Patents

Literature

54results about How to "Solve the missing problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leakage detection method based on hydraulic model calibration of urban water supply network

InactiveCN104866899ASolve the missing problemSolutionData processing applicationsBiological modelsUrban water supplyEngineering

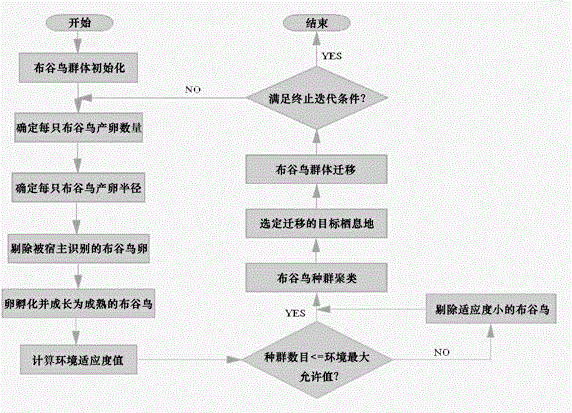

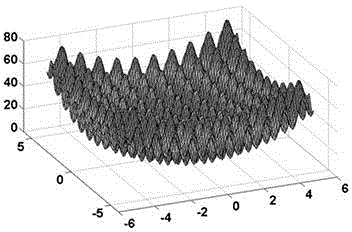

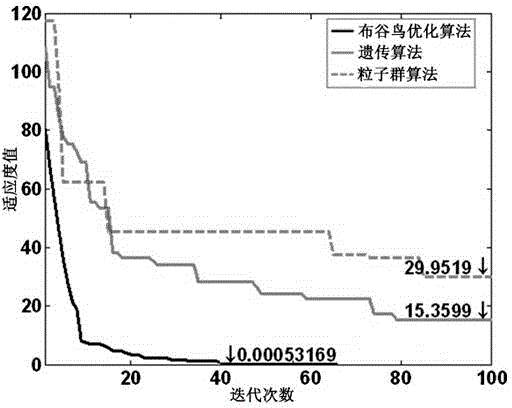

The invention discloses a leakage detection method based on hydraulic model calibration of an urban water supply network. The method comprises the following steps: A) establishing a pressure-related leakage positioning model; B) determining a leakage detection target function; C) determining a constraint condition; and D) solving the pressure-related leakage positioning model. Urban water supply pipeline leakage is avoided, problems in a traditional leakage detection method are solved, the pressure-related leakage detection model is established on the basis of model calibration by a Cuckoo optimization algorithm, and the leakage detection method is quick and effective. In addition, a new pressure-related leakage detection method can detect leakage which is difficult to detect by a traditional method. A situation that a leakage area is detected before the engineers go to a scene is very useful for engineers, and the engineers can carry out intensive examination in a predicted area and can quickly detect an accurate position of a leakage hot water spot.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

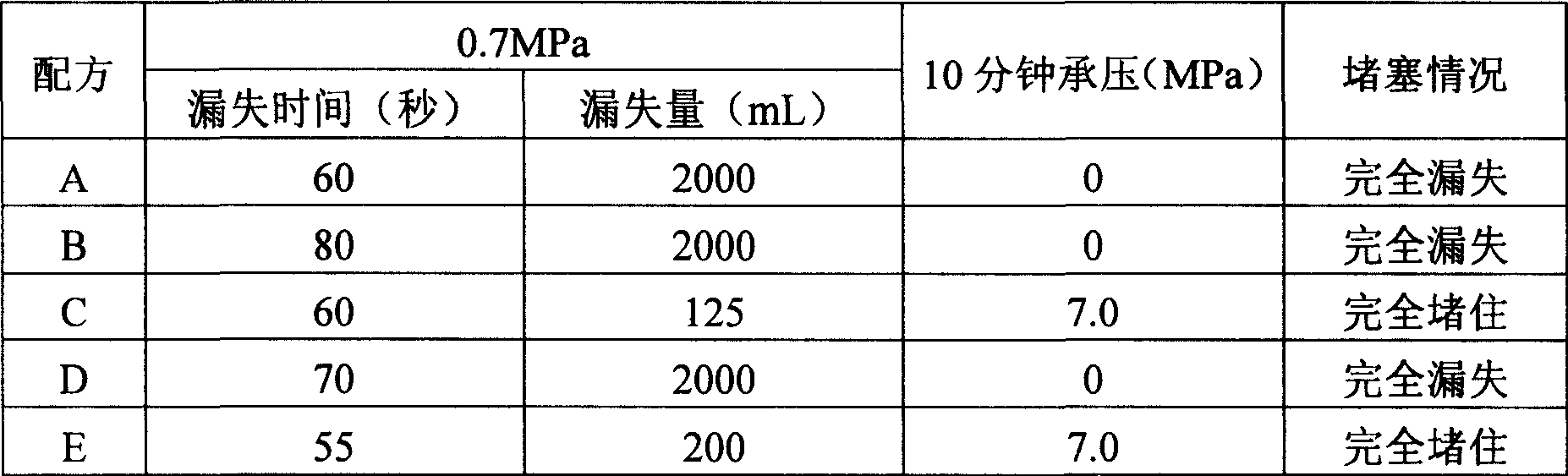

Plugging agent suitable for large leakage, its preparation method and leaking stopping technology

InactiveCN102443382AEnhanced interactionImprove structural strengthDrilling compositionSealing/packingBiologyPetroleum

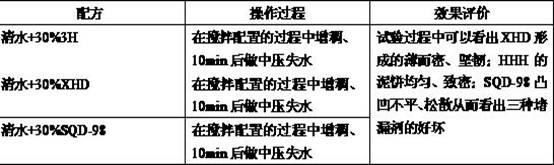

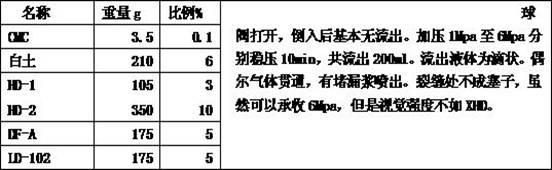

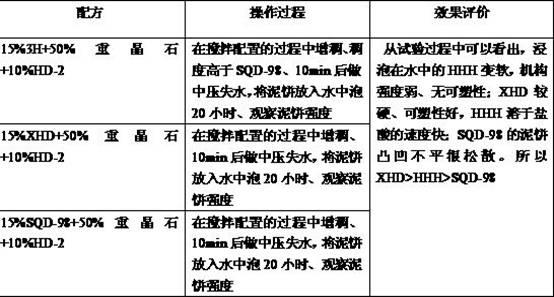

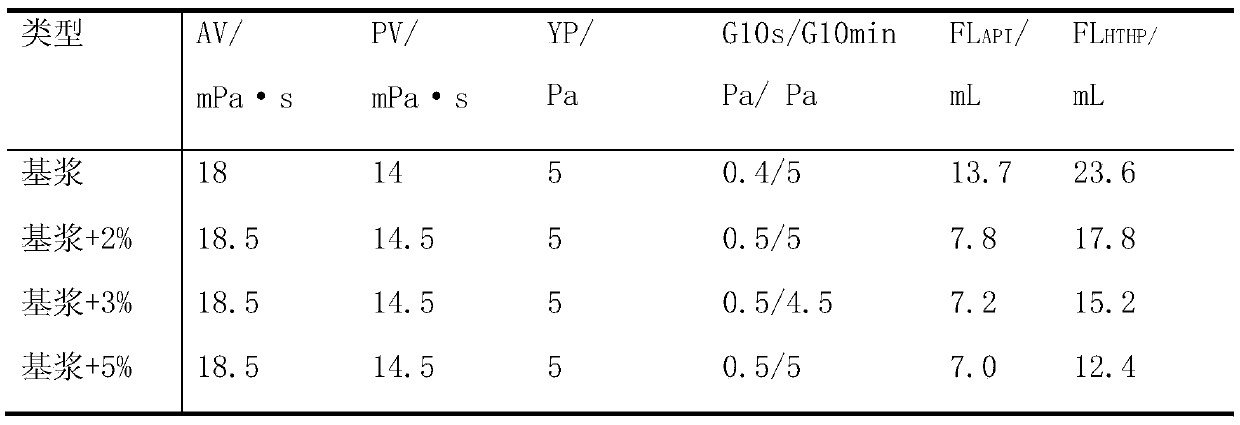

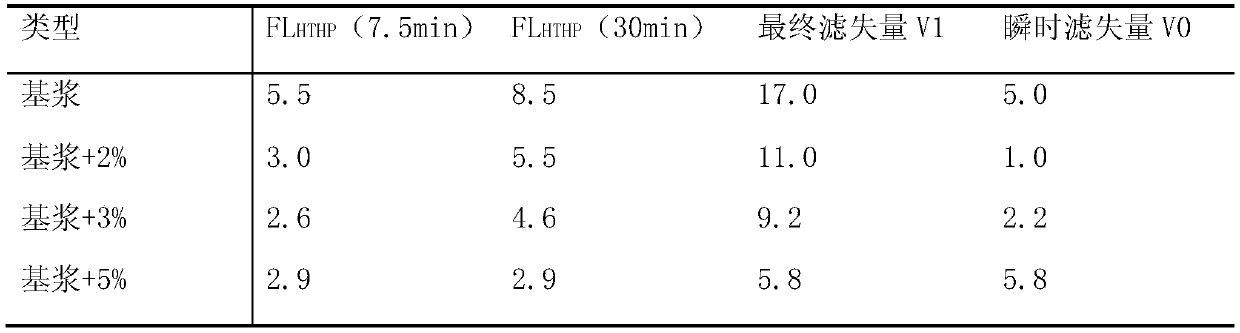

The invention relates to a plugging agent suitable for large leakage, its preparation method and a leaking stopping technology. The invention is suitable for repeatable large leakage, belonging to the field of petroleum drilling. The plugging agent comprises the following ingredients by the following weight ratio: clear water: HSD (HHH): HD-1: HD-2: LD-102: DF-A: barite = 100: 12-15: 4-5: 7-8: 4-5: 30. According to the invention, by reinforcing the interaction among ingredients, maximizing the structural strength of the plugging agent entering a leak layer, maintaining the trend that the leak layer is gradually enhanced with time after injecting the plugging agent in the leak layer, and further increasing the pressure bearing capacity of the leak layer, the leakage problem of a repeatable return-lost large-scale absorption well can be solved, the problem of leaking stopping existing in the prior art can be overcome, and the one-time leak stopping success rate is increased.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Oil well cement leak-proof toughening agent

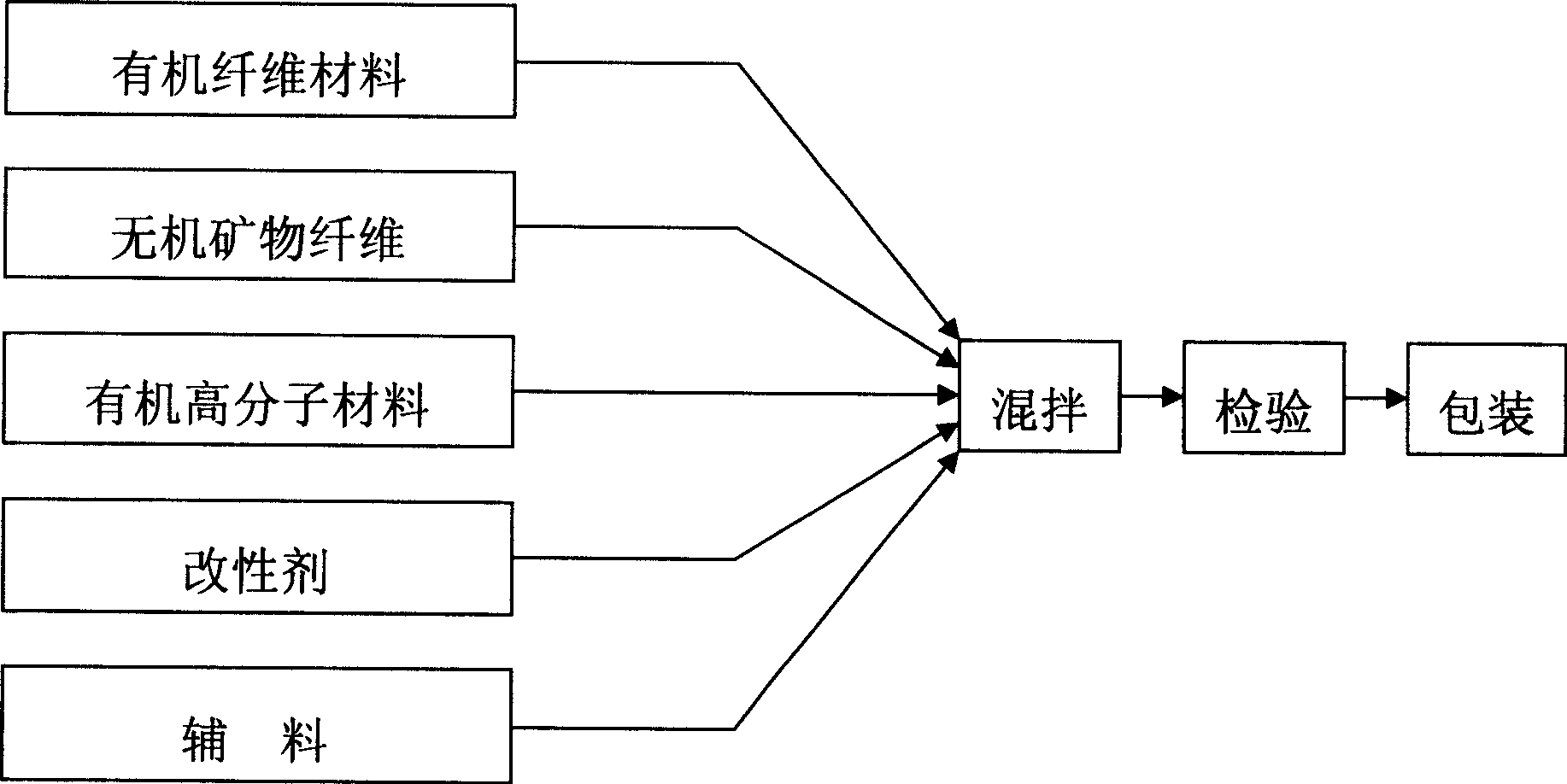

The invention discloses an oil-well cement leakage-proof toughener which not only has leakage-proof function and improves the toughness of cement rocks, but also has good multiple-purpose project performance, so as to have double effects and solve the technical problems of slurry loss and the inherent brittleness of the cement rocks in the process of well cementation; the oil-well cement leakage-proof toughener comprises the components based on the weight percentage: 5-30% of organic fiber material, 35-70% of special type inorganic fiber, 1.0-10% of organic polymer material, 5.0-15% of modifying agent and 1.0-10% of auxiliary material.

Owner:NANJING UNIV OF TECH +1

Oil well plugging fluid

The invention provides an oil well plugging fluid. The oil well plugging fluid comprises, by weight parts, 10-20 parts of rigid leaking stoppage material, 20-35 parts of flexible leaking stoppage material, 1-5 parts of composite fiber material, 0.5-5 parts of strength regulator, 0.1-0.5 part of tackifier, 0.5-5 parts of surfactant and 45-55 parts of water. The oil well plugging fluid is simple in formula and small in viscosity, apparent viscosity is reduced to 35 mPa.s, the oil well plugging fluid is favorable for on-site preparation and construction, invasion of formation fluid can be effectively restrained; a very high strength can be achieved after injection of a leaking layer, heat resistance is high, and the pressure bearing capacity can reach 12 MPa when the oil well plugging fluid is at 150 DEG C. A loss problem of return loss type leaking well is solved, the one-time leaking stoppage can be improved, and the leakage rate is as low as 5%. A method for preparing the oil well plugging fluid is simple and convenient, and the oil well plugging fluid is suitable for large-scale industrial production.

