Organic light-emitting display device and preparation method thereof

A light-emitting display and organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as low product reliability, poor product appearance, packaging impact, etc., achieve better packaging effect, shorten the drilling time Hole time, effects of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

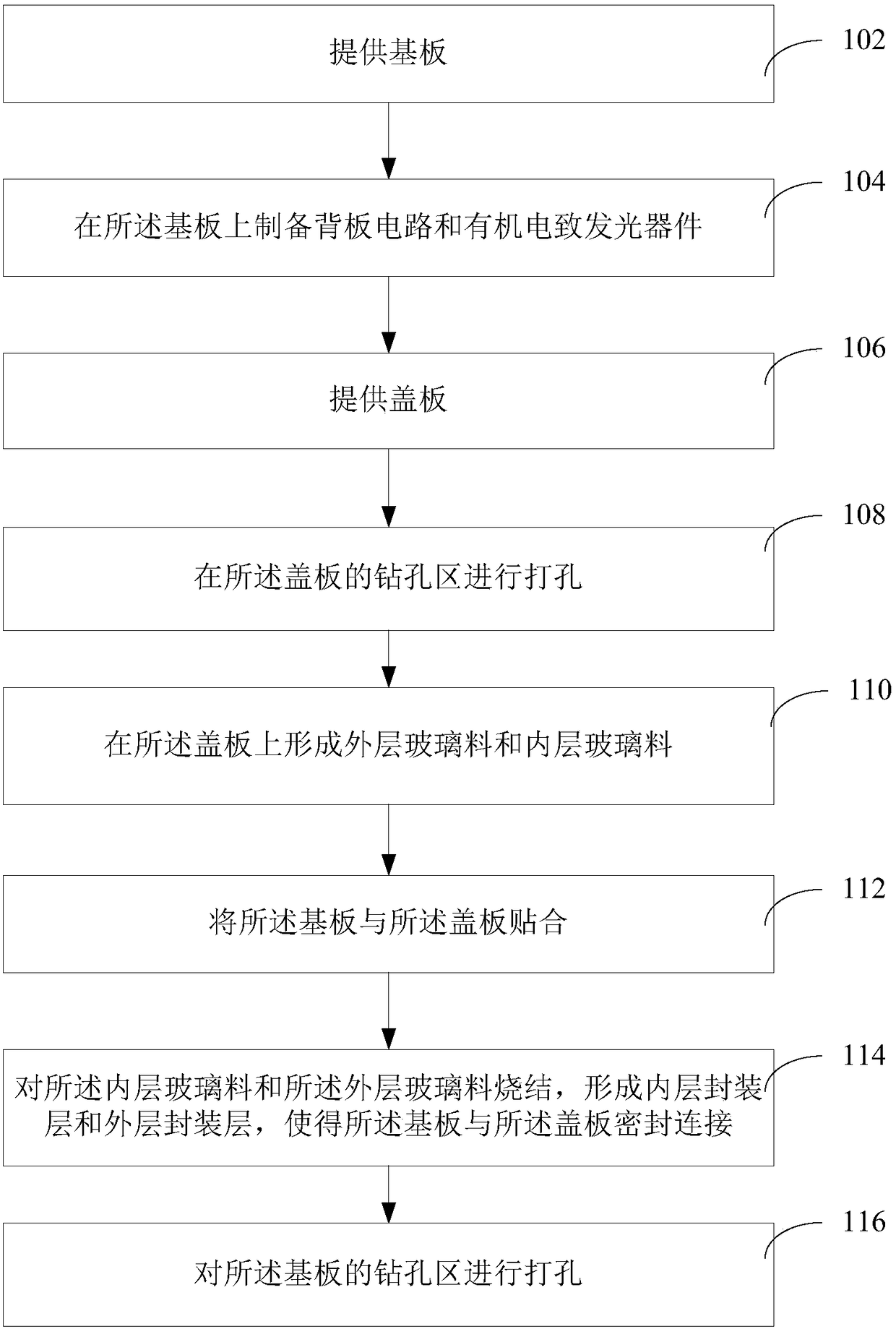

[0044] For example, a method for preparing an organic light-emitting display device includes: providing a substrate; preparing a backplane circuit and an organic electroluminescent device on the substrate; providing a cover plate; drilling holes in the drilling area of the cover plate; Forming an outer layer of glass frit and an inner layer of glass frit on the cover plate; attaching the substrate to the cover plate; sintering the inner layer of glass frit and the outer