Ultrasonic vibration cord coring drill tool

A coring tool and ultrasonic technology, which is applied to vibration drilling, undisturbed core extraction devices, drilling equipment, etc., can solve the problems of low drilling efficiency and high cost in highly drillable formations, improve drilling efficiency and reduce drilling costs. Intensity, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

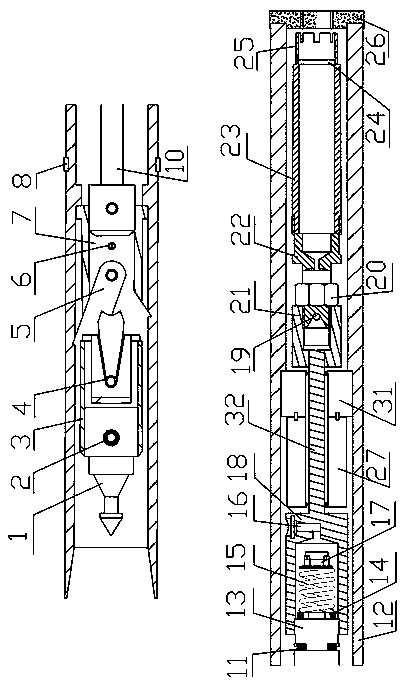

[0017] see figure 1 and figure 2 As shown, the spear head 1 of the present invention is connected with the cartridge recovery pipe 3, and the cartridge recovery pipe 3 forms a movable connection with the cartridge seat 7 through the first elastic pin 2. When the cartridge recovery pipe 3 goes up, the bullet caliper 5 Gravity falls, and the bullet caliper 5 is connected with the bullet holder 7 through the second elastic pin 6,

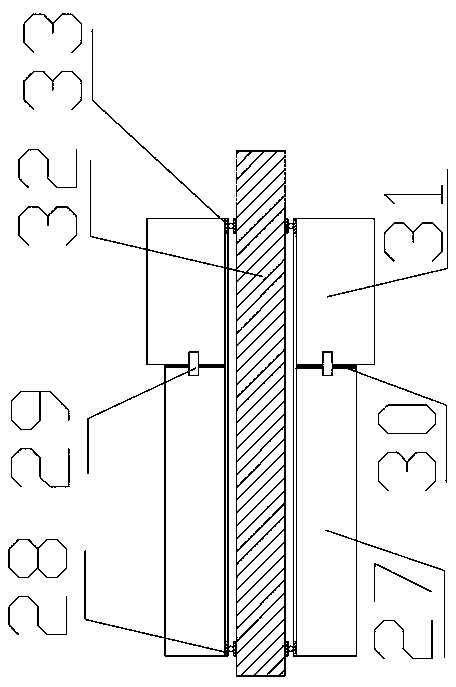

[0018] When the bullet holder 7 goes down, it drives the bullet caliper 5 to go down together. When the bullet caliper 5 is closed by the thrust of the bullet recovery tube 3, the two pieces of the bullet caliper 5 remain open, and the two pieces of the bullet caliper 5 are stuck on the spring 4 to ensure that the inner tube 23 will not go up due to the thrust generated during the drilling process; the piezoelectric ceramic vibrator 31 reaches the inner diameter reinforcement of the outer tube 12, the battery 27 and the piezoelectric ceramic vibrator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com