Owner:JINGZHOU JIAHUA TECH

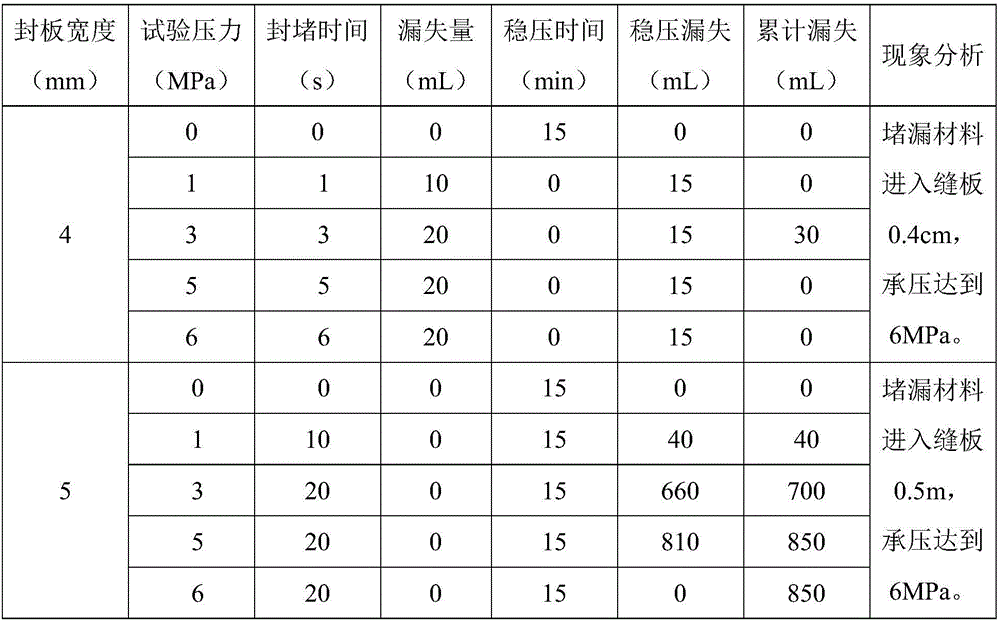

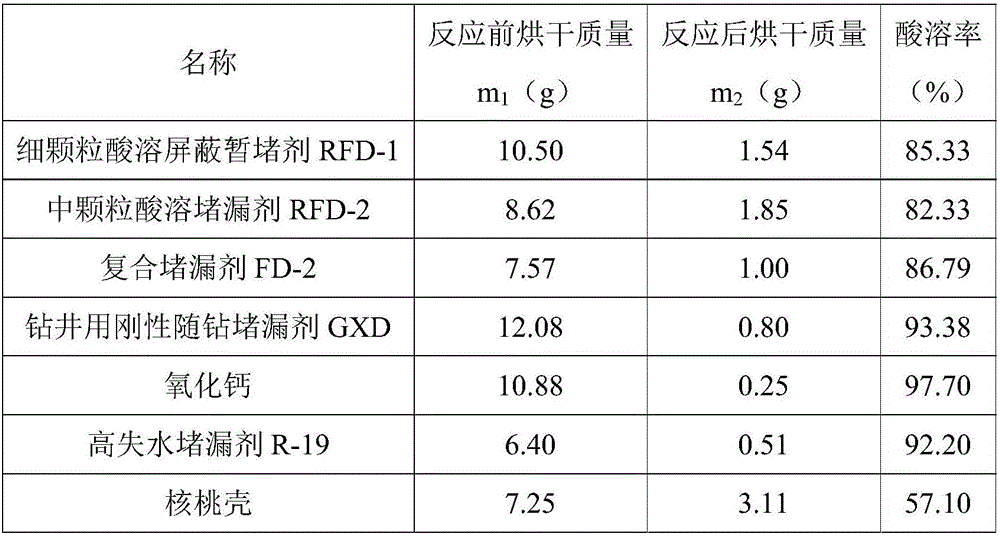

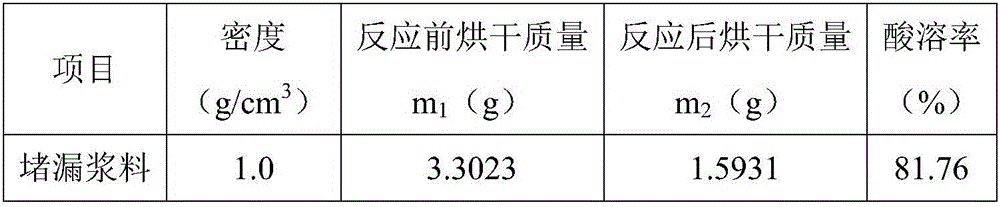

Plugging material and plugging slurry for protecting reservoir stratum with low fracturing fracture ability

The invention discloses a plugging material and plugging slurry for protecting a reservoir stratum with the low fracturing fracture ability. The plugging material is prepared from, by weight, 5-6 parts of walnut shell powder, 2-3 parts of a composite plugging agent, 1.5-2 parts of an agent for plugging while drilling, 4-5 parts of an acid soluble plugging agent, 4-5 parts of a high-dehydration-rate plugging agent and 0.2-0.3 part of calcium oxide. The natural plant inertia material, the fiber plugging agent and the acid soluble plugging agent are mixed according to the certain matching ratio to form the acid soluble plugging material in granule and fiber shapes. The material has the advantages that the bridging effect of a bridging material is good and the plugging success rate is high, and also has the advantages that the density is low, stratum pressure is effectively balanced, the stratum damage is small, the plugging property is strong and acid solubility is achieved. The plugging slurry prepared from the plugging material and water has the advantages of being low in density, high in pressure bearing capability, good in malignant leakage plugging effect, high in acid solubility and the like; the on-site preparation process is simple, construction is safe and reliable, and the purposes of reducing well leakage loss and protecting the reservoir stratum can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Easy-to-absorb liquid fertilizer with seedling expansion function and preparation method of easy-to-absorb liquid fertilizer

The invention discloses an easy-to-absorb liquid fertilizer with a seedling expansion function. The easy-to-absorb liquid fertilizer is prepared from the following raw materials in parts by weight: 24-26 parts of sodium bicarbonate, 6-8 parts of light calcined magnesia, 4-5 parts of ginkgo leaves, 280-320 parts of powdery potassium silicate, 15-25 parts of chlormequat chloride preparation, 5-9 parts of tealeaf residues, 6-8 parts of egg shell meal, 4-6 parts of peeled bean pulp, 3-5 parts of pumpkin seeds, 2-3 parts of paraffin, 17-23 parts of potassium iodide, 8-12 parts of medical stone, 3-5 parts of brown sugar, 8-12 parts of a mepiquat-chloride preparation and 800-900 parts of an assistant. According to the liquid fertilizer disclosed by the invention, the problem of loss of microelement ions in soil is solved; the easy-to-absorb liquid fertilizer is abundant in raw materials; a plurality of nutrient elements are mixed to obtain the liquid fertilizer with high stability by a chelating method; nutrient components can be rapidly absorbed and utilized by crops in a form of ion state when the easy-to-absorb liquid fertilizer is used; and a good foundation is laid for high yield of the crops.

Owner:安徽省中日农业环保科技有限公司

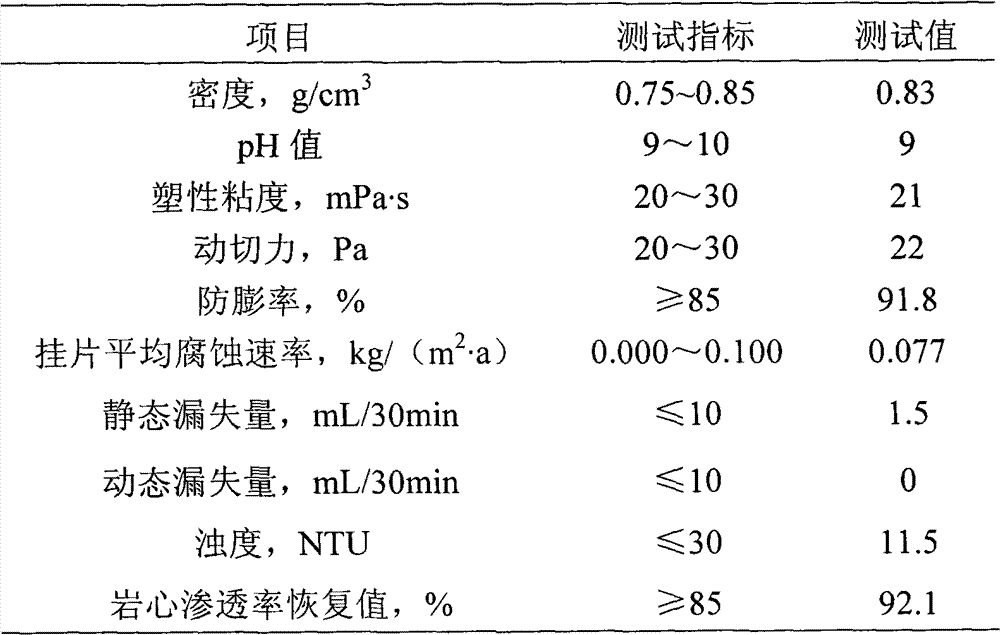

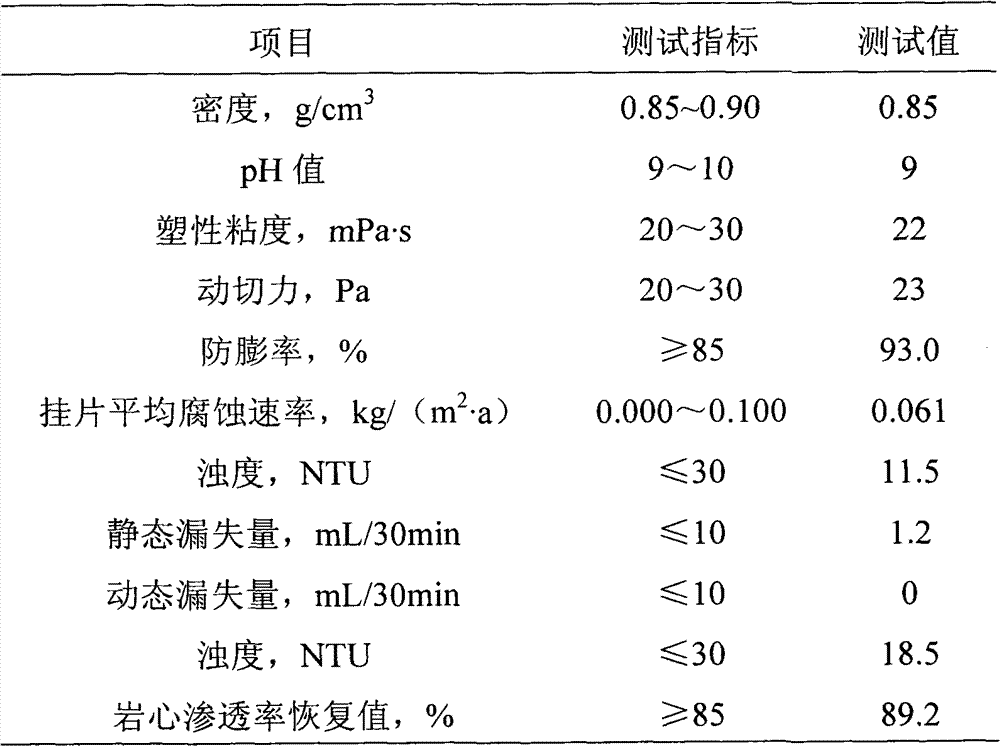

Perforating fluid for well completion

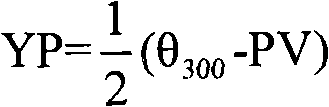

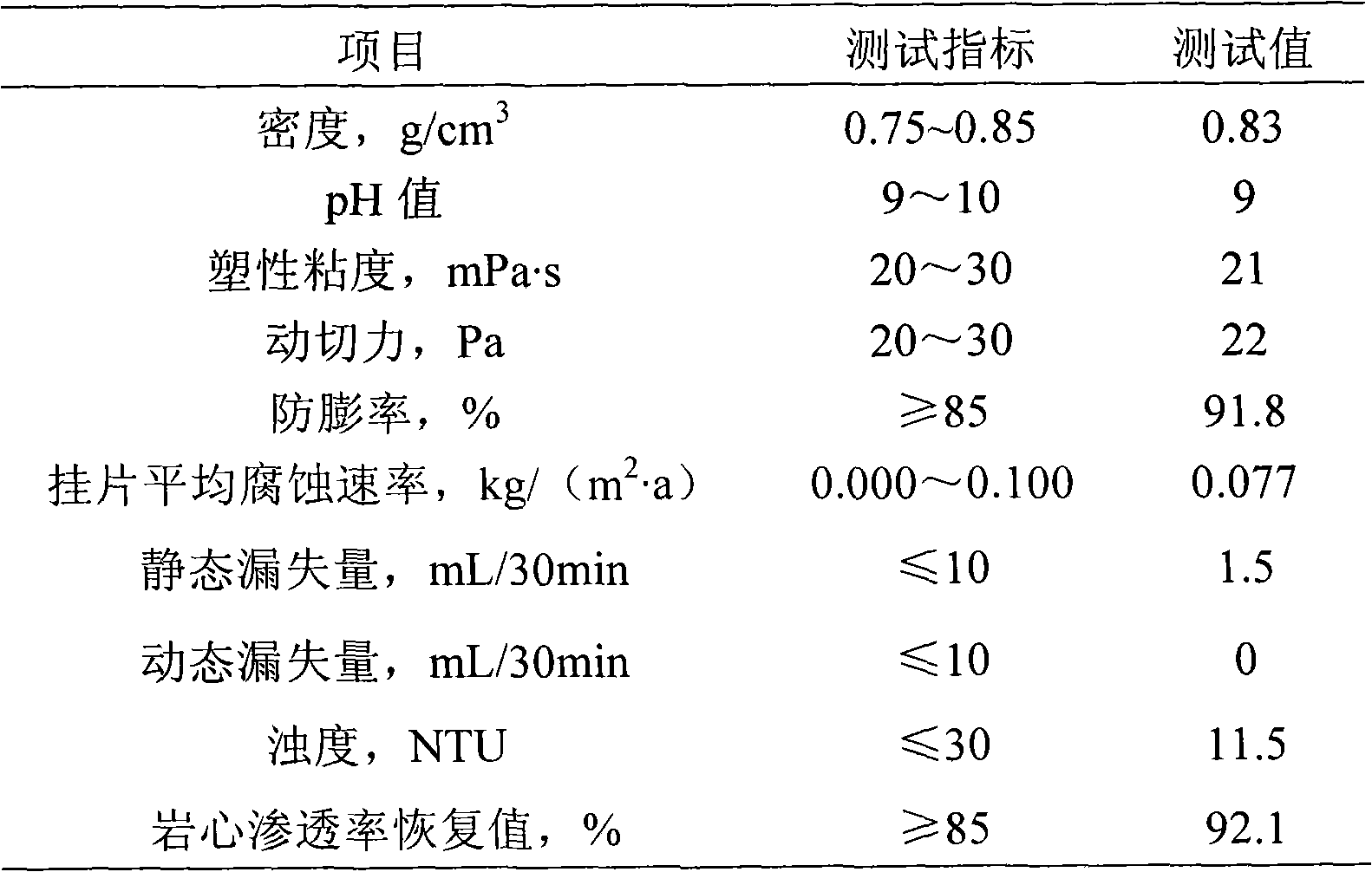

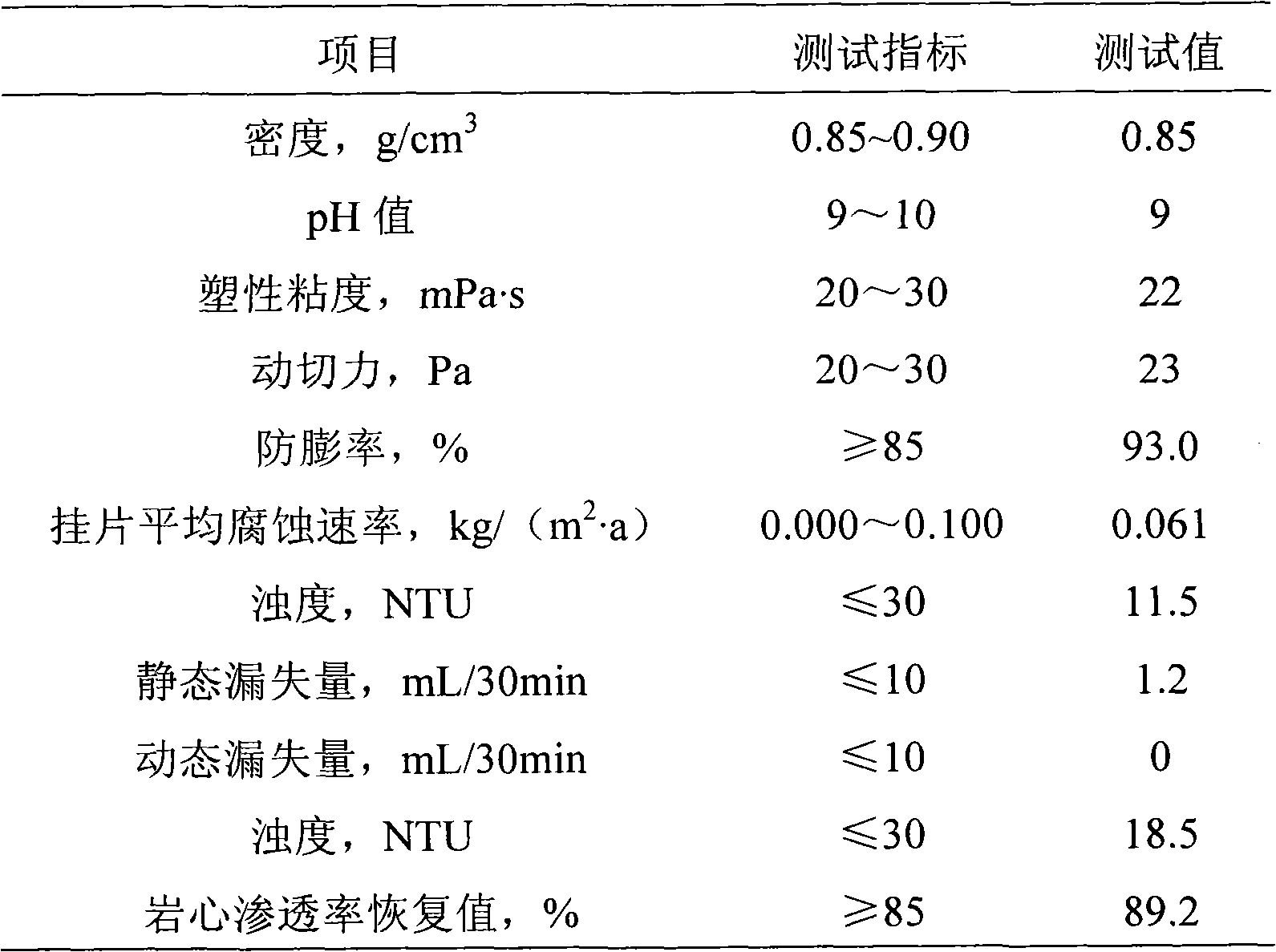

ActiveCN101974315AOvercome the disadvantage of difficult density controlInhibition of hydration swelling capacityDrilling compositionFoaming agentNitrogen

The invention discloses a low-temperature microfoam perforating fluid for an offshore oil well completion, comprising the following materials: water, sodium carbonate, flow pattern regulators, foaming agents and stabilizers, wherein the ratio of the water, the sodium carbonate, the flow pattern regulators, the foaming agents to the stabilizers is 100:(0.1-0.3):(0.3-0.4):(0.1-0.2):(0.2-0.4) in parts by weight. The low-temperature microfoam perforating fluid also comprises clay stabilizers, inhibiters and waterproof locking agents. The low-temperature microfoam perforating fluid for the offshore oil well completion is a novel perforating fluid, not only has the advantages of the traditional common perforating fluid, but also newly increases the advantages of leakage prevention and leakage stoppage on performance, solves the problem of leakage loss in the completion process and also has adjustable density. The invention overcomes the defects of numerous and jumbled nitrogen foam configuration equipment and difficult control of circular foam density on use and has simple and easy configuration equipment and convenient and easy density adjustment.

