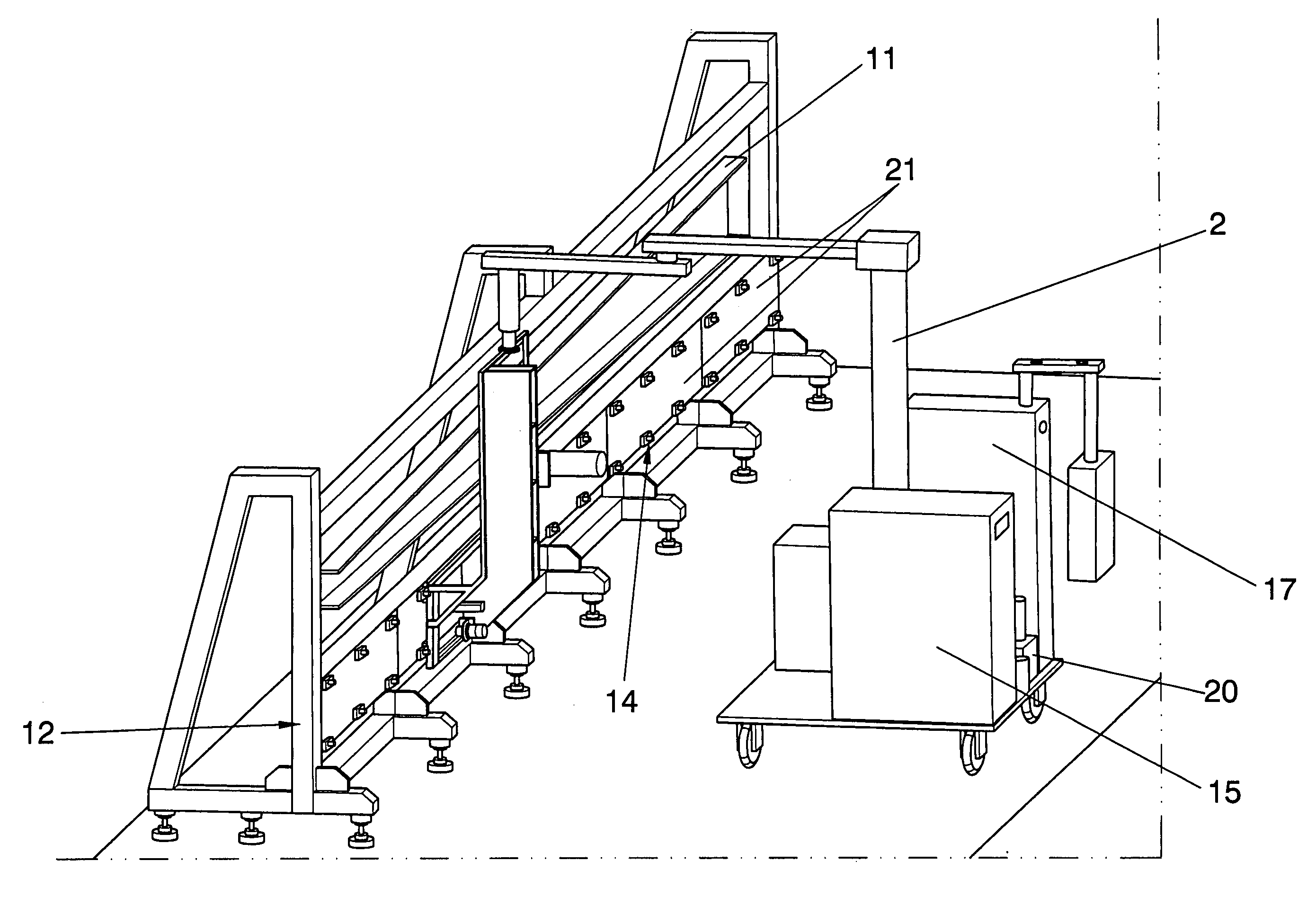

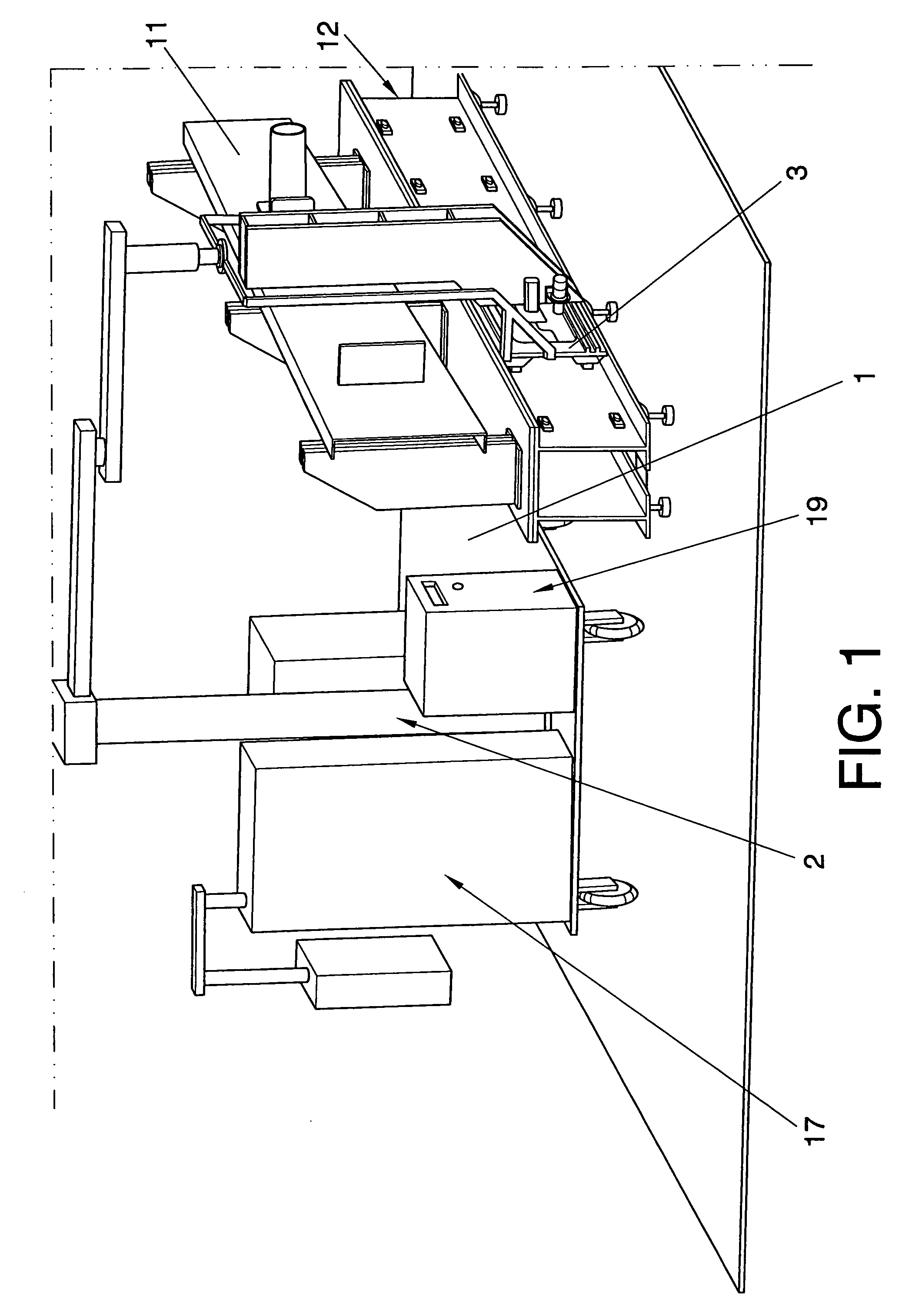

Portable robot

InactiveUS8347470B2Shorten drilling timeSave production timeDrilling/boring measurement devicesThread cutting machinesEngineeringMechanical engineering

Portable robot for carrying out the drilling process in the assembly of aeronautical components which are secured on a support known as a stand. The robot comprises a displaceable platform in order to permit it to be located close to the stand, and an arm, which supports a frame comprising a beam intended to support a drilling head that can be displaced in the three axes.

