Drilling fluid recycling method suitable for continental stratum containing high-activity clay

A drilling fluid and high activity technology, applied in the field of oil drilling, can solve the problems of occupying land, slow drilling speed, and high liquid viscosity, and achieve the effects of easy solid-liquid separation, excellent wellbore quality, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

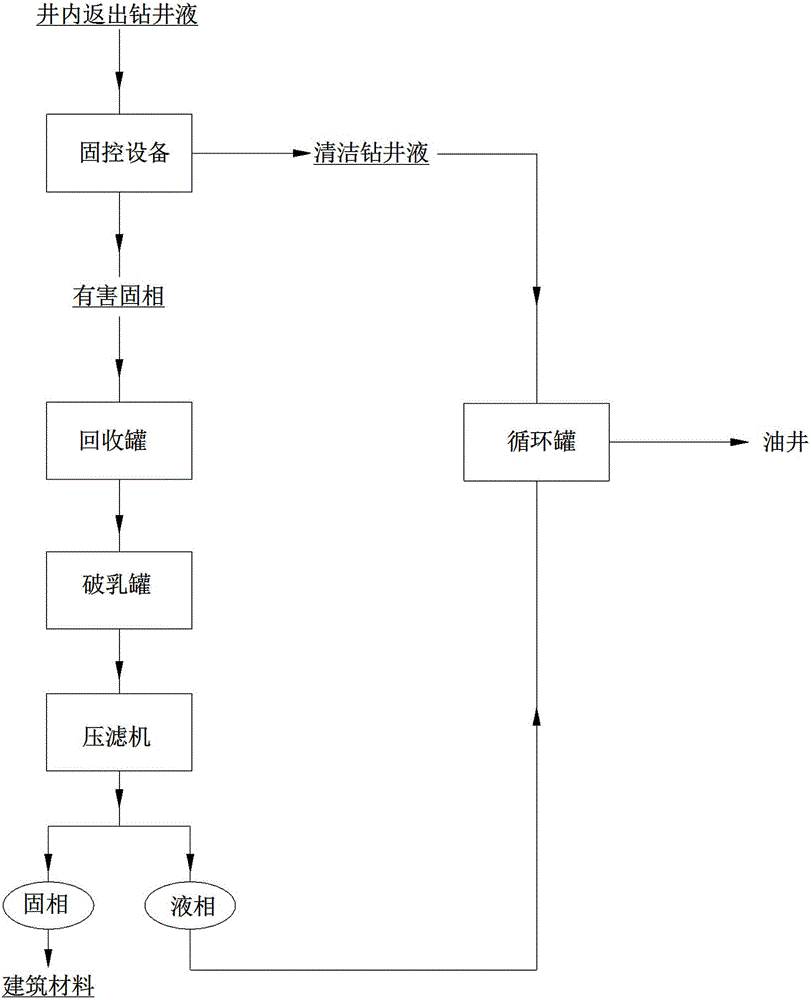

[0021] [Example 1] A method suitable for non-landing drilling fluid in continental formations containing high active clay. According to the different geological structures of the upper and middle and lower formations, different treatment methods are adopted. The process flow is as follows figure 1 shown, including the following steps:

[0022] S1. Upper drilling fluid treatment: the upper part is a strong slurry formation, including the following sub-steps:

[0023] S11. The prepared concentration of 3% CaCl 2 The solution is pumped into the circulation tank, and the CaCl in the circulation tank 2 The solution is pressed into the oil well through the tubing of the drilling bit, CaCl 2 The solution is mixed with the drilling fluid in the oil well, and the soil phase in the drilling fluid is flocculated to ensure that the drilling fluid is clean;

[0024] S12. Remove the flocs to the recovery tank through solid control equipment, enter the demulsification tank and add demulsi...

Embodiment 2

[0028] [Example 2] A method suitable for non-landing of drilling fluid in continental formations containing highly active clay. Different treatment methods are adopted for the different geological structures of the upper and middle and lower formations, including the following steps:

[0029] S1. Upper drilling fluid treatment: the upper part is a strong slurry formation, including the following sub-steps:

[0030] S11. The prepared concentration of 3.5% CaCl 2The solution is pumped into the circulation tank, and the CaCl in the circulation tank 2 The solution is pressed into the oil well through the tubing of the drilling bit, CaCl 2 The solution is mixed with the drilling fluid in the oil well, and the soil phase in the drilling fluid is flocculated to ensure that the drilling fluid is clean;

[0031] S12. Remove the flocs to the recovery tank through solid control equipment, enter the demulsification tank and add demulsifier to demulsify, and then pass through the filter ...

Embodiment 3

[0035] [Example 3] A method for keeping the drilling fluid from landing in continental formations containing highly active clay. Different treatment methods are adopted for the different geological structures of the upper and middle and lower formations, including the following steps:

[0036] S1. Upper drilling fluid treatment: the upper part is a strong slurry formation, including the following sub-steps:

[0037] S11. The prepared concentration of 4% CaCl 2 The solution is pumped into the circulation tank, and the CaCl in the circulation tank 2 The solution is pressed into the oil well through the tubing of the drilling bit, CaCl 2 The solution is mixed with the drilling fluid in the oil well, and the soil phase in the drilling fluid is flocculated to ensure that the drilling fluid is clean;

[0038] S12. Remove the flocs to the recovery tank through solid control equipment, enter the demulsification tank and add demulsifier to demulsify, and then pass through the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com