Owner:CHINA NAT OFFSHORE OIL CORP +1

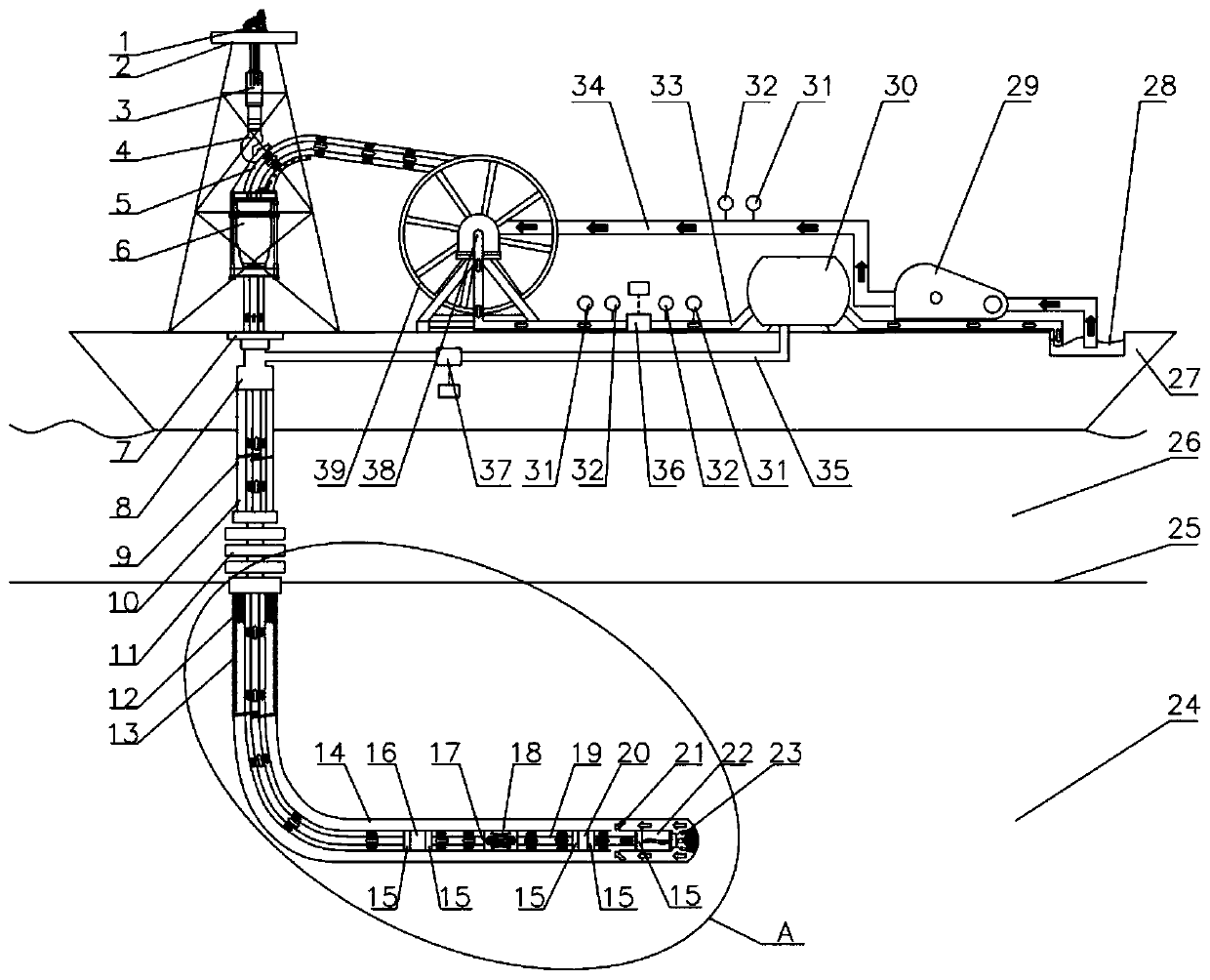

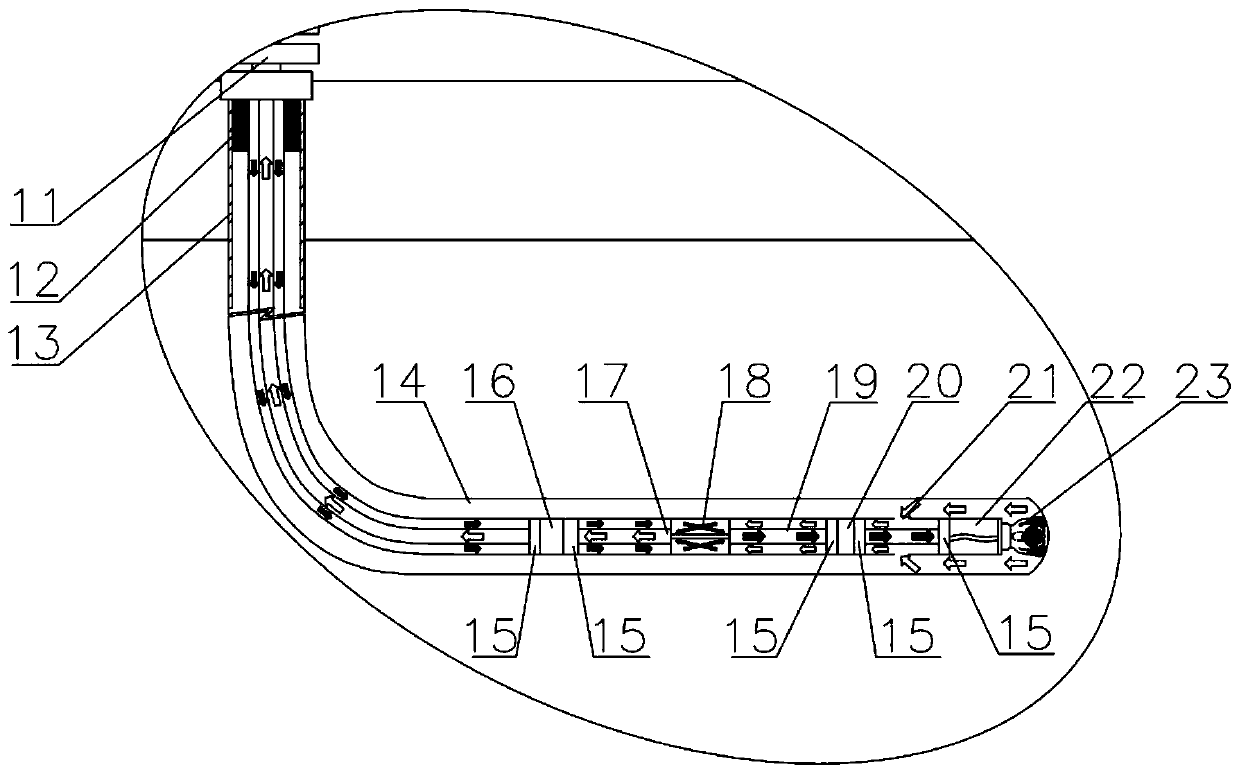

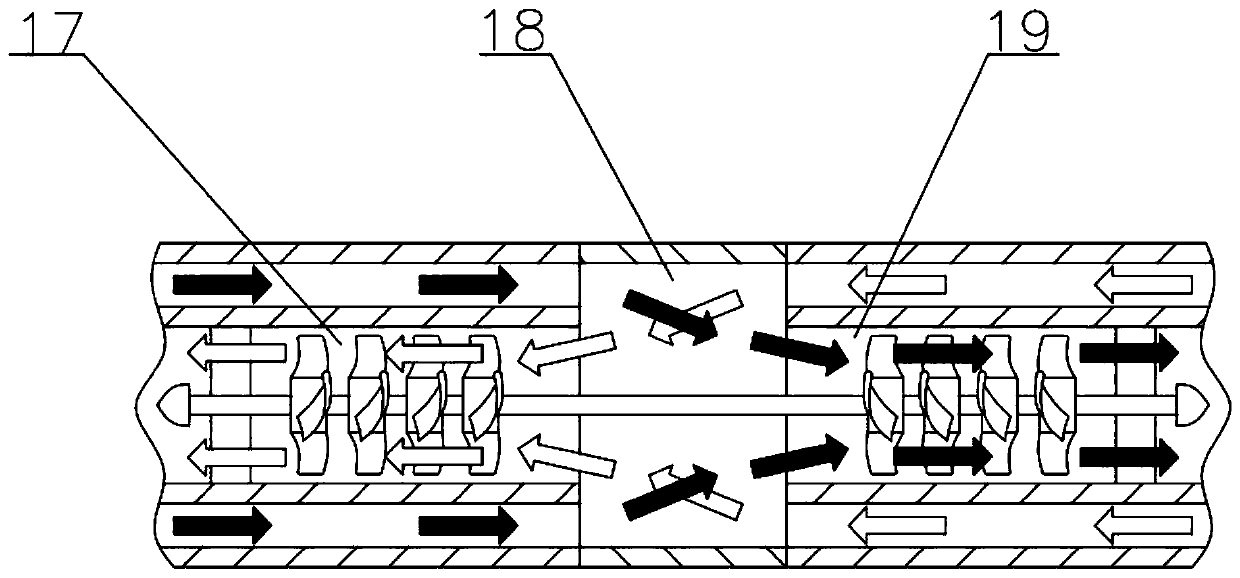

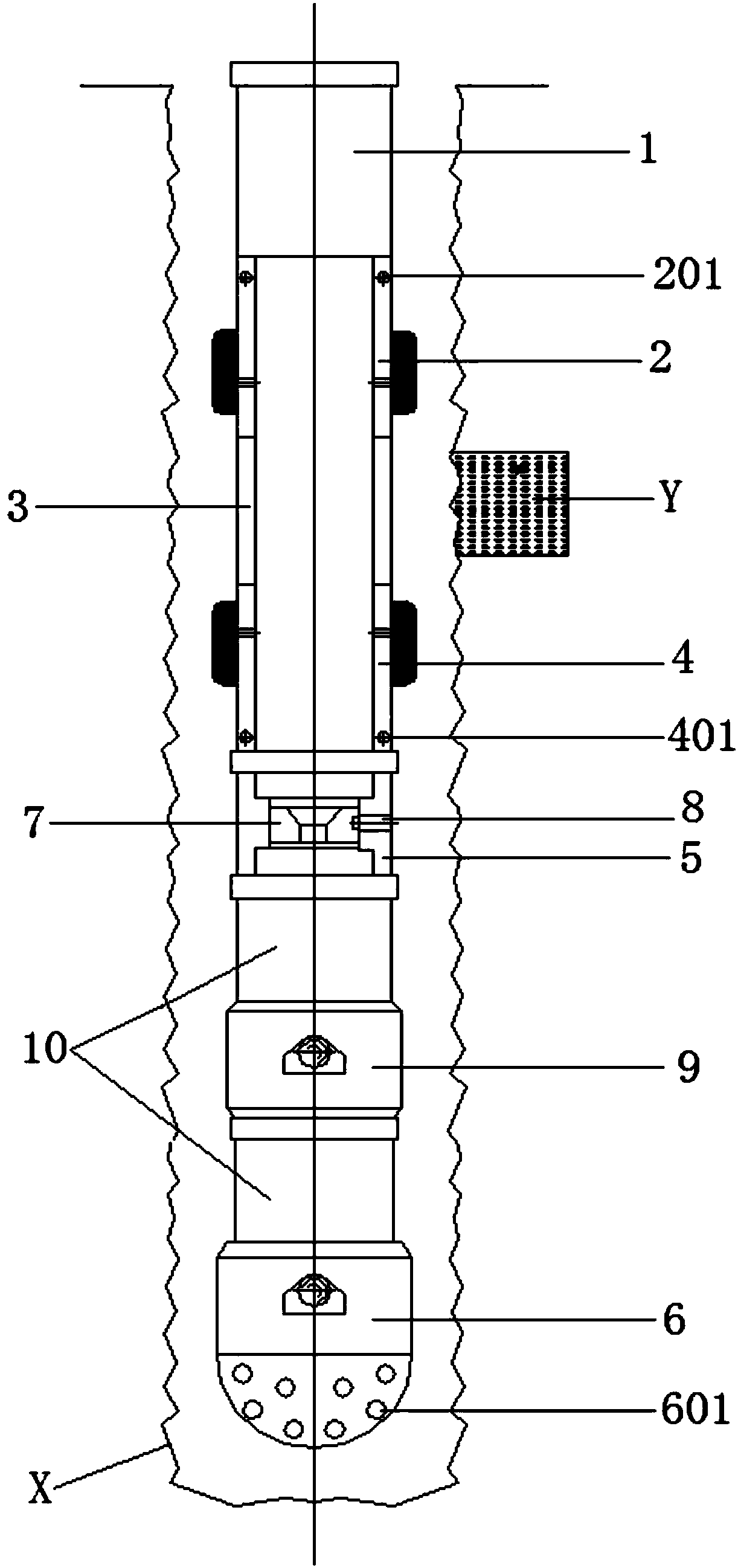

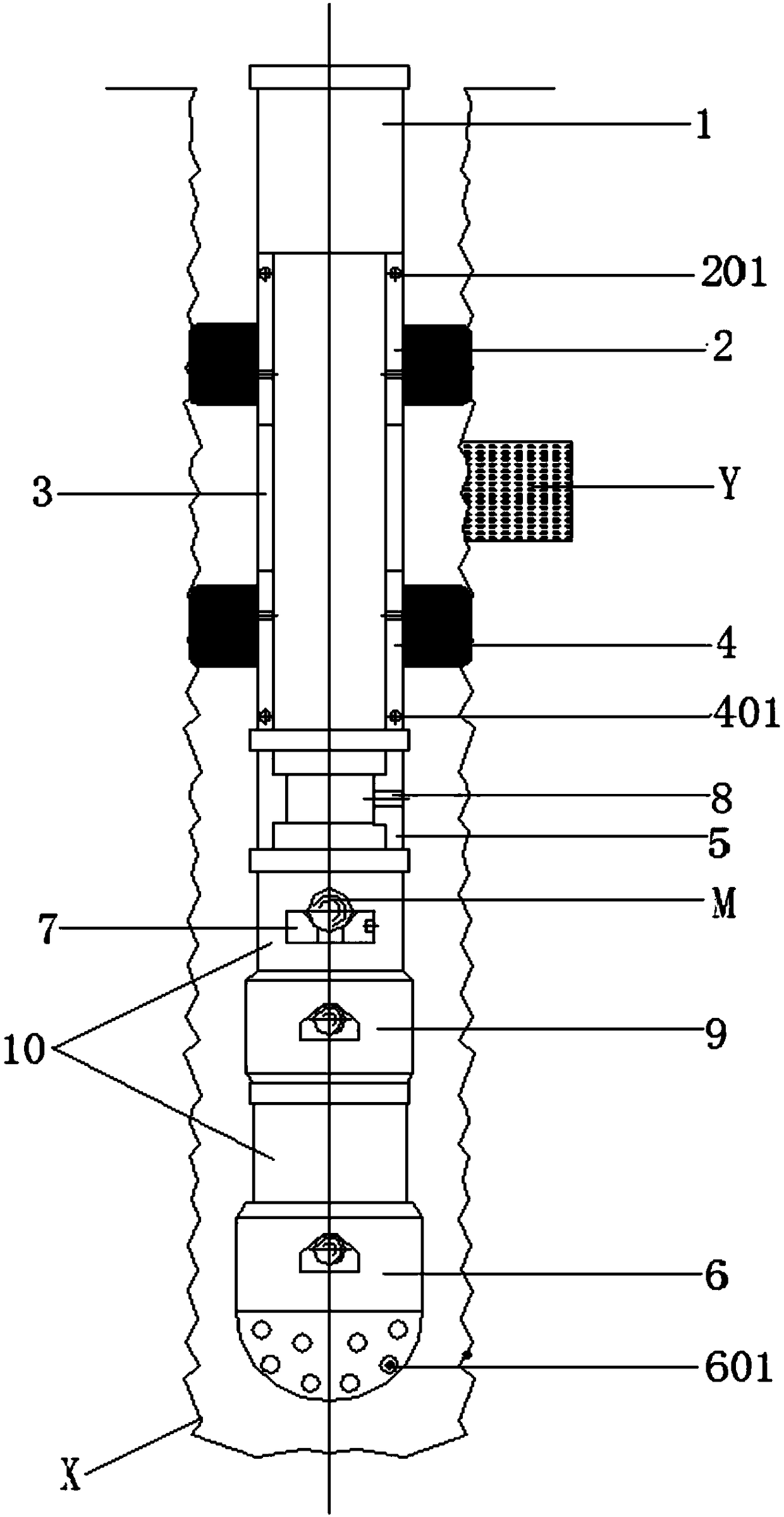

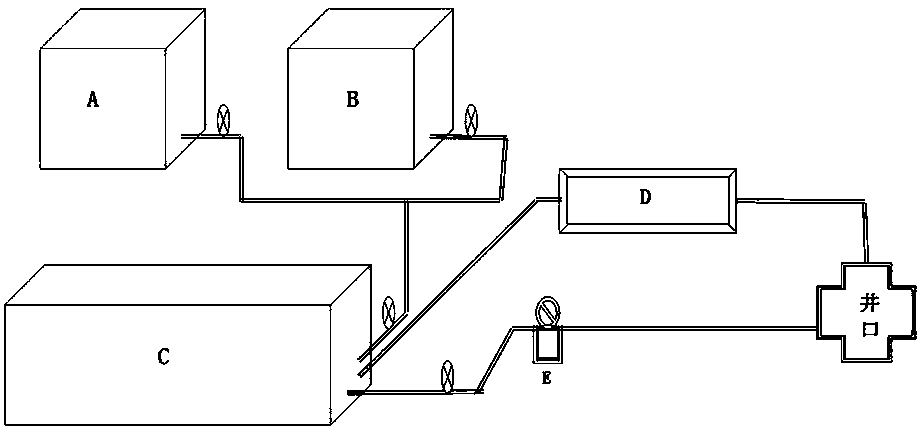

Double-layer continuous pipe double-gradient drilling system

PendingCN111021958AReduce security risksSave on hazard control costsSurveyWaterborne vesselsThrottle controlBottom hole pressure

The invention discloses a double-layer continuous pipe double-gradient drilling system. On the basis of conventional drilling equipment, the double-layer continuous pipe double-gradient drilling system includes a double-layer continuous pipe system, isolation fluid, a downhole lifting pump system, a throttle control system and a data monitoring system; power fluid is injected by a drilling pump package, passes through a conversion joint and enters a double-layer pipe annulus, passes through a downhole lifting pump, enters a double-layer continuous pipe inner pipe through a bridge type channel,and then passes through a power drill tool and a drill bit and enters a bottom hole; and return fluid passes through a recovery hole and enters an annulus channel of a double-layer continuous pipe, then enters the double-layer continuous pipe inner pipe through the bridge type channel and enters the downhole lifting pump, and then passes through the conversion joint and the throttle control system successively and enters a solid control system. According to the double-layer continuous pipe double-gradient drilling system, a drill pipe does not need to be connected, the drilling time is saved,through monitoring of the isolation fluid and adjustment and control of the drilling pump package, the bottom hole pressure gradient is adjusted and controlled, the problem of narrow safety drillingdensity windows is solved, the advantages of lowering the drilling cost, reducing the drilling risk, and improving the efficiency are achieved, and the practicability is high.