Owner:AIRBUS OPERATIONS SL

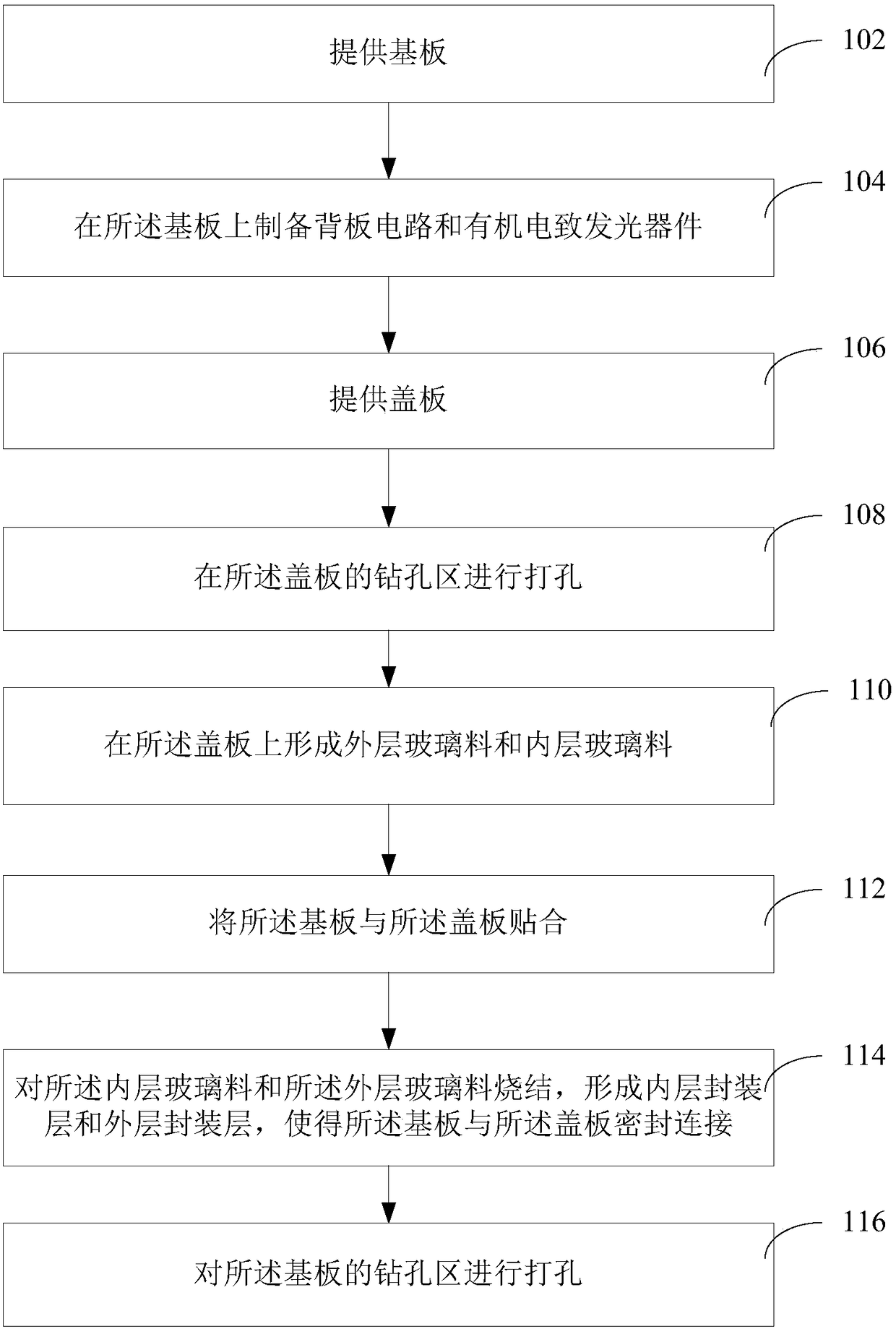

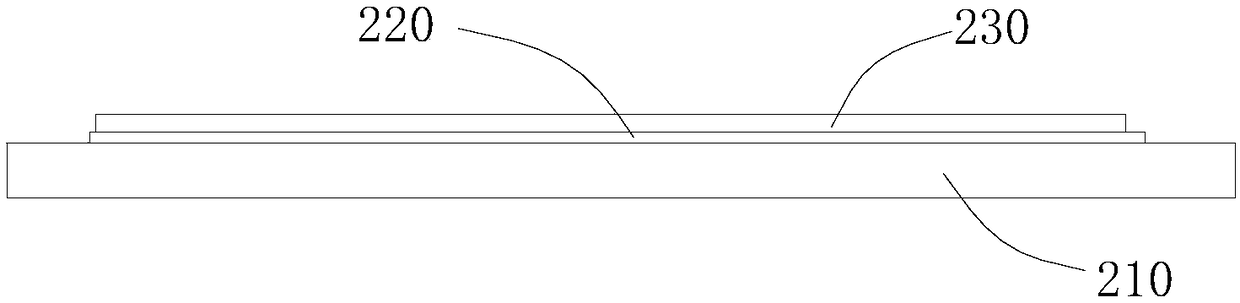

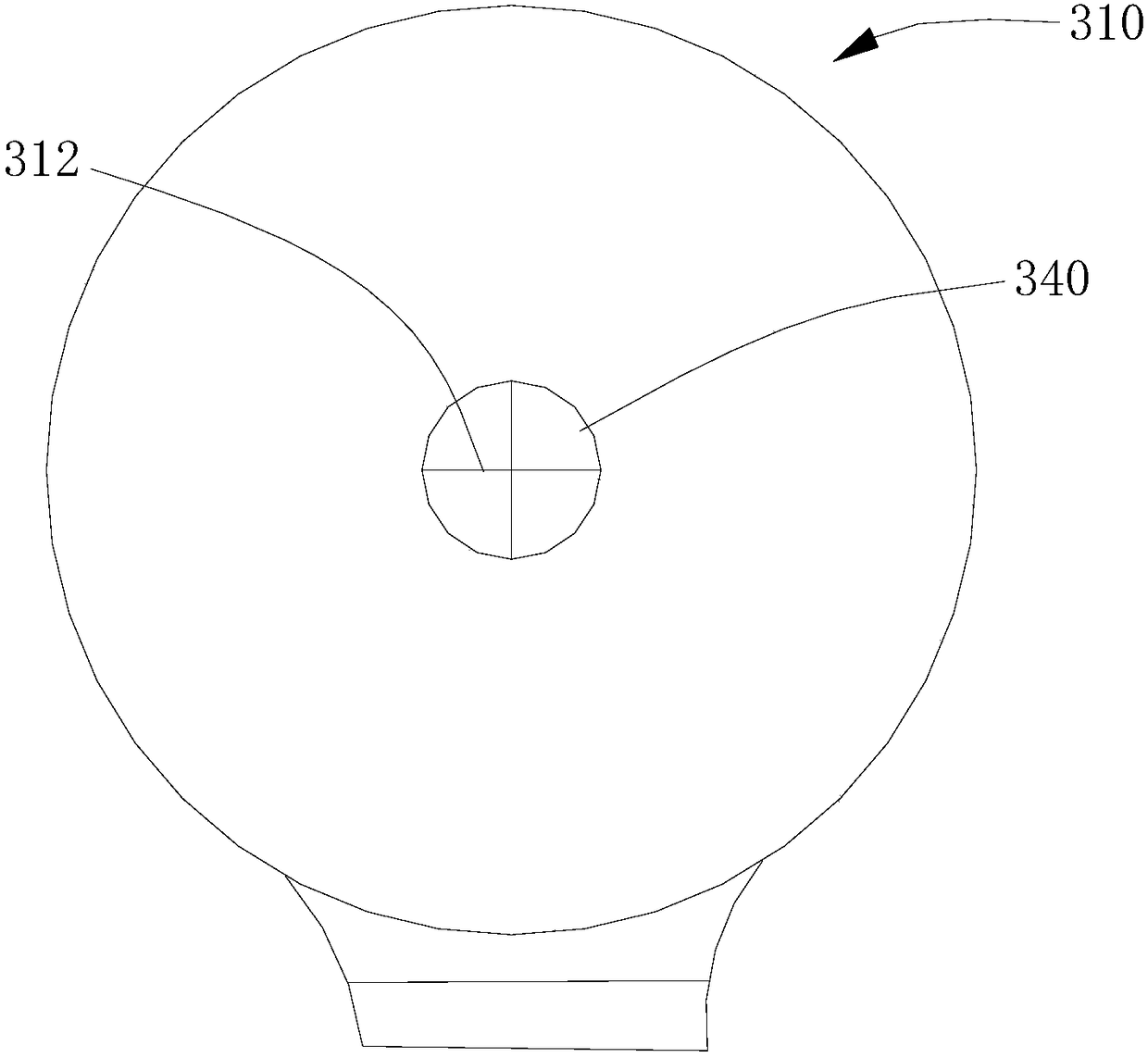

Organic light-emitting display device and preparation method thereof

ActiveCN108336242AGood lookingShorten drilling timeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceDisplay device

The invention relates to an organic light-emitting display device and preparation method thereof. The method comprises the following steps: providing a substrate; preparing a backboard circuit and anorganic electroluminescent device on the substrate; providing a cover plate; drilling on a drilling area of the cover plate; forming outer frit and inner frit on the cover plate; fitting the substratewith the cover plate, sintering the outer frit and the inner frit, thereby enabling the substrate to