Brine-based drilling fluid and preparation method thereof

A preparation method, drilling fluid technology, applied in the direction of chemical instruments and methods, drilling composition, etc., can solve the problem of engraving and testing its performance, to avoid clay softening and drill bit balling, increase drilling cost and drilling time, anti-pollution It can reduce the probability of sticking, reduce the drilling time and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The brine base drilling fluid described in the present embodiment 1 is constituted by the following components in mass percentage:

[0035] 1% fluid loss reducer JHFR-HP, 0.2% lubricant JHFD-S, 4% bentonite, 20%~84% special calcium chloride weighting agent, and the balance is water.

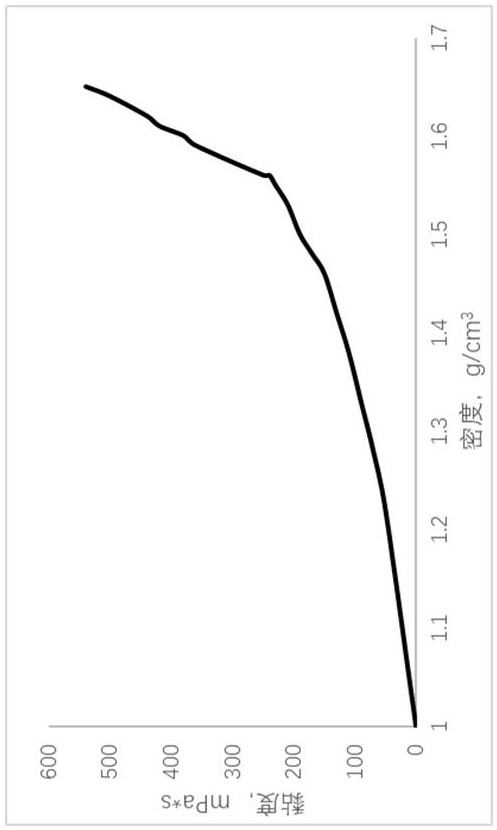

[0036] For the brine-based drilling fluid obtained in Example 1, the curve of the viscosity of the brine-based drilling fluid tested at 80°C as a function of density is as follows: figure 1 shown (see figure 1 ).

[0037] From figure 1 It is clearly seen that when the density of the brine drilling fluid of embodiment 1 reaches 1.60g / cm 3 When , the viscosity of the brine drilling fluid system can reach 200mPa·s, fully meeting the sand-carrying requirements during on-site drilling.

Embodiment 2

[0039] Each component of the brine base drilling fluid described in the present embodiment 2 is calculated according to the following mass percentages:

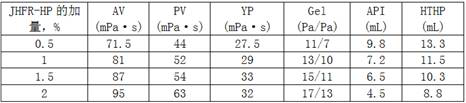

[0040] 0.5%~2% of JHFR-HP, 0.10% of JHFR-S, 50% of special calcium chloride weighting agent, 4% of bentonite, and the balance is water.

[0041] The preparation of the brine base drilling fluid of embodiment 2:

[0042] Step 1, a) Weigh respectively 0.5% JHFR-HP, 0.10% JHFR-S, 50% special calcium chloride weighting agent, 4% bentonite and water by mass percentage;

[0043] b) Weigh and weigh 1% of JHFR-HP, 0.10% of JHFR-S, 50% of special calcium chloride weighting agent, 4% of bentonite and water in percentage by mass;

[0044] c) Weigh and weigh 1.5% of JHFR-HP, 0.10% of JHFR-S, 50% of special calcium chloride weighting agent, 4% of bentonite and water according to mass percentage;

[0045] d) Weigh and weigh 2% of JHFR-HP, 0.10% of JHFR-S, 50% of special calcium chloride weighting agent, 4% of bentonite and water accordin...

Embodiment 3

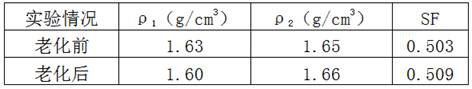

[0052] The brine base drilling fluid described in the present embodiment 3 is made up of following mass percentage:

[0053] JHFR-HP: 1%;

[0054] JHFR-S: 0.05%~0.20%;

[0055] Bentonite: 2%;

[0056] Special calcium chloride weighting agent: 70%;

[0057] The preparation of the brine base drilling fluid of embodiment 3:

[0058] Step 1, a) Weigh 1% of JHFR-HP, 0.05% of JHFR-S, 70% of special calcium chloride weighting agent, 2% of bentonite and water by mass percentage;

[0059] b) Weigh 1% of JHFR-HP, 0.10% of JHFR-S, 70% of special calcium chloride weighting agent, 2% of bentonite and water according to mass percentage;

[0060] c) Weigh 1% of JHFR-HP, 0.15% of JHFR-S, 70% of special calcium chloride weighting agent, 2% of bentonite and water according to mass percentage;

[0061] d) Weigh 1% of JHFR-HP, 0.20% of JHFR-S, 70% of special calcium chloride weighting agent, 2% of bentonite and water according to mass percentage;

[0062] Step 2. Put the weighed special cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com