Owner:SOUTHWEST PETROLEUM UNIV

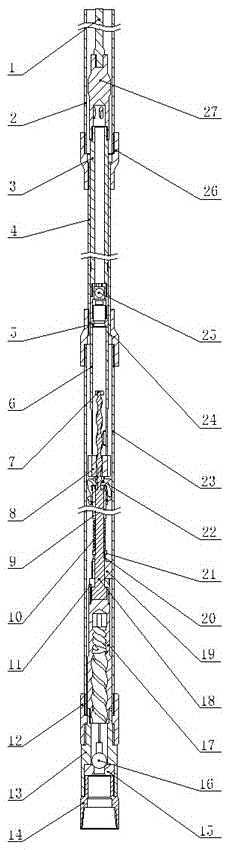

Pipe string for well completion and cementation and method

ActiveCN108119091AIncrease success rateEffective isolationDrilling rodsSealing/packingPetroleum engineering

The invention discloses a pipe string for well completion and cementation and a method, and belongs to the field of oil exploitation equipment. The pipe string comprises a sleeve string, an upper packer, an annular hollow casing, a lower packer, a ball base casing and a float shoe which are connected and communicated with one another from top to bottom. The pipe string also includes a ball base arranged in the ball base casing through shearing nails, a cement slurry outlet hole is formed in the upper end of the upper packer, and a cement slurry inlet hole is formed in the lower end of the lower packer. An annular cavity is formed in the wall of the annular hollow casing, and the upper and lower ends of the cavity are communicated with the cement slurry outlet hole and the cement slurry inlet hole respectively. By using the upper and lower packers to isolate an oil layer, cement slurry is not directly in contact with the oil layer, pollution caused by the cement slurry to the oil layeris avoided, the cement slurry is prevented from extruding the oil layer and causing a leakage problem, and the leakage problem of the oil layer is solved. In short, the pipe string for the wall completion and cementation and the method can not only ensure well completion and cementation operation but also increase the success rate of the well completion and cementation operation.

Owner:PETROCHINA CO LTD

Composite fast-hardening silicate leakage stopping slurry and leakage stopping method thereof

InactiveCN106147732AHigh salinityIncrease moisture contentDrilling compositionSealing/packingOrganic EsterSlurry

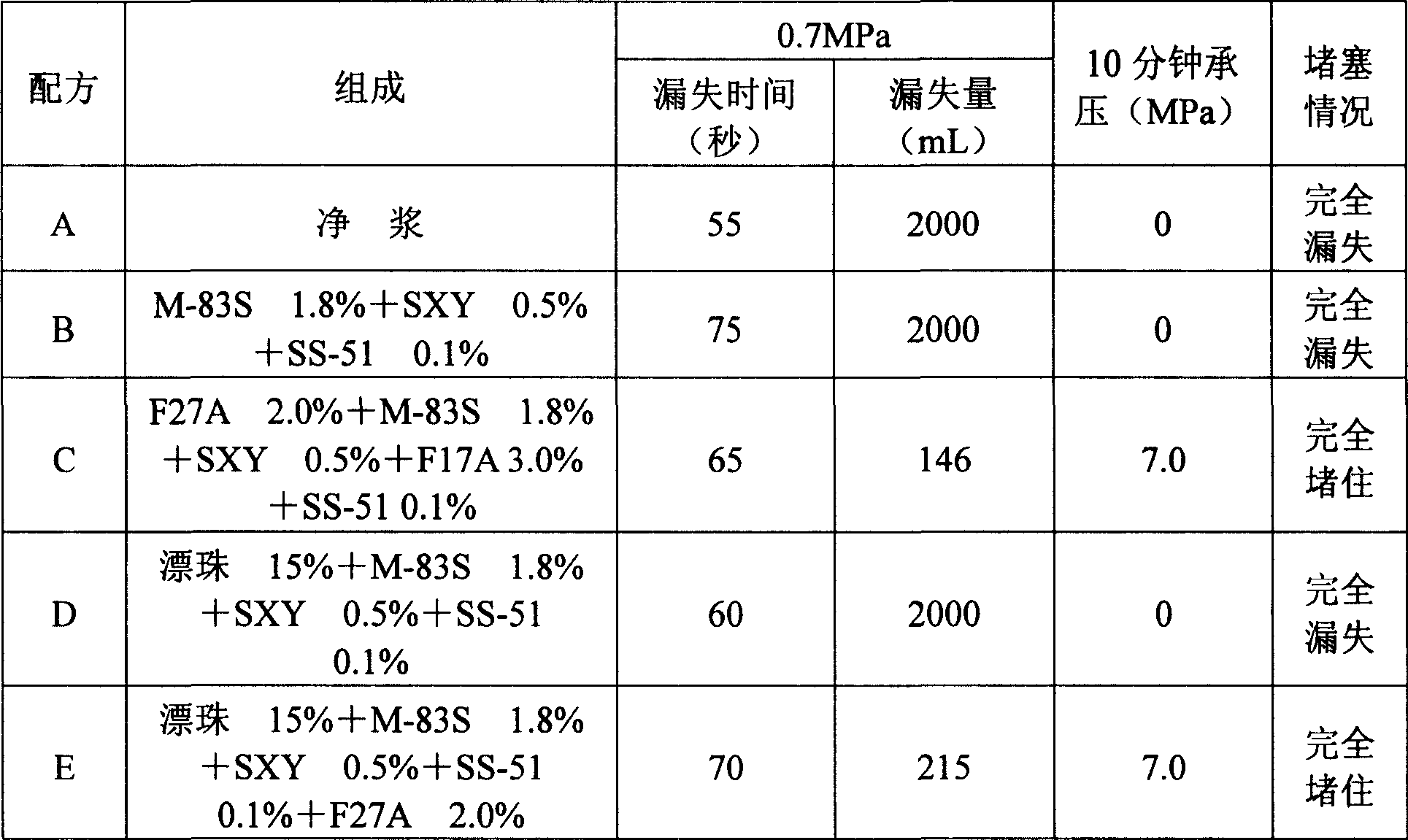

The invention provides composite fast-hardening silicate leakage stopping slurry and a leakage stopping method thereof. The silicate leakage stopping slurry comprises a main agent and a curing agent, a volume ratio of the main agent to the curing agent is 5:1, and the main agent and the curing agent are mixed to form solid gel. Industrial sodium silicate serving as the main agent and organic ester serving as the gel delay curing agent to form the solid gel under an alkaline condition to realize leakage stopping, water repellency of a leakage stopping system is improved, strength of a leakage stopping layer is improved, mixed alternation of formation water and the leakage stopping slurry can be effectively inhibited, gradual enhancement along with time after injection of the slurry into a leak layer is kept, pressure bearing capacity of the leak layer is improved, the problem of leakage of loss return type absorption wells is solved, one-time leakage stopping success rate is increased and exceeds 50%.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

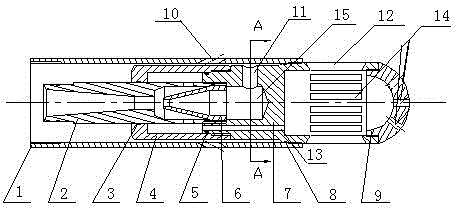

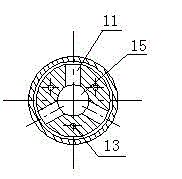

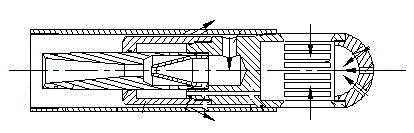

Negative-pressure sand washer of horizontal well

InactiveCN106285523ASimplify the construction processImprove construction efficiencyFlushingEngineeringWellbore

The invention provides a negative-pressure sand washer of a horizontal well. The negative-pressure sand washer comprises an outer barrel, a throat pipe, a center pipe, a nozzle, a connector and a baffle head. The upper portion of the connector is nested in the outer barrel to be in threaded connection with the same, the end face of the lower portion of the connector is connected with the baffle head, the outer wall of the front end of the connector is connected with the lower end of the center tube, the inner hole of the front end of the connector is connected with the lower end of the throat pipe, the throat pipe penetrates the upper end face of the center pipe from the inside of the center pipe, the nozzle is disposed in an inner hole of the lower portion of the throat pipe, the lower end face of the nozzle buttes against the end face of the inner hole of the front end of the connector, and an annular space is formed between the inner wall of the outer barrel and the outer walls of the center pipe and the front end of the connector. Continuous negative-pressure sand washing is realized in the horizontal-section shaft, meanwhile, the negative-pressure sand washer has functions of in-bushing scale removal and cement breaking, and the problem of incontinuity and serious dropout in the horizontal-well sand washing process is solved.

Owner:PETROCHINA CO LTD

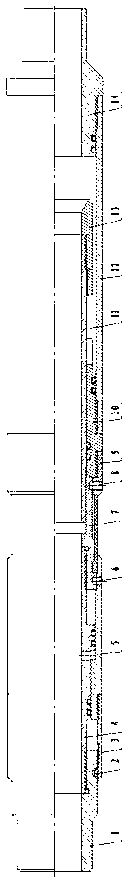

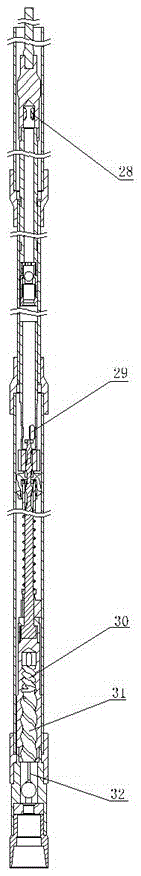

Horizontal well concentric tubing continuous negative pressure sand pump process tubular column

ActiveCN105041243AChange sand removal processSolve the missing problemFlushingSteel ballHigh pressure water

The invention belongs to the technical field of oilfield workover in the conditions of perforated casing completion, and discloses a horizontal well concentric tubing continuous negative pressure sand pump process tubular column, wherein a high pressure water faucet is connected with a tool tubing through a reversing joint, the lower end of the tool tubing is connected with a concentric tubing combination through a conversion joint, the lower end of the concentric tubing combination is connected with a negative pressure sand pump device, a steel ball and a ball seat are arranged in the reversing joint, the steel ball is connected with a spring, the other end of the spring is fixed on an upper position of the ball seat, a discharge hole is arranged on the wall of the reversing joint which is arranged below the ball seat, and a sliding sleeve which blocks the discharge hole is arranged on the outer wall of the reversing joint. The horizontal well concentric tubing continuous negative pressure sand pump process tubular column achieves negative pressure sand pumping under the premise that the demands of oilfield horizontal well continuous tubular column downward operation are met, simultaneously has the functions that scales are cleaned up and cements are crushed in a sleeving. The horizontal well concentric tubing continuous negative pressure sand pump process tubular column integrates the functions of sand removal, scale clean and cement crushing in a shaft firstly and achieves once integration operation, greatly simplifies construction procedure, and improves construction efficiency.

Owner:PETROCHINA CO LTD

Compensator for water injection pipe

The invention provides a compensator for a water injection pipe. The compensator for the water injection pipe comprises a retreat stopping part, a locking part and a control part, wherein the retreat stopping part comprises a retreat stopping ring and a thrusting cover; the locking part comprises a locking pipe core, a locking pipe, a locking coupling and a locking pawl spring; the control part comprises a locking pipe dowel and a shearing-off dowel; the inner side and the outer side of the lower end of an upper joint are respectively connected with the pipe locking core and the thrusting cover, the thrusting cover is fixedly connected with the locking pipe, and the locking pipe core and the locking pipe are respectively connected with the inner side and the outer side of the locking coupling; the locking pipe compacts the locking pawl spring onto the locking coupling, the bottom of the locking coupling is fixedly connected with a center pipe, the center pipe can be in externally sliding cover with a suspension short joint, and the bottom end of the center pipe is fixedly provided with an inclination guiding joint; and the upper end of the suspension short joint is fixedly connected with the locking pawl spring, the lower end of the suspension short joint is fixedly connected with an outer pipe, and the bottom of the outer pipe is connected with a lower joint.

Owner:PETROCHINA CO LTD

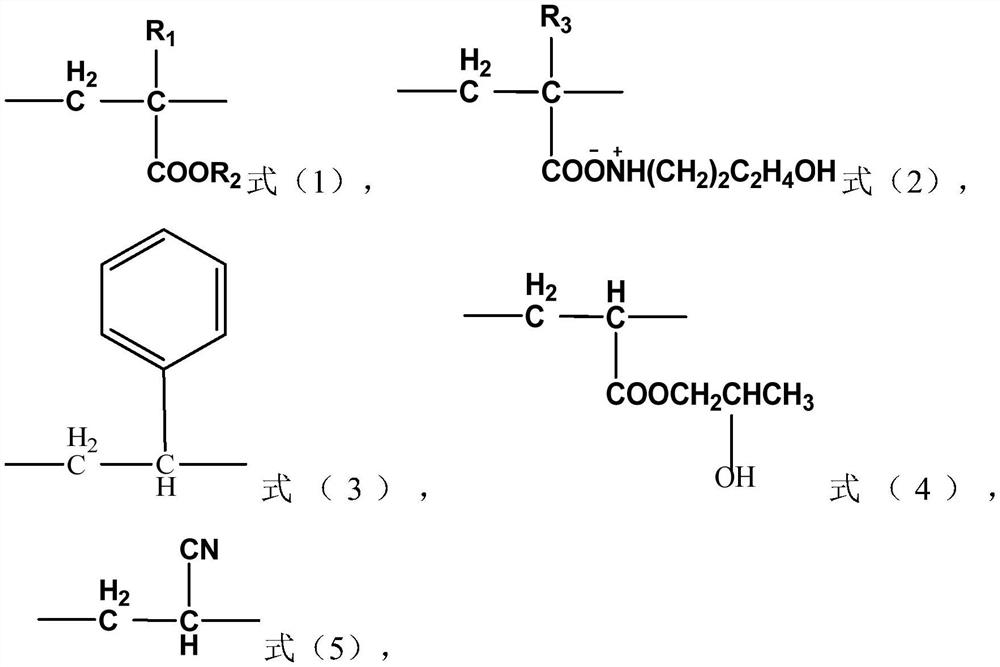

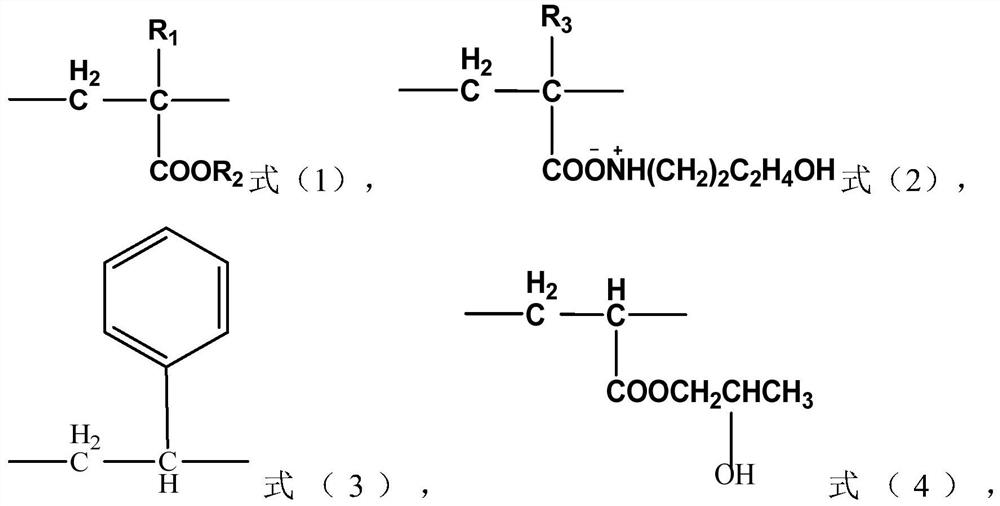

Copolymer, preparation method thereof, application of the copolymer as plugging agent, oil-based drilling fluid and application of oil-based drilling fluid