hermetically connect with the cover plate; and drilling the drilling area of the substrate. The substrate is drilled before fitting and packaging the substrate and the cover plate, so that the drilling process is reduced after the substrate and the cover plate are packaged, thereby effectively shortening the drilling time on the substrate, reducing drilling heat quantity, and avoiding the influence on the packaged frit; the package effect is better, and the whole appearance of the organic light-emitting display device is better.

Owner:TRULY HUIZHOU SMART DISPLAY

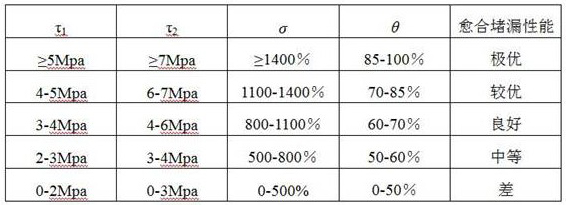

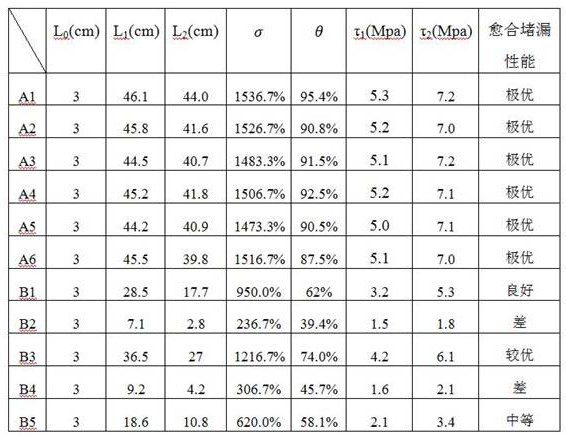

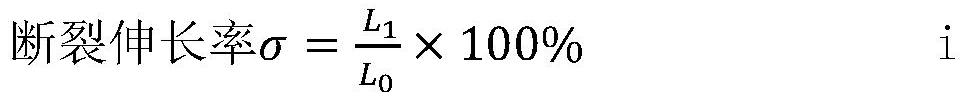

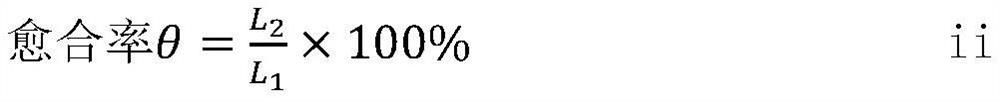

Non-covalent bond synergistic self-healing gel plugging agent as well as preparation method and application thereof

