Double-layer continuous pipe double-gradient drilling system

A coiled tubing, dual gradient technology, applied in drilling equipment, subsea drilling, drilling pipes, etc., can solve the problems of high drilling safety risk, poor wellbore stability, narrow safety pressure window, etc. Effective control of bottom pressure and the effect of widening the density window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

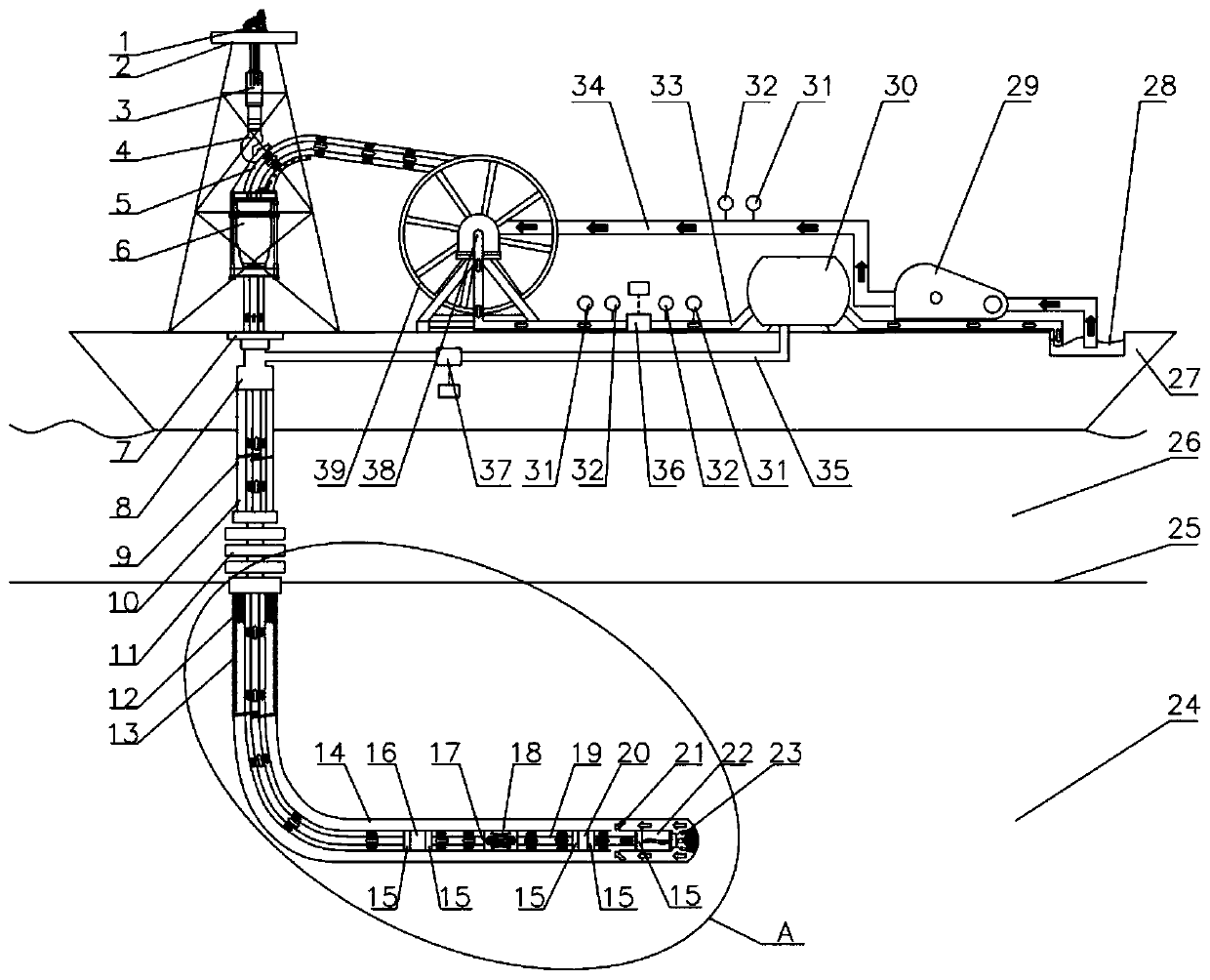

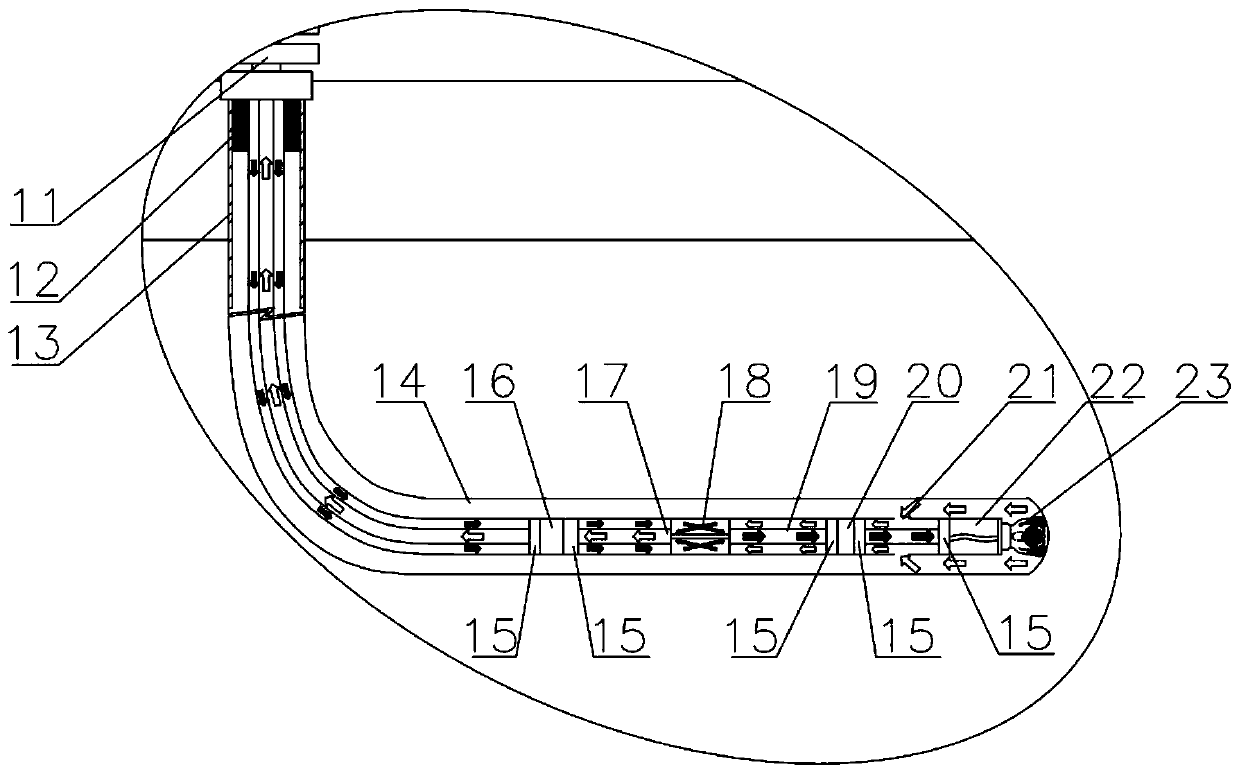

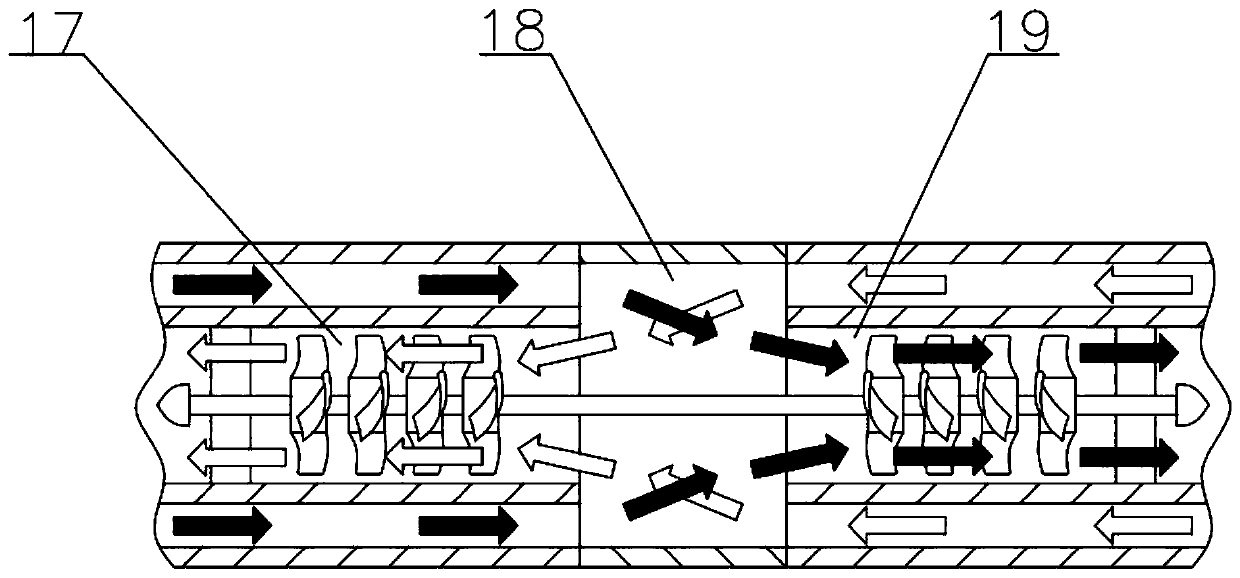

[0028] Such as Figure 1-3 As shown, this embodiment provides a double-layer coiled tubing dual-gradient drilling system, including a double-layer coiled tubing system, a drilling fluid circulation system, and a downhole lift pump system. The double-layer coiled tubing system and the drilling fluid circulation system are installed on the drilling ship 27; the double-layer coiled tubing system includes a double-layer coiled tubing 5, a drum 29, a double-layer coiled tubing injection head 6 and a conversion joint 38, and the double-layer coiled tubing 5 includes a continuous outer tube and a continuous tube fixed inside the continuous outer tube by an adjustment sleeve. An annular channel is formed between the inner pipe, the continuous outer pipe and the continuous inner pipe. The top of the double-layer continuous pipe 5 is wound on the rotating shaft of the drum 39 and connected to the drilling fluid circulation system through the conversion joint 38. The drum 39 is used for l...

Embodiment 2

[0050] like Figure 4 As shown, the present embodiment provides a double-layer coiled tubing dual-gradient drilling system, wherein the driving component is preferably a motor 41. When the lift pump 17 uses the motor 41 instead of the hydraulic motor 19 to provide power, its power is passed through the cable 40 or The supply of the double-layer coiled tubing 5 with an insulating layer can reduce the energy consumption of the drilling fluid 14 before reaching the bottom of the well, and reduce the burden on the drilling pump group 29 .

[0051] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com