Negative-pressure sand washer of horizontal well

A horizontal well and negative pressure technology, which is applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc., can solve problems such as leakage and discontinuity, and achieve the effects of solving leakage, improving adaptability, and simplifying construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

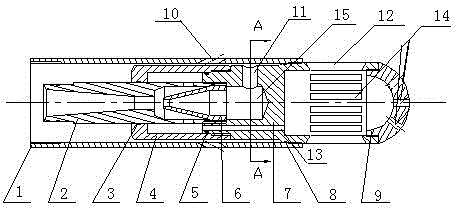

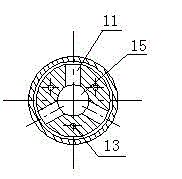

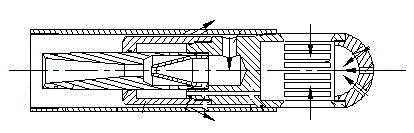

[0031] In order to overcome the problems of discontinuity and serious leakage in the sand flushing process of existing horizontal wells, this embodiment provides a method such as figure 1 , figure 2 , image 3 The horizontal well negative pressure sand extractor shown includes an outer cylinder 1, a throat pipe 2, a central pipe 4, a nozzle 6, a connecting head 7 and a baffle head 9, and the upper part of the connecting head 7 is inserted into the outer cylinder 1 and connected with it Threaded connection, the lower end surface of the connecting head 7 is connected with the baffle head 9, the outer wall of the front end of the connecting head 7 is connected with the lower end of the central pipe 4, the inner hole of the front end of the connecting head 7 is connected with the lower end of the throat pipe 2, and the throat pipe 2 is connected from the The inside of the central pipe 4 passes through the upper end surface of the central pipe 4. The nozzle 6 is placed in the inn...

Embodiment 2

[0037]On the basis of Example 1, this example provides the process string matching and construction process of the horizontal well negative pressure sand extractor of the present invention in the sand washing construction process:

[0038] 1. Wellhead matching

[0039] as attached Figure 4 As shown, the wellhead was replaced with "wellhead cross + continuous circulation wellhead device" before construction.

[0040] 2. Supporting process column

[0041] Firstly, carry out sand exploration and drilling operations, determine the position of the sand surface and ensure the passing performance of the wellbore above the sand surface; secondly, connect the process string, and the process string is designed (from downhole to wellhead): negative pressure sand pump for horizontal wells 16+ single concentric tubing (tool tubing + built-in tubing 17 + concentric tubing coupling 18) + sealing cup 21 + adapter 22 + tool tubing 20 (the design length is related to the position of the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com