ActiveCN113501910AStrong pressure capacityStrong pressure resistanceDrilling compositionActive agentSurface-active agents

The invention relates to a non-covalent-bond synergistic self-healing gel plugging agent as well as a preparation method and application thereof, and belongs to the technical field of leakage prevention and plugging of drilling fluid. The plugging agent comprises the following raw materials in parts by weight: 15-30 parts of a first copolymerization reaction monomer, 12-35 parts of a second copolymerization reaction monomer, 0.3-7 parts of a surfactant, 0.01-1 part of an initiator, 0.5-4 parts of a first cross-linking agent, 1-4 parts of a second cross-linking agent, 0.05-0.3 part of an accelerant and the balance of a sodium chloride aqueous solution, and the sum of the raw materials is 100. On the basis of dual non-covalent bonds prepared by two-step polymerization, a weak network is formed at a target horizon by virtue of ionic bonds to quickly realize primary healing, and then a strong network based on hydrophobic association reaction is formed on the basis of the weak network of the ionic bonds, so that an energy dissipation mechanism based on the strong / weak network is formed, and good mechanical strength is ensured; and compared with covalent bonds, the multiple non-covalent network self-healing gel has a better healing effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

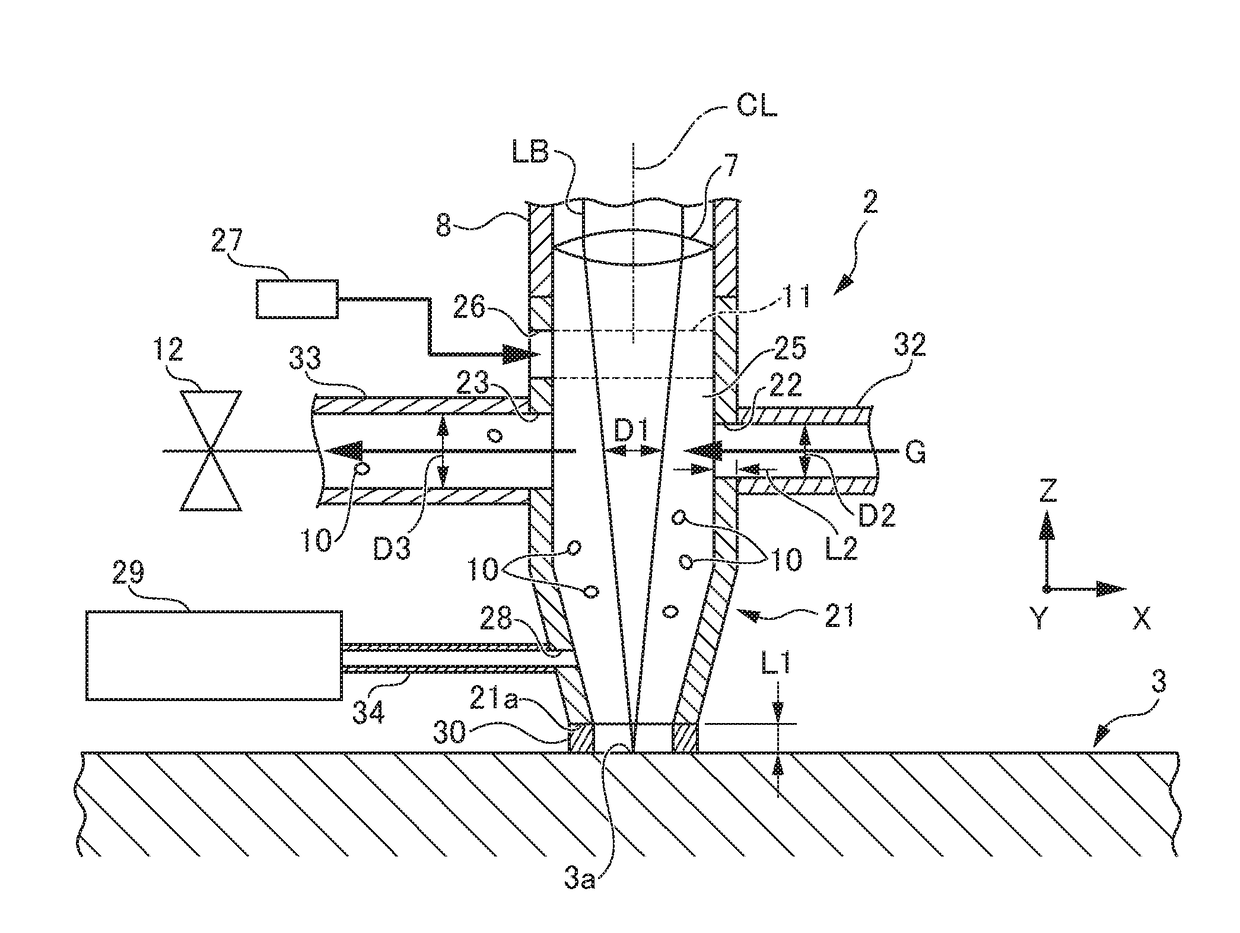

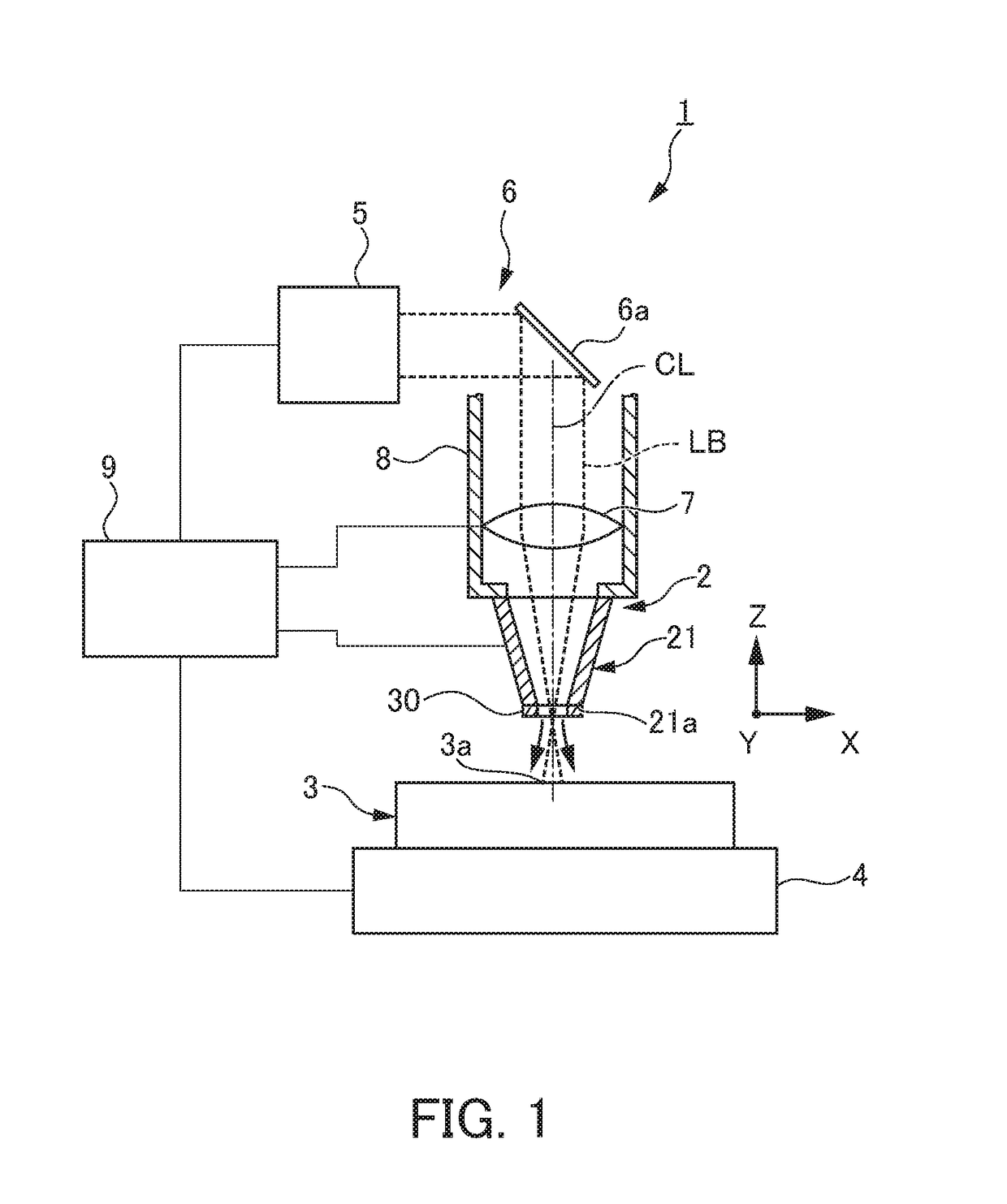

