Vortex self-cleaning oil well pump

A self-cleaning, oil well pump technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of fixed valve clogging and sealing, short pump inspection period, fixed valve full of falling objects, etc. , to prevent blockage of the pump valve, increase fullness, and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

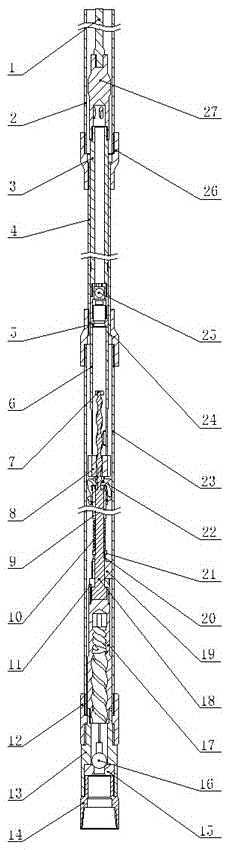

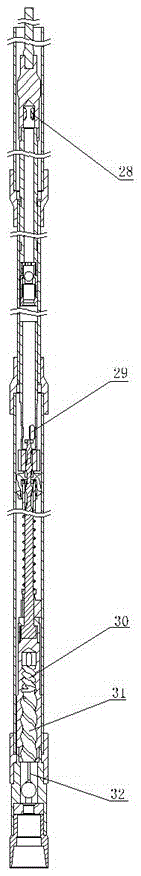

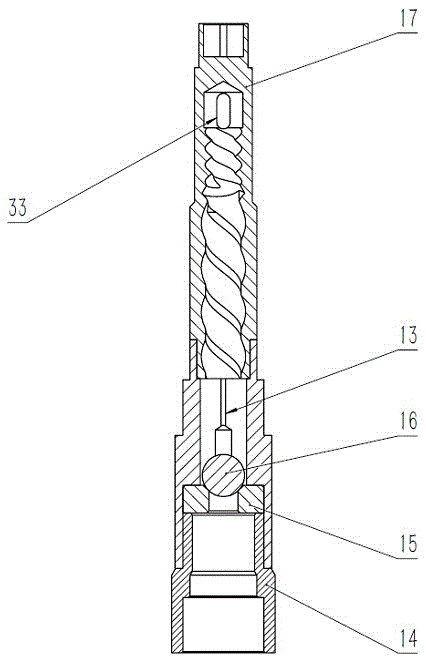

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Referring to Figures 1, 2 and 3, a vortex self-cleaning oil well pump includes a plunger assembly, a pump barrel assembly, a vortex spinner and a swirl fixed valve assembly; the plunger assembly includes a plunger 3, The upper end of the plunger is connected to the traveling valve cover 27, and the lower end is connected to the downstream traveling valve assembly 25; the lower end of the downstream traveling valve assembly 25 is threadedly connected to the lower pressure seat 5, and the lower pressure seat 5 squeezes the transition cylinder 6; the plunger assembly is located in the pump Inside the barrel assembly, the pump barrel assembly includes the oil pipe 2, the oil pipe 2 is connected to the oil pipe collar 26, the lower end of the oil pipe collar is connected to the pump barrel 4 and the pump barrel collar 24; the lower end of the pump barrel col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com