Deep-hole smooth tunnel blasting system and construction method for tunnel

A construction method and deep hole technology, applied in the field of blasting, to achieve the effect of perfecting blasting procedures, reducing damage and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

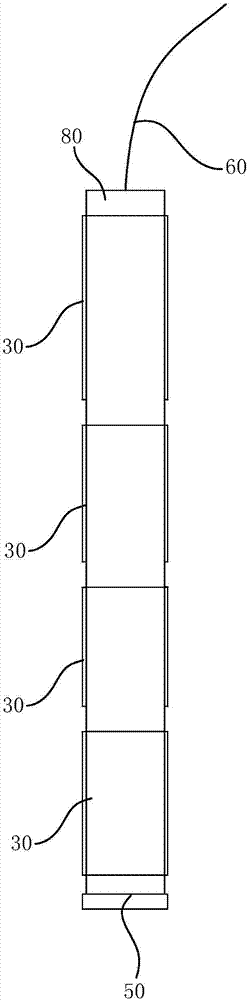

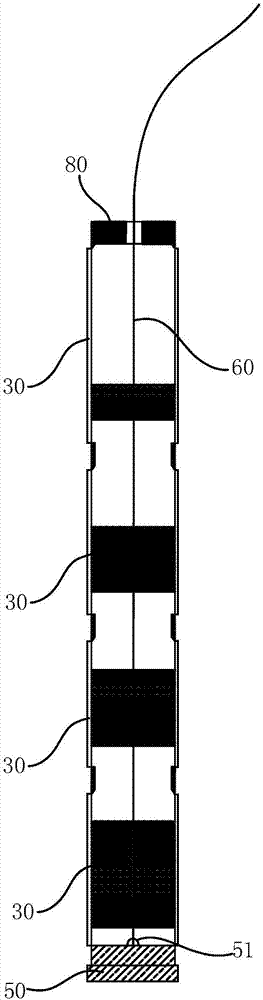

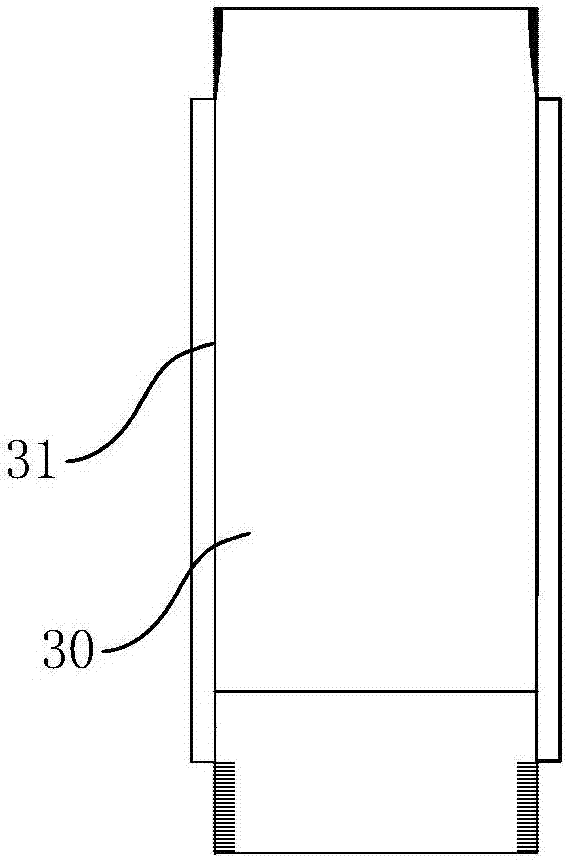

[0059] combine Figure 1 to Figure 10 , the present invention is further described:

[0060] The deep-hole smooth tunnel blasting system includes a multi-axis drilling mechanism for drilling coal mines, and a deep-hole smooth blasting mechanism is arranged in the blast hole drilled by the multi-axis drilling mechanism;

[0061] The multi-axis drilling mechanism includes a drilling rod 20 arranged on the adjustment bracket 10, the long direction of the drilling rod 20 is horizontal and one end is connected with a horizontal driving mechanism, and the horizontal driving mechanism drives the drilling rod 20 to move horizontally and implement the drilling operation , the spatial position of the drill rod 20 located on the adjustment bracket 10 is adjustable;

[0062] The deep hole smooth surface blasting mechanism includes a plurality of charging tube standard sections 30 arranged in the blast hole, the mouths of the charging tube standard sections 30 are sequentially connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com