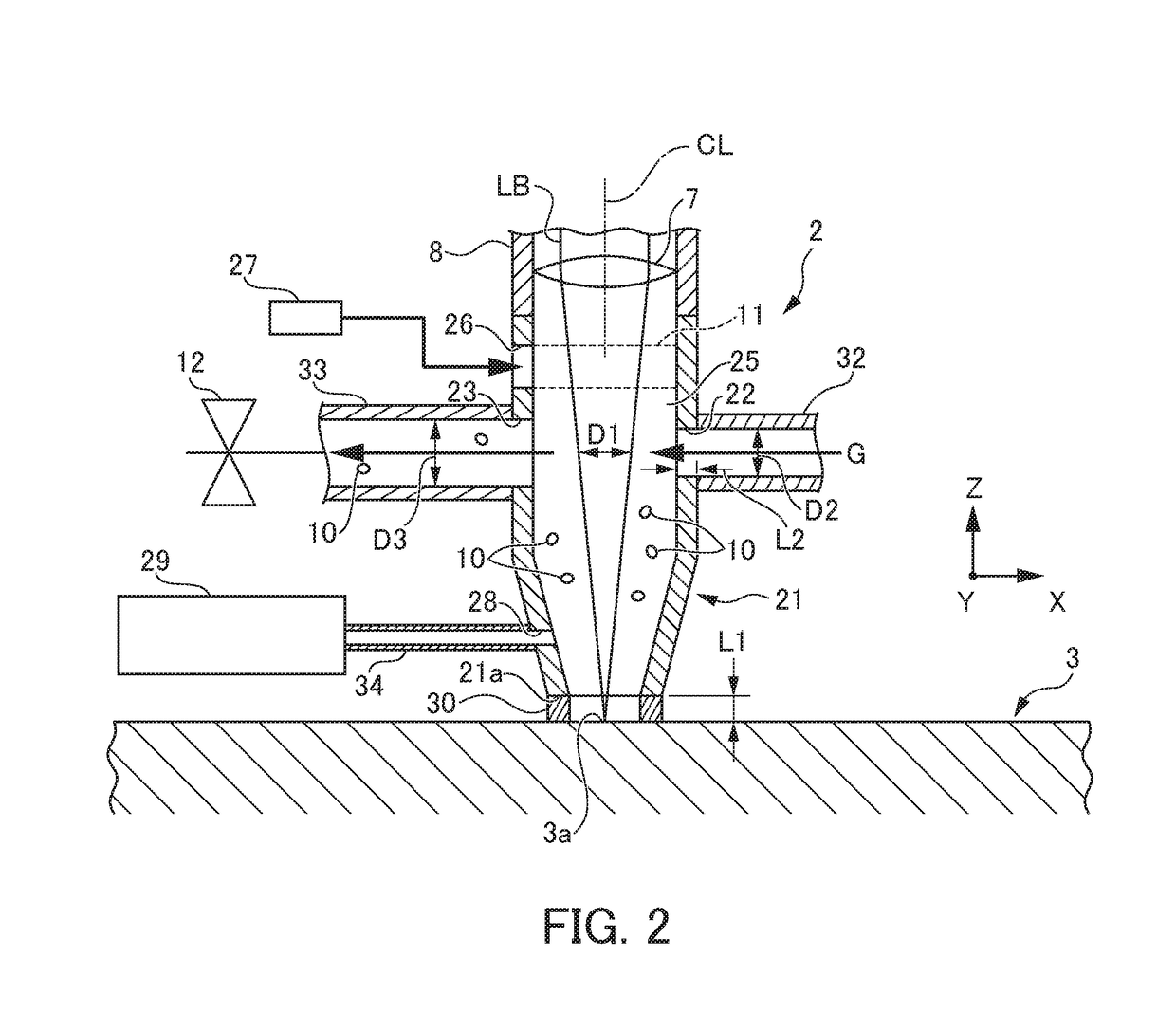

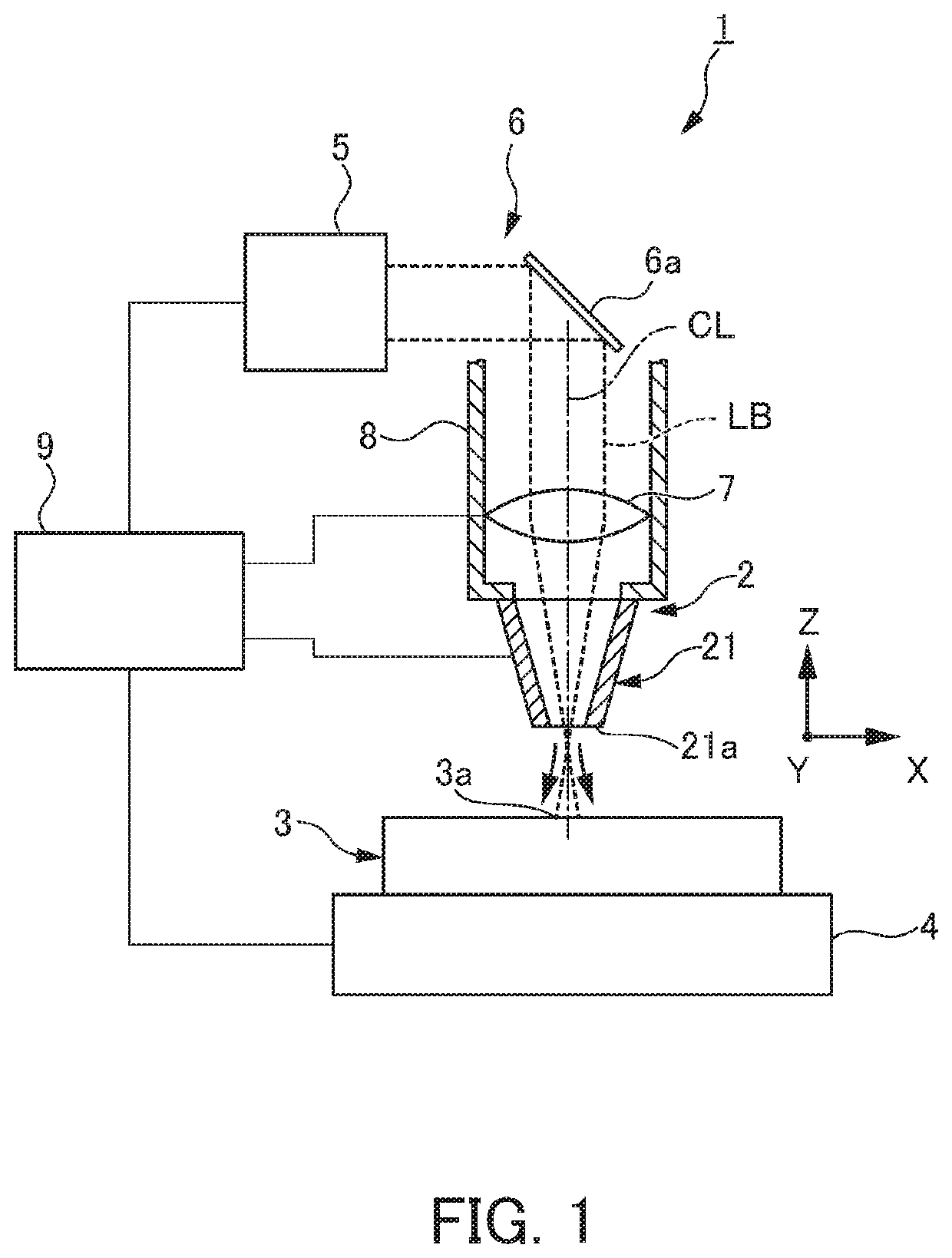

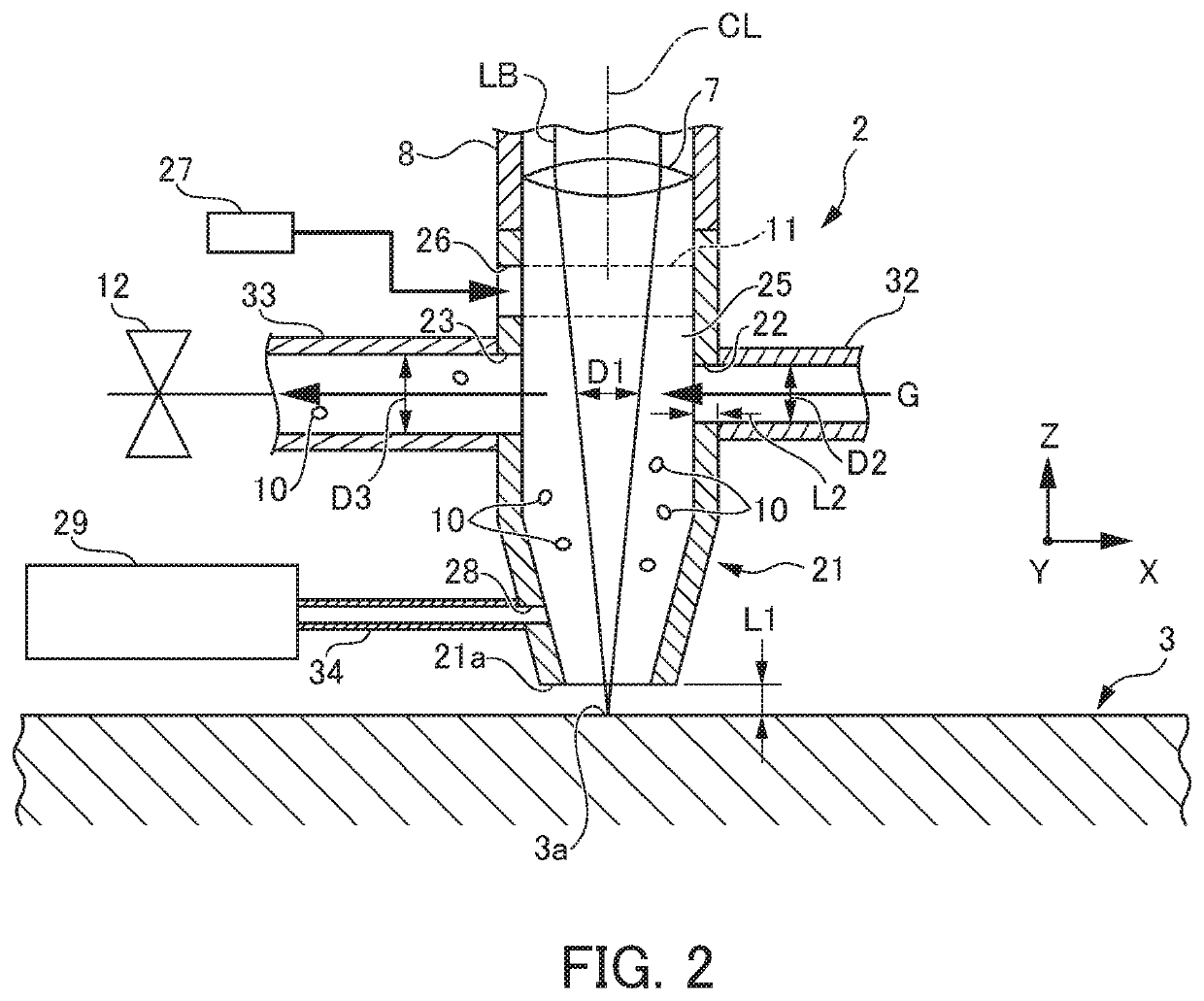

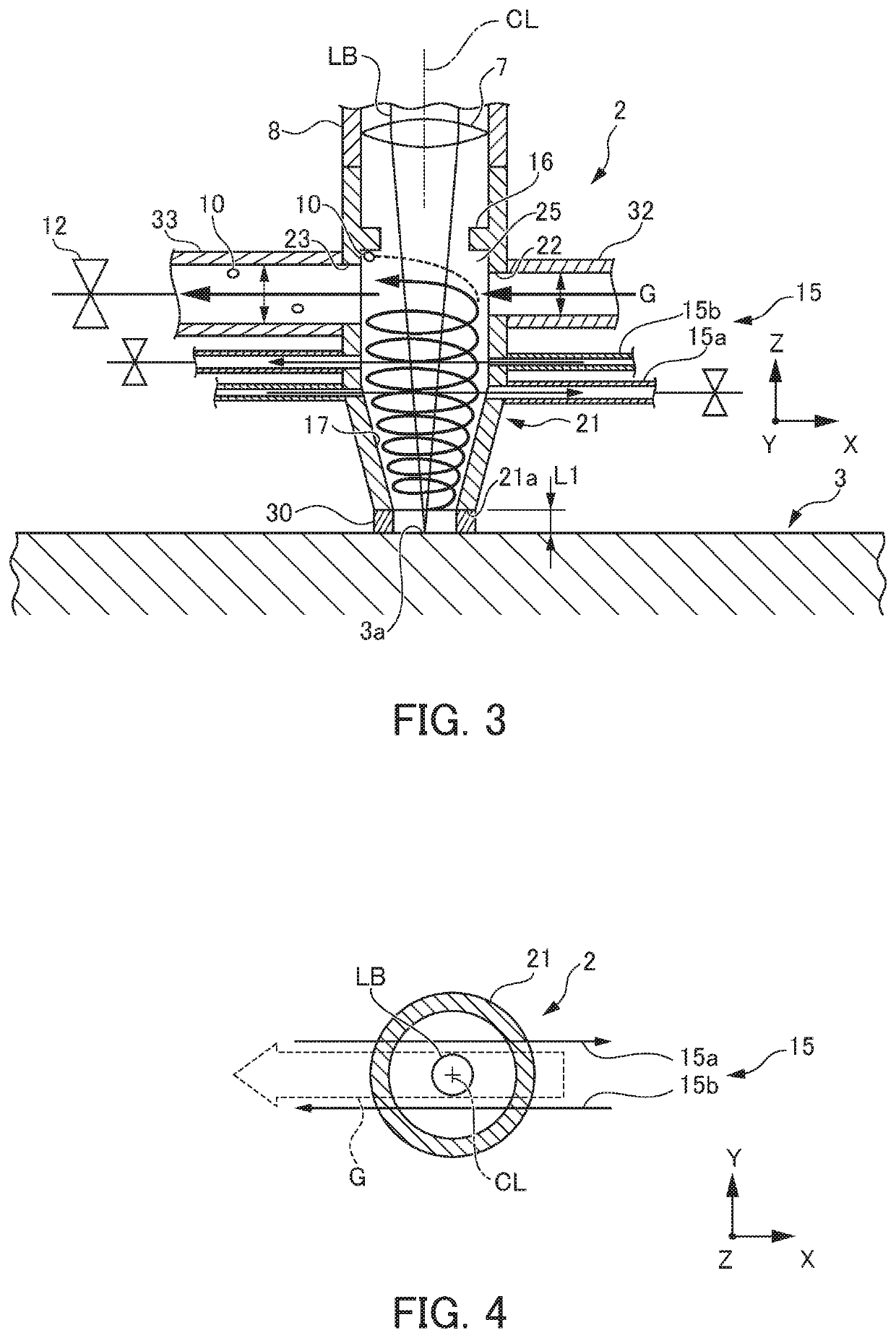

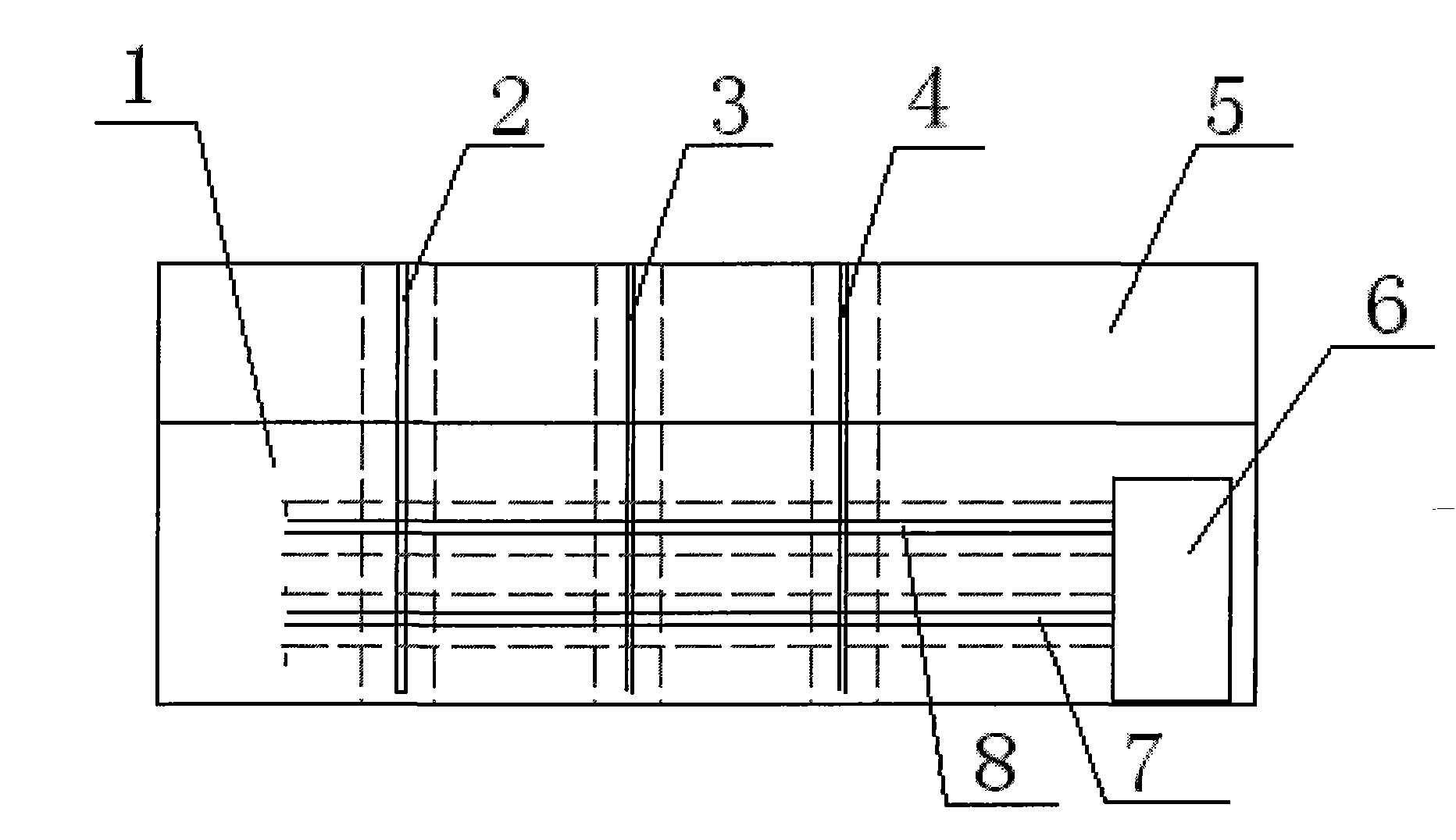

Nozzle for laser processing head

ActiveUS20180200832A1Adhesiveness decreaseDrilling time be reduceLaser beam welding apparatusSmall holeNozzle

To provide a nozzle for laser processing head capable of reliably drilling a small hole when drilling of the workpiece is performed by using a laser machine. A nozzle includes: a nozzle tip body that irradiates a workpiece with a laser beam; a charge port formed in the nozzle tip body; an exhaust port formed in the nozzle tip body so as to oppose to the charge port; and an elastic member that is provided in a tip end of the nozzle tip body and contacts with the workpiece while elastically extending and contracting in the axial center direction of the nozzle tip body. The nozzle supplies gas to the inside of the nozzle tip body along a gas flow path extending from the charge port to the exhaust port in a form of crossing across the laser beam in the nozzle tip body, to generate a negative pressure in the vicinity of an opening part of a tip end of the nozzle tip body. The elastic member contacts with the workpiece and improves the degree of enclosure of the nozzle tip body by the workpiece. Thereby, higher negative pressure than the negative pressure is generated.

Owner:FANUC LTD

Drilling machine for exploration engineering