ActiveCN111808224AGood hydrophilic and lipophilicSolve the missing problemDrilling compositionWell drillingOrganic chemistry

The invention relates to the field of well drilling in the petroleum industry. The invention particularly relates to a copolymer, a preparation method thereof, application of the copolymer as a plugging agent, oil-based drilling fluid and application of the oil-based drilling fluid. The copolymer contains a structural unit A, a structural unit B, a structural unit C, a structural unit D and a structural unit E, wherein the structural unit A is a structural unit with a structure as shown in a formula (1), the structural unit B is a structural unit with a structure as shown in a formula (2), thestructural unit C is a structural unit with a structure as shown in a formula (3), the structural unit D is a structural unit with a structure as shown in a formula (4), and the structural unit E isa structural unit with a structure as shown in a formula (5); R1, R2 and R3 are each independently H or C1-C10 alkyl. When the copolymer provided by the invention is used as a plugging agent, the problem of leakage of underground oil-based drilling fluid can be efficiently solved, and leakage pores and cracks with different sizes can be plugged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Message acquisition method and device, equipment and storage medium

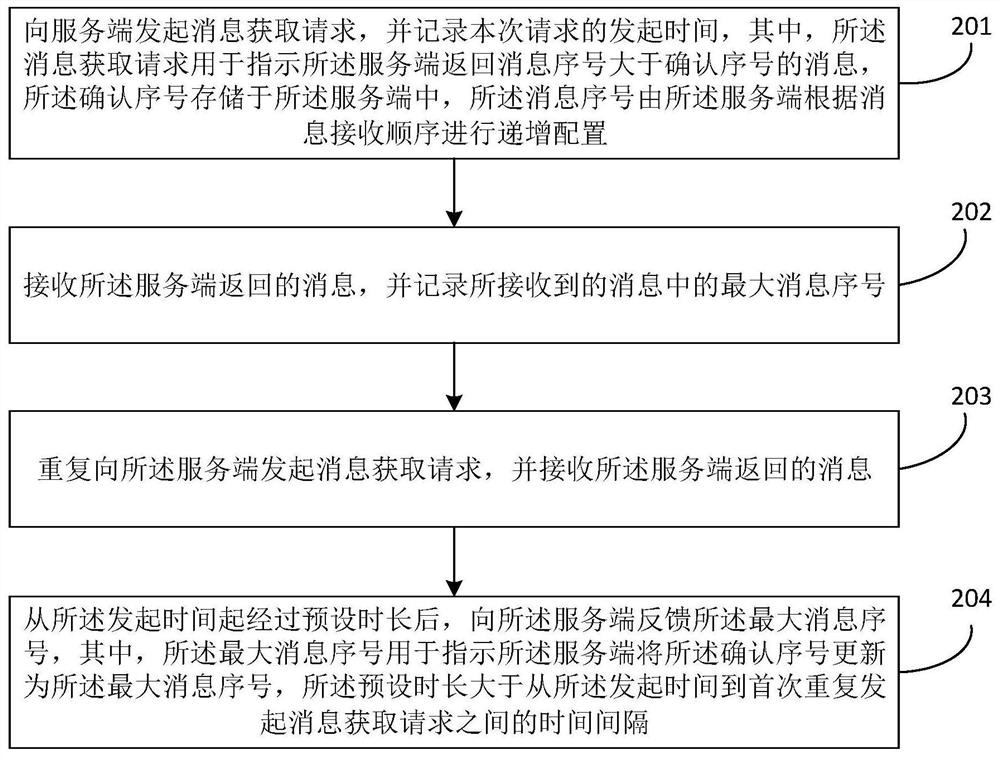

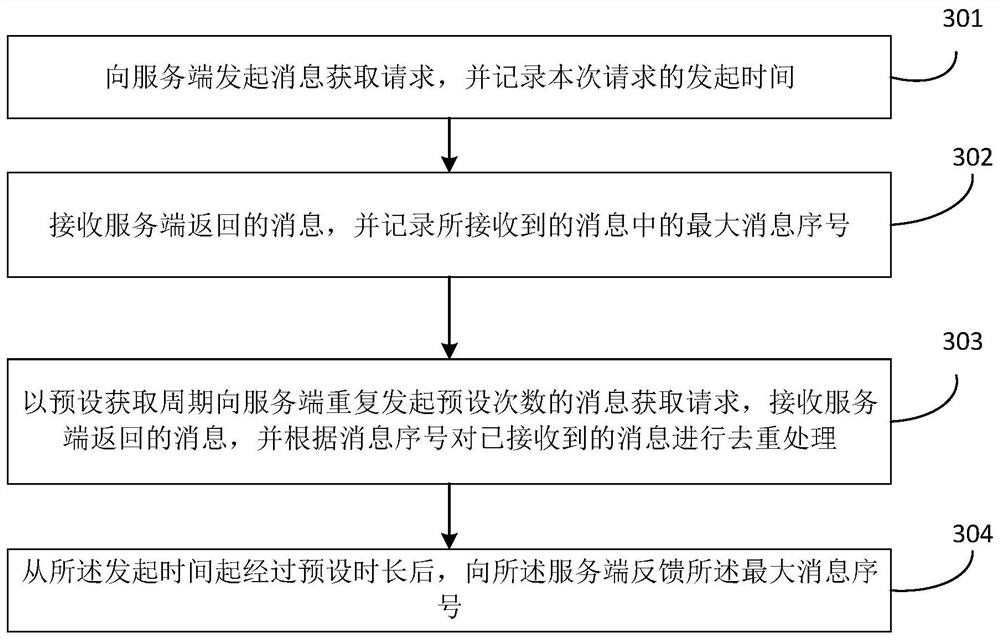

ActiveCN112367149AIncrease the probability of successful acquisitionTo achieve redundant acquisitionError prevention/detection by using return channelEngineeringSerial code

The embodiment of the invention discloses a message acquisition method and device, equipment and a storage medium. The method comprises the steps of: initiating a message acquisition request to a server, recording the initiation time of the request, wherein the message acquisition request is used for indicating the server to return a message of which the message serial number is larger than a confirmation serial number, the message returned by the server is received, and the maximum message serial number in the received message is recorded; and repeatedly initiating the message acquisition request to the server side, receiving a message returned by the server side, and feeding back the maximum message serial number to the server side after a preset duration from the initiation time, the maximum message serial number being used for indicating the server side to update the confirmation serial number to the maximum message serial number. According to the technical scheme provided by the embodiment of the invention, the probability that the message is successfully acquired can be improved, and the problem of message acquisition missing of the client is effectively solved.

Owner:BIGO TECH PTE LTD

Manufacturing method for bar-type array tellurium-zinc-cadmium detector

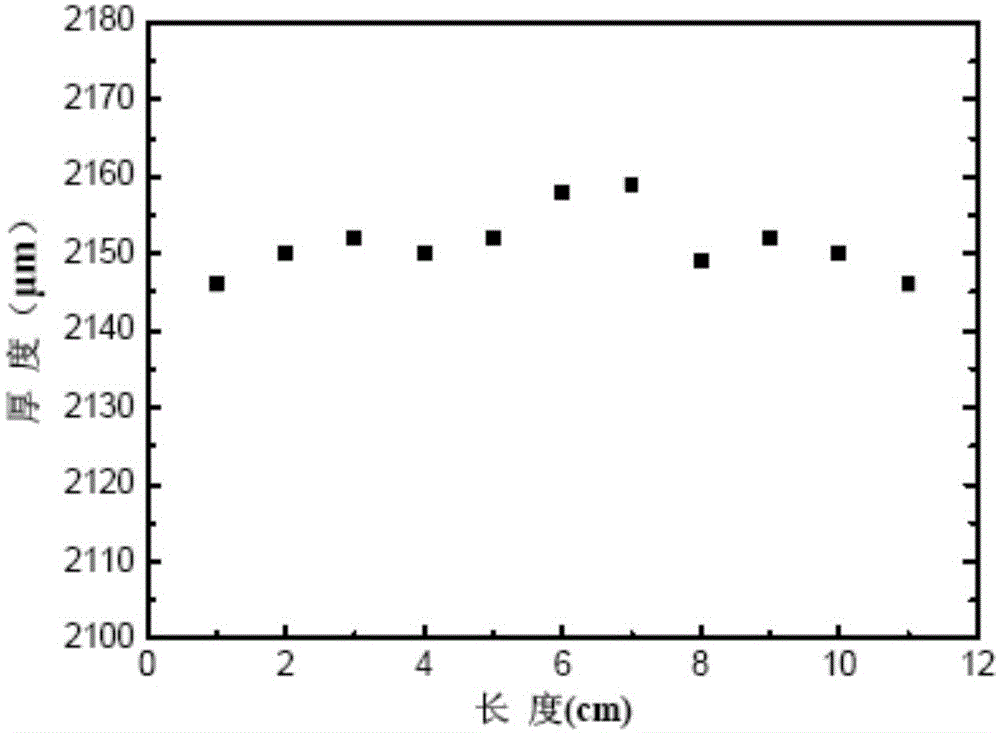

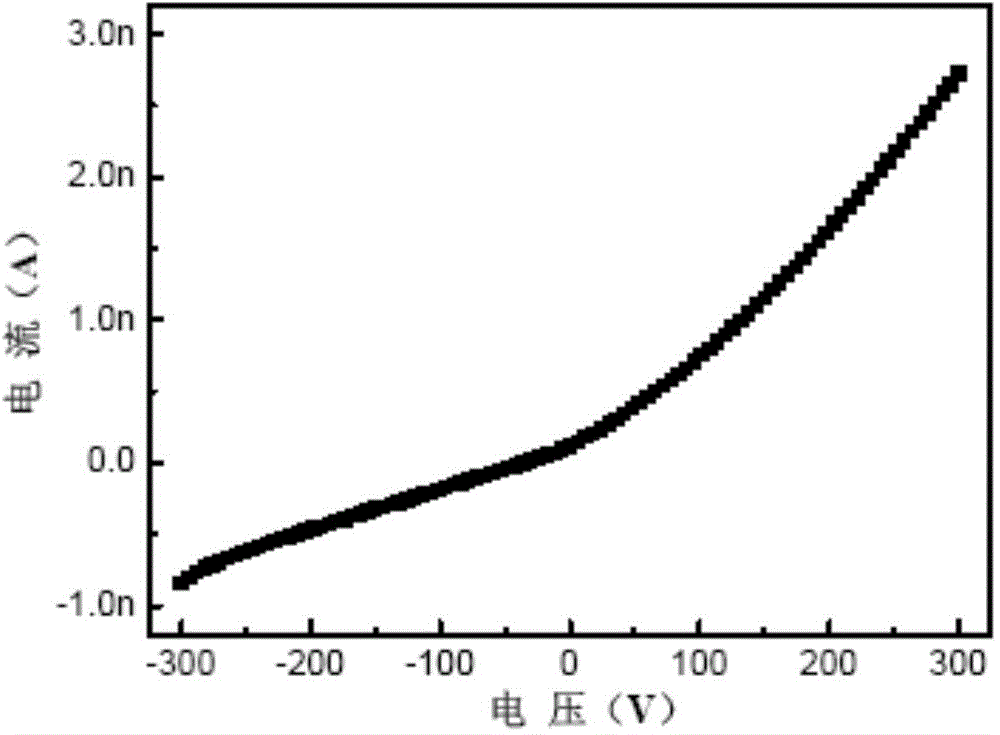

ActiveCN103560167AOvercome edge collapseUniform coatingFinal product manufactureRadiation intensity measurementEngineeringSingle crystal

The invention discloses a manufacturing method for a bar-type array tellurium-zinc-cadmium detector. The manufacturing method is used for solving the technical problem that a photoetching image edge is deficient when an existing method is used for manufacturing a bar-type array tellurium-zinc-cadmium detector. According to the technical scheme, a plurality of bar-type array patterns are made at a time through photoetching on a large-size tellurium-zinc-cadmium single crystal wafer with the small length-width ratio, photoresist is used for protecting a bar-type array electrode, a wafer scriber is used for ripping the peripheral contour of the photoetched patterns, and an independent bar-type tellurium-zinc-cadmium detector is formed. The problems that the turned-down edge is generated and photoetched electrode patterns are incomplete in the wafer polishing process due to the large length-width ratio are solved, and the problem that short circuit is caused due to the wafer with nonuniform thicknesses during the inversion connection of a pixel electrode is solved. Due to the fact that the photoresist is used for protecting the bar-type array electrode to conduct scribing cutting, a photoetched electrode is protected, and wafer edge cracking caused by cutting is avoided. Four to eight 1*8-1*32 pixel array bar-type detectors can be manufactured at a time, and manufacturing cost is reduced.

Owner:IMDETEK

Preparation method and application of nano microcrystalline blocking agent for drilling fluid

PendingCN111269706AEvenly dispersedGood dispersionDrilling compositionProductsAluminium chlorideFreeze-drying

The invention discloses a preparation method of a nano microcrystalline blocking agent for drilling fluid. The preparation method comprises the following steps: dispersing nano cellulose in deionizedwater, and carrying out ultrasonic dispersion to obtain a solution; then sequentially adding aluminum chloride and tannic acid for reaction; then adjusting the pH value of the reacted solution to be 9by using alkali liquor; then washing with ethanol and deionized water, and centrifugally layering; removing the suspension liquid at the lower part of the supernatant liquid, repeatedly washing and centrifugally layering, freeze-drying the obtained suspension liquid at the lower part to obtain the nano microcrystalline blocking agent of which the surface is modified with the aluminum-tannic acidfilm layer, performing vacuum drying, and then performing size stabilization and sieving to obtain the nanocrystalline blocking agent. According to the preparation method and application of the nano microcrystalline blocking agent for the drilling fluid, and the nano microcrystalline blocking agent is obtained by modifying nanocellulose and can be uniformly dispersed in the drilling fluid and effectively blocks micro-nano cracks of a shale stratum and provides technical support for keeping the stability of the well wall.

Owner:中石化石油工程技术服务有限公司 +2

Hydrophobic gel composite cement and plugging method thereof

ActiveCN101863643BOvercoming the fatal flaw of not repelling waterHigh solid contentOther chemical processesSealing/packingCement slurryUltimate tensile strength

The invention discloses hydrophobic gel composite cement, and relates to the technical field of cement slurry plugging in petroleum drilling. The composite cement comprises the following components in percentage by weight: 0.15 to 0.25 percent of hydrophobic gel, 10 to 30 percent of hydrophobic curing agent, 8 to 15 percent of coagulant, and the balance of cement. The invention provides a preparation method for the composite cement at the same time. By introducing the hydrophobic gel into a cement system, the water repellency of the cement slurry system is improved, the strength of a plugginglayer is improved, the mixing alternation of stratum water and cement slurry can be effectively inhibited, the tendency of gradual enhancement along with the time after the composite cement is injected into a leakage layer is ensured, the pressure bearing capacity of the leakage layer is improved, the loss problem of a loss return leakage well is solved, and the one-time plugging success rate is improved and exceeds 50 percent.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

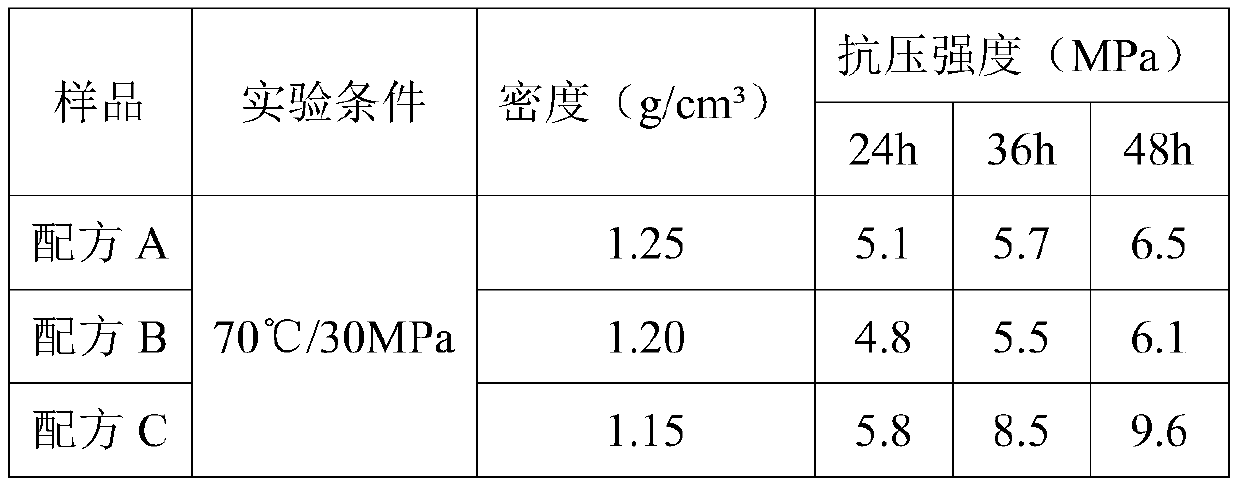

Low-density cement paste for well cementation operation, and cement composition for well cementation operation

InactiveCN111019616AImprove stabilityImprove liquidityDrilling compositionMicrofine cementPhysical chemistry

The invention relates to low-density cement paste for well cementation operation, and a cement composition for well cementation operation, and belongs to the technical field of oil well drilling engineering. The low-density cement paste for well cementation operation comprises water and the following components in parts by weight: 70-100 parts of oil well cement, 0-30 parts of superfine cement, 35-80 parts of a lightening material and 15-20 parts of micro-silicon, wherein the lightening material comprises at least one of floating beads and glass micro-beads. According to the invention, the cement paste is good in performance of each component material and moderate in addition proportion, the density of the cement paste prepared from various components can reach 1.15-1.25 g / cm<3>, and the cement paste is high in stability, good in fluidity and high in strength, so that the risk of well cementation leakage can be reduced, and the well cementation quality and the displacement efficiency are improved.

