Plugging agent suitable for large leakage, its preparation method and leaking stopping technology

A plugging agent, a large-scale technology, applied in the field of oil drilling, can solve the problems of loss of plugging time and plugging costs, bridge plug plugging can not meet the requirements, increased probability of well leakage recurrence, etc., to save plugging time and plugging Leakage costs, enhance the success rate of a single plugging, and improve the effect of a single plugging success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

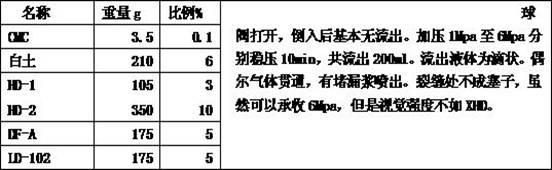

Embodiment 1

[0030] A plugging agent suitable for large-scale leakage, including components in the following mass ratio: water: HSD (HHH): HD-1: HD-2: LD-102: DF-A: barite = 100: 12: 4 :7:4:30, among them, HSD (HHH) is an acid-soluble plugging agent for drilling fluid, the main component is asbestos fiber; HD-1, HD-2 are comprehensive plugging agents for drilling fluid, the main component is walnut shell , almond husk, cottonseed husk, sawdust, and brown silk are pulverized and mixed. Type 1 is mainly coarse-grained, and Type 2 is mainly fine-grained; LD-102 is rubber granules for drilling fluid, with a particle size of 5 mesh; DF-A is One-way pressure plugging agent for drilling fluid; barite is a weighting agent for drilling fluid, chemical formula BaSO4, particle size 20 mesh, all of the above drugs are sold in the market.

[0031] A preparation method of a plugging agent suitable for large-scale leakage, which is prepared by the following components in the following mass ratio: water: ...

Embodiment 2

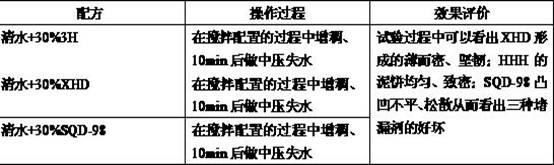

[0036]3500ml water+0.4%GD-1+6%DF-A+5%HD-2+2%LD-102+0.4%GD-1 Glue-based slurry sand bed plugging experiment

[0037]

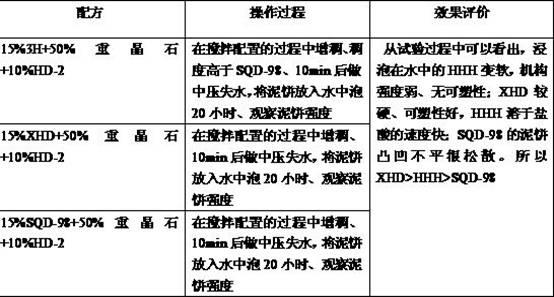

Embodiment 3

[0039] 3500ml water+0.8%GD-1+15%HD-1+4%HD-2+4%LD-102+3%DF-A+20%limestone+3%pebbles

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com