InactiveCN109577879ASimple structureEasy to operateEarth drilling toolsConstructionsSprocketUltimate tensile strength

The invention belongs to the technical field of drilling machines, and particularly relates to a drilling machine for exploration engineering. The drilling machine comprises an L-shaped mud blocking rod, a jack, a Z-shaped rod, a sleeve, a spring, a connecting rod, a mounting frame, a guide rod, a first chain wheel, a threaded rod, a sliding block, a first motor, a shaft rod, a second chain wheel,a chain, a push handle, a fixing rod, a mounting plate, a second motor, a drill pipe, rollers, a U-shaped plate and a steel wire brush. According to the drilling machine for the exploration engineering, due to the cooperation of the chain wheels, the threaded rod, the mounting plate, the sliding block, the jack and the chain, better and quicker drilling can be carried out, the working intensity of workers is greatly reduced, a large amount of labor is liberated, and meanwhile, the drilling efficiency is improved. The steel wire brush, the L-shaped mud blocking rod, the sleeve, the spring andthe U-shaped plate are matched with one another so that soil on the surface of the drill pipe can be better cleaned away, the problem that the drilling efficiency is poor due to too much soil on the surface of the drill pipe is avoided, and the drilling time is greatly shortened.

Owner:XUZHOU SHENWEI FOUND MACHINERY TECH CO LTD