layer of glass frit to form an inner encapsulation layer and an outer encapsulation layer, so that the substrate and the cover plate are hermetically connected; and drilling holes in the drilling area of the substrate.

[0045] In the above embodiment, the cover plate is drilled before the base plate and the cover plate are bonded and packaged, so that the drilling process after the base plate and the cover plate are packaged is reduced, the drilling time of the base plate is effectively shortened, the drill...

Embodiment 1

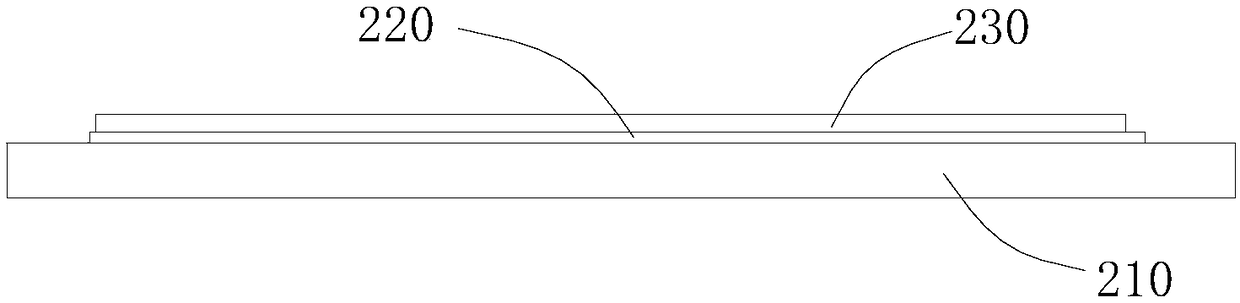

[0101] Step 1. Fabricate the backplane circuit and anode on the glass substrate according to the conventional LTPS process. Remove all the metal and photoresist at the punch hole and encapsulation layer. Subsequently, organic light-emitting and cathode and other functional layers are prepared, such as figure 2 .

