Compensator for water injection pipe

A compensator and water injection pipe technology, which can be used in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve problems such as packer leakage, and achieve the effects of reducing leakage, reducing production costs, and improving operational reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

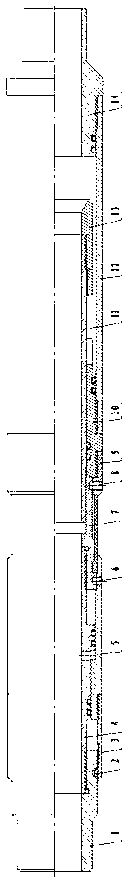

[0022] A water injection pipe compensator of the present invention, the water injection pipe compensator includes: a backstop part, including a backstop ring and a thrust sleeve; a locking part, including a lock tube core, a lock tube, a lock collar and a lock claw spring; and The control part includes a lock tube pin and a shear pin; the inner side and the outer side of the lower end of an upper joint are respectively connected to the lock tube core and the thrust sleeve, the thrust sleeve is fixedly connected to the lock tube, and the lock tube core and the thrust sleeve are respectively connected. The locking tube is respectively connected to the inner side and the outer side of the locking collar; the locking tube presses the locking claw spring onto the locking collar, and the bottom of the locking collar is fixedly connected to a central tube, so that The central tube is slidably sleeved with a suspension short, and the bottom end of the central tube is fixed with a bevel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com