Self-healing gel leakage-proof agent while drilling under covalent bond-non-covalent bond composite action and preparation method and application thereof

ActiveCN113943558ASolve the shortcomings of insufficient strengthReduce drilling timeDrilling compositionPolymer scienceCross linker

The invention relates to a self-healing gel leakage-proof agent while drilling under covalent bond-non-covalent bond composite action and a preparation method and application thereof. The self-healing gel leakage-proof agent while drilling comprises the following raw materials in parts by weight: 20-40 parts of a first comonomer, 10-20 parts of a second comonomer, 0.01-1 part of an initiator, 1-4 parts of a first cross-linking agent, 1-3 parts of a second cross-linking agent, 1-3 parts of a hydrogen bond enhancer and the balance of an acetic acid aqueous solution, and the sum of the raw materials is 100. The material is injected into a stratum fracture in a form of particles, and can be healed into integral gel with good mechanical strength in the stratum fracture, so that good plugging of fracture pores is realized, and due to the self-healing characteristic of the material, micro cracks generated by a plugging layer can be self-repaired, so that good and stable plugging is formed, and the bearing capacity is high, and the applicable temperature is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Laser machine

ActiveUS10562131B2Reliably drillingPreventing an optical system from being contaminatedLaser beam welding apparatusLaser processingLight guide

