Technology for constructing and stopping leakage of freezing borehole

A technology of freezing drilling and technology, which is applied in the direction of earthwork drilling, shaft equipment, mining equipment, etc., can solve the problems of long plugging time, unsatisfactory effect, low specific gravity, etc., achieve low cost, easy to popularize and use, and variety many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

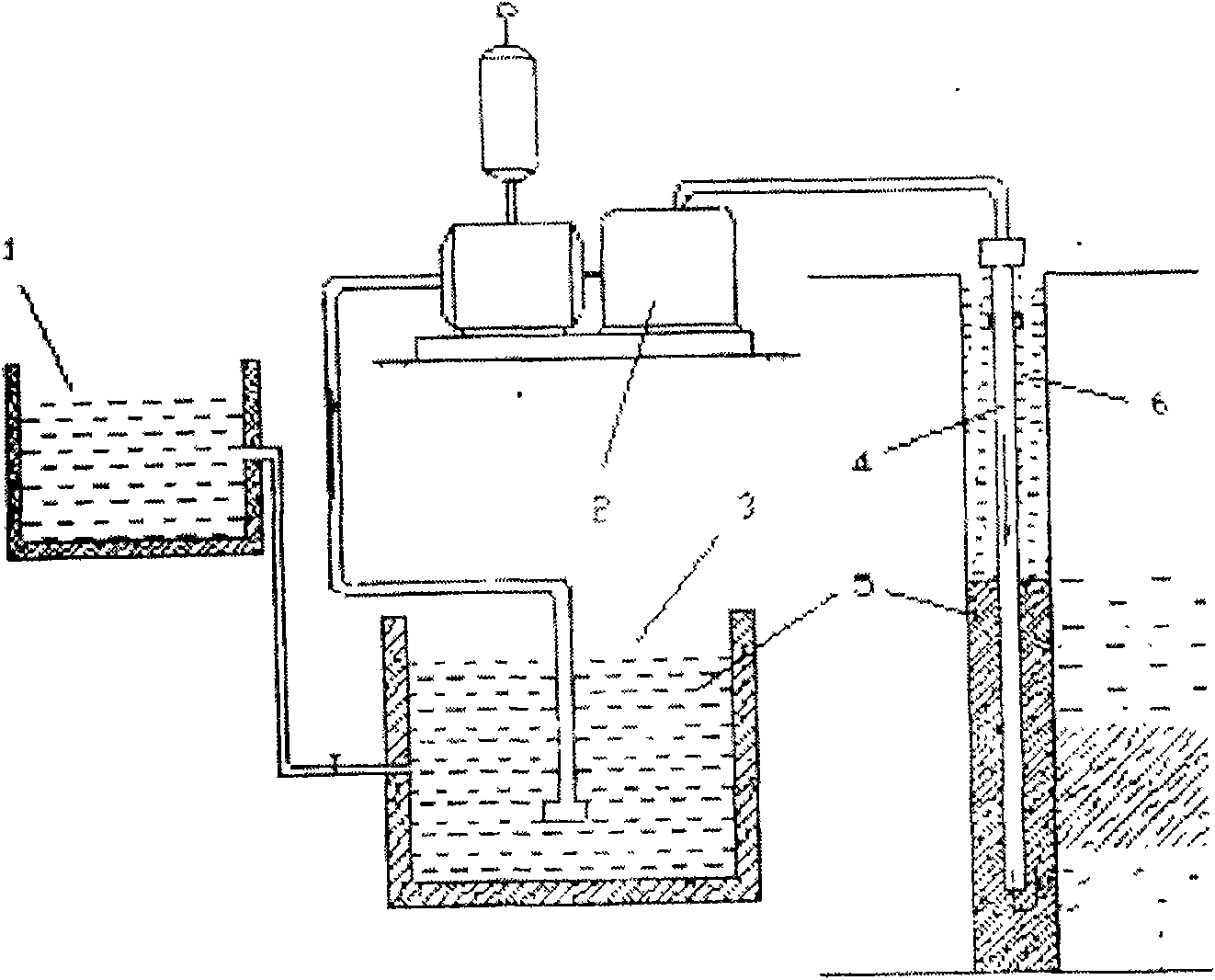

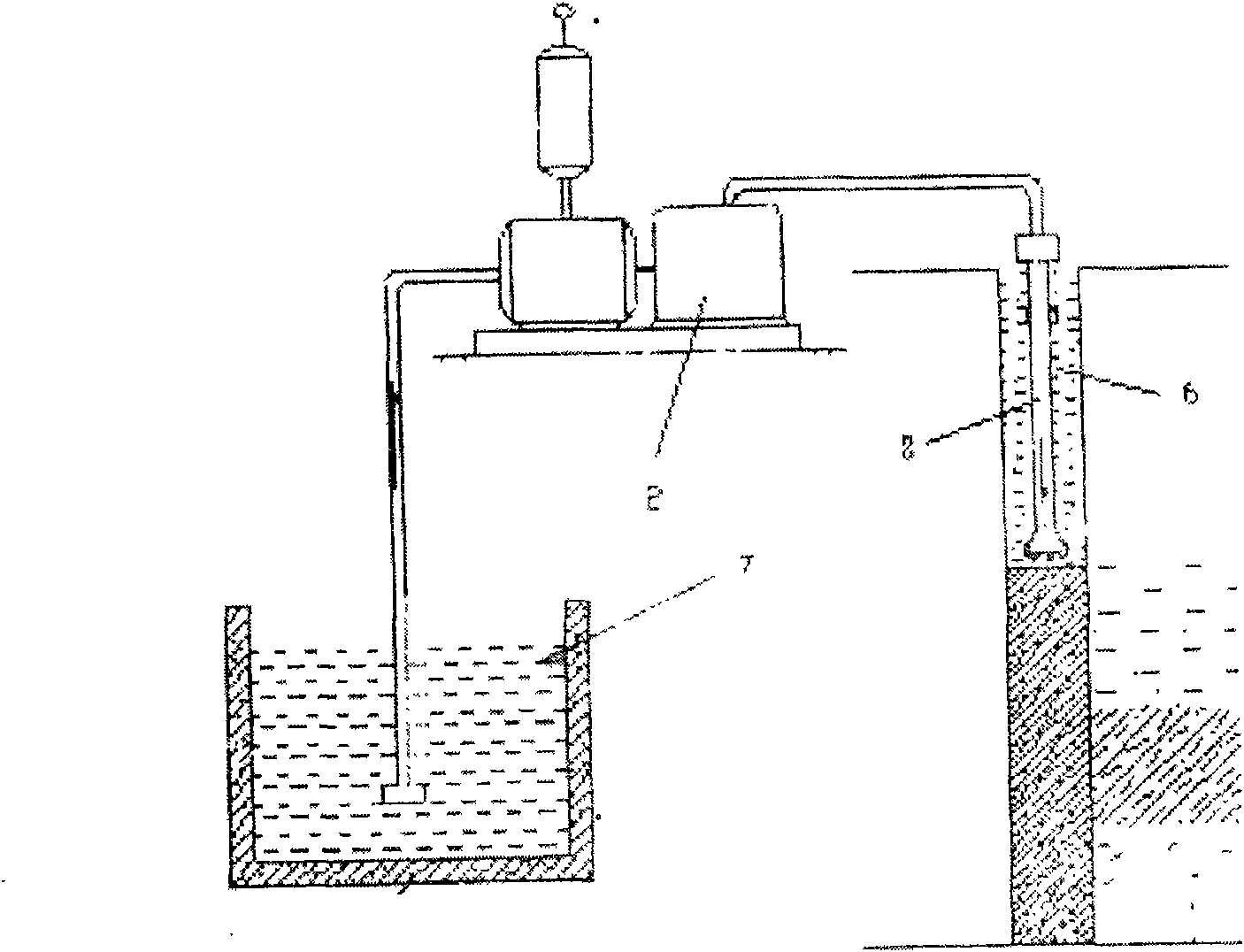

[0017] As shown in the figure, a freeze-drilling construction plugging process, the process steps are: ①Prepare a certain amount of two-liquid chemical slurry 5 in the slurry tank 3 according to the leakage situation, ②Put out the drilling tool, remove the drill bit, Set the hollow drill pipe 4 to the position of the leakage layer. If the hollow drill pipe 4 is placed at a distance of 2 to 5 m from the bottom of the hole, ③Use a high-pressure pipeline to connect the mud pump 2 outlet to the position of the leakage layer. The upper end of the hollow drill pipe is sealed and connected, and the pumping port of the mud pump 2 is connected with the mud storage tank 3 with a high-pressure pipeline. ④Stir the two-liquid chemical slurry 5 in the mud storage tank 3 evenly. ⑤Start the mud pump and store the The well-stirred two-liquid chemical slurry 5 in the slurry tank 3 is pressed into the freezing hole through the hollow drill pipe 4 with a slurry pump 2 to inject the clean water in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com