Owner:CHINA PETROCHEMICAL CORP +2

Perforating fluid for well completion

ActiveCN101974315BOvercome the disadvantage of difficult density controlInhibition of hydration swelling capacityDrilling compositionFoaming agentNitrogen

The invention discloses a low-temperature microfoam perforating fluid for an offshore oil well completion, comprising the following materials: water, sodium carbonate, flow pattern regulators, foaming agents and stabilizers, wherein the ratio of the water, the sodium carbonate, the flow pattern regulators, the foaming agents to the stabilizers is 100:(0.1-0.3):(0.3-0.4):(0.1-0.2):(0.2-0.4) in parts by weight. The low-temperature microfoam perforating fluid also comprises clay stabilizers, inhibiters and waterproof locking agents. The low-temperature microfoam perforating fluid for the offshore oil well completion is a novel perforating fluid, not only has the advantages of the traditional common perforating fluid, but also newly increases the advantages of leakage prevention and leakage stoppage on performance, solves the problem of leakage loss in the completion process and also has adjustable density. The invention overcomes the defects of numerous and jumbled nitrogen foam configuration equipment and difficult control of circular foam density on use and has simple and easy configuration equipment and convenient and easy density adjustment.

Owner:CHINA NAT OFFSHORE OIL CORP +1

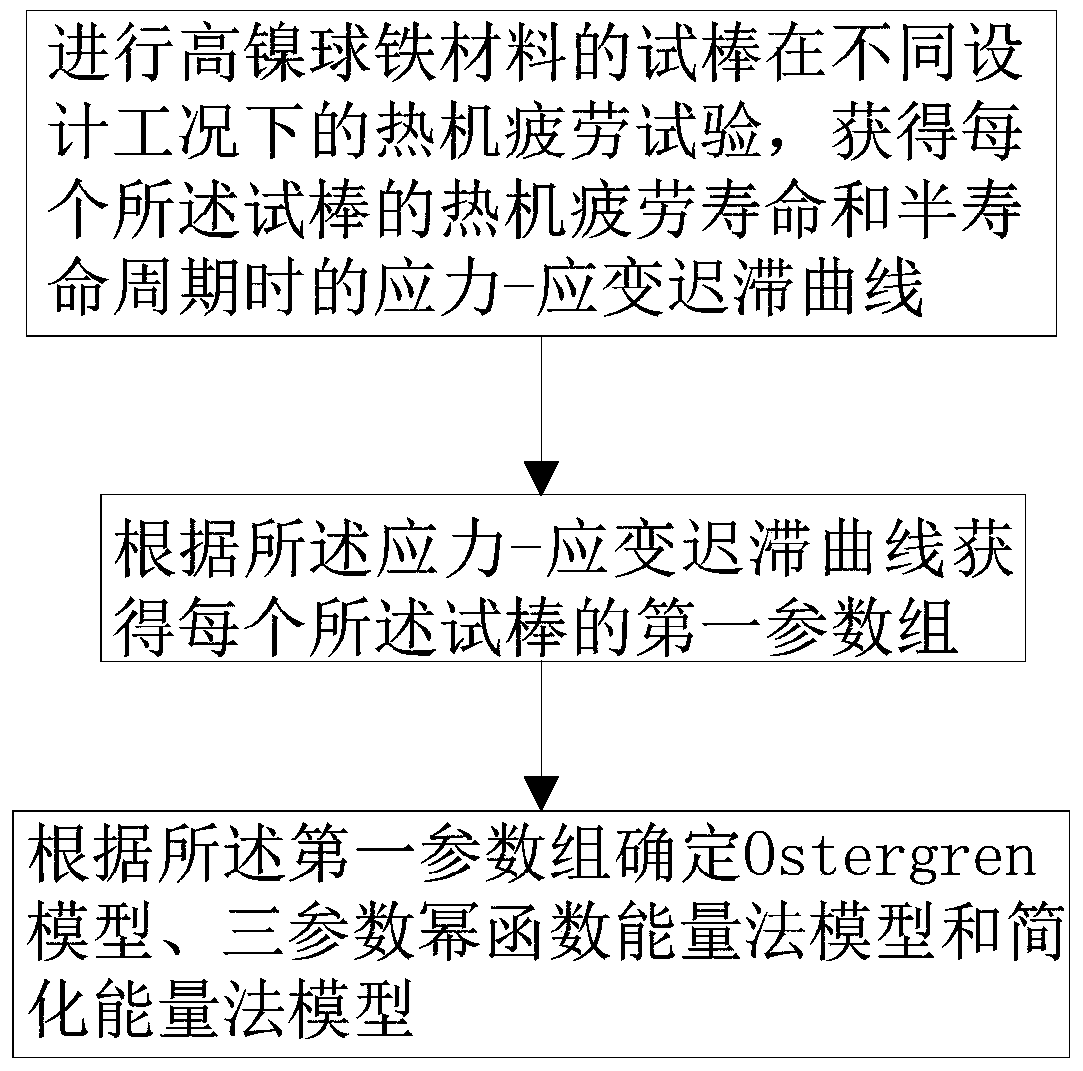

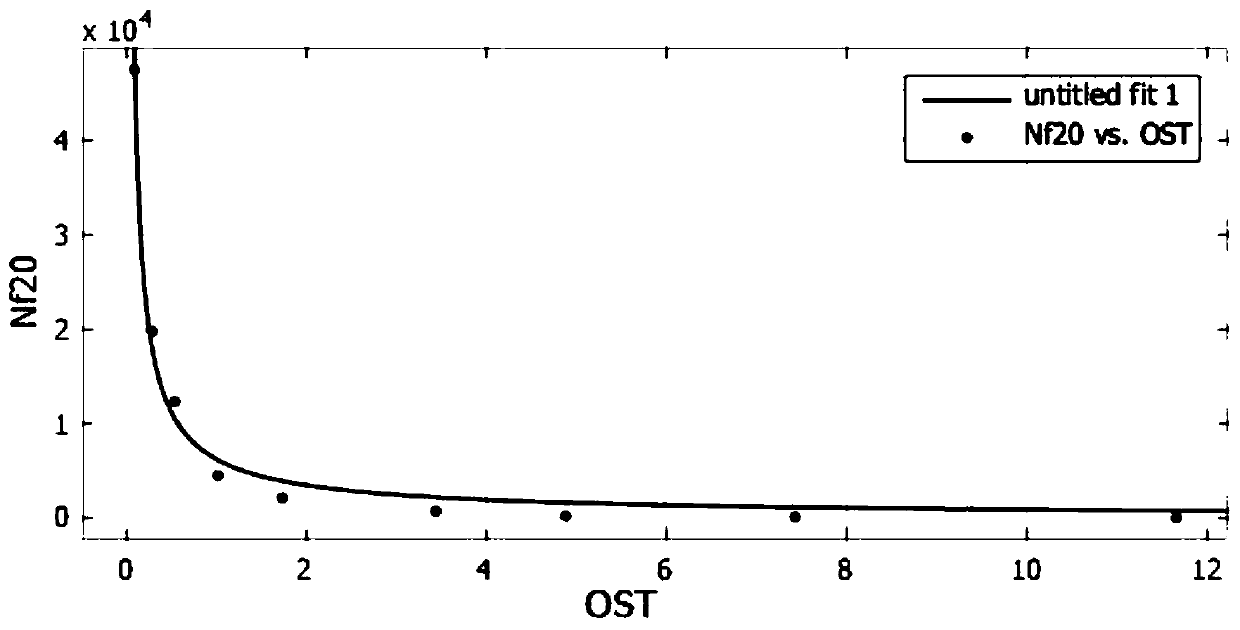

Method for establishing high-nickel ductile iron material exhaust manifold heat engine service life prediction model

PendingCN110750857ASolve the problem of lack of thermal engine fatigue life prediction modelAutomate and standardizeDesign optimisation/simulationHeat engineGasoline

The invention belongs to the technical field of engines, and discloses a method for establishing high-nickel ductile iron material exhaust manifold heat engine life prediction model. The method comprises: carrying out heat engine fatigue tests of high-nickel ductile iron material test bars under different design working conditions, and obtaining a stress-strain hysteresis curve of each test bar inthe heat engine fatigue life and half life cycle; obtaining a first parameter group of each test rod according to the stress-strain hysteresis curve; and according to the first parameter group, determining an Ostergren model, a three-parameter power function energy method model and a simplified energy method model. The method has the beneficial effects that heat engine fatigue life prediction iscarried out on the gasoline engine high-nickel ductile iron material exhaust manifold, the deviation is within two times of the line, and the engineering design requirement can be met; the problem that a gasoline engine high-nickel ductile iron material exhaust manifold heat engine fatigue life prediction model is lacked is solved, a heat engine fatigue life prediction method is solidified, and life prediction automation and standardization are achieved.

Owner:CHINA FIRST AUTOMOBILE

Online fracturing fluid and preparation method therefor

The invention relates to online fracturing fluid and a preparation method therefor. The online fracturing fluid contains the ingredients in parts by mass: 0.8-5 parts of agent A, 0.2-1 part of agent B and 94-99 parts of water; the agent A contains the ingredients in parts by mass: 10-20 parts of chitin, 10-20 parts of starch, 5-20 parts of acrylamide, 2-5 parts of bioactivator, 0.1-1 part of sugar, 0.1-0.5 part of sodium polyaspartate, 10-20 parts of environment-friendly solvent and 13.5-62.8 parts of water; and the agent B contains the ingredients in parts by mass: 5-20 parts of alkaline proteinase, 10-20 parts of bioactivator, 5-10 parts of EDTA-4Na, 0.1-0.2 part of sodium ethylenediamine disuccinate, 0.5-1 part of sodium polyaspartate, 0.2-1 part of sodium acetate, 0.5-1 part of sodium lactate, 0.5-1 part of potassium lactate, 0.5-1 part of sugar, 5-10 parts of ethanol and 34.8-72.7 parts of water. The online fracturing fluid has the characteristics that online continuous preparation is achieved, the operation is simple, the working concentration is low, the viscosifying speed is high, the sand carrying performance is good, the friction drag is low, the damage is low, the online fracturing fluid is heat-resistant and shear-resistant, the viscosity of flowback fluid is low, the applicable range is wide, the cost is low, the production increase effect is good, and the like.

Owner:SUNCOO PETROLEUM TECH

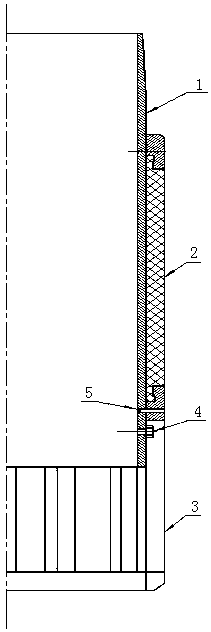

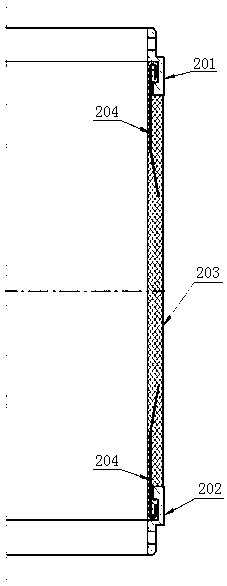

Leakage prevention and stoppage tool for loess layer and using method of leakage prevention and stoppage tool

The invention relates to a leakage prevention and stoppage tool for a loess layer and a using method of the leakage prevention and stoppage tool. The leakage prevention and stoppage tool at least comprises a pipe body and further comprises a rubber cylinder assembly and a sliding sleeve which are sequentially arranged on the pipe body in a sleeving mode from top to bottom; and an upper steel ringand a lower steel ring are arranged at the two ends of the rubber cylinder assembly correspondingly, the upper steel ring is fixed to the upper part of the pipe body, a shear pin is arranged between the lower steel ring and the lower part of the pipe body, when the lower pressure is greater than the bearing capacity of the shear pin, the shear pin is sheared off, the sliding sleeve moves upwards,and thus the sliding sleeve is extruded axially. During using, the leakage stoppage tool is connected with a guide pipe string entering a well to be lowered into a loess borehole, after the guide pipestring reaches the well bottom, the sliding sleeve makes contact with the well bottom, guide pipes downwards press the sliding sleeve through the self weight, the shear pin is sheared off, and the guide pipe string continues moving downwards to extrude a rubber cylinder; and the rubber cylinder is compressed in the axial direction and expanded in the radial direction to make contact with the wellwall so as to be sealed. According to the using method, an annulus between the guide pipe string and the borehole in the loess layer is reliably packed and blocked at the well bottom, so that duringsubsequent drilling, circulating drilling fluid does not make contact with the loess layer, and the leakage prevention and stoppage effects are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of online fracturing fluid and preparation method thereof

Owner:DONGYING SHENGSHI PETROLEUM TECH CO LTD

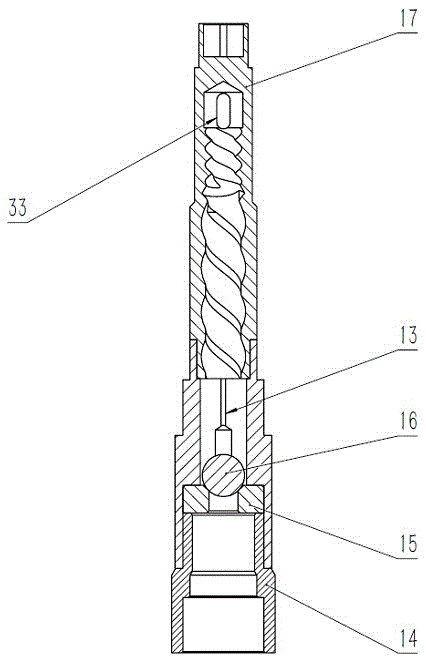

Vortex self-cleaning oil well pump

InactiveCN105484995AAvoid depositionAvoid cloggingPositive displacement pump componentsFlexible member pumpsCouplingEngineering

The invention discloses a vortex self-cleaning oil well pump which comprises a plunger assembly, a pump cylinder assembly, a vortex rotary lifting device and a rotational flow fixing valve assembly. The vortex rotary lifting device comprises a rotor, a stator, a compression spring, a guiding cylinder, an upper straightening block and a lower straightening block. The rotational flow fixing valve assembly comprises a rotational flow guiding cylinder, a fixing valve cover, a fixing valve and a fixing valve seat. The pump cylinder assembly comprises a pump cylinder and a pump cylinder coupling. The pump cylinder coupling is connected with a lengthened short joint. The vortex rotary lifting device is arranged in the lengthened short joint. The stator is connected with the rotational flow guiding cylinder through a stator connector. The lower straightening block is arranged on the stator in a sleeving manner and is located through a locking nut. The upper end of the locking nut is sleeved with a spring seat and the compression spring. The upper end of the guiding cylinder is sequentially connected with the rotor, the upper straightening block and a stop nut. The rotational flow fixing valve assembly is arranged at the lower end of the lengthened short joint and is connected with the lower end of the coupling through the upper end of the fixing valve cover. Vortex is generated in a pump cavity, impurities which are sucked in are carried out of the oil well pump, the pump cavity is cleaned, impurities are prevented from being deposited in the fixing valve, the overhaul period is prolonged, and production efficiency is improved.

Owner:XI'AN PETROLEUM UNIVERSITY

Pressure-bearing plugging agent for offshore drilling fluid and application method thereof

The invention discloses a pressure bearable plugging agent for a marine drilling fluid and an application method therefor. The pressure bearable plugging agent consists of the following components in parts by weight: 10-20 parts of bauxite powder,10-20 parts of sodium soil, 20-35 parts of coal ash, 20-25 parts of wood fiber powder, 10-15 parts of composite salt-resistant polymer, 10-25 parts of furfural residue powder, and 0.5-1 parts of a crosslinking agent. When in use, 15-25 kg per cubic meter of a pressure bearable plugging agent is added to well drilling mud, then a drilling operation is performed; the pressure bearable plugging agent can greatly improve permeability resistance performance of drilling fluid, so that the drilling fluid and filtrate fluid of the drilling fluid are stooped from infiltrating into a deep portion of an oil-gas layer, thereby realizing near zero fluid loss drilling, and thus basically solving a pollution problem caused by the oil-gas layer in drilling engineering. Meanwhile, as the membrane structure is formed on a shallow surface of a permeable layer, and does not permeate the deep portion of the oil-gas layer; when there is a counter pressure in a wellbore, the plugging agent can be removed by itself; and a recovery value of permeability may be above 90%, thereby effectively protecting an oil-gas layer.