To provide a laser machine capable of reliably drilling a small hole when drilling of the workpiece is performed. A laser machine 1 includes: a laser oscillator; a light guide path; a processing head; and a nozzle. The nozzle includes: a nozzle tip body that irradiates the workpiece with the laser beam; a charge port formed in the nozzle tip body; and an exhaust port formed in the nozzle tip body so as to oppose to the charge port. The nozzle supplies gas to the inside of the nozzle tip body along a gas flow path extending from the charge port to the exhaust port in a form of crossing across the laser beam in the nozzle tip body, to generate a negative pressure in the vicinity of an opening part of a tip end of the nozzle tip body.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[apparatus and methods for induction-sfl logging] [apparatus and methods for induction-sfl logging]](https://images-eureka.patsnap.com/patent_img/0511fc5c-0d89-43c5-9520-671b7e0a3125/US20050127917A1-20050616-D00000.png)

![[apparatus and methods for induction-sfl logging] [apparatus and methods for induction-sfl logging]](https://images-eureka.patsnap.com/patent_img/0511fc5c-0d89-43c5-9520-671b7e0a3125/US20050127917A1-20050616-D00001.png)

![[apparatus and methods for induction-sfl logging] [apparatus and methods for induction-sfl logging]](https://images-eureka.patsnap.com/patent_img/0511fc5c-0d89-43c5-9520-671b7e0a3125/US20050127917A1-20050616-D00002.png)