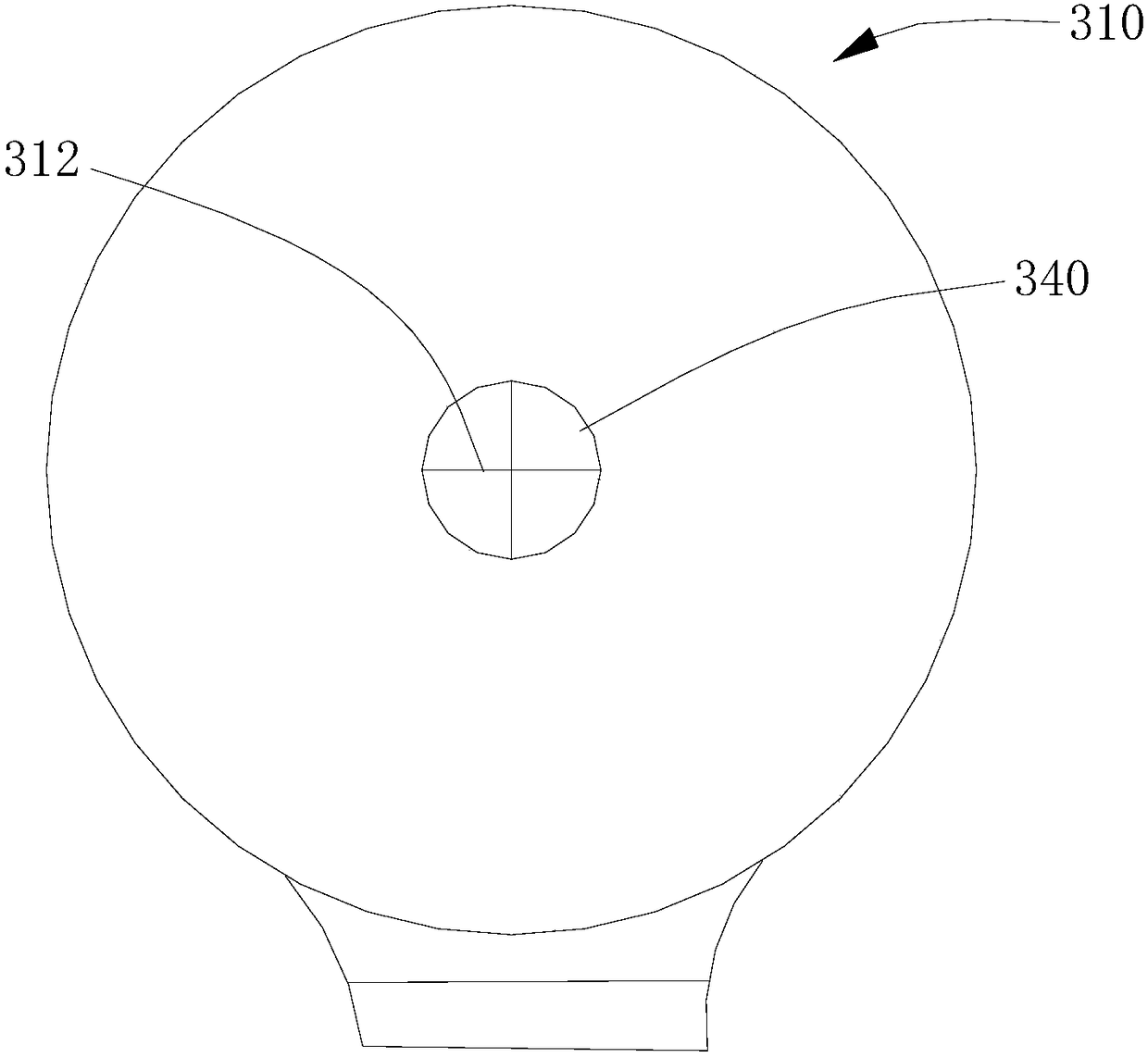

[0102] Step 2. Screen-print the coordinates of the hole on the cover, and mark the hole as the center of a circle or a "ten" or similar shape. Such as image 3 . The diameter of the opening is smaller than the diameter of the frit pattern of the inner ring.

[0103] Step 3: Use punching equipment to make holes on the cover plate according to the position of the hole mark.

[0104] Step 4. Silk-screen the Frit pattern on the cover, including the outer pattern Frit and the inner pattern Frit, such as Figure 4 .

[0105] Step 5: The base plate and the cover plate are bonded together, and the frit pattern of the inner ring is laser sintered first, and then the f...

Embodiment 2

[0108] Step 1. According to the conventional LTPS process, make the backplane circuit on the glass substrate and remove all the metal and photoresist at the position of the anode hole and the position of the packaging layer, and then prepare functional layers such as organic light emitting and cathode, such as figure 2 .

[0109] Step 2. Screen-print the coordinates of the opening on the cover plate. The opening is marked as a circle or a "ten", such as image 3 .

[0110] Step 3: Use punching equipment to make holes on the cover plate according to the position of the hole mark.

[0111] Step 4. Silk-screen the Frit pattern on the cover, including the outer pattern Frit and the inner pattern Frit, such as Figure 4 .

[0112] Step 5: The base plate and the cover plate are bonded together, and the frit pattern of the inner ring is laser sintered first, and then the frit pattern of the outer ring is sintered, such as Figure 5 .

[0113] Step 6: Opening holes on the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com