Owner:SHANDONG SHENGHAI SCI & TRADE CO LTD

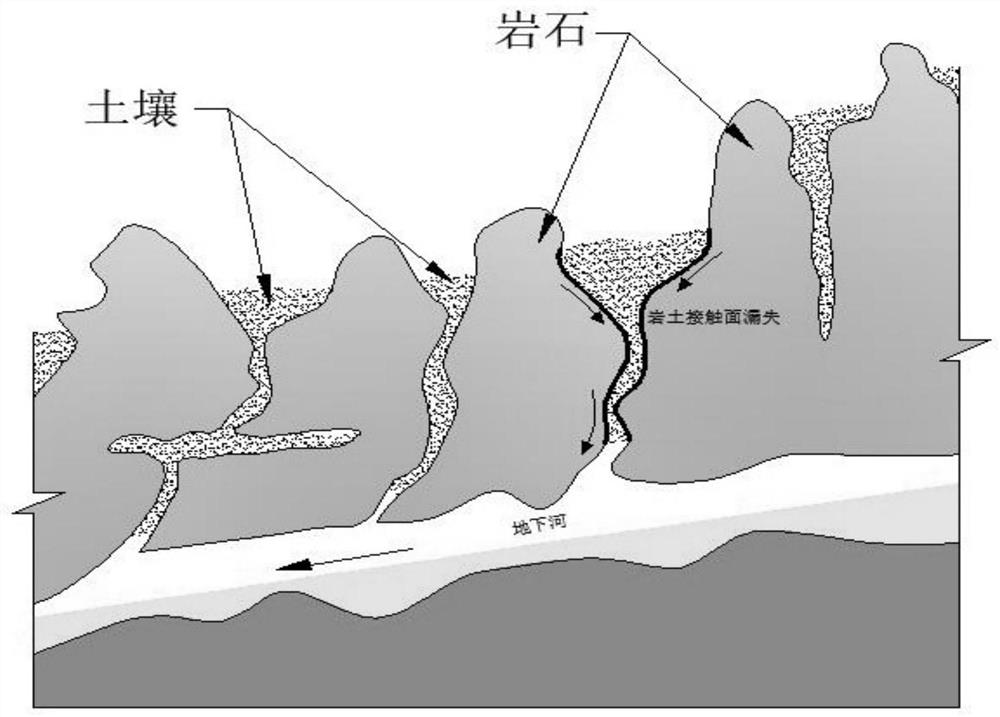

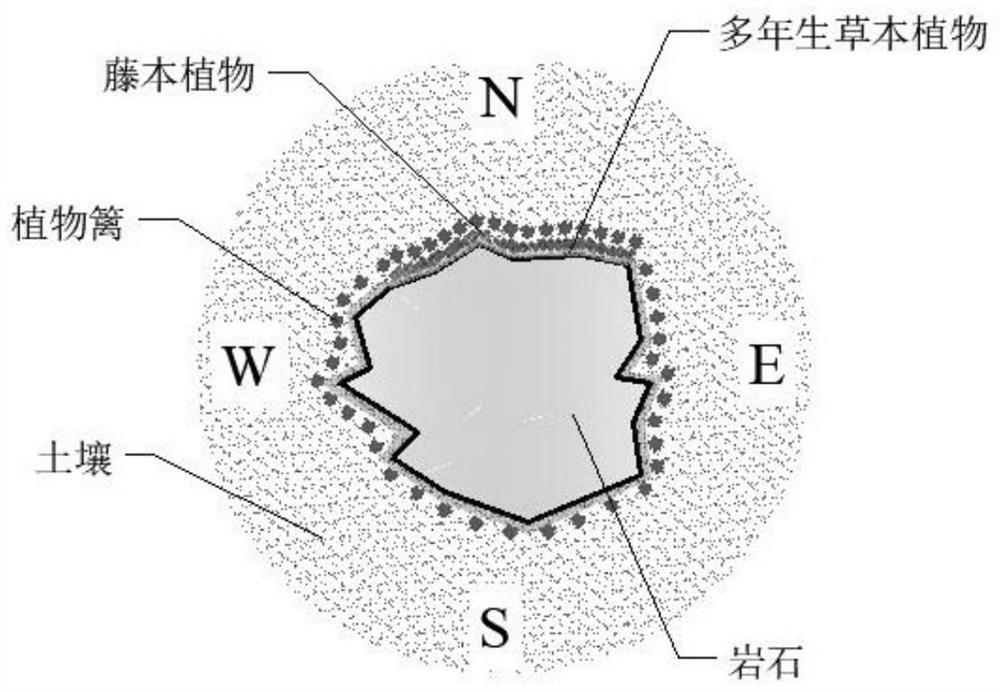

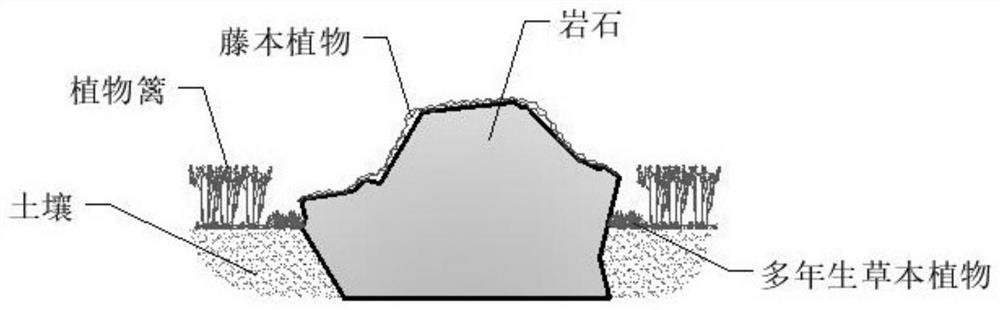

Soil leakage resistance control method for rock-soil contact surface in karst region

ActiveCN113079958AReduce disturbanceSolve the missing problemFlowers cultivationHops/wine cultivationSoil scienceRocky desertification

The invention relates to a soil leakage resistance control method for a rock-soil contact surface in a karst region. The soil leakage resistance control method for the rock-soil contact surface in the karst region includes the steps that plants are planted in soil of the rock-soil contact surface in the karst region, and the plant measure layout is as follows: bare rock of the karst region is taken as the center, and the periphery of the bare rock is divided into four plant measure implementation and layout areas of an upslope position, a downslope position, a left slope position and a right slope position; herbaceous plants are planted in the area close to the bare rock and around the bare rock for a circle; creeping liana plants are planted at the upslope position of the bare rock and close to the outer side of the herbaceous plants; and fast-growing plant hedges are planted on the outer sides, close to the herbaceous plants, of the downslope position, the left slope position and the right slope position of the bare rock, and on the outer sides, close to the liana plants, of the upslope position of the bare rock. The soil leakage resistance control method for the rock-soil contact surface in the karst region is suitable for soil leakage resistance control of the rock-soil contact surface around the bare rock in the karst region, and rocky desertification treatment and water and soil conservation in the southwest rock karst region can be promoted.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

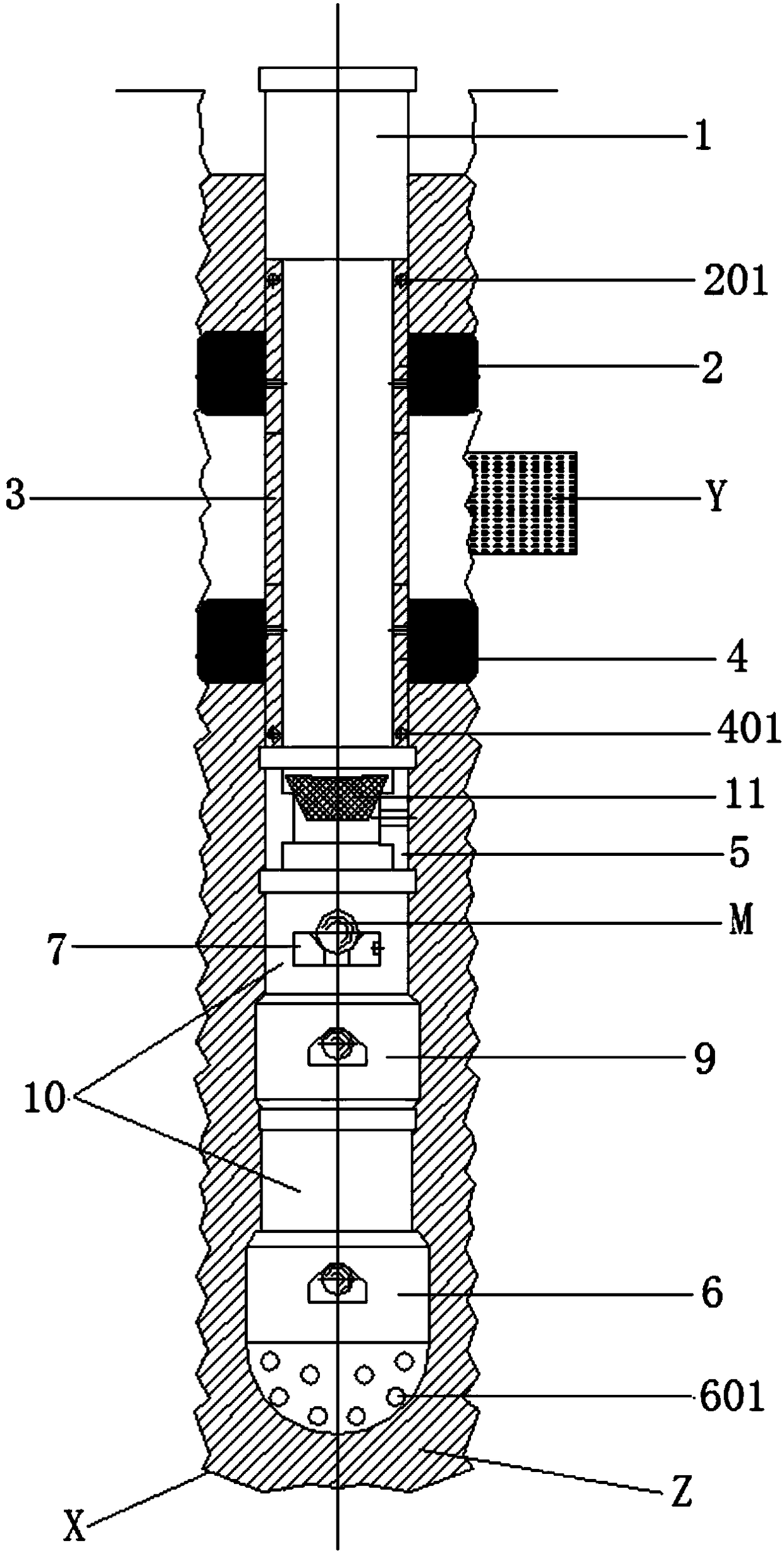

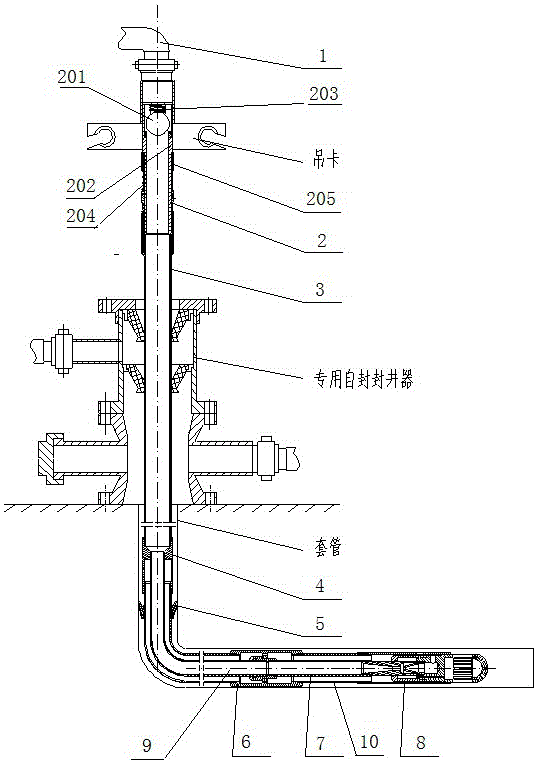

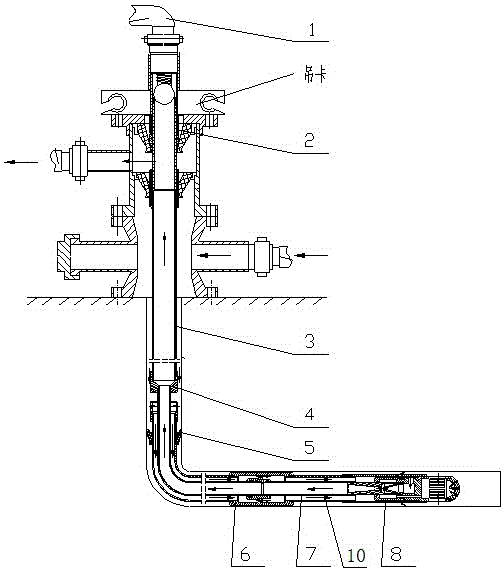

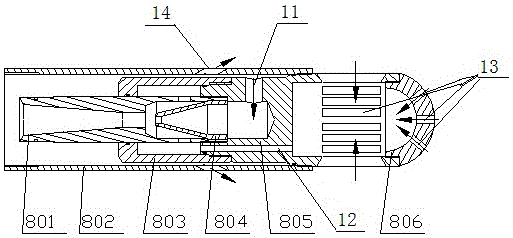

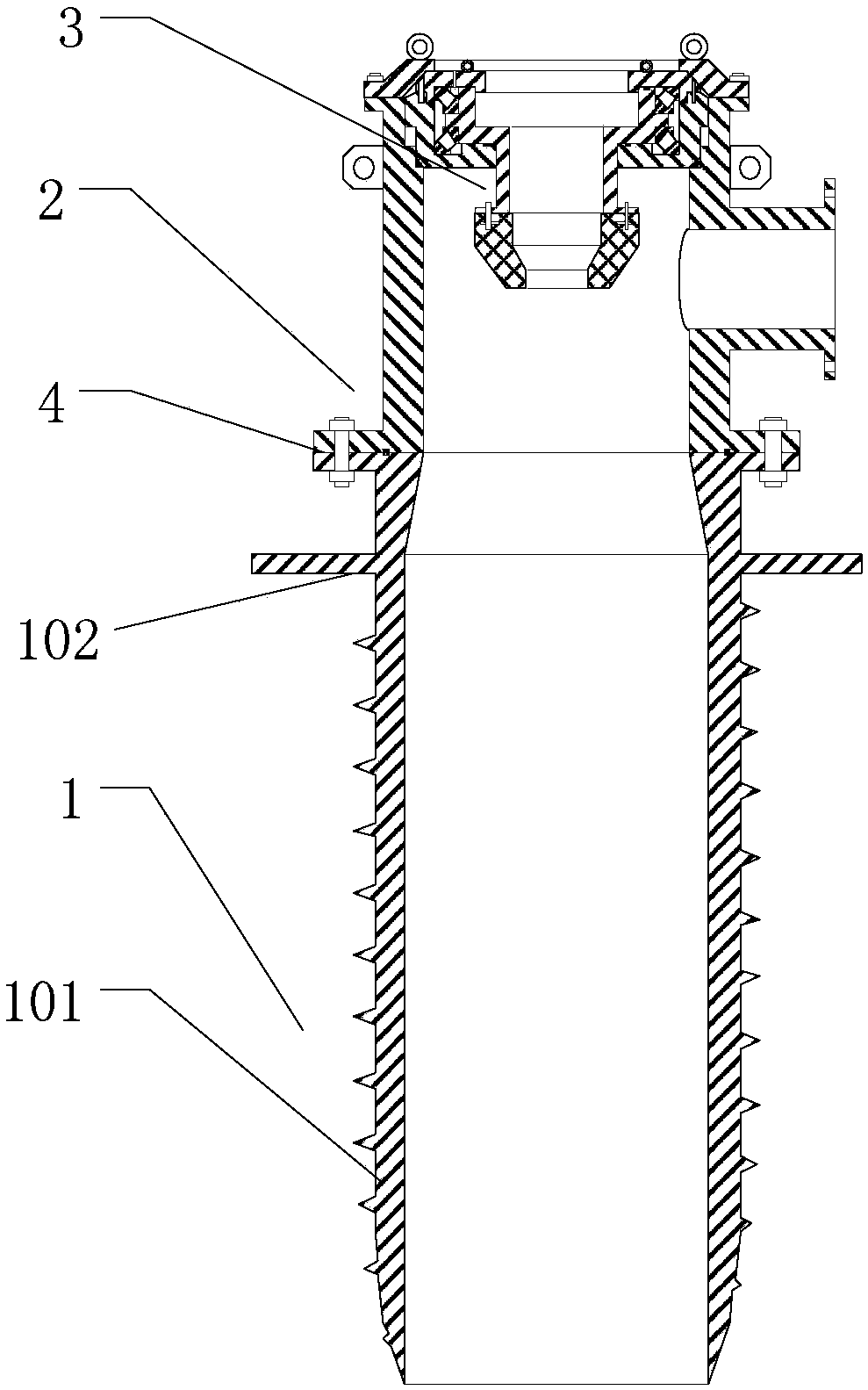

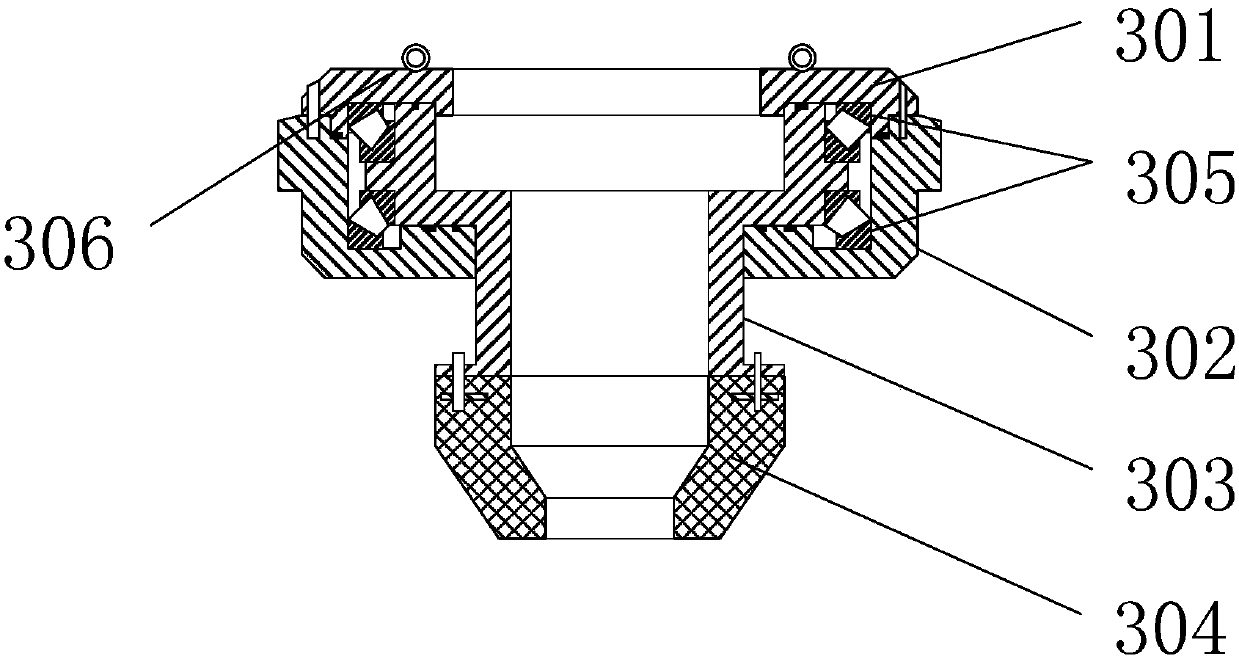

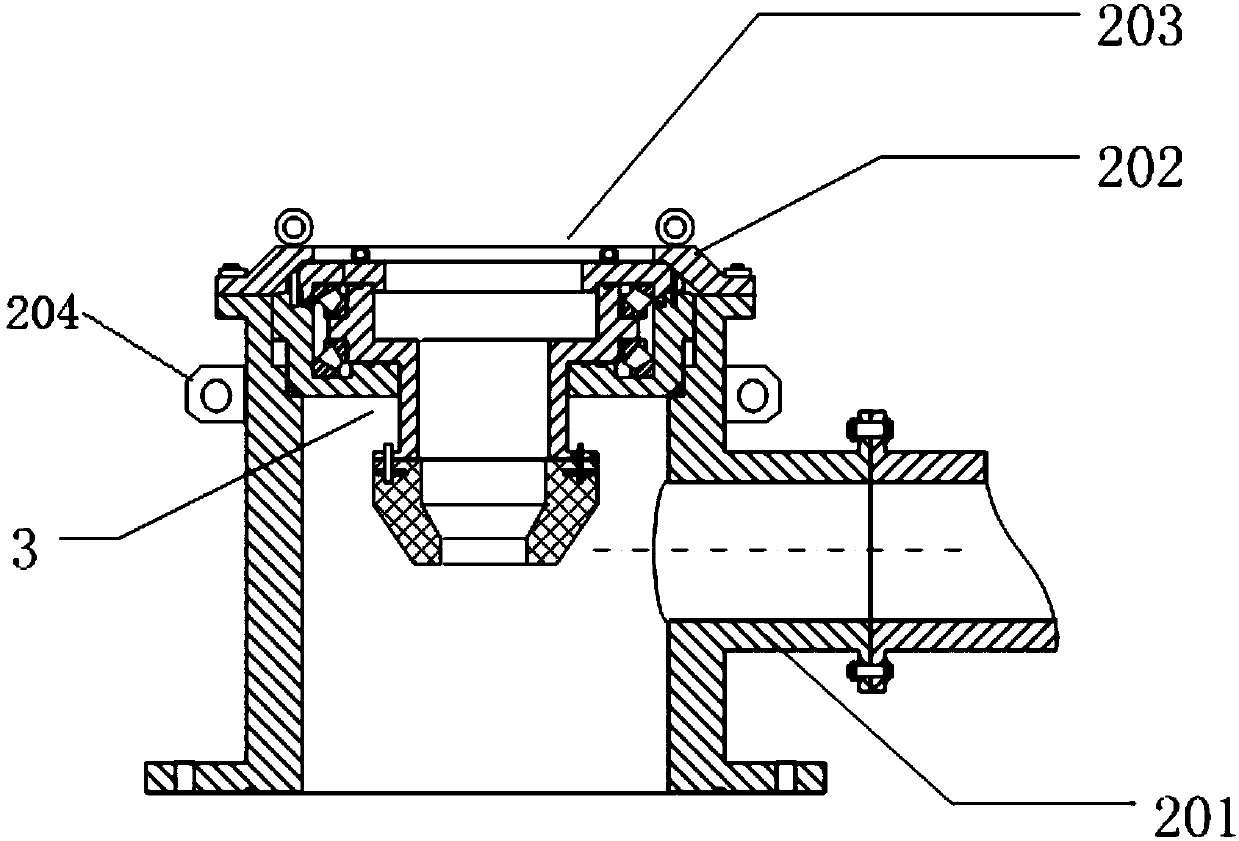

Gas drilling wellhead device without borehole and method for drilling stratum surface layer

ActiveCN107829702ASolve the missing problemIncrease ROPLiquid/gas jet drillingSealing/packingWell drillingThrust bearing

The invention discloses a gas drilling wellhead device without a borehole and a method for drilling a stratum surface layer. The device comprises a supporting sealing cylinder, a sealed outer housing,and a rotating sealing device. An upper part of the supporting sealing cylinder is provided with a raised edge. External threads are arranged below the raised edge. The supporting sealing cylinder isconnected with the sealed outer housing through a flange in a sealed manner. The side wall of the sealed outer housing is provided with a bypass, an inner wall is provided with steps, and a top is screwed with an upper cover. An upper sealing body and a lower sealing body of the rotating sealing device are connected in a sealed manner, a holding cavity is formed in the rotating sealing device, aninner rotating cylinder is mounted in the holding cavity, the bottom of the inner rotating cylinder is fixedly provided with a rubber core, and an outer side is provided with a thrust bearing. The rotating sealing device is arranged in the sealed outer housing in a sealed manner. When an upper cover of the sealed outer housing is screwed with the sealed outer housing, positions of the upper sealing body and the lower sealing body of the rotating sealing device are fixed. The supporting sealing cylinder is used to embed the gas drilling wellhead device into a stratum and isolate a near-surfacestratum. Under a condition without a borehole, a wellhead sealing device is established. The device is suitable for shallow stratum low-pressure gas to drill a stratum surface layer and establish a borehole.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

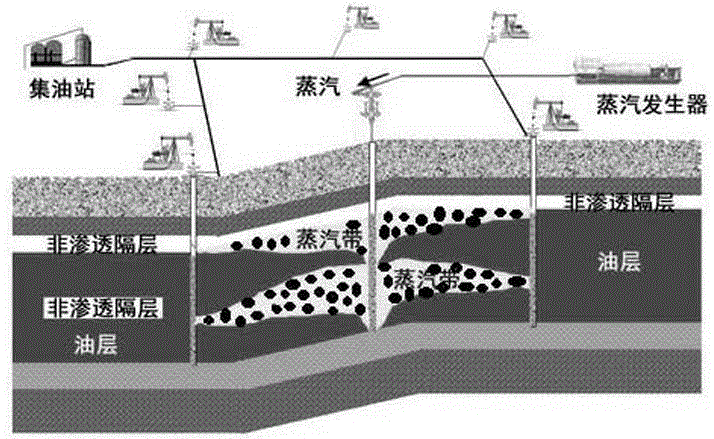

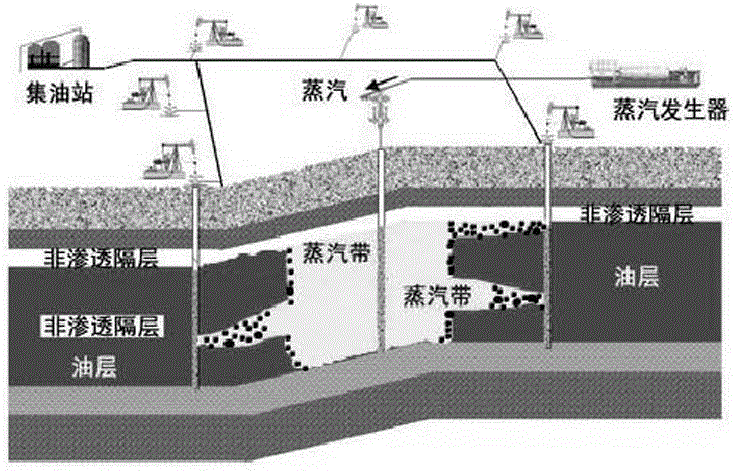

Technical method of steam channeling and plugging of thick oil

InactiveCN106351604ASolve the missing problemEnhanced overall recoveryFluid removalSealing/packingSolid particleEngineering

The invention relates to the technical field of the technical method of steam channeling and plugging, a technical method of steam channeling and plugging of thick oil; the method comprises the following steps: the first step, stirring evenly the cottonseed hull with solid particle qulity percentage of 30% to 60% and water with quality percentage of 40% to 70% and squeezing into the steam channels with high pressure pump; the second step, after the completion of the first step, continuing to mix evenly the wood chips with percentage of 30% to 60% and the water with quality percentage of 40% to 70% and squeezinginto the steam channels with high pressure pump. The invention discloses a technical method of steam channeling and plugging of thick oil, which can effectively solve the problem of leakage of plugging agent. Sawdust and cottonseed hulls are solid soft particles that can be inflated by water and can be effectively plugged in the steam channel to improve oil exploiting rate. The method can save energy and reduce consumption, so as to reduce mining cost.

Owner:XINJIANG KARAMAY CAIFENG IND

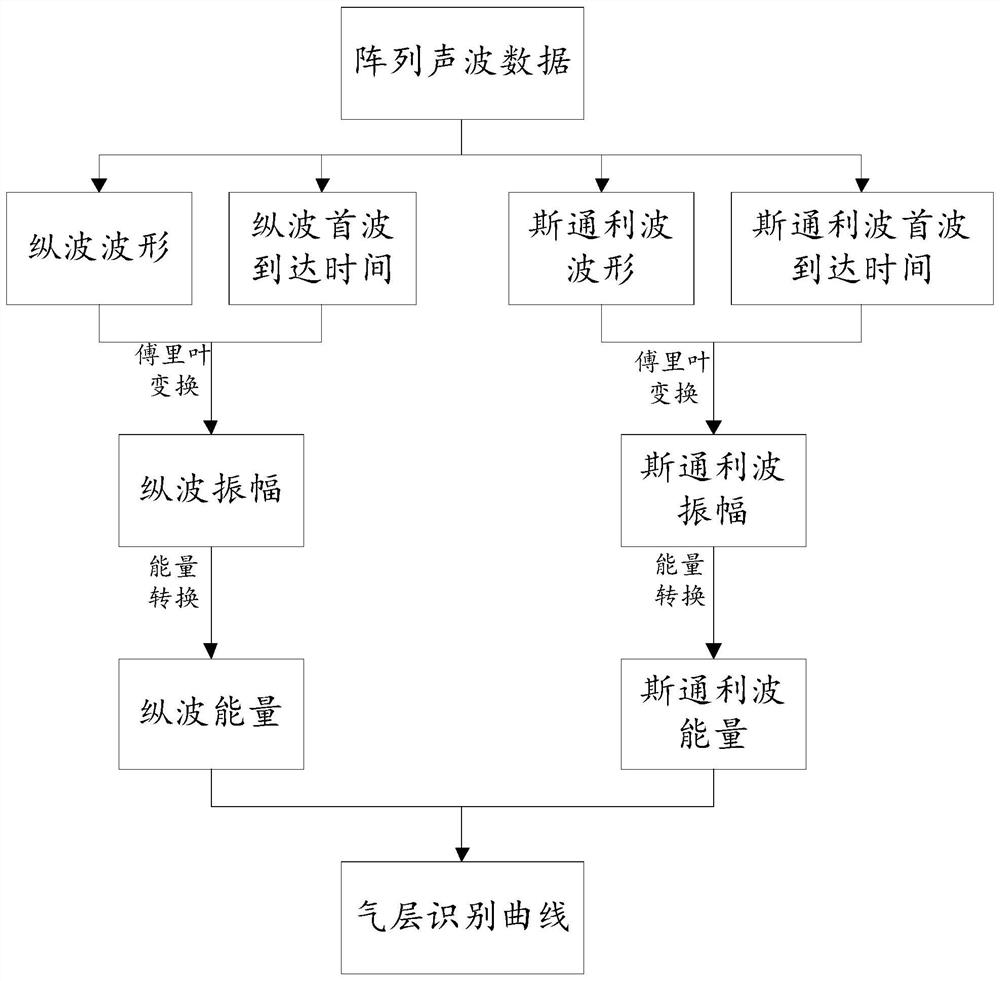

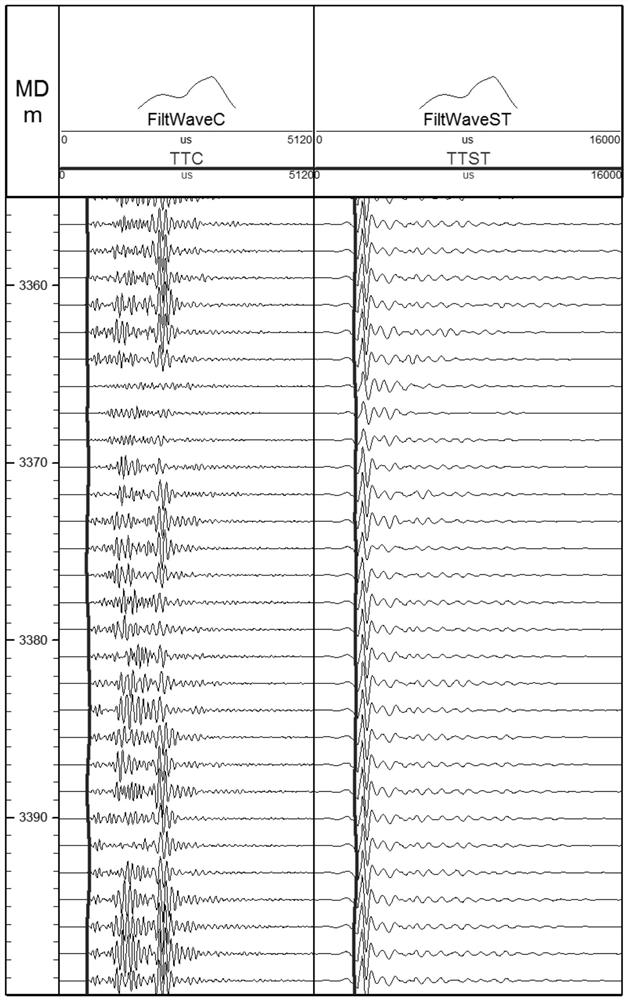

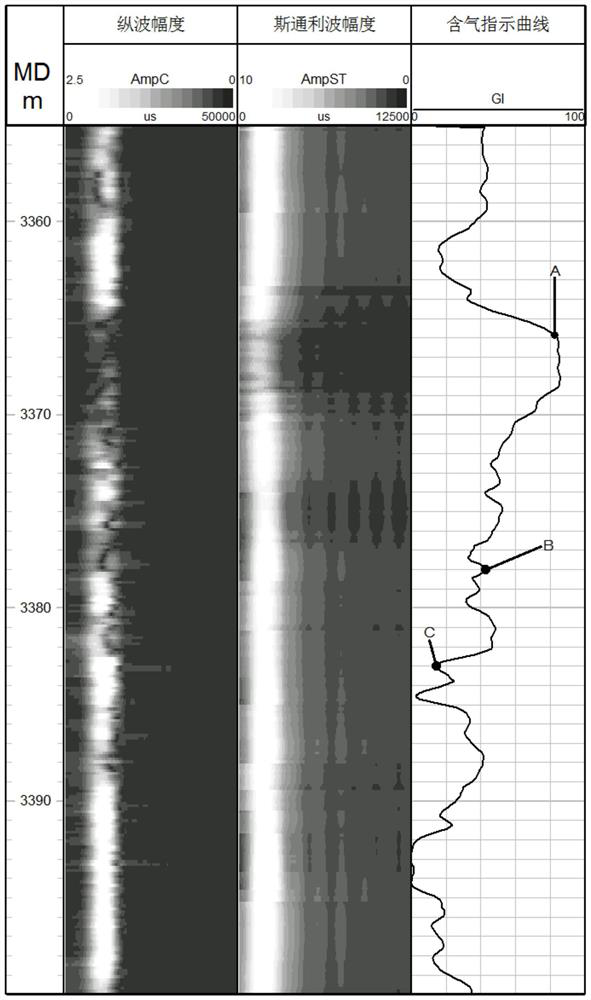

A method and device for identifying gas layers using longitudinal waves and Stoneley waves

ActiveCN107816348BEffective judgment positionSolve the problem of air layer identificationSurveyLongitudinal waveWave shape

The invention discloses a method and device for recognizing a gas layer by using a longitudinal wave and a stoneley wave. The method comprises the steps of S1: acquiring a longitudinal wave waveform and a stoneley wave waveform after wave filtering, a head wave arrival time curve of the longitudinal wave, and a head wave arrival time curve of the stoneley wave; S2: respectively conducting Fouriertransformation to the longitudinal wave and the stoneley wave; S3: acquiring amplitudes in a preset time window length of the longitudinal wave and the stoneley wave; S4: transforming the amplitude ofthe longitudinal wave into a longitudinal wave energy, and transforming the amplitude of the stoneley wave into a stoneley wave energy; S5: acquiring a recognition curve of the gas layer according tothe longitudinal wave energy and the stoneley wave energy. According to the method, by using the longitudinal wave energy of an array acoustic wave and the stoneley wave energy, an indicative curve of stratum gas content is calculated, response characteristics of natural gas to the longitudinal wave attenuation and the stoneley wave attenuation are amplified, the influence of only the longitudinal wave attenuation response or the stoneley wave attenuation response in some gas layers is eliminated, sensitivity can be effectively improved, and the position of a gas-bearing stratum is accuratelyjudged.

Owner:北京